Effect of Addition of Zeolite and Sodium Chloride on Changes in

Bacterial Content and Turbidity in Industrial Wastewater Treatment

into Drinking Water using Electrocoagulation Process

Sutanto

1

and Nanang Rohadi

2

1

Department of Electrical Engineering, State Polytechnic of Jakarta, Depok, Jakarta

2

Department of Electrical Engineering, Faculty of Mathematics and Natural Sciences, Padjajaran

University,Jatinangor, Indonesia

Keywords: zeolite, bacterial, turbidity, electrocoagulation, wastewater

Abstract: The treatment wastewater of electrical industry was investigated through electrocoagulation process. The

study was conducted by flowing of 4,5 liters of wastewater into the three cells of electrocoagulation process

tank. Each cell is filled 1.5 liters of waste water. The electrocoagulation process is carried out at a voltage of

12 V and interval time for observation of bacterial content and turbidity in the water is done every 10

minutes. Subsequently, the same procedure was performed with added 100 g of the zeolite and at the end of

study was added 100 g of zeolite + 0.5 g of NaCl. To determine of bacterial content and turbidity was done

using Pour Plate Methode and turbidity meter, respectively. The electrocoagulation process for 120 minutes

can be reduced the bacterial content from 5125 CFU/mL to 2769 CFU/mL or equal of 45,97 % and

turbidity from 44,10 NTU to 18,24 NTU or equal 58,64 %. The electrocoagulation process for 120 minutes

with added of 100 g of zeolite can be reduced the bacterial content from 5125 CFU/mL to 2629 CFU/mL

or equal of 48,70 % and turbidity from 44,10 NTU to 16,34 NTU or equal 62,95%. The electrocoagulation

process for 120 minutes with added of 100 g of zeolite + 0.5 g NaCl can be reduced the bacterial content

from 5125 CFU/mL to 1429 CFU/mL or equal of 72,12 % and turbidity from 44,10 NTU to 1,34 NTU or

equal 96,96%.

In conclusion the electrocoagulation process with added 100 g zeolite and 0.5 g NaCl is

the best condition

compared to the other processes.

1 INTRODUCTION

Industrial or domestic wastewater generally contains

organic pollutants and heavy metals and has the

potential to be reused into clean or drinking water

through many methode processes. The water

parameters in water drinking that made from

wastewater must be accordanced with the

regulation of Indonesian Ministry of Health No. 492

/ Menkes / Per / IV / 2010. On the Minister of Health

regulation No. 492 / Menkes / Per / IV / 2010

mentioned that the water parameters in water

drinking are 5 NTU for turbidity, 0 per 100 mL for

Coliform bacteria and 0 per 100 mL for Escherichia

Coli (E Coli) bacteria.

One methode in water treatment from waste

water into drinking water or clean water is

electrocoagulation process. Anode and cathode

made from aluminum or iron plates are needed to

operate of the electrocoagulation process (Kourdali

et al, 2018).

When the electrocoagulation process is operated,

a coagulant compound will be generated in the

wastewater. Coagulant compounds are used as an

adsorbant material to absorb organic and inorganic

pollutants in wastewater (

Díaz et al, 2018)

In generally, pollutants in wastewater are formed

from organic and inorganic materials. As a result of

mixed organic and inorganic pollutants can reduce

the electrical conductivity in the water. If the

electrical conductivity process is very low, then the

process of forming coagulant compounds in

wastewater becomes less and less. To increase the

electrical conductivity in wastewater can be added

sodium chloride (NaCl) into wastewater (

Daniel,

2018). Sodium chloride has has the ability to kill

microorganisms ( bacteria) and can produce a strong

electrolyte solution. Zeolite also can be added in

wastewater to increase speed up of reducing

Sutanto, . and Rohadi, N.

Effect of Addition of Zeolite and Sodium Chloride on Changes in Bacterial Content and Turbidity in Industrial Wastewater Treatment into Drinking Water using Electrocoagulation Process.

DOI: 10.5220/0009873700002905

In Proceedings of the 8th Annual Southeast Asian International Seminar (ASAIS 2019), pages 67-73

ISBN: 978-989-758-468-8

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

67

pollutant in the wastewater. Because zeolite is easy

to adsorb pollutants in wastewater.

