Design of Prototype Electric Car using 4 Motors as Future City Car in

Indonesia

Widodo

1

and Mochamad Syamsiro

1

1

Departement of Mechanical Engineering, Janabadra University, Jalan Tentara Rakyat Mataram 55-57 Yogyakarta 55231

Keywords:

Electric Vehicle, City Car, Energy Consumption, Performance.

Abstract:

The availability of non-renewable energy used by motorized vehicles will eventually run out. According to

Ministry of Energy and Mineral Resources, crude oil reserves in Indonesia are declining. In 2030 or next

11-12 years, oil in Indonesia will be run out. In the other hand, fuel consumption increase significantly for

13.5 million barrels, from 374.7 million barrels to 388.2 million barrels. Electric vehicles for the future of

alternative solutions are emerged by this situation. This study aims to design, fabricate and tested the electric

car as the future city car in Indonesia. The test results of electric cars are as follows: 1) the average speed

of 8 km mileage was 12.52 minutes; 2) the uptake is tested at a distance of 10 meters with a slope of 25

◦

by

1387,266 watts; 3) the acceleration and deceleration of 100 meters followed by braking and the stop distance

after braking was 5.3 takes 8.643 seconds; 4) The acceleration was 2.49 m/s2 and 50 total Energy consumption

of Energy used in 8 km was 587,782 Wh.

1 INTRODUCTION

The increasing numbers of fossil fuel vehicles makes

humans dependent and lead to energy crisis. The

availability of non-renewable energy used for motor

vehicle fuel has gradually diminished over time. The

demand for fossil fuel continuously increases. An-

other problem that arises from vehicles with fossil

fuel is environmental pollution. Pollution is caused

by carbon dioxide in exhaust gas as a result of com-

bustion. Excessive carbon dioxide will cause long-

term effects such as various respiratory diseases, the

greenhouse effect. In 2030 or next 11-12 years there

will be run out of oil in Indonesia.

In the other hand, fuel consumption increase sig-

nificantly for 13.5 million barrels, from 374.7 million

barrels to 388.2 million barrels (of Energy and of In-

donesia (MEMRI), 2019). Therefore, the alternative

energy sources have been developed such as pyrolytic

oil from waste plastic and tire as partial substitute for

fossil fuel (Syamsiro et al., 2018); (Syamsiro et al.,

2019a) and also tested in the combustion engine to

assess the thermal performance of that fuel (Syamsiro

et al., 2019b). However, the combustion based engine

was still used in this system, so that the alternative

engine need to be developed to solve these problems.

Electric vehicles for the future of alternative so-

lutions are emerged by the petroleum supplies cri-

sis; moreover fossil fuel generates air pollution and

noise in our society and environment (Bambang et al.,

2011).

Exhaust gas emissions such as CO, NOx, SOx, HF

are polluting the environment, thus the emission of

exhaust gas must be in accordance with the laws and

regulations so that it is safe for the environment. Hy-

drogen fluoride is a compound of hydrogen and fluo-

rine with the chemical formula of HF. Fluorine is in

halogens elements group, which all combine with hy-

drogen in the same way to form hydrogen halide. At

room temperature and normal pressure, hydrogen flu-

oride is a colorless gas with a boiling point of 19.5

◦

C,

and allows it to exist as a liquid at room temperatures.

Hydrogen fluoride can be produced by the reaction of

metal fluorides. Hydrogen fluoride is very toxic and

very corrosive. Inhaling gas damages the respiratory

system and can cause pulmonary edema and death.

Nitrogen oxide (NOx) is a type of air pollution;

NOx is a group of gas which mainly consists of two

main components, namely nitric oxide (NO) and

nitrogen dioxide (NO2) gas, and other very small

amounts of nitrogen oxides. NO is a colorless and

odorless gas, in contrary NO2 is brown reddish and

has a strong odor. In general the NOx gas formation

reaction process is as follow:

Widodo, . and Syamsiro, M.

Design of Prototype Electric Car using 4 Motors as Future City Car in Indonesia.

