Release Profile of the Antimicrobial Agent from Clove Oil

Encapsulated in a Polyurethane Shell

Chicha Nuraeni

1

, Dwinna Rahmi

1

, Retno Yunilawati

1

, Emmy Ratnawati

1

, Tiara Mailisa

1

, Trisny

Andrianty

1

, Irwinanita

1

, Bunda Amalia

1

and Arief Riyanto

1

1

Balai Besar Kimia dan Kemasan, Badan Penelitian dan Pengembangan Industri

Kementerian Perindustrian, Jakarta, Indonesia

Keywords: Clove Oil, Encapsulation, Polyurethane Shell, Release Profile.

Abstract: The essential oil has been known for its antimicrobial properties and has the potency to be utilized as an

active agent in food preservative, packaging, and textile. Eugenol and caryophyllene are a major

antimicrobial component in the clove oil, which is proved against several bacterial and fungal strains. Due

to the clove oil is easily oxidized and have a strong smell, it needs to be encapsulated so it can be used for

long-term application. The encapsulation of the clove oil in the polyurethane shell was prepared by

polymerization in an oil-in-water emulsion. The FTIR spectra of the microcapsules showed that the clove

oil was successfully encapsulated. The release profile of the antimicrobial agent from the microcapsules was

measured using Headscape GC. From the prediction based on the release profile showed that the

microcapsules could emit the eugenol for 59 days and the caryophyllene for 15 days. Therefore, it could be

concluded that the microcapsules of clove oil in the polyurethane shell is suitable for long term application.

1 INTRODUCTION

Clove (Syzygium aromaticum) is one of the native

Indonesian plants that are well known worldwide.

Clove oils collected from the distillation of the

clove’s leaves have proved against several bacterial

and fungal strains (Cortés-Rojas et al., 2014). The

antimicrobial agent from natural plants such as the

clove oil is considered safe, so it has more consumer

preference than the chemical antimicrobial agent

(Han, 2003). Therefore, the oils have been

developed for widespread applications such as food

preservatives (Cui et al., 2015), active packaging

(Hosseini et al., 2009), and textiles (Kim and

Sharma, 2011). However, clove oils are easily

oxidized and have a strong smell, so they are not

suitable for long-term use. The encapsulation

process had been known could reduce those

weaknesses (Kfoury et al., 2016).

Encapsulation is the process through which one

substance or a combination of materials is coated or

trapped in another material or system. The coated

material is referred to as active or core material, and

the coating material is referred to as a shell, wall

material, carrier, or encapsulant (Madene et al.,

2006). Chemical encapsulation using polymerization

technique has been known as easy to be scaled-up,

generically fast, and provides high encapsulation

efficiency (Carvalho et al., 2016).

Many lists of researches regarding encapsulation

by polymerization method, but only a few were

using the essential oil, especially clove oil, as core

material. Scarfato et al. (2007) provided

encapsulation of essential oils by interfacial

polymerization in o/w emulsion between

polyfunctional isocyanates and diamines. They used

essential oils from lemon balm (Melissa officinalis

L.), lavender (Lavandula angustifolia Miller), sage

(Salvia officinalis L.), and thyme (Thymus vulgaris

L.). Liu et al. (2015) proposed a process for

nanocapsules containing cologne essential oil for

textile applications. Methyl methacrylate (MMA)–

styrene (St) copolymer was used as a shell material

to prepare nanocapsules containing cologne essential

oil as a core material by miniemulsion

polymerization. Chung et al. (2013) encapsulated

thyme oil using melamine–formaldehyde

prepolymer.

Nuraeni, C., Rahmi, D., Yunilawati, R., Ratnawati, E., Mailisa, T., Andrianty, T., Irwinanita, ., Amalia, B. and Riyanto, A.

Release Profile of the Antimicrobial Agent from Clove Oil Encapsulated in a Polyurethane Shell.

DOI: 10.5220/0009954900290036

In Proceedings of the 2nd International Conference of Essential Oils (ICEO 2019), pages 29-36

ISBN: 978-989-758-456-5

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

29

Gezundhait and Pelah (2017) used polyurethane

as the shell for the encapsulation of essential oils in

which the polyurethane shell made from the reaction

of TDI (toluene diisocyanate) and polyethylene

glycol 4000. In this paper, polyurethane from

methylene diphenyl diisocyanate (MDI) was used as

an encapsulation shell for the clove oil. According to

Allport et al. (2003), MDI is less hazardous

compared to TDI. Polyurethane was chosen as shell

material because it is inexpensive and has high

durability, then it is possible for a broad application

(Engels et al., 2013).