The combination of zeolite and NaCl into

wastewater is intended to help reduce the content of

bacteria and pollutants in wastewater (Thanasia,

2019).

Anode and cathode made from aluminum or iron

plates are needed to operate of the

electrocoagulation process (Ghalwa et al, 2018). If in

electrocoagulation process using anode made from

aluminum, then the equation of reaction as follows (

Kobya et al, 2013):

anode (oxidation process ):

2Al 2Al

+3

+ 6e

-

(1)

cathode (reduction process) :

6H

2

O+6e

-

6OH

-

+3H

2

(2)

in overall :

2Al+6H

2

O2Al(OH)

3

+3H

2

(3)

The coagulant Al(OH)

3

in equation 3 is formed

that has a function as an absorbent compound for

pollutants or bacteria in wastewater.

The results of the study (Karicappan et al,

2014) showed that in domestic wastewater treatment

using electrocoagulation process was able to reduce

the total solid content (TS) to 98.45% and Coliform

bacteria to 96.34%.

The results of a study on the electrocoagulation

process in liquid waste showed that process can

reduce lead content (Pb) over of 90% (Eiband et al,

2014).

The equation for calculating the weight of Al

+ 3

metal ions that formed in the continuous

electrocoagulation process as follows (Kurmar et al,

2010):

m =(S)(A)(a

r

)(I)/[(Q)(96.500)(n)] (4)

where m: mass Al + 3 released by the anode (gram),

S: process bath height (cm), A: cross-sectional area

of process bath (cm

2

), a

r

: relative atomic mass, I:

electric current (ampere), Q: discharge wastewater

(cm

3

/sec) and n: change in oxidation number. Based

on equation 4 can be explained that in use of high

electric currents, so more will be generated of Al

+3

ions.

The equipments for the electrocoagulation

process consists of process tank, DC source (direct

current), anode and cathode. Process tank must be

made from insulator materials, anodes and cathode

can be made from aluminum or iron (Shanthi et al,

2011).

If the electrocoagulation process is added

Na

2

SO

4

(Sodium Sulfate) or NaCl (Sodium

Chloride) in wastewater, then can be formed strong

electrolyte. Therefore the solution is easy to conduct

electric current which can increase the coagulant

compound to absorb pollutant in wastewater (Rios

et al, 2014).

The electrocoagulation process with the addition

of NaCl as much as 740 mg/L can be reduced the

chemical oxygen demand (COD) up to 98% and

total suspended solid (TSS) up to 93%

(Thirugnanashambandam et al., 2013). Hypochlorite

(HOCl) compounds as byproducts will be produced

at during occur of process. Hypochlorite is an

oxidizing agent which can kill bacteria in waste

water. The mechanism of hypochlorite formation

can be explained by reaction equation as follows :

NaClNa

+

+Cl

-

(5)

2Cl

-

Cl

2

+2e (6)

Cl

2

+H

2

OHOCl+Cl

-

+H

+

(7)

HOCl OCl

-

+ H

+

(8)

The electrocoagulation process that added NaCl

can be increased the dissolution of Al from the

anode (Eskibalci et al, 2018). In studies conducted

with the addition of 0.5 gr/L of NaCl on stirring

speed of 180 rpm and a residence time of 55 seconds

can be reduced total suspended solid (TTS),

detergents, oils and fats, total phosphate and

turbidity up to 100% (Agustin et al, 2008).

The process of adsorption of metal ion by

zeolites can be explained as follows

(Meng et al,

2017

) :

Na

2

-Z+M

+

MZ+Na

+

(9)

Z-H + M

+

MZ + H

+

(10)

where M

+

is a metal ion that absorbed by zeolite.

The approach equation of Freundlich isotherm in ion

exchange process as follows (Hong et al,2019):

c

e

= k (q

e

)

n

(11)

where

c

e

: M

+

concentration in solution at equilibrium

(meq/L), k: constant,

q

e

: the amount of absorbed M

+

/

zeolite weight at equilibrium (meq/g), n: constant. If

n is between 2 and 10, the adsorption process is

very faster and can be approached in

isoterm

Langmuir equation as follows (

Li et al, 2018):

q

e

=q

0

kc

e

/(1+kc

e

) (12)

where q

e

: the amount of absorbed M

+

/zeolite weight

at equilibrium (meq/g),

q

0

: maximum absorption

ASAIS 2019 - Annual Southeast Asian International Seminar

68

capacity on the surface/weight of zeolite (meq/g),

k :

constant,

c

e

: M

+

concentration in solution at

equilibrium (meq/L)

. Equation 12 changed to as

follows (Munagapati et al, 2017):

1/q

e

=(1/q

0

k)(1/c

e

)+1/q

0

(13)

By making a curve of the relationship between 1/q

e

to 1/c

e

, can be obtained slope 1/q

0

k and intercept

1/q

0

. The constant value and maximum absorption

capacity (q

0

) of zeolite can be estimated easily

(Padilla et al, 2018).

