A Modification of Pile Unit Skin (f) of Frictional Resistance (Q

s

)

on Clayey Layer at Central of Jakarta

Putera Agung Maha Agung

1

, Andreas Rudi Hermawan

1

, and I Ketut Sucita

1

1

Department of Civil Enginering, Politeknik Negeri Jakarta, Depok, Indonesia

Keywords: frictional resistance, pile foundation, CPT, and PDA test.

Abstract: The evaluation of pile unit skin friction (f) is important and difficult in determining frictional resistance (Q

s

)

of single pile. A modification was conducted on curves and table design of (f) in clayey soil from Nottingham

& Schmertmann and Schmertmann methods. PDA test was used as the valid data to compare the prediction

analysis result using these methods. Resistance friction (Q

s(u)

) and (Q

s(Ru)

), respectively of single pile were

obtained by 5 random points of CPT analyzed by Schmertmann methods and 2 points of PDA test evaluated

by CASE and CAPWAP methods from study site. From the result of modification of unit skin friction analysis

using CPT data approaching to the real data from PDA test results.

1 INTRODUCTION

Generally, cone penetration test (CPT) is extensively

used in the building project. Cone penetration testing

(CPT) is an easy, a fast and a reliable means of

conducting building design site investigations for

exploring soils and soft ground for support of

foundations. For the small to medium project,

engineer has to design with using CPT data only, so

they must search the confirmatory data through some

correlation between parameter from CPT data results

to complete the shortage data. Thus, the all prediction

for frictional resistance (Q

s(u)

) parameter design of

axial bearing capacity (Q

u

) from CPT results must be

examined by a loading test results at the field in

determinating the safety factor (SF).

There are many methods for evaluation (Q

s(u)

)

based on CPT data (Aoki and De Alencar (1975),

Clisby et al (1980), Schmertmann (1978), de Ruiter

and Beringen (1979), Bustamante and Gianeselli

(LCPC/LCP) (1982), Tumay and Fakhroo (1982),

Philipponnat (1980), Price and Wardle (1982)

methods. However, it was not for all methods showed

the best capability (Titi and Abu-Farsakh, 1999) in

predicting of (Q

s(u)

) using (PPC) piles driven into a

certain area. This research effort was focused on the

applicability of one of CPT methods to predict the

frictional resistance of piles from CPT data

(Schmertmann, 1978). The predicted capacity (Q

s(u)

)

using CPT data was compared to the reference pile

load capacity (Q

s(Ru)

) obtained from the pile load test

using PDA method. The CPT method were used to

investigate the load carrying capacity of square

precast prestressed concrete (PPC) piles of 30 cm in

size driven into Jakarta clayey soil (SNI 2847, 2013).

Criteria for acceptance of (Q

s(u)

) (ultimate frictional

resistance from CPT) should be equals or less than ≤

(Q

(sRu)

) (from PDA results). Some previous studies

for clayey soil, Cummings et al, (1950), Seed and

Reese (1955), Bjerrum et al. (1958), Soderberg

(1962), Begemann (1965), Tomlinson (1957), and

Poulos (1989), etc were suggested to determine the

unit skin friction (f) in determining the frictional

resistance (Q

s(u)

) of single pile by direct and or

indirect approaches. This study proposed the

modification parameter analysis for unit skin friction

(f) in determining (Q

s(u)

) of clayey soil layers at

central of Jakarta.

2 METHODOLOGY

2.1 CPT Data

Soil investigation uses a set of CPT equipment

complete with the auxiliary devices. The CPT is a

light weight model with a compressive capacity of 2.5

tons. Conus used is friction cone type (biconus type)

with a cross-sectional area unit of 10 cm

2

, area of

blanket 123 cm

2

. CPT is carried out continuously at

intervals of 20 cm depth penetration to show

maximum cone (tip) resistance and maximum shear

126

Maha Agung, P., Hermawan, A. and Sucita, I.

A Modification of Pile Unit Skin (f) of Frictional Resistance (Qs) on Clayey Layer at Central of Jakarta.