The release profile is an important thing for the

application of the encapsulated clove oil as an

antimicrobial agent. The active compounds are

expected can be released at a specific rate for a long

time period as possible. The aim of this research is

to study the release of antimicrobial compounds

from clove oil encapsulated in a polyurethane shell.

According to the literature, antimicrobial agents in

clove oil are eugenol and caryophyllene. Marchese

et al. (2017) described the mechanism of action of

eugenol on bacteria and fungi. The antimicrobial

activity of eugenol can be attributed to the presence

of a free hydroxyl group in the molecule that able to

bind to proteins, preventing enzyme action. The

eugenol also disrupts the cytoplasmatic membrane

and alters the permeability of the membrane, which

leads to cell death. Dahham et al. (2015) proved that

β-caryophyllene showed antimicrobial activity

against Staphylococcus aureus and showed better

antifungal activity than Kanamycin (a common

antifungal drug on the market).

2 MATERIAL AND METHOD

Materials used in this study were methylene

diphenyl diisocyanate (MDI) prepolymer, obtained

from PT Covestro Polymers Indonesia; polyethylene

glycol 400 (PEG) “Bratachem”; sodium lauryl

sulphate (SLS) “Emal 10 N” Kao Chemicals;

xanthan gum and clove oil. All materials were used

without further purification.

Clove oil was obtained from Java area. The

composition of the clove oil was analysed using GC-

MS (Gas Chromatography–Mass Spectrometry)

“Agilent” 7890B coupled to “Agilent” 5977. The

analysis was performed using a non-polar capillary

column (DB-5MS, 30 m × 250μm, film thickness

0.25 µm). Then, the compounds were identified by

matching their mass spectra with GC-MS libraries

(Wiley Registry).

Encapsulated clove oils were prepared by

polymerization of polyurethane in an oil-in-water

emulsion. At room temperature, the mixture of 150

mL of water and 25 grams of PEG were mixed at

400 rpm. Simultaneously, 8 grams of MDI and 25

grams of clove oil were mixed and then was added

to the mixture. After the “clump” of polyurethane-

clove oil was formed, add SLS and xanthan gum as

much as 1 gram, respectively, while continuously

stirring for 2 hours. The resultant microcapsules

were strained from the liquid phase and then were

rinsed with water twice. The process was conducted

at room temperature. At last, the microcapsule

powders were stored in chiller around 10

o

C before

analysed.

The microcapsules were examined its

morphology using the microscope “Olympus BX53”

and were characterized using FTIR (Fourier

transform infrared) “Nicolet iS5” with an iD5 ATR

diamond tip adapter.

The release properties of the clove oil

encapsulated in polyurethane shells were

qualitatively and quantitatively analysed by

headspace-analysis technique using a Perkin Elmer

Headspace GC Clarus® 680 (column 30.0m x

250μm). Sample as much as 2 grams of

microcapsules was equilibrated at 40°C in the

headspace unit before the injection. The carrier gas

was helium; the detector temperature was 300 °C;

the oven temperature was programmed from 40 °C

(5 min hold) to 250 °C (10 min hold) increasing at

20°C/min. A split injector was used at 200° in split

mode at a ratio of 1:50. The measurements were

conducted in 0 day, 1

st

day, 3

rd

day, 8

th

day, and 10

th

day.