2 METHOD

The research method consists of materials,

equipments and work procedures.

2.1 Materials

The materials needed are the Aluminum HTC 16-35

as an electrode, zeolite, NaCl and industrial

electronics wastewater

2.2 Equipments

The equipments needed are process tanks, DC

sources, ampermeters, flow meters, AAS (Atomic

Absorption Spectrophotometer), Soxhlet, pH meters,

turbidity meters and colony counter

2.3 Procedure

2.3.1 Measuring Wastewater Quality

The parameters of wastewater measured were metal

concentration using AAS, turbidity using

turbidimeter and bacterial using colony counter.

The measurement results shown as follows:

bacterial is 5125 CFU/mL and turbidity

is 44,10 NTU.

2.3.2 Constructing Research Equipments

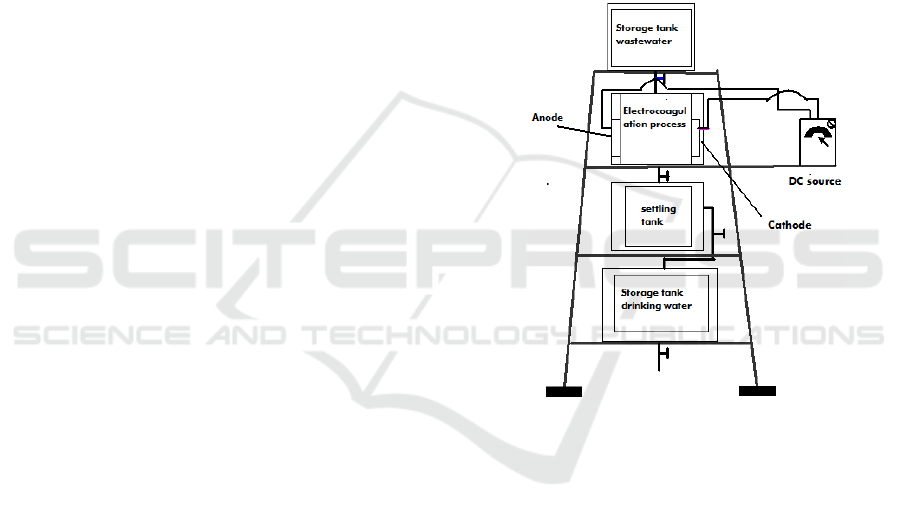

The series of research tools can be seen in figure 1.

The equipments needed are a DC source, an

avometer, a wastewater storage tank, an

electrocoagulation process tank, a sewage settling

tank and a water reservoir.

2.3.3 Research Implementation

The resaerch was conducted by flowing 4.5 liters of

wastewater from storage tank into an

electrocoagulation tank which was divided into three

cells. The DC source is turned on at a voltage of 12

V and the electric current can be read on the ampere

meter. The process is turn off after 10 minutes.

Water from the electrocoagulation process tank was

drained into the sewage settling tank. After a few

minutes sediment are formed at the bottom of the

tank. Bacterial content in the water of sewage

settling tank is measured by the Pour Plate Method

and turbidity by a turbidimeter. Re-measurements

were carried out with a processing time of 20, 30,

40, 50, 60, 70, 80, 90, 100, 110 and 120 minutes.

Subsequenty, research was carried out by adding

100 g of zeolite and a mixture of 100 g of zeolite

with 0.5 g of NaCl.

