Surface Texture of Thin Gallium Nitride Grown on Closed to

Van Der Wall Layer of Molybdenum Disulfide

Iwan Susanto

1,2

, Ing-Song Yu

1

, Dianta Mustofa Kamal

2

, Belyamin

2

, Fuad Zainuri

2

,

Sulaksana Permana

2,3

, Chi-Yu Tsai

1

, Yen-Ten Ho

4

, Ping-Yu Tsai

5

1

Department of Materials Science and Engineering, National Dong Hwa University, Hualien 97401, Taiwan ROC

2

Department of Mechanical Engineering, State Polytechnic of Jakarta, Depok 16424, Indonesia

3

Center of Mineral Processing and Corrosion Research, Department of Metallurgy and Materials Engineering,

University of Indonesia, 16424 Depok, Indonesia

4

International College of Semiconductor Technology, National Chiao Tung University, Hsinchu 300, Taiwan ROC

5

Department of Electronic Systems Research Division, Chung-Shan Institute of Science & Technology,

Tao-Yan 325, Taiwan ROC

belyamin@mesin.pnj.ac.id, fuad.zainuri@mesin.pnj.ac.id, sulaksana@yahoo.com

Keywords: Gallium Nitride, Surface Texture, Molybdenum Disulfide, Molecular Beam Epitaxy

Abstract: A comprehensive analysis of surface texture of gallium nitride (GaN) films grown on the MoS

2

layer via

plasma-assisted molecular beam epitaxy was performed. Scanning electron microscopy (SEM) was used to

explore the surface morphology of GaN films. The smooth surface with attending the amount of Ga particle

created on the GaN films. The great of Ga-N bonding elements more than 80 % explored by XPS core level

(CL) 3d Ga was also obtained in the GaN films. Moreover, investigating the results of surface contour by

atomic force microscopic (AFM) exhibited a smoother surface texture with RMS of 2.17 nm for scan area 3

x 3 µm. Finally, the higher growth temperature served by substrate could facilitate the smoother surface

with the minimum of Ga metallic.

1 INTRODUCTION

Understanding the surface properties of GaN-based

on semiconductor materials is important things to

develop the technology for electronic and

optoelectronic applications (Chen et al., 2019; Tian

et al., 2019). Several studies of GaN have been

devoting continually for applied to those fields like

HEMTs, LEDs, sensors, solar cells, etc(Chapin et

al., 2017; Chen et al., 2017; Aissat and Vilcot, 2019;

Husna Hamza and Nirmal, 2020). In general, the

GaN thin film grows on foreign material, since the

creating of bulk GaN has not been effective in cost

(Liu and Edgar, 2002; Yang et al., 2017). However,

the growing GaN layer on those substrates could

generate the defect structure in the interface up to

the surface films due to residual stress (Kuwano et

al., 2014; Mynbaeva et al., 2016). Several studies

continue to be promoted to overcome the existing

matter by growing the 2D transition-metal

dichalcogenides (TMDs) layer above the layer that

has the van der wall epitaxy (Ajayan, Kim and

Banerjee, 2016). This layer does not have a strong

bond to the substrate, so the residual stress will be

released on the surface boundary, and the defects

can be minimized as the film is cooled to room

temperature.

Recently, MoS

2

including to TMDs has good

properties to be applied for next-generation

electronics and optoelectronics devices in the

semiconductor materials (Choi et al., 2017). Even

more interesting, the structure of its material is

hexagonal with a close lattice-matched with GaN

(Yamada et al., 1999; Susanto, C.-Y. Tsai, et al.,

2019). Therefore, MoS

2

has an opportunity to be

promising as a substrate for deposition the GaN film.

So, the growth of GaN layers on the MoS

2

layer

might produce high quality of GaN films which

could promise for electronics and optoelectronic

applications. Besides, the MoS

2

layer has a van der

wall bonding that may facilitate to reduce the

residual stress in the films. More interesting, the

layer can be also transferred to a foreign substrate to

attach the GaN layer for another device (Liu et al.,

22

Susanto, I., Yu, I., Kamal, D., Belyamin, ., Zainuri, F., Permana, S., Tsai, C., Ho, Y. and Tsai, P.

Surface Texture of Thin Gallium Nitride Grown on Closed to Van Der Wall Layer of Molybdenum Disulfide.

DOI: 10.5220/0009870400002905

In Proceedings of the 8th Annual Southeast Asian International Seminar (ASAIS 2019), pages 22-26

ISBN: 978-989-758-468-8

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2019). Until now, several studies have been

conducted on growing MoS

2

layers on GaN

materials (Wan et al., 2018; Zhang et al., 2018).