DOI: 10.5220/0009954100002905

In Proceedings of the 8th Annual Southeast Asian International Seminar (ASAIS 2019), pages 126-131

ISBN: 978-989-758-468-8

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

of 250 kg/cm

2

, or up to a maximum depth of 30

meters. Data set presented are the cone tip resistance

and the total friction (q

c

) and ratio local friction (t

f

)

against cone tip resistance or (t

f

/q

c

) or friction ratio

(F

R

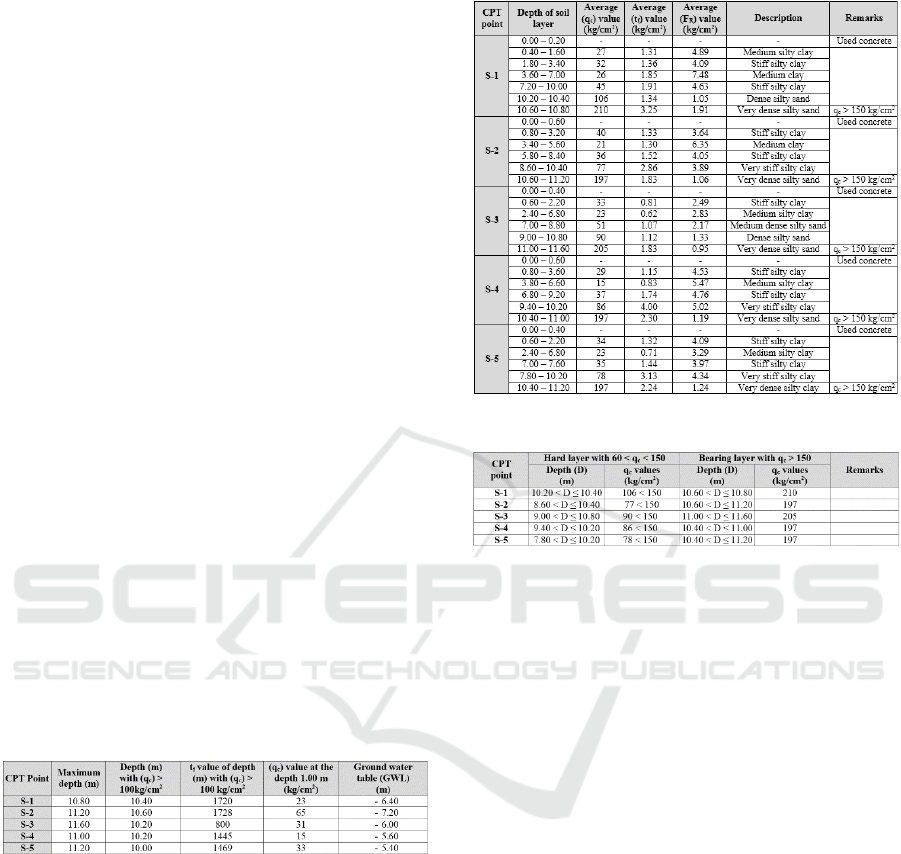

) values to a maximum depth of 30 meters. Table

1 shows the results of the soil investigation using CPT

shows in the table below related with maximum depth

of CPT, depth of hard soil, t

f

and q

c

values for all soil

layers at the surface area. Table 2 identifies that the

estimation of geostratigraphic profile using several

methods (Begemann, 1965; Schmertmann, 1978; and

Robertson and or et al, 1986; 1990). Table 3 shows 5

(five) CPT data (S-1 to S-5) provides the information

of hard layer depth with (q

c

) value between 60 < q

c

<

150 kg/cm

2

and thickness of the bearing layer with

(q

c

) value > 150 kg/cm

2

. Then, Figure 1 shows that

geostratigraphic soil profile based on cone

penetration test (CPT) of study site. Based on the 5

(five) CPT (S-1 to S-5), it could be indicated the

condition of surface layers consisting of medium to

stiff silty clay with cone resistance (q

c

) values

between 27 to 34 kg/cm

2

and at the depth between

0.40 to 3.60 m.

CPT data normally can be used to determine the

other of soil parameter using some correlations

required for deep foundation design, especially in

determining frictional resistance of single pile (Q

s(u)

).