Figure 1: The series of research tools

3 RESULT AND ANALYSIS

The results measurements of changes in bacterial

content and water turbidity showed based on the

elctrocoagulation process (Elc), elctrocoagulation

process with added zeolite (Elc + zeolite) and

elctrocoagulation process with added zeolit and

NaCl (Elc + zeolite+Nacl)

3.1 The Effect of Electrocoagulation

(Elc) Processes on Changes in

Bacterial Content and Water

Turbidity

The results of measurements of bacterial content and

water turbidity from electrocoagulation wastewater

treatment processes are shown in table 1. Based on

Effect of Addition of Zeolite and Sodium Chloride on Changes in Bacterial Content and Turbidity in Industrial Wastewater Treatment into

Drinking Water using Electrocoagulation Process

69

table 1, it can be explained that the

electrocoagulation process can reduce bacterial

content and water turbidity. Bacterial content can be

reduced from 5125 CFU / mL to 2769 CFU / mL or

equivalent to 45.97% at 120 minutes of processing

time. While with the same time the turbidity can be

reduced from 44.10 NTU to 18.24 NTU or

equivalent to 58.64%. The electrocoagulation

process until to 120 minutes did not produce

drinking water standard, because the bacterial

content was more than 0 CFU/mL and the turbidity

of the water was more than 5 NTU.

The coagulant compound of Al (OH)

3

will be

generated when the electrocoagulation process is

carried out using aluminum as anode. The

compounds of AlOH)

3

is an adsorbant material that

can absorb bacteria and pollutants in the water.

Therefore bacterial content and turbidity will be

reduced from the wastewater.

Table 1: Results of measurements of bacterial content and

water turbidity from the electrocoagulation process (Elc)

Time Bacterial content Turbidity

(minute) (CFU/mL) (NTU)

0 5125 44.10

10 5000 44.02

20 496 5 43.20

30 4876 42.52

40 4629 40.14

50 4560 38.02

60 4365 36.50

70 4100 34.32

80 3845 31.23

90 3676 28.52

100 3423 25.14

110 3156 22.32

120 2769 18.24

3.2 The Effect of Electrocoagulation

Process by Addition of Zeolite (Elc

+ Zeolite) on Changes in Bacterial

Content and Water Turbidity

The results of measurements of bacterial content and

turbidity from the treatment wastewater by

electrocoagulation process which added zeolite,

shown in table 2. Based on table 2, it can be

explained that the electrocoagulation process can

reduce bacterial content and turbidity in the water.

Bacterial content can be reduced from 5125

CFU/mL to 2629 CFU/mL or equivalent to 48.70%

with 120 minutes processing time. While with the

same time the turbidity of water can be reduced

from 44.10 NTU to 16.34 NTU or equivalent to

62.95%. The addition of 100 g zeolite in the

electrocoagulation process was able to increase

bacterial removal by 2.73% and increase turbidity

removal by 4.31%. However, this process also

cannot produce drinking water, because the bacterial

content was more than 0 CFU/mL and the turbidity

of the water was more than 5 NTU.

The reducing of bacterial content and turbidity

in the water was accelerated by added of zeolites.

Because zeolite has the property of easily absorbing

bacterial and pollutants in the wastewater

Table 2: Results of measurements of bacterial content and

water turbidity from the electrocoagulation process (Elc)

added zeolite (Elc + zeolite)

Time Bacterial content Turbidity

( menit) (CFU/mL) (NTU)

0 5125 44.10

10 4978 43.82

20 4875 42.40

30 4776 41.52

40 4519 39.74

50 4369 37.42

60 4125 35.90

70 3990 33.22

80 3755 28.83

90 3426 26.52

100 3213 24.34

110 2936 21.52

120 2629 16.34

3.3 The Effect of Electrocoagulation

Process by Addition of Zeolite and

Sodium Chloride (Elc + zeolite +

NaCl) to Changes in Bacterial

Content and Water Turbidity

The results of measurements of bacterial content

and water turbidity from the treatment wastewater

by electrocoagulation process which added zeolite

and NaCl, are shown in table 3. Based on table 3, it

can be explained that the electrocoagulation process

added by zeolite and NaCl can be reduced bacterial

content and turbidity in the water. The bacterial

content can be reduced from 5125 CFU/mL to 1429

CFU/mL or equivalent to 72.12% with 120 minutes

processing time. While with the same time the

turbidity of water can be reduced from 44.10 NTU

to 1.34 NTU or equivalent to 96.96%. The addition

of 100 g zeolite and 0.5 g NaCl in the

electrocoagulation process was able to increase

bacterial removal by 26.15% and increase turbidity

removal by 50.99%. In this treatment the turbidity

ASAIS 2019 - Annual Southeast Asian International Seminar

70

value is below 5 NTU, but the bacterial content is

still more than 0 CFU/mL.Therefore this treatment

also has not been able to produce drinking water

standard.