3 RESULTS AND DISCUSSION

3.1 The Composition of the Clove Oil

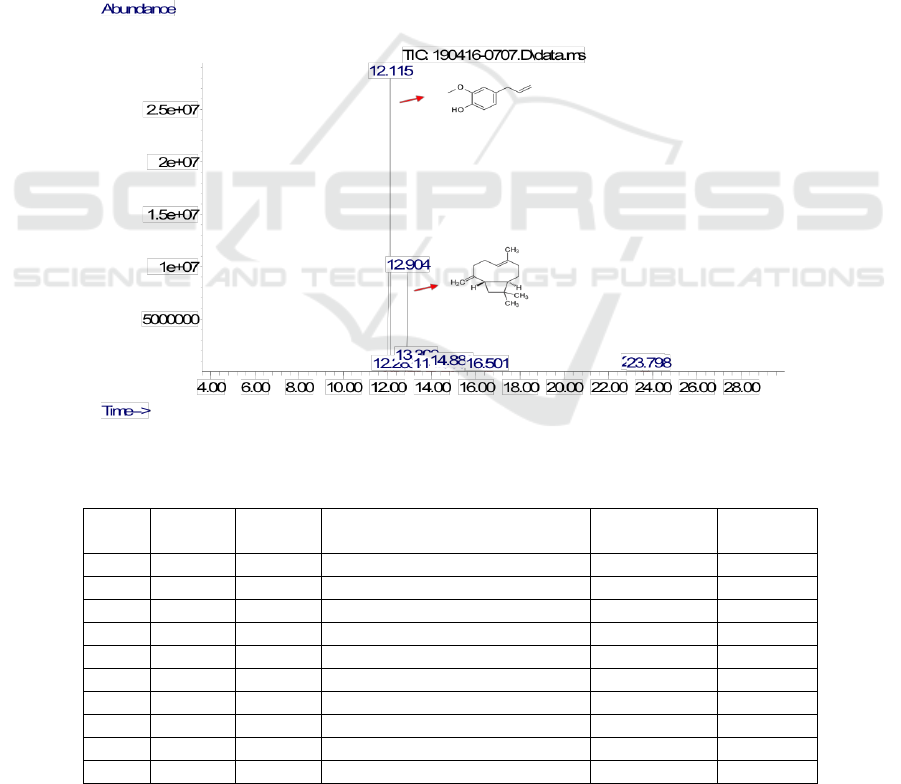

The clove oil analysis performed by GC-MS shows

10 (ten) peaks (Figure 1). From the chromatogram,

was obtained major components clove oil that are

81.64% eugenol, 15.86% trans-caryophyllene,

1.15% alpha-caryophyllene, 0.47% caryophyllene

oxide, 0.29% trans-anethole (Table 1).

3.2 The Morphology of the Clove Oil

Encapsulated in a Polyurethane

Shell

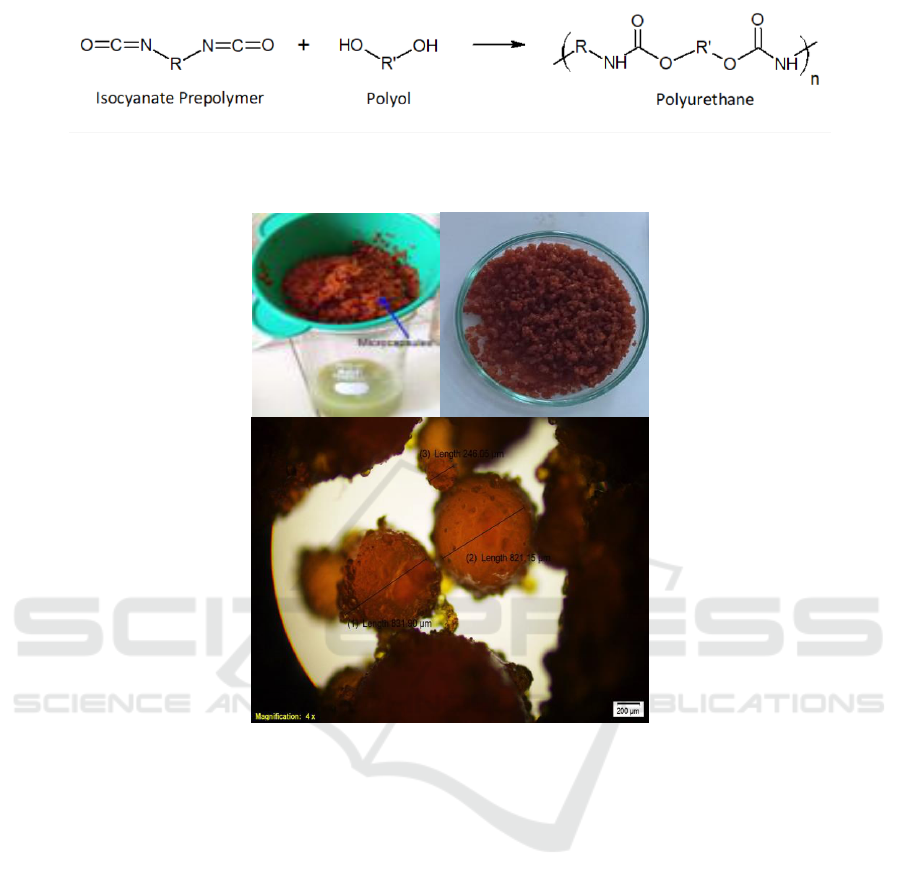

The creation of microcapsules of clove oil in

polyurethane shell due to the reaction of a diol with

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

30

a diisocyanate (Figure 2). In this study, a diol is

referred to as PEG, whereas the diisocyanate is

referred to as MDI. The diol is dissolved in the

aqueous phase and the diisocyanate in the organic.

The reaction at the oil–water interface produces the

encapsulating shell (Yow & Routh, 2006).