From some previous design reports and studies,

Schmertmann (1978) method was selected and

considered suitable for study area, besides the method

was widely used CPT methods in determining bearing

capacity (Q

u

) in Indonesia.

Table 1: The results of CPT data.

2.2 PDA Data

The PDA test is to evaluate the ultimate load

carrying-capacity (Q

u

) of the pile, the integrity /

integrity of the pile and pole drop. PDA test normally

are used as field test additional to replace the

conventional loading test. Data results of PDA test

was obtained from 2 locations of pile foundation

system configuration at a sub-structure of BPJS

Building of Central Jakarta project (See Appendix).

All calculation results of (Q

(sRu)

) by PDA test

actually uses top force pile and velocity signals,

obtained using instrumentation or device, such as :

Table 2: The results of geostratigraphic profile from CPT.

Table 3: The results of hard and bearing layers from CPT.

piezoelectric accelerometers and bolt-on of strain

transducers attached to the pile near its top. PDA

conditions and calibrates these signals and velocity.

Using case method solutions, the PDA calculates the

results on BPJS Building project site (Figure 2)

described in the following section. PDA test were

applied in two piles load testing sites for axial bearing

capacity and one pile for lateral displacement. To help

examine the soil conditions and design calculation,

the results of the investigations which nearest the

PDA pile tested for CPT-S1 and CPT-S2 as shown as

Table 1; 2; and 3.