DOI: 10.5220/0009877600430047

In Proceedings of the 2nd International Conference on Applied Science, Engineering and Social Sciences (ICASESS 2019), pages 43-47

ISBN: 978-989-758-452-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

43

N

2

+ O

2

→ 2NO

2NO + O

2

→ 2NO

2

(1)

Nitrogen oxides (NOx) is formed from oxidation

of nitrogen molecules in fuel combustion process,

consisting of 95% NO and 5% NO2. SOx (sulfurox-

ide) is one of the components of pollutants in the at-

mosphere resulting from the combustion process of

oil and coal and other processes containing sulfates

(Wark et al., 1998). SOx gas is very dangerous for

living things because it plays an important role in

the accumulation of acid in the air which causes acid

rain (Benitez, 1993). In certain concentrations SOx

can cause lung disease and respiratory problem, es-

pecially for people with asthma, bronchitis, and other

respiratory diseases (Bruce and Bruce, 2003).

CO (carbon monoxide) is a colorless and odorless

gas produced from an incomplete combustion pro-

cess from carbon-based materials such as wood, coal,

fuel oil and other organic substances (Grant and Clay,

2002). Claude Bernard in 1857 discovered that the

toxic effect of carbon monoxide caused by the re-

lease of oxygen bonds from hemoglobin into carboxy-

haemoglobin.

The energy produced from fossil fuels is increas-

ingly expensive and scarce and one day it will surely

run out, Indonesia’s oil production is now far less than

the needs of the population and industry, currently it

is estimated to have a deficit of around 500,000 bar-

rels/day (BP Statistical Review Of World Energy) as

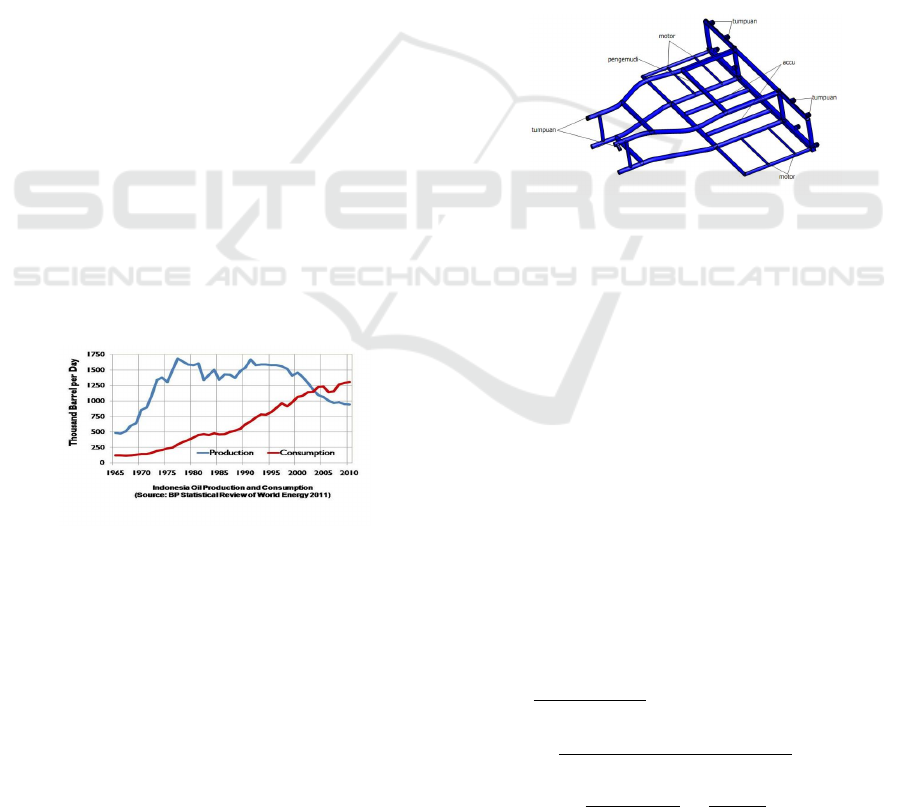

seen in Figure 1 ((BPS), 2010)

Figure 1: Petroleum production and consumption in In-

donesia

2 METHODOLOGY

2.1 Battery

Electric cars are vehicles that are driven by an elec-

tric motor, using electrical energy stored in batteries

or other energy storage. Electric Energy is converted

into mechanical energy by a motor. The power from

the electric motor is then transmitted to the wheel so

that it becomes the rotating energy which drives the

wheels of the car.