However the growing layer of GaN films above the

MoS

2

layer has not been observed completely.

In this report, we investigate surface conditions

related to morphology, composition, and roughness

of Ga thin film grown on MoS

2

layer which has

vdW bonding using molecular beam epitaxy. The

surface texture was further observed in detail trough

both the 2D scan area and the contour profile of

AFM. Meanwhile, the surface composition related to

boding element was examined absolutely with XPS

spectra. Finally, the surface condition accordance

with surface roughness for substrate and GaN films

was analyzed and served according to both AFM

images and de-convoluted of 3d Ga in the fitting

curve.

2 EXPERIMENTAL METHOD

In the experiment procedure, we grew GaN film on

2D MoS2 layer by PA-MBE method. The growth

temperature was carried out for 20 minutes at 600 C

with a 10 rpm rotation speed of the substrate

(Susanto et al., 2019). During the growth of the GaN

layer, the thermal cleaning process was done at 600

C for 40 minutes to trough out the contaminants on

the surface substrate. Further, the deposition both of

Ga and N atoms used K-cell at 800 C and nitrogen

gun with a flow rate of 0.8 sccm at Rf power 500

Watt, respectively. Thus, the growth of GaN film

was carried out in N-rich condition with a flux ratio

of N/Ga at 161 (Susanto et al., 2017). Other hand,

MoS

2

layer used for growing GaN was a single

crystal of c-plane sapphire deposited by the PLD

system (Ho et al., 2015). The deposited temperature

was served at 800 C with 8 x 10-6 Torr of a

background pressure. Finally, the ex-situ

characterizations of SEM and XPS spectra were

performed to investigate the morphology and surface

composition of GaN films. While the AFM was

execute to observe in detail surface texture related to

the roughness both of MoS

2

substrate and GaN

films.