In the process of encapsulation by emulsion

polymerization, surfactants play major roles such as

solubilising of highly water-insoluble monomers,

determining the mechanism of particle nucleation,

determining the number of particles nucleated and

therefore the rate of polymerization, maintaining

colloidal stability during the particle growth stage,

and controlling average particle size and the size

distribution of the final system (El-Aasser, 1990). In

this study, sodium lauryl sulphate (SLS) was chosen

because SLS is an anionic surfactant and a very

strong type of surfactant and is a common emulsifier

for most heterogeneous systems. SLS also helps

reduce the size of the capsules by lowering the

surface tension in the matrix (Lakkis, 2016)

Figure 3 shows the appearance of clove oil

encapsulated in polyurethane shell. At four times

magnification, it shows that the capsules gave

spherical shape with size range from 246 m to 832

m. The size is larger compared to other researches,

because this study uses a lower stirring rate. The

increase in the stirring rate led to the formation of

smaller particles and narrower distributions

(Leimann et al., 2009), but the higher stirring rate

might less efficient in scale-up manufacturing.

Mamaghani and Naghib (2017) demonstrated that

the stirring rate at 400 rpm is affordable for

production regarding the energy consumed.

Figure 1: Chromatogram of the clove oil.

Table 1: Compounds identified from clove oil using GC-MS.

Peak

No.

RT

(min)

Area %

Name

CAS

% Sim

1

12.115

81.64

Eugenol

97-53-0

98

2

12.283

0.14

Alpha-copaene

3856-25-5

98

3

12.904

15.86

trans-caryophyllene

87-44-5

99

4

13.304

1.15

alpha-caryophyllene

753-98-6

99

5

14.111

0.14

1-S-cis-calamenen

483-77-2

97

6

14.501

0.07

cis-jasmone

488-10-8

64

7

14.879

0.47

Caryophyllene oxide

1139-30-6

81

8

16.505

0.12

3-methoxycinnamic acid

6099-04-3

46

9

23.563

0.29

Trans-anethole

4180-23-8

46

10

23.802

0.13

6-Nitro-2,4-diphenylquinoline

138432-74-3

53

RT (min): retention times in minutes; Area%: relative area counts; CAS: CAS numbers; %Sim: % similarities to

reference library spectrum

Release Profile of the Antimicrobial Agent from Clove Oil Encapsulated in a Polyurethane Shell

31

Figure 2: Synthesis of polyurethane.

Figure 3: The morphology of clove oil microcapsule in a polyurethane shell.

The parameters that affect the morphology and

size of the microcapsules have been reported by

previous researches. Bouchemal et al. (2004)

reported that the increase in the molecular weight of

polyol tends to increase the mean size of capsules.

Zhenxing et al. (2011) showed that the

microcapsules from emulsion polymerization were

influenced by the concentration of surfactant SLS.

The higher concentrations of the surfactant, the

smaller particle size would be created.

The increase of the SLS concentration means

more surfactants can be adsorbed, and hence the

surface charge density should increase. Therefore, it

will lead to an increase in the particle number

density, along with the decrease of particle size.