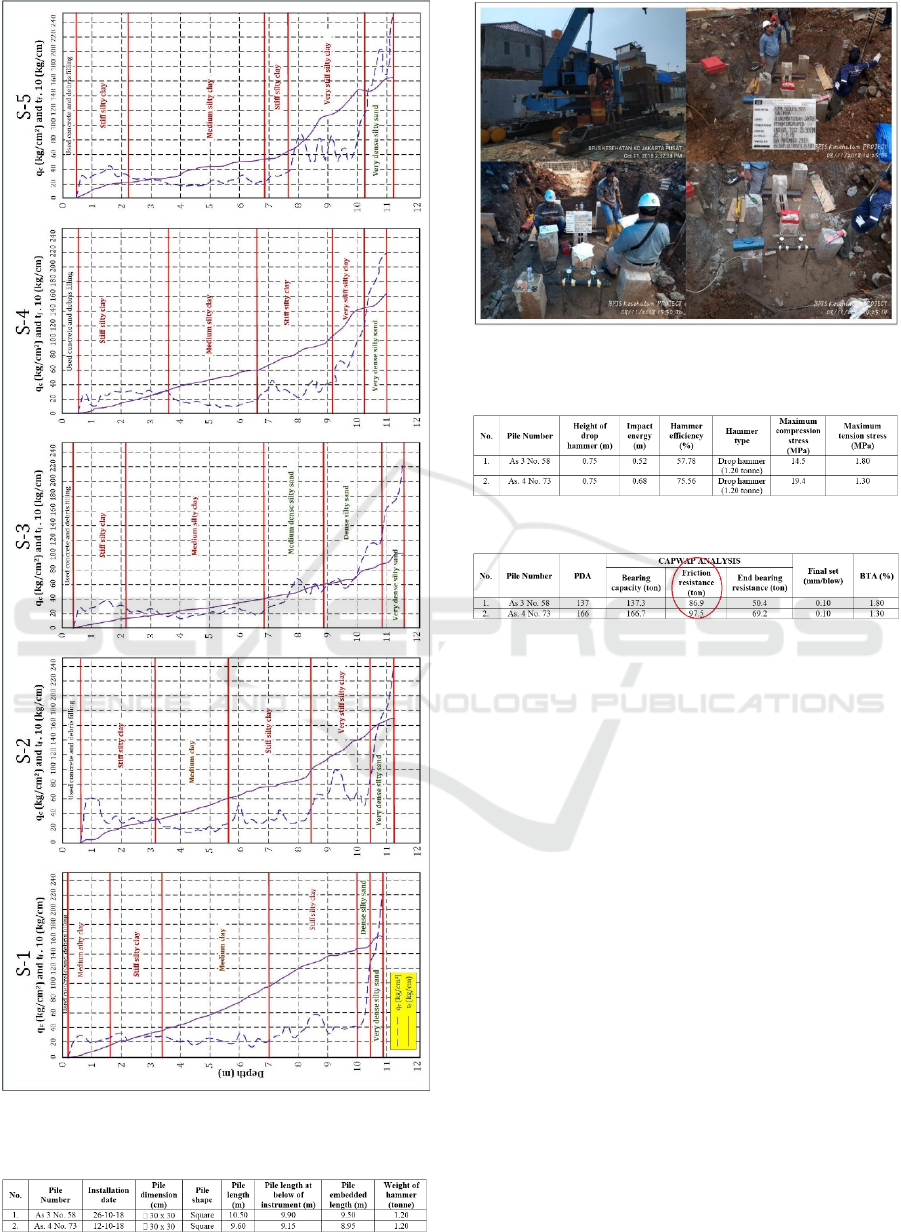

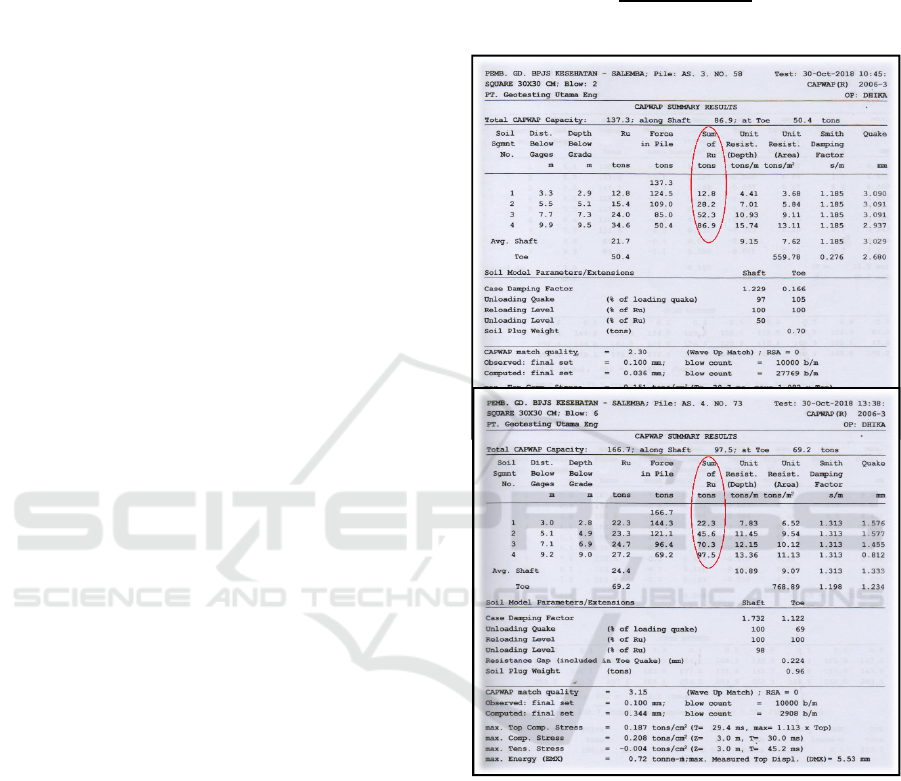

Pile testing data results are shown from Table 4 to

6. Table 4 shows the existing pile data for evaluation

of bearing capacity and settlement. Table 4 shows the

maximum compression and tension stresses results

from field testing. Table 5 identifies the PDA test data

reading result from field test and after analysis using

manually CASE analysis and CAPWAP (Case Pile

Wave Analysis Program) software. Both

measurements and analyses generate the end bearing

capacity (Q

b

) and shaft friction (Q

s

). However, this

study will discuss shaft or skin friction (f) only as

shown as with “RED ELLIPSE-CIRCLE” on the data

of Table 6. This frictional resistance from PDA test

(Q

(sRu)

) or “Actual Values” will be compared with the

calculation using CPT data (Q

s(u)

) or “Estimation

Values” for this study.