2.2 Frame or Chassis

Chassis is an important part of the vehicle. Chassis

serves to support and mount the components in the

vehicle. For this reason, material selection must be

considered in accordance with its use. In selecting the

most important material is the analysis of mechanical

properties, namely the concept of the voltage acting

on the structure and the stress of the material used.

From this analysis we can find the maximum voltage

and deflection. Once the maximum voltage and de-

flection is known, we can determine the material and

size of the material. In this analysis we use the 2009

Autodesk Inventor software (Curtis and Loren, ).

Figure 2: Chassis of an Electric Car

2.3 Motor

Before determining the motor power, the first consid-

eration is vehicle’s trail force the following data are

known:

a) Wheel Base (L): 1500 mm

b) Center Weight (l1): 754 mm from the front axle

c) Center Weight (l2): 746 mm from the rear axle

d) Weight point height (h): 250 mm

e) Vehicle weight (W): 250.10 = 2500 N

f) Glinding resistance coefficient (fr): 0.3

Wheel adhesion coefficient with road surface (µ):

0.3 using the rear wheel drive then the vehicle’s trail

force can be calculated (Mott, 2009).

F =

µW (l1 − f

r

.h)

L − µ.h

=

0, 3.2500.(0,754 − 0, 3.0, 25)

1, 5 − 0, 3.0, 25

=

750.0, 679

1.5 − 0, 075

=

509, 25

1, 425

= 357, 4N (2)

ICASESS 2019 - International Conference on Applied Science, Engineering and Social Science

44

So the force needed to drive the car is at least

357.4 N. From this calculation, the BLDC 500 watt

motor is able to move. The performance of the BLDC

500 watt motor is as follows:

Table 1: Reference table for motor determination of electric

car (Champion and Arnold, 1954)

Torq

ue(

Nm)

Volt

a

ge

(volt)

Cur

re

nt

(am

pere)

Inp

ut

Pow

er

(wa

tt)

Rot

at

ion

(rpm)

Out

put

Po

wer

(watt)

Effic

ency

(%)