The reducing of bacterial content and turbidity

in the water was accelerated by added of zeolites and

NaCl. Because zeolite has the property of easily

absorbing bacterial and pollutants in the wastewater

and NaCl easily killing of bacterial.

The addition of NaCl can also increase the

electrical conductivity of wastewater, so that the

current in the electrocoagulation process becomes

even greater. The greater of electric current will be

accelerated the formation of Al (OH)

3

coagulant.

The compounds of Al (OH)

3

easily to absorb

bacterial and pollutants in the water, so that the

bacterial content and water turbidity was decreased

from the water.

Table 3: Results of measurements of bacterial content and

water turbidity from the electrocoagulation process (Elc)

added zeolite (Elc + zeolite +NaCl)

Time Bacterial content Turbidity

(menit) (CFU/mL) NTU

0 5125 44.10

10 4888 41.22

20 4665 38.20

30 4446 36.52

40 4129 32.54

50 3869 27.92

60 3575 25.70

70 3196 21.26

80 2765 18.93

90 2526 15.52

100 2018 11.34

110 1836 6.52

120 1429 1.34

3.4 Comparison Curves of

Wastewater Treatment

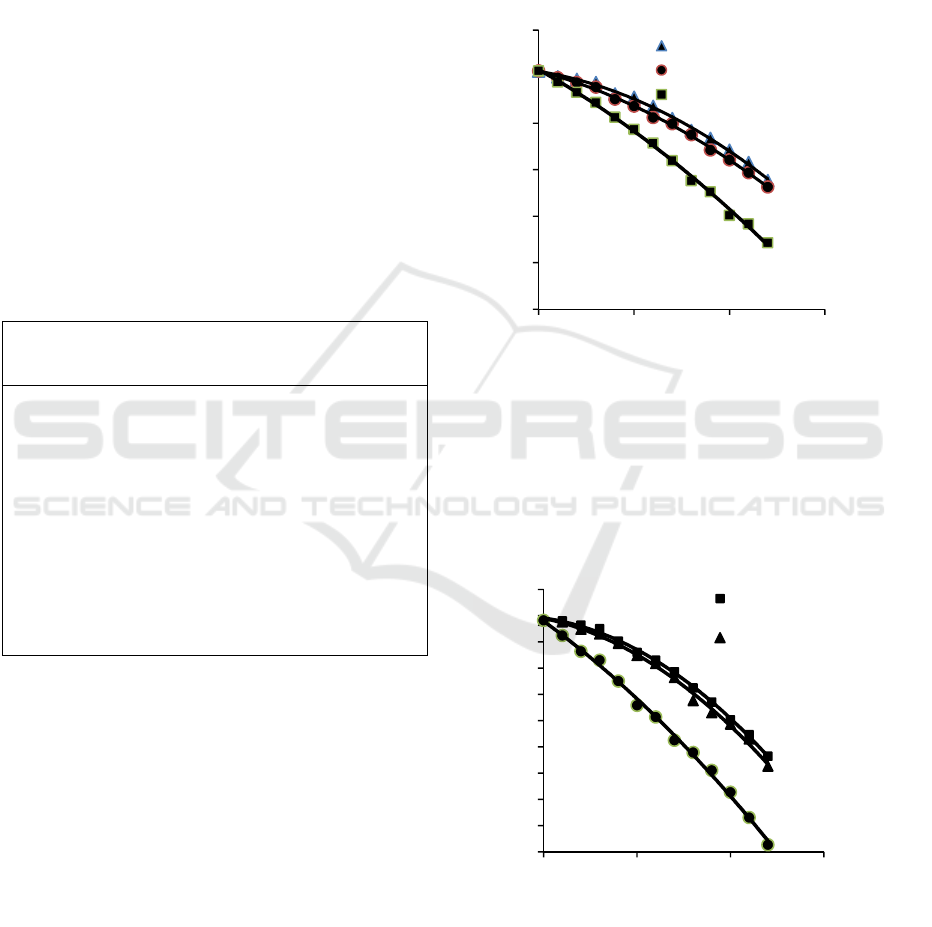

Figure 2 is curve for result of measurement of

bacterial content based on the results of the

electrocoagulation process (Elc), the

electrocoagulation process added zeolite (Elc +

zeolite) and the electrocoagulation process added

zeolite and NaCl (Elc + zeolite + NaCl) based on tables

1, 2 and 3.