A Modification of Pile Unit Skin (f) of Frictional Resistance (Qs) on Clayey Layer at Central of Jakarta

127

Figure 1: Soil profile based on (CPT) parameters.

Table 4: Pile data for PDA test.

Figure 2: Piling and instalation of PDA test.

Table 5: Maximum compression and tension stresses.

Table 6: PDA analysis data results (CASE & CAPWAP)

2.3 Frictional Resistance using CPT

Estimating the frictional or skin resistance (Q

s

) of

piles in clay layers is almost as difficult a task as

estimating that in sand layers, due to the presence of

several variables that can not easily be quantified.

Several methods for obtaining the unit frictional

resistance of piles are described in the literature

(Vijayvergiya and Focht, 1972, etc). However, in this

study some analyses use Nottingham and

Schmertmann (1975) and Schmertmann (1978) only

in determining (Q

s(u)

).

The correlation to evaluate unit skin friction (f) in

clay (with = 0) to be:

Generally, axial bearing capacity equation:

ub s

QQ Q

(1)

Frictional resistance from CPT data (Q

s(u)

):

.'...

su c

QfpL fpL

(2)

Unit skin friction can be determined by:

'.

c

f

f

(3)

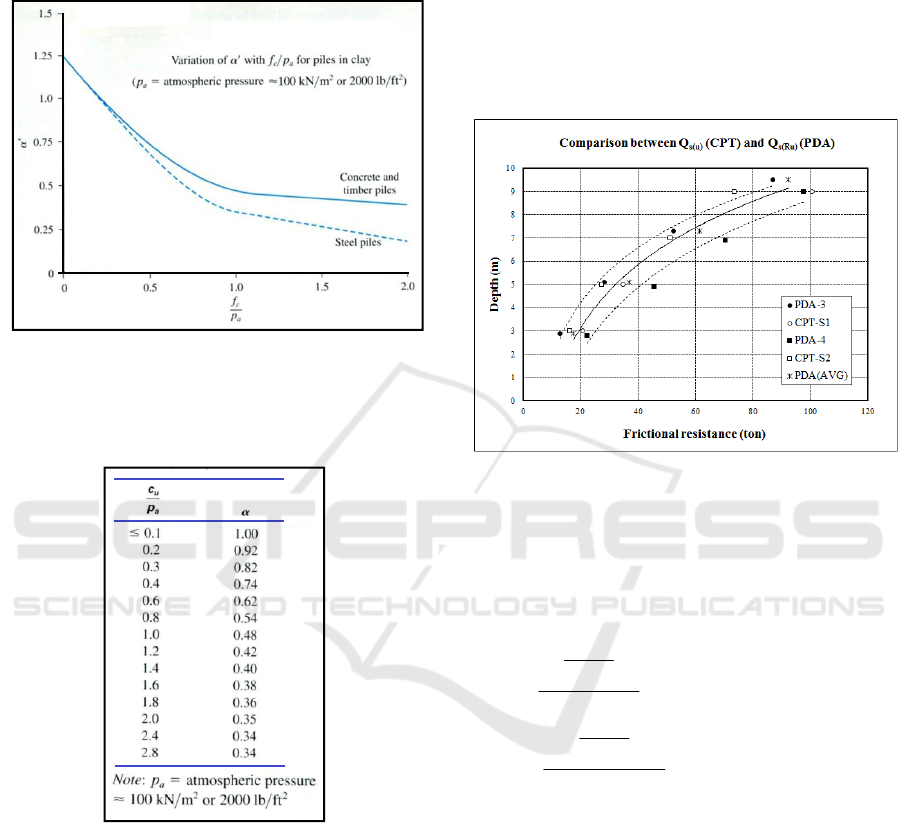

The variation of (’) with the frictional resistance

(f

c

) is shown in Figure 2.

Where ( equals an empirical adhesion factor.

The approximate variation of the value of ( is

shown in Table 7. It is important to realize that the

ASAIS 2019 - Annual Southeast Asian International Seminar

128

values of a gives in Table 7 may vary somewhat,

since ( is actually a function of vertical effective

stress (’

o

) and the undrained cohesion (c

u

).