3.3 The IR Spectrum of the

Microcapsules

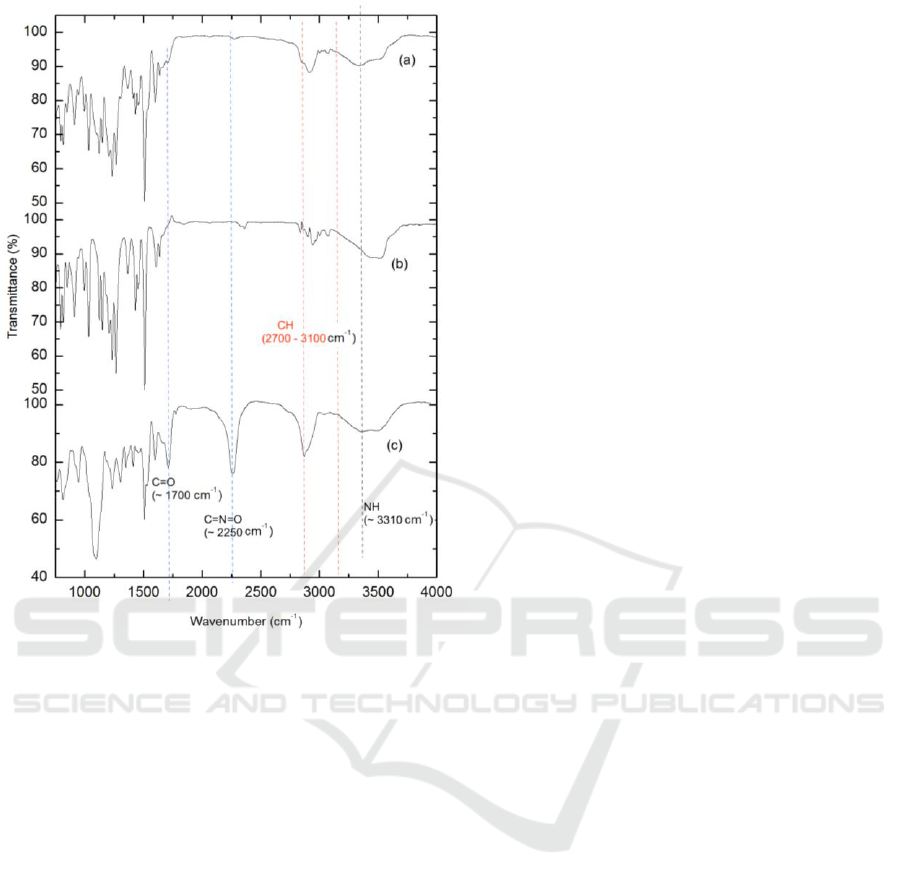

The FTIR spectra of the clove oil encapsulated in

polyurethane shell, clove oil, and polyurethane as

the shell material are presented in Figure 4. As is

shown in Figure 4, all the absorption peaks in the

curve (b) could be found in the curve (a), it means

that the clove oil was successfully encapsulated by

polyurethane.

The peaks at ≈1700 cm

-1

, 2250 cm

-1

, and 3310

cm

-1

correspond to C=O, excess isocyanate C=N=O,

and -NH, respectively, are associated group in

polyurethane. A small amount of polyurethane

existed in clove oil microcapsule, which is showed

by C=O and –NH in both curves (a) and (c).

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

32

Figure 4: IR spectrum: (a) clove oil encapsulated in

polyurethane shell, (b) clove oil, and (c) polyurethane.

3.4 The Release Profile of

Antimicrobial Agent from the

Microcapsules

According to Attaei (2017), the release of active

ingredients can occur due to diffusion or rupture

(due to thermal or mechanical) or dissolution. In this

study, the release of antimicrobial agent due to

thermal activity in which the microcapsule was

heated 40

o

C prior to the measurement of release

using GC headscape.