3 RESULT AND DISCUSSION

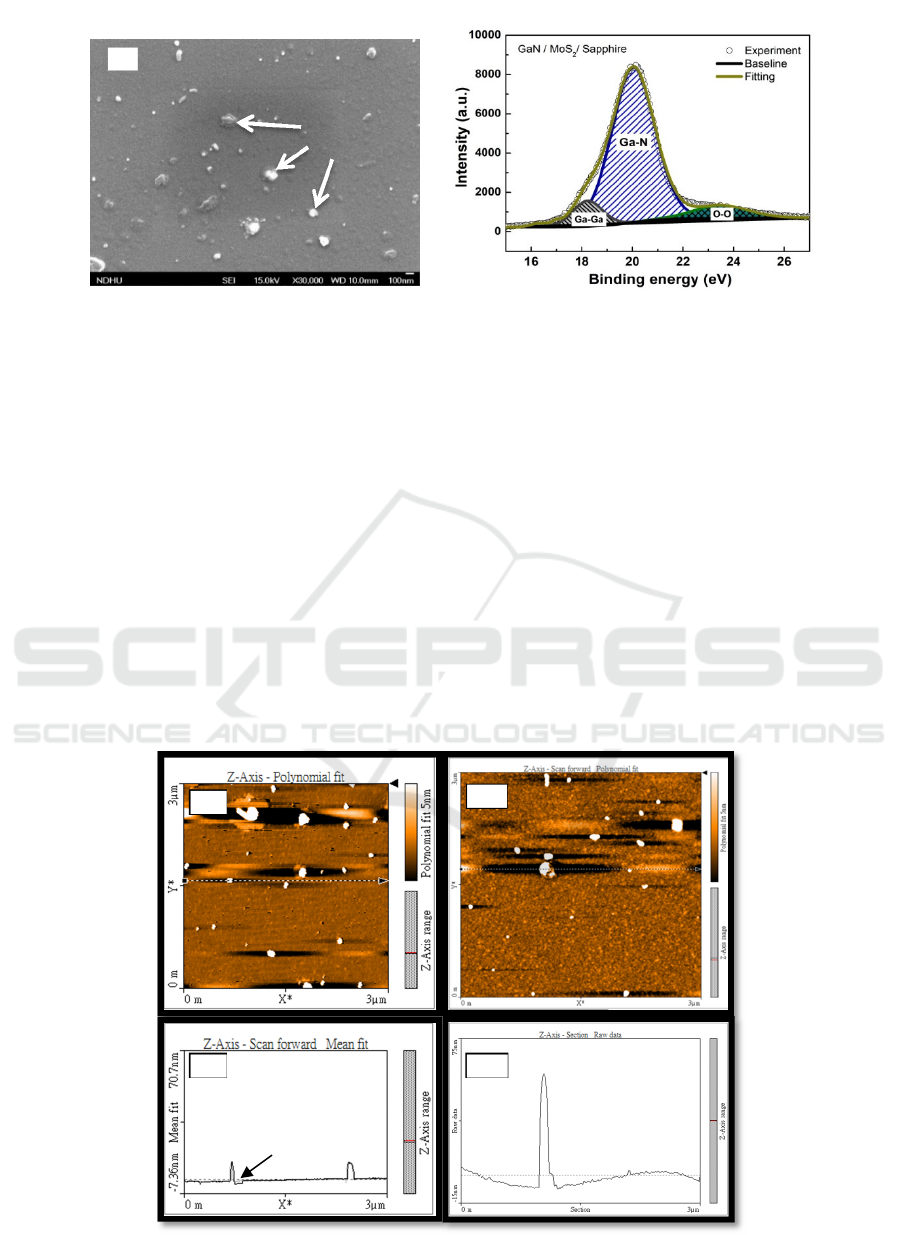

Morphology and surface composition of GaN films

served by SEM image and XPS fitting curve was

presented completely in Figure 1. The GaN films

grew and covered throughout on the surface of the

MoS

2

layer Figure 1(a). The morphology of GaN

films seems smooth with a large flat area indicating

that GaN was grown epitaxial by the 2D mode layer.

However, several Ga particles spread irregularly on

the surface with size in the range up to 150 nm.

Attending the particles associated with low growth

temperature on the system. The low heat energy

provided by the substrate might be caused the atoms

are not sufficiently mobile to reach the favourable

sites at the step edges (Susanto, Kan and Yu, 2017).

They are incorporated at random position and

accumulated to construct the cluster on the surface.

In Ga-rich growth condition, the particle can be even

bigger formed like the droplets on the surface. By

the less energy desorption, both Ga and N atoms

became retarded to mobilize in creating 2D layer

epitaxy. Further, the composition of Ga cluster

related to Ga metallic bonding will be inspected

carefully by the XPS measurement.

In Figure 1(b), the XPS result was demonstrated the

semi-quantitative analysis by the peak fitting of XPS

spectra. The surface composition of GaN film was

displayed in detail by de-convoluted Ga-3d core

level spectra. The peak positions of bonding

elements were located at 18.25, 20.05, and 23.50 eV

for Ga-Ga, Ga-N and O-O, respectively (Yu et al.,

2014; Mishra et al., 2015). Meanwhile, the

percentages of those bonding elements were 8.8,

81.0 and 10.2 %, serially. According to the results,

GaN bonding has been constructed on the surface of

the MoS2 layer with great composition related to a

higher percentage of 80 %. However, the presenting

of Ga-Ga bonding was formed due to the

accumulation of Ga atoms, deposited on the surface

of GaN films. The result was consistent with the

SEM result in Figure 1(a) that the Ga-Ga related

with Ga particles was come on the surface GaN

films(Susanto et al., 2017; Susanto, Kan and Yu,

2017). Unfortunately, there is an O-O bonding

element also detected in higher binding energy. It

could be related to oxygen absorbed on the GaN

surface as was contacted to the air. Furthermore, the

surface features correspond with morphology and

roughness condition will be observed clearly by

AFM.

Surface Texture of Thin Gallium Nitride Grown on Closed to Van Der Wall Layer of Molybdenum Disulfide

23

Ga particles

(a)

(b)

Figure 1. (a) SEM images and (b) De-convoluted Ga-3d XPS spectra for the surface composition of the GaN films

Detail of surface morphology of MoS

2

layers and

GaN films was exhibited clearly by AFM

observation in Figure 2 (a, c) and (b, d), serially. By

the scan area of 3 x 3 µm, the bright area likes

particles and the dark relates with thick striped

demonstrating the character both of surface feature.

The bright areas describe the pattern of rising

surface peaks, and dark areas illustrate the valleys

formed on the surface. The broader area of dark and

bright regions with a root mean square (RMS) of

3.01 nm was exhibited on the surface of MoS

2

in

Figure 2(a). After deposition of GaN films, the

reduction of those areas with RMS of 2.17 nm was

demonstrated on Figure 2(b). The reduction in the

size of these two regions represented that decline

peak and valley formed on the film’s surface. The

narrowing of both areas could describe that a

smoother surface has constructed on the GaN films.