Figure 2: Variation of f

c

/ P

a

and ’ (Nottingham &

Schmertmann (1975); Schmertmann (1978)).

Table 7: Variation of f

c

/ Pa and

(Terzaghi, Peck, and Mesri (1996); Das, 2007).

From the detail explanation above, in determining

value requires laboratory testing for undisturbed

samples. However, for this study, soil investigation

was carried out CPT only. Thus, this study conducted

needs to propose a modification values in

determining pile unit skin (f) from the comparison

between (Q

s(u)

) and (Q

s(Ru)

), so that it would be

suitable for study site in determining (Q

u

) of a pile.

3 RESULT AND DISCUSSION

Frictional resistance analysis based on CPT

(Schmertmann, 1978) (Q

s(u)

) and PDA (CASE and

CAPWAP methods) (Q

s(Ru)

) data are compared each

other and obtained the Figure 3. In the field, the

position of CPT-S1 is near PDA-3, and also S-2

closes to PDA-4, respectively.

Figure 3: (Q

s(u)

) and (Q

s(Ru)

).

From Figure 3, parameter of (f) or (f

c

) and and or ’

can be determined by back analysis using average of

line equation of (Q

(s(Ru)

) directly. Thus, to calculate (f)

or (f

c

) can be used the Equation (4) and (5),

respectively:

()uRu

Q

f

pL

(4)

()

'

uRu

c

Q

f

pL

(5)

where

'.

c

f

f

.

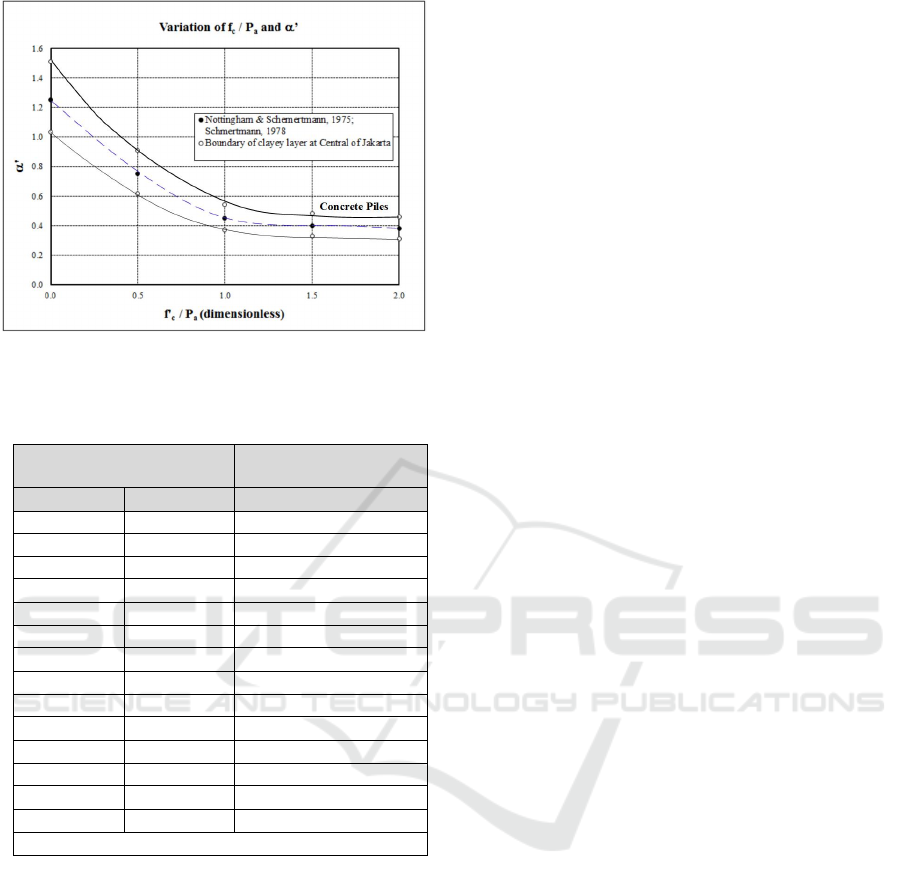

And, the results of modification of Nottingham &

Schmertmann (1975) and Schmertman (1978) can be

shown in Figure 4 and Table 8.