1.2 48.0

7

2.42

2

116

.4

720

.6

9.5 8.2

1.7 48.0

9

3.44

5

165

.7

719

.5

13.4 8.1

2 48.0

6

3.44

4

165

.5

720

.7

14.2 8.6

2 48.0

4

3.45

6

116 720

.7

14.3 8.6

2 48.0

7

3.44

8

165

.7

718

.5

14.9 9

3.7 48.0

2

4.33

3

208

.1

718

.2

27.5 13.2

7.5 48.0

1

4.68

7

225 715

.7

56.5 25.1

11 47.9

9

4.84

9

232 712

.4

79.8 34.4

19 47.9

6

5.93

4

284

.6

70

7.9

142

.6

50.1

26 47.9 6.97

3

334 702

.4

190 56.9

41 48 9.72

5

466

.8

697

.6

297

.4

63.7

52 47.6 11.6

18

553

.01

690

.5

373

.3

67.5

67 47.7

9

13.2

89

660

.1

686

.2

480

.8

72.4

85 47.9

6

16.2

36

778

.7

674

.6

598

.1

76.8

99 47.5

2

18.3

14

870

.3

662

.4

688

.4

79.1

123 47.6

4

21.7

2

1034

.7

644

.1

830

.8

80.3

157 47.4

1

25.1

06

1190

.3

590

.7

968

.9

81.4

200 47.2

6

28.1

21

1328

.9

529

.6

111

1

83.6

247 47.5

4

30.4

83

1449

.2

478

.3

123

4.7

85.2

275 47.4

8

31.7

04

1505

.3

431

.9

124

4.8

82.7

320 48.0

1

32.3

02

1548

.7

375

.3

125

7.5

81.2

336 47.2

3

31.4 1507

.1

332

.4

116

9.5

77.6

356 47.3

5

30.5

81

1478 305

.7

113

9.5

77.1

382 47.1

9

27.1 1304

.8

290

.2

916

.5

70.2

426 47.4

2

25.9

32

1203

.8

270

.6

840

.3

69.8

453 47.1

9

24.3

56

1149

.4

240

.7

743

.9

64.7

484 47.1

6

23.7

82

1121

.6

220

.6

654

.8

58.4

511 47.1

4

23.4

53

1105

.6

201

.1

610

.9

55.3

542 47.2

6

22.8

92

1081

.8

160

.6

550

.7

50.9

581 47.3

7

24.5

5

1162

.9

111

.3

452

.8

38.9

605 47.5

1

25.0

68

1190

.9

70.2 359

.4

30.1

639 47.2 26.5

14

1251

.5

43.5 276

.6

22.1

3 RESULTS AND DISCUSSION

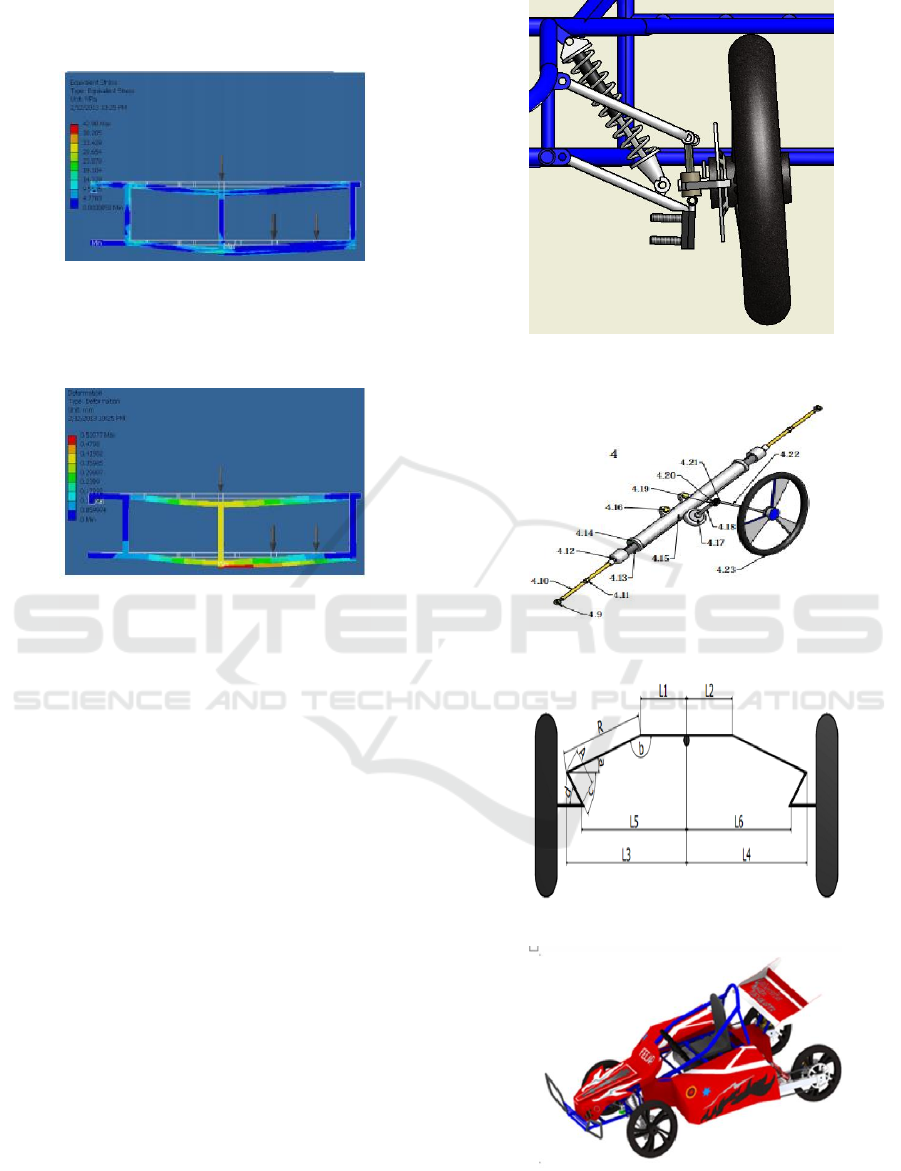

3.1 Trial Framework Design

The results of the framework design analysis is shown

in Table 2.