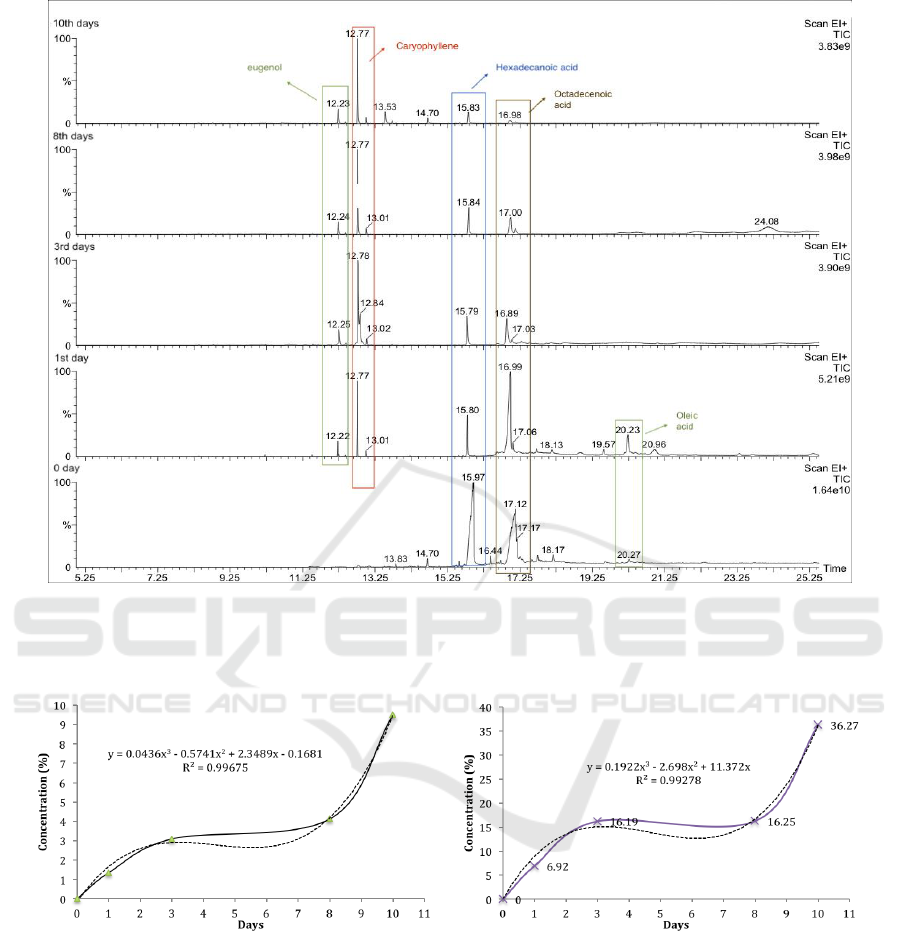

GC headspace chromatogram of clove oil encapsulated in

polyurethane shell is presented in

Figure 5. The chromatogram indicated the major

compounds that are eugenol, caryophyllene and

some fatty acid (hexadecanoid acid, octadecenoid

acid and oleic acid). The fatty acid was not detected

through the GC-MS analysis of the clove oil but

occurred in the headspace analysis of the

microcapsule. The reason is might due to the

reaction of fatty acid with polyol resulting fatty acid

in an ester form during the process of

polymerization. Free fatty acids in the essential oil

suspected because of the hydrolysis reaction during

storage (Minhal et al., 2017)

In this case, the occurrence of fatty acid can be

an advantage because fatty acid and fatty acid ester

had been identified their antimicrobial bioactivities

(Arora et al., 2017; Nakayama et al., 2015). Fatty

acids have known modulate immune responses by

acting directly on T cells so they have antibacterial

and antifungal properties (Aparna et al., 2012).

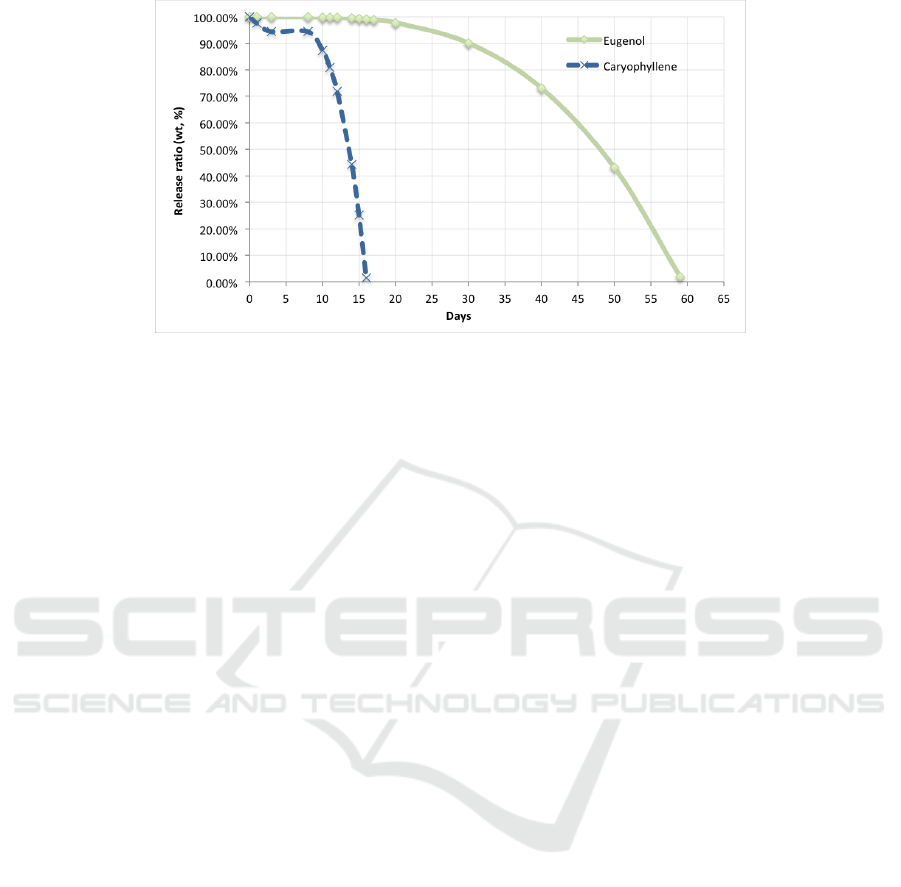

The release of eugenol and caryophyllene in each

day was summarized then were plotted and added

with a trend line using Microsoft Excel®. The

equation and R-square (R

2

) were calculated based on

the trend line. R

2

higher than 0.98 indicates the

equation fits with the data. As presented in Figure 6,

the concentration of caryophyllene were released

based on the equation C = 0.1922x

3

- 2.698x

2

+

11.372x, while the equation of released eugenol is C

= 0.0436x

3

- 0.5741x

2

+ 2.3489x - 0.1681 with x

refers to number of days.