Since the study is only for concrete piles, the Figure

4 is applicable for deep foundation of pile made from

reinforcement concrete or square precast prestressed

concrete (PPC) piles system. And, Figure 4 is only

valid for clayey layers at central of Jakarta. However,

this study can be developed for another places in

Indonesia which is same as Jakarta soil

geostratigraphy.

A Modification of Pile Unit Skin (f) of Frictional Resistance (Qs) on Clayey Layer at Central of Jakarta

129

Figure 4: Modification relationships between variation of f

c

/ P

a

and ’ values

Table 8: Modification of Terzaghi et al (1996)

Terzaghi et al (1996)

Clayey layer of

Jakarta Central

c

u

/P

a

Range of

0.1 1.00 0.83 – 1.21

0.2 0.92 0.76 – 1.11

0.3 0.82 0.68 – 0.99

0.4 0.74 0.61 – 0.90

0.6 0.62 0.51 – 0.75

0.8 0.54 0.45 – 0.65

1.0 0.48 0.40 – 0.58

1.2 0.42 0.35 – 0.51

1.4 0.40 0.33 – 0.48

1.6 0.38 0.31 – 0.46

1.8 0.36 0.30 – 0.44

2.0 0.35 0.29 – 0.42

2.4 0.34 0.28 – 0.41

2.8 0.34 0.28 – 0.41

Note: Pa = atmospheric pressure 100 kPa

4 CONCLUSIONS

Study analysis investigations have indicated that

unit skin friction (f) in determining frictional

resistance (Q

s

) on clayey layers of Jakarta Central

reaches about ± 17 to 18 percent of the previous

studies (Nottingham & Schmertmann, 1975;

Schmertman, 1978). This matter, it can be shown in

Figure 4 and Table 8, where and or ’ values on

each modification has a certain range of these values.

However, in application it should be considered with

vertical effective stress (’

o

) and the undrained

cohesion (c

u

) from laboratory data for undisturbed

sample.

These values obtained were within ranges established

by governmental authority regulations. Pile unit

friction (f) showed significant changes during

instalation for any time period. and or ’ values of

CPT data proved more sensitive than c

u

values

changes for determining frictional resistance during

the pilling. Losses of unit friction (f) can increase with

pore water pressure around pile shaft.

ACKNOWLEDGEMENTS

This work was supported by Tambora Consultant

Company for Deep Foundation System Designer;

Tribina Wahana Cipta for Soil Investigation of CPT

data; Geotesting Utama Engineering for PDA data;

and the Central BPJS Office as the project Owner.

REFERENCES

Aoki, N. and de Alencar, D. 1975. An Approximate Method

to Estimate the Bearing Capacity of Piles, Proceedings,

the 5th Pan-American Conference of Soil Mechanics

and Foundation Engineering, Buenos Aires, Vol. 1, pp.

367-376.

Bjerrum, L., Brinch Hansen, J., and Sevaldson. 1958.

Geotechnical Investigations For a Quay Structure in

Horten. Publ. No. 28, Norwegian Geotech. Inst, pp. 1-

17.

Bustamante, M., and L. Gianeeselli. 1982. Pile Bearing

Capacity Predictions by Means of Static Penetrometer

CPT. Proceedings of the 2nd European Symposium on

Penetration Testing, ESOPT-II, Amsterdam, Vol. 2, pp.

493-500.

Cummings, A.E., Kerkkhoff, G.O., and Peck, R.B. 1950.

Effect of Driving Piles into Soft Clay. Trans. ASCE,

Vol. 115, pp. 275-86.

Clisby, M.B., Scholtes, R.M., Corey, M.W., Cole, H.A.,

Teng, P., and Webb, J.D. 1978. An Evaluation of Pile

Bearing Capacities, Volume I, Final Report,

Mississippi State Highway Department.

Begemann, H.K. 1965. The Friction Jacket Cone as an Aide

in Determining the Soil Profile. Proceedings, 6th

International Conference on Soil Mechanics and

Foundation Engineering, Vol. 1, Montreal, QC,

Canada, 1965, pp. 17–20.