Table 2: Framework design analysis

Name Minimum Maximum

Equivalent Stress 3.086e-003

MPa

42.96 MPa

Maximum Princi-

pal Stress

-33.68 MPa 29.72 MPa

Minimum Princi-

pal Stress

-80.81 MPa 7.48 MPa

Deformation 0.0 mm 0.5398 mm

Safety Factor 4.816 N/A

Considered from the critical stress the design is

safe, because the maximum stress acting on the con-

struction is smaller than the material tensile stress

(42.98 <345). Based on the results of the analysis

above, the material used for the framework is a low

Design of Prototype Electric Car using 4 Motors as Future City Car in Indonesia

45

carbon steel pipe with the diameter of 3/4 ”and 1/2”

and thickness of 2 mm, this specification is safe

Figure 3: Load Analysis Low

Figure 4: Load Analysis Medium

3.2 Steering Design Test

The steering mechanism used in this mode was the

type of ackerman with rack and pinion. When the

steering wheel was rotated, the swivel force will for-

warded to the pinion by the steering wheel shaft. Then

the rotational motion was changed to horizontal with

a straight gear rack-gear mechanism. Furthermore,

this horizontal movement was forwarded to knuckle

arm/ackerman by tie-rod. Ackerman which is con-

nected to knuckle will bend the wheel.

The Ackerman type steering system mechanism

shows that the knuckle is angled to form a trapezoid.

In this construction, there is a joint point on Acker-

man and the tie-rod tip so that a different turning an-

gle occurs between the left wheel and the right wheel

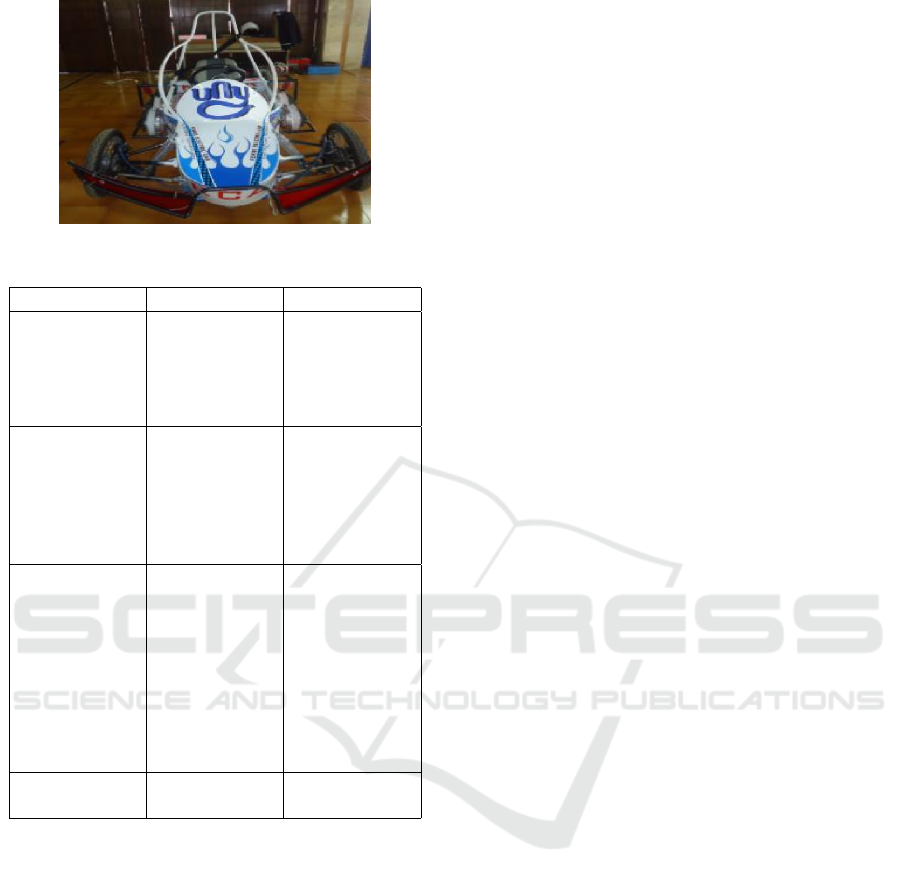

3.3 Test Result for Electric Car

The results of the electric car performance test is

shown in Table 3 using the fabricated car shown in

Figure 9.