Based on figure 2, shows that the

electrocoagulation process (Elc) is able to reduce

bacterial content in water. Zeolite 100 g added to

the electrocoagulation process (Elc + zeolite) is able

to accelerate of reduce bacterial content in water

compared to the electrocoagulation process only. If

the electrocoagulation proses was added zeolite 100

g and NaCl 0.5 g, then the decrease in bacterial

content is faster than the only electrocoagulation

process or the electrocoagulation process which is

added zeolite. In be concluded that the most rapid to

reduce bacterial content in the water was found in

the electrocoagulation process which was added 100

g zeolite and 0.5 g NaCl.

Figure 2: Curve changes of bacterial content in water

Figure 3 is curve for result of measurement of

turbidity based on the results of the

electrocoagulation process (Elc), the

electrocoagulation process added zeolite (Elc +

zeolite) and the electrocoagulation process added

zeolite and NaCl (Elc + zeolite + NaCl) based on tables

1, 2 and 3.

Figure 3: Curve changes of turbidity in water

Based on figure 3, shows that the electrocoagulation

process (Elc) is able to reduce turbidity in water.

Zeolite 100 g added to the electrocoagulation

0

1000

2000

3000

4000

5000

6000

0 50 100 150

Concentration of bacteria, CFU

Time, minute

Elc

Elc+Zeolite

Elc+zeolite+NaCl

0

5

10

15

20

25

30

35

40

45

50

0 50 100 150

Turbidity, NTU

Time, minute

Elc

Elc+Zeolite

Effect of Addition of Zeolite and Sodium Chloride on Changes in Bacterial Content and Turbidity in Industrial Wastewater Treatment into

Drinking Water using Electrocoagulation Process

71

process (Elc + zeolite) is able to accelerate of reduce

turbidity in water compared to the only

electrocoagulation process. If the electrocoagulation

proses was added zeolite 100 g and NaCl 0.5 g, then

the decrease in turbidity is faster than the only

electrocoagulation process or the electrocoagulation

process which is added zeolite. In be concluded that

the most rapid to reduce turbidity in the water was

found in the electrocoagulation process which was

added 100 g zeolite and 0.5 g NaCl

4 CONCLUSION

The addition of zeolites and NaCl to the

electrocoagulation process can be reduced bacterial

content and turbidity in the water.

Electrocoagulation process at 12 V for 120 minutes

by adding zeolite 100 g and NaCl 0.5 can be

reduced bacterial content from 5125 CFU/mL to

1429 CFU / mL or equivalent to 72.12% and

turbidity from 44.10 NTU to 1.34 NTU or

equivalent to 96.96%.

ACKNOWLEDGEMENTS

The authors wish to acknowledge Ministry of

Research and Technology Directorate General of

Higher Education of the Republic of Indonesia for

the financial support awarded to carry out this re-

search for the third year, also Afiliation-Laboratory

FMIPA University of Indonesia UI those have

helped a lot in the data collection required.

REFERENCES

Agustin , M.B., Sengpracha, W.P. and W. Phutdhawong

W., 2008. Electrocoagula tion of Palm Oil Mill

Effluent, Int. J. Environ. Res. Public Health.

Athanasia,A.Z.,Tekerlekopouloub,G.and Vayenasac, D.V.,

2019. a Hybrid System for Groundwater Denitrification

using Electrocoagulation and Adsorption, Journal of

Environmental Management

Daniel, B., Sara, W., Couperthwaiteab, J. and Millarab,

G.J.,2018.

I

nfluence of operating parameters during

electrocoagulation of sodium chloride and sodium

bicarbonate solutions using aluminium electrodes,

Journal of water process engineering.

Díaz, J.C.,

Silva, T.P.,

Segura, E. G.

and

Cruz, A.C.,2017.