Based on the equation of the release profile, it

can be predicted the percentage of weight ratio for

the next days (after the 10

th

day). The release

concentrations were compared with concentration of

eugenol or caryophyllene in the clove oil that is

81.64% and 17.01% respectively (Table 1). The

prediction is presented in Figure 7. It shows that the

eugenol could release for 59 days but the

caryophyllene only for 15 days.

Release Profile of the Antimicrobial Agent from Clove Oil Encapsulated in a Polyurethane Shell

33

Figure 5: GC headspace chromatogram of clove oil encapsulated in polyurethane shell.

Figure 6: Release profile of clove oil encapsulated in polyurethane shell: (a) eugenol, (b) caryophyllene.

(a)

(b)

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

34

Figure 7: Predicted release of eugenol and caryophyllene.

4 CONCLUSIONS

The concentration of eugenol was released based on

the equation C = 0.0436x

3

- 0.5741x

2

+ 2.3489x -

0.1681, whereas the equation of released

caryophyllene is C = 0.1922x

3

- 2.698x

2

+ 11.372x

with x refers to number of days. From this release

profile, it was found that the clove oil encapsulated

in polyurethane shell could emit eugenol for 59 days

and caryophyllene for 15 days. Therefore, it could

be concluded that the microcapsules of clove oil in

polyurethane shell is suitable for long term

application.

ACKNOWLEDGEMENTS

We would like to thank to PT Covestro Polymers

Indonesia who gave us the sample of MDI as

material for this research.

REFERENCES

Allport, D, C., Gilbert, D, S., Outterside, S., 2003. MDI

and TDI: Safety, Health and the Environment: A

Source Book and Practical Guide. John Wiley &

Sons. West Sussex, England.

Aparna, V., Dileep, K.V., Mandal, P.K., Karthe, P.,

Sadasivan, C., Haridas, M., 2012. Anti-Inflammatory

Property of n-Hexadecanoic Acid: Structural Evidence

and Kinetic Assessment. Chemical Biology & Drug

Design, 80(3), 434-439.

Arora, S., Kumar, G., Meena, S., 2017. Screening and

Evaluation of Bioactive Components of Cenchrus

ciliaris L. by GC-MS Analysis. International Research

Journal of Pharmacy, 8(6), 69-76.

Attaei, M., 2017. Microencapsulation of Isocyanate

Compounds for Autoreactive, Monocomponent

Adhesive. Técnico Lisboa. Portugal.

Bouchemal, K., Briançon, S., Perrier, E., Fessi, H.,

Bonnet, I., Zydowicz, N., 2004. Synthesis and

Characterization of Polyurethane and Poly(Ether

Urethane) Nanocapsules Using A New Technique of

Interfacial Polycondensation Combined to

Spontaneous Emulsification. International Journal of

Pharmaceutics, 269, 89-100.

Carvalho, I.T., Estevinho, B, N., Santos, L., 2016.

Application of Microencapsulated Essential Oils in

Cosmetic and Personal Healthcare Products–A

Review. International journal of cosmetic science,

38(2), 109-119.

Chung, S.K., Seo, J.Y., Lim, J.H., Park, H.H., Yea, M, J.,

Park, H, J., 2013. Microencapsulation of Essential Oil

for Insect Repellent in Food Packaging System.

Journal of Food Science, 78(5), E709-E714.

Cortés-Rojas, D.F., de Souza, C, R, F., Oliveira, W, P.,

2014. Clove (Syzygium aromaticum): A Precious

Spice. Asian Pacific Journal of Tropical Biomedicine,

4(2), 90-96.

Cui, H., Zhao, C., Lin, L., 2015. The Specific

Antibacterial Activity of Liposome-Encapsulated

Clove Oil and Its Application in Tofu. Food Control,

56, 128-134.

Dahham, S, S., Tabana, Y, M., Iqbal, M, A., Ahamed, M,

B, K., Ezzat, M, O., Majid, A, S, A., Majid, A, M, S,

A., 2015. The Anticancer, Antioxidant and

Antimicrobial Properties of the Sesquiterpene β-

Caryophyllene from the Essential Oil of Aquilaria

crassna. Molecules, 20(7), 11808.

Release Profile of the Antimicrobial Agent from Clove Oil Encapsulated in a Polyurethane Shell

35

El-Aasser, M, S., 1990. Emulsion polymerization. In:

Candau, F. & Ottewill, R.H. (eds.). An Introduction to

Polymer Colloids. Springer. Dordrecht. 1

st

edition.