Moreover, the line roughness will be confirmed

more clearly with one dimension of contour scan in

Figure 2(c), (d) demonstrating the profile of the

valley and peaks feature. They can be compared to

the results from the striped scan in Figure 2 (c) and

(d). There are several grooves with a smaller curve

in Figure 2(c) than in Figure 1(d). The curve relates

to the peak formed on the surface layer, while the

groove correlates with the valley constructed on the

surface as well. The high peak and the deep of the

valley for both surface contours is 0.51 nm and 0.31

nm for MoS

2

layer, and 1.11 nm and 0.73 nm for

GaN films, respectively. Based on the AFM results,

the surface of GaN film was smoother than the MoS

2

layer even though the peak and valley GaN films

higher and deeper than the MoS

2

layer. It could be

come due to the line roughness of the GaN film

taken in the highest and the deepest area.

Figure 2. (a) 2D AFM images of the surface of MoS

2

/Sapphire and (b) GaN films with scan area 3 x 3 µm, while (c) scan

profile contour as long 3 µm on MoS

2

/Sapphire and (d) for GaN films.

(b)

(c) (d)

(a)

Pea

k

Groove

Valley

Valley

Ga-3d

Pea

k

ASAIS 2019 - Annual Southeast Asian International Seminar

24

4 CONCLUSIONS

In conclusion, we are successful to deposit the GaN

films on the MoS

2

layer by the MBE system. The

surface texture of the GaN films formed was a

smooth surface with a large flat area correlated with

the 2D mode layer. The great of Ga-N bonding

created on the surface with less Ga-Ga and O-O was

obtained higher than 80 %. The reduction of surface

roughness was initiated by the GaN layer covered

the substrate. The RMS of GaN film with scan area

3 x 3 µm was archived at 2.17 nm. The diminution

of peak size and groove related to the valley was

also demonstrated on the contour of the scan profile.

However, attending several Ga particles spread

irregularly on the surface with size in the range up to

150 nm that was constructed due to low growth

temperature provided by the system. Further, the

higher growth temperature served by substrate could

facilitate the smoother surface of GaN film with the

minimum of Ga metallic.

ACKNOWLEDGMENTS

All authors would like to thank to Ministry of

Research and Technology / Research Council and

National Innovation Republic of Indonesia (BRIN)

and also Ministry of Science and Technology,

Taiwan for financially supporting this study (MOST

107-2221-E-259- 001-MY2 and 107-3017-F-009-

002).

REFERENCES

Aissat, A. and Vilcot, J. P. (2019) ‘Development of

InxGa1-xN/GaN axial multiple quantum well

nanowire for solar cell applications’, Optik. Elsevier

GmbH., p. 163844. doi: 10.1016/j.ijleo.2019.163844.

Ajayan, P., Kim, P. and Banerjee, K. (2016) ‘Two-

dimensional van der Waals materials’, Physics Today,

69(9), pp. 38–44. doi: 10.1063/PT.3.3297.

Chapin, C. A. et al. (2017) ‘InAlN/GaN high electron

mobility micro-pressure sensors for high-temperature

environments’, Sensors and Actuators, A: Physical.

Elsevier B.V., 263, pp. 216–223. doi:

10.1016/j.sna.2017.06.009.

Chen, Y. et al. (2017) ‘High efficiency GaN LEDs with

submicron-scale 2D periodic structures directly

fabricated by laser interference ablation’, Optics and

Laser Technology. Elsevier, 90(August 2016), pp.

211–215. doi: 10.1016/j.optlastec.2016.08.019.

Chen, Y. et al. (2019) ‘GaN in different dimensionalities:

Properties, synthesis, and applications’, Materials

Science and Engineering R: Reports, 138(January), pp.

60–84. doi: 10.1016/j.mser.2019.04.001.

Choi, W. et al. (2017) ‘Recent development of two-

dimensional transition metal dichalcogenides and their

applications’, Biochemical Pharmacology. The

Author(s), 20(3), pp. 116–130. doi:

10.1016/j.mattod.2016.10.002.

Ho, Y. T. et al. (2015) ‘Layered MoS

2

grown on c -

sapphire by pulsed laser deposition’, Physica Status

Solidi - Rapid Research Letters, 9(3), pp. 187–191.

doi: 10.1002/pssr.201409561.

Husna Hamza, K. and Nirmal, D. (2020) ‘A review of

GaN HEMT broadband power amplifiers’, AEU -

International Journal of Electronics and

Communications. Elsevier GmbH, p. 153040. doi:

10.1016/j.aeue.2019.153040.