Figure 5: Adjustable wheel tilt model

Figure 6: Gear and pinion rake system

Figure 7: The ackerman

Figure 8: Full body design

ICASESS 2019 - International Conference on Applied Science, Engineering and Social Science

46

Figure 9: Fabricated electric car.

Table 3: Framework design analysis

Category Information Result

Average

speed

Distance of

8 km, time

12.52 min-

utes = 751.2

seconds

38.34

km/hour

Climbing

Power

Tested at a

distance of 10

meters with a

slope of 25

◦

Climb Power

was 1387,266

watts (read on

display mea-

suring instru-

ments)

Acceleration

& Decelera-

tion

Tested at a

distance of

100 meters

then braked

and the stop-

ping distance

after braking

is 5.3

Readable

acceleration

on the display

devicemea-

sure was 2.49

m / s2 and

result decel-

eration takes

8.643 seconds

Energy Con-

sumption

Total Energy

used in 8 km

587,782 Wh

4 CONCLUSIONS

The test results of acceleration, deceleration, grade-

ability, show very good data results. However the av-

erage speed efficiency shows relatively good results,

this is influenced by the transmission system that has

not been suppressed by the development of a combi-

nation of gears automatically. Model 4 BLDC motors

with 1 motor each of 500 watts, this is suitable for

large torque speeds, but vehicle speed was still lower

than it required.

ACKNOWLEDGEMENTS

The author would like to send the gratitude to the

Chancellor, Dean, Lecturer and TEAM of Yogyakarta

State University for providing good support for the

development of this electric car research.

REFERENCES

Bambang, K., Soebagio, M., and Hery, P. (2011). Design

and development of small electric vehicle using mat-

lam/simulink. Institute of Technology, Indonesia.

Benitez, J. (1993). Process engineering and design for air

pollution control. Prentice-Hall.

(BPS), B. P. S. (2010). Bps statistical review of world en-

ergy.

Bruce, E. N. and Bruce, M. C. (2003). A multicompartment

model of carboxyhemoglobin and carboxymyoglobin

responses to inhalation of carbon monoxide. Journal

of Applied Physiology, 95(3):1235–1247.

Champion, R. C. and Arnold, E. C. (1954). Motor vehicle

calculations and science, volume 2. E. Arnold.

Curtis, W. and Loren, J. Mastering autodesk inventor 2010

copyright

c

2009 by wiley publishing. Inc., Indi-

anapolis, Indiana ISBN, pages 978–0.

Grant, M. J. C. and Clay, B. (2002). Accidental car-

bon monoxide poisoning with severe cardiorespira-

tory compromise in 2 children. American Journal of

Critical Care, 11(2):128–131.

Mott, R. L. (2009). Elemen-elemen mesin dalam perancan-

gan mekanis. Penerbit ANDI, Yogyakarta.

of Energy, M. and of Indonesia (MEMRI), M. R. (2019).

Data konsumsi energi indonesia.

Syamsiro, M., Dwicahyo, M., Sulistiawati, Y., Ridwan, M.,

and Citrasari, N. (2019a). Development of a rotary

kiln reactor for pyrolytic oil production from waste

tire in indonesia. In IOP Conference Series: Earth and

Environmental Science, volume 245, page 012044.

IOP Publishing.

Syamsiro, M., Mathias, D. Y., Saptoadi, H., Sawitri, D. R.,

Nizami, A.-S., and Rehan, M. (2018). Pyrolysis of

compact disc (cd) case wastes to produce liquid fuel as

a renewable source of electricity generation. Energy

Procedia, 145:484–489.

Syamsiro, M., Saptoadi, H., Kismurtono, M., Mufrodi, Z.,

and Yoshikawa, K. (2019b). Utilization of waste

polyethylene pyrolysis oil as partial substitute for

diesel fuel in a di diesel engine. International Jour-

nal of Smart Grid and Clean Energy, 8(1):38–47.

Wark, K., Warner, C. F., et al. (1998). Air pollution: its

origin and control. Addison-Wesley.

Design of Prototype Electric Car using 4 Motors as Future City Car in Indonesia

47