Engels, H-W., Pirkl, H-G., Albers, R., Albach, R, W.,

Krause, J., Hoffmann, A., Casselmann, H., Dormish,

J., 2013. Polyurethanes: Versatile Materials and

Sustainable Problem Solvers for Today’s Challenges.

Angewandte Chemie International Edition,

52(36):9422-9441.

Gezundhait, Y., Pelah, A., 2017. Non-woven fabric

containing microencapsulated essential oils for

preservation of crops. US 20170245493A1.

Han, J, H., 2003. Antimicrobial Food Packaging. In:

Ahvenainen, R. Cambridge: Woodhead Publishing

Ltd.

Hosseini, M, H., Razavi, S, H., Mousavi, M, A., 2009.

Antimicrobial, Physical and Mechanical Properties of

Chitosan-Based Films Incorporated With Thyme,

Clove and Cinnamon Essential Oils. Journal of Food

Processing and Preservation, 33(6):727-743.

Kfoury, M., Hadaruga, N, G., Hadaruga, D, I.,

Fourmentin, S., 2016. 4 - Cyclodextrins as

Encapsulation Material for Flavors and Aroma.

London. Academic Press.

Kim, J, R., Sharma, S., 2011. Acaricidal Activities of

Clove Bud Oil and Red Thyme Oil using

Microencapsulation Against HDMs. Journal of

Microencapsulation, 28(1):82-91.

Lakkis, J, M., 2016. Encapsulation and Controlled

Release Technologies in Food Systems. Blackwell

Publishing. USA. 1

st

edition.

Leimann, F, V., Gonçalves, O, H., Machado, R, A, F.,

Bolzan, A., 2009. Antimicrobial Activity of

Microencapsulated Lemongrass Essential Oil and the

Effect of Experimental Parameters on Microcapsules

Size and Morphology. Materials Science and

Engineering, 29(2):430-436.

Liu, C., Liang, B., Shi, G., Li, Z., Zheng, X., Huang, Y.,

Lin, L., 2015. Preparation and Characteristics of

Nanocapsules Containing Essential Oil for textile

Application. Flavour and Fragrance Journal,

30(4):295-301.

Madene, A., Jacquot, M., Scher, J., Desobry, S., 2006.

Flavour Encapsulation and Controlled Release – a

Review. International Journal of Food Science &

Technology, 41(1):1-21.

Mamaghani, K, R., Naghib, S, M., 2017. The Effect of

Stirring Rate on Electrodeposition of Nanocrystalline

Nickel Coatings and Their Corrosion Behaviors and

Mechanical Characteristics. Int. J. Electrochem. Sci.,

12:5023-5035.

Marchese, A., Barbieri, R., Coppo, E., Orhan, I.E., Daglia,

M., Nabavi, S.F., Izadi, M., Abdollahi, M., Nabavi, S,

M., Ajami, M., 2017. Antimicrobial Activity of

Eugenol and Essential Oils Containing Eugenol: A

Mechanistic Viewpoint. Critical Reviews in

Microbiology, 43(6):668-689.

Minhal, L., Harahap, L, A., Daulay, S, B., 2017. Uji Suhu

Uap Pada Alat Penyuling Minyak Atsiri Cengkeh Tipe

Uap Langsung (Temperature Test on Clove Oil

Distillator Direct Steam Type). Jurnal Rekayasa

Pangan dan Pertanian, 5(2):375-378.

Nakayama, M., Tomiyama, D., Ikeda, K., Katsuki, M.,

Nonaka, A., Miyamoto, T., 2015. Antibacterial Effects

of Monoglycerol Fatty Acid Esters and Sucrose Fatty

Acid Esters on Bacillus spp. Food Science and

Technology Research, 21(3):431-437.

Scarfato, P., Avallone, E., Iannelli, P., De Feo, V.,

Acierno, D., 2007. Synthesis and Characterization of

Polyurea Microcapsules Containing Essential Oils

with Antigerminative Activity. Journal of applied

polymer science, 105(6):3568-3577.

Yow, H.N., Routh, A.F., 2006. Formation of Liquid Core–

Polymer Shell Microcapsules. Soft Matter, 2(11):940-

949.

Zhenxing, H., Xiaowei, Y., Junliang, L., Yuping, Y., Ling,

W., Yanwei, Z., 2011. An Investigation of the Effect

of Sodium Dodecyl Sulfate on Quasi-Emulsifier-Free

Emulsion Polymerization for highly Monodisperse

Polystyrene Nanospheres. European Polymer Journal,

47(1):24-30.

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

36