Kuwano, N. et al. (2014) ‘Behavior of defects in a-plane

GaN films grown by low-angle-incidence

microchannel epitaxy (LAIMCE)’, Journal of Crystal

Growth. Elsevier, 401, pp. 409–413. doi:

10.1016/j.jcrysgro.2013.11.032.

Liu, L. and Edgar, J. H. (2002) ‘Substrates for gallium

nitride epitaxy’, Materials Science and Engineering:

R: Reports, 37(3), pp. 61–127. doi: 10.1016/S0927-

796X(02)00008-6.

Liu, Y. et al. (2019) ‘Transferable GaN Films on

Graphene/SiC by van der Waals Epitaxy for Flexible

Devices’, Physica Status Solidi (A) Applications and

Materials Science, 216(11), pp. 1–6. doi:

10.1002/pssa.201801027.

Mishra, M. et al. (2015) ‘Pit assisted oxygen

chemisorption on GaN surfaces’, Physical Chemistry

Chemical Physics. Royal Society of Chemistry,

17(23), pp. 15201–15208. doi: 10.1039/c5cp00540j.

Mynbaeva, M. G. et al. (2016) ‘TEM study of defect

structure of GaN epitaxial films grown on GaN/Al

2

O

3

substrates with buried column pattern’, Journal of

Crystal Growth. Elsevier, 445, pp. 30–36. doi:

10.1016/j.jcrysgro.2016.04.011.

Susanto, I. et al. (2017) ‘Effects of N/Ga flux ratio on GaN

films grown on 4H-SiC substrate with 4° miscutting

orientation by plasma-assisted molecular beam

epitaxy’, Journal of Alloys and Compounds. Elsevier

B.V, 710, pp. 800–808. doi:

10.1016/j.jallcom.2017.03.320.

Susanto, I. et al. (2019) ‘Morphology and surface stability

of GaN thin film grown on the short growth time by

Plasma Assisted Molecular Beam Epitaxy’, J. Phs :

Conference Seriese, 1364(012067). doi:

10.1088/1742-6596/1364/1/012067.

Susanto, I., Kan, K. and Yu, I. (2017) ‘Temperature

effects for GaN fi lms grown on 4H-SiC substrate with

4 miscutting orientation by plasma-assisted molecular

beam epitaxy’, Journal of Alloys and Compounds.

Elsevier B.V, 723, pp. 21–29. doi:

10.1016/j.jallcom.2017.06.224.

Susanto, I., Tsai, C.-Y., et al. (2019) ‘The influence of 2D

MoS

2

layers on the growth of GaN films by plasma-

assisted molecular beam epitaxy’, Applied Surface

Surface Texture of Thin Gallium Nitride Grown on Closed to Van Der Wall Layer of Molybdenum Disulfide

25

Science, 496(July), p. 143616. doi:

10.1016/j.apsusc.2019.143616.

Tian, J. et al. (2019) ‘Optoelectronic properties of two-

dimensional GaN adsorbed with H, N and O: A first-

principle study’, Physics Letters, Section A: General,

Atomic and Solid State Physics. Elsevier B.V.,

383(24), pp. 3018–3024. doi:

10.1016/j.physleta.2019.06.007.

Wan, Y. et al. (2018) ‘Epitaxial Single-Layer MoS

2

on

GaN with Enhanced Valley Helicity’, Advanced

Materials. doi: 10.1002/adma.201703888.

Yamada, a. et al. (1999) ‘Molecular beam epitaxy of GaN

on a substrate of MoS

2

layered compound’, Applied

Physics A: Materials Science & Processing, 69(1), pp.

89–92. doi: 10.1007/s003390050976.

Yang, Z. P. et al. (2017) ‘Effects of substrate and

annealing on GaN films grown by plasma-assisted

molecular beam epitaxy’, Surface and Coatings

Technology. Elsevier B.V., 320, pp. 548–553. doi:

10.1016/j.surfcoat.2016.11.019.

Yu, I.-S. et al. (2014) ‘Characterization and density

control of GaN nanodots on Si (111) by droplet

epitaxy using plasma-assisted molecular beam

epitaxy.’, Nanoscale research letters, 9(1), p. 682. doi:

10.1186/1556-276X-9-682.

Zhang, Z. et al. (2018) ‘Interface Engineering of

Monolayer MoS

2

/GaN Hybrid Heterostructure:

Modified Band Alignment for Photocatalytic Water

Splitting Application by Nitridation Treatment’, ACS

Applied Materials and Interfaces. doi:

10.1021/acsami.8b01286.

ASAIS 2019 - Annual Southeast Asian International Seminar

26