Electrocoagulation-Adsorption

to Remove Anionic

and

Cationic

Dyes from Aqueous Solution by

PV-

Energy,

Journal of

C

hemistry

Eiband, M.M.S, Trindade, K.C.D.A, Gama, K., Melo,

J.V.D., Huitle C.A.M, and Ferro ,S., 2014 .Elimination

of Pb

2+

Through Electrocoagulation Applicability

of Adsorptive Stripping Voltammetry for Monitoring

The Lead Concentration During its Elimination,

Journal of Electroanalytical Chemistry.

Eskibalci, M.F. and Ozkan, M.F., 2018. An investigation

of the effect of NaCl concentration on the

electrocoagulation of coal preparation plant tailings,

Physicochem. Probl. Miner. Process.

Ghalwa, N.M.A, Romia, R.S. and Farhat, N.B., 2018.

Application of Electrocoagulation on Adsorption of

Styrene Acrylate Polymer from Aqueous Solutions,

International Journal of Scientific Research in

Environmental Science and Toxcicology

Hong,M.,Yu,L., Wang, Y., Jiahang, J. Zhuwen Chen, Z.,

Dong, L., Zan, Q. and Li, R., 2019. Heavy metal

adsorption with zeolites: The role of hierarchical pore

architecture, Chemical Engineering Journal.

Karichappan, Venkatachalam, S. and P.M. Jeganathan,

P.M.,2014.Optimation of Electrocoagulation Process

to Treat Grey Waste wate in Bach Mode using

Response Surface Methodology, Journal of

Environmental Health Science and Engineering.

Kobya, M., Akyol. A, Demirbas E., and Oncel,M.S.S,

2013. Removal of Arsenic from Drinking Water

by Batch and Continuous Electrocoagulation

Processes Using Hybrid Al-Fe Plate Electrode,

American Institute of Chemical Engineers Environ

Prog.

Kourdali,S., Badis,A., Boucherit,A.and Boudjema,

K., 2018. Electrochemical Disinfection of Bacterial

Contamination: Effectiveness and Modeling Study

of E. Coli inactivation by Electro-Fenton,Electro-

Peroxi-Coagulation and Electrocoagulation, Journal of

Environmental Management.

Kumar,N.S, and Goel, 2010. Factors Influencing Arsenic

and Nitrate Removal from Drinking Water in a

Continuous Flow Electrocoagulation (EC) Process.

Journal of Hazardous Materials.

Li,Z.,Wang,L.,Meng,J.,Liu,X.,Xu, J.,Wang, F.,Brookes,P.,

2018. Zeolite-supported nanoscale zero-valent iron:

New findings on simultaneous adsorption of Cd (II),

Pb (II), and As (III) in aqueous solution and soil,

Journal of Hazardous Materials.

Meng, Q., Chen, H., Lin, J. Zhang Lin, Z. and Sun, J.,

2017. Zeolite A synthesized from alkaline assisted pre-

activated halloysite for efficient heavy metal removal

in polluted river water and industrial wastewater,

Journal of Environmental Sciences.

Munagapati, S.V. ,Yarramuthi, V. and Kim,D.S.,2017.

Methyl orange removal from aqueous solution using

goethite, chitosan beads and goethite impregnated with

chitosan beads, Journal of Molecular Liquids

Padilla, I., Andrés, S.L. and Delgado, A.L., 2018. Al-

Waste-Based Zeolite Adsorbent Used for the Removal

of Ammonium from Aqueous Solutions, International

Journal of Chemical Engineering.

Rios, K.C., Ocampo,G.T. and Palma, R.A.T., 2014.

Experimental Design to Measure Escherichia Coli

ASAIS 2019 - Annual Southeast Asian International Seminar

72

Removal in Water Through Electrocoagulation,

International Journal of Electrocemical Science.

Shanthi, V., Ramanathan, K., and Basha, A., 2011.

Domestic Sewage Treatment Using Batch Stirred Tank

Electrochemical Reactor, International Journal of

ChemTech Research.

Thirugnanashambandam,K.,Sivakumar,V. and Maran,J.P.,

2013. Optimization of Electrocoagulation to Treat

Biologically Pretreated Bagasse Effluent, Journal of

the Serbian Chemical Society.

Effect of Addition of Zeolite and Sodium Chloride on Changes in Bacterial Content and Turbidity in Industrial Wastewater Treatment into

Drinking Water using Electrocoagulation Process

73