De Ruiter, J., and F.L. Beringen. (1979). Pile Foundations

for Large North Sea Structures. Marine Geotechnology,

Vol. 3, No. 3, pp. 267-314.

Das, B, M. 2007. Principles of Foundation Engineering.

Global Engineering Publisher, 200 First Stamford

Place, Suite 400, Stamford, CT 06902, USA.

Nottingham, L. C. 1975. Use of quasi-static friction cone

penetrometer data to estimate capacity of displacement

piles. Ph. D. Thesis, Dept, of Civil Engng., Univ. of

Florida, 553 p.

ASAIS 2019 - Annual Southeast Asian International Seminar

130

Nottingham, L. and Schmertmann, J. 1975. An investigation

of pile capacity design procedures, Final Report D629

to Florida Department of Transportation from

Department of Civil Engineering, Uni-versity of

Florida: 159 pp.

Price, G. and Wardle, I.F. (1982). A Comparison Between

Cone Penetration Test Results and the Performance of

Small Diameter Instrumented Piles in Stiff Clay,

Proceedings, the 2nd European Symposium on

Penetration Testing, Amsterdam, Vol. 2, pp. 775-780.

Philipponnat, G. (1980). Methode Pratique de Calcul d’un

Pieu Isole a l’aide du Penetrometre Statique. Revue

Francaise de Geotechnique, 10, pp. 55-64.

Poulos, H.G. 1989. Pile behaviour—theory and application.

Géotechnique, Volume 39 Issue 3, September, pp. 365-

415.

Robertson, P.K., R.G. Campanella, D. Gillespie, and J.

Greig. 1986, Use of Piezometer Cone Data, Use of In-

Situ Tests in Geotechnical Engineering (GSP 6),

American Society of Civil Engineers, Reston, Va., pp.

1263–1280.

Robertson, P.K. 1990. Soil Classification Using the Cone

Penetration Test. Canadian Geotechnical Journal, Vol.

27, No. 1, pp. 151–158.

SNI 2847, 2013. Beton Struktural untuk Bangunan Gedung.

Soderberg. L.O. 1962. Consolidation Theory Applied to

Foundation Pile Time Effects. Geotechnique, Vol. XII,

No. 3 (Sept), pp. 217-25.

Seed, H. B. & Reese, L. C. 1955. The action of soft clay

along friction piles. Proc. Am. Sot. Civ. Engrs 81, Paper

842.

Schmertmann, J. H. 1978. Guidelines for cone test,

performance and design. Federal Highway

Administration, Report FHWA-TS-78209,

Washington, 145 p.

Titi, H, H., Murad Y Abu-Farsakh. (1999). Evaluation of

Bearing Capacity of Piles Bearing Capacity of Piles

from Cone Penetration Test Data. Louisiana

Transportation Research Center 4101 Gourrier Avenue

Baton Rouge, LA 70808.

Tumay, M.T., and Fakhroo, M. 1982. Friction Pile

Capacity Prediction in Cohesive Soils Using Electric

Quasi-Static Penetration Tests. Interim Research

Report No. 1, Louisiana Department of Transportation

and Development, Research and Development Section,

Baton Rouge, LA, 275 p.

Terzahi, K., Peck, R.B., and Mesri, G. 1996. Soil

Mechanics in Engineering Practice. John and Willey

and Sons. Canada.

Tomlinson, M.J. 1957. The adhesion of piles driven in clay

soils. Proc. 4th Internatl. Conf. Soil. Mech. Found.

Engrg., Vol. 2, London, pp. 66-71.

Vijayvergiya,V.N.,and Focht, J.A. 1972. A new way to

predict capacity of piles in clay. In Proceedings of the

Offshore Technology Conference, Houston, Texas,

USA.

Vesic, A.S. 1967. A Study of Bearing Capacity of Deep

Foundation. Final Report, Project B-189, Georgia

Institute of Technology, Atlanta, pp. 231-6.

APPENDIX

PDA DATA

A Modification of Pile Unit Skin (f) of Frictional Resistance (Qs) on Clayey Layer at Central of Jakarta

131