Extraction of Garlic Oil

using Microwave Ultrasonic Assisted Extraction Method

Achmad Ferdiansyah Pradana Putra, Nanda Novalia Nabila and Sofia Putri Salsabila

Institut Teknologi Sepuluh Nopember

Keywords: Garlic Oil, Microwave, Ultrasonic, Extraction.

Abstract: Garlic production depends on the garlic harvest season, which triggers prices to fluctuate. Furthermore,

peeling garlic can cause a burning sensation on our hands caused by Alliin substance. Extraction of natural

materials conventionally takes a long time, and thus, we need a faster method that is by using Microwaves-

Assisted Extraction (MAE) and Microwaves-Assisted Ultrasonic Extraction (MUAE) methods. Garlic slices

were mixed with 96% ethanol and put into an extraction flask. The maceration process lasted 30 minutes

before being put into the microwaves. The same treatment was carried out on the MUAE method by adding

ultrasonic waves. Extraction time lasted from 30 minutes to 240 minutes. The results of the research show

that the best method obtained was MUAE with an optimum yield of 14,09% for 150 minutes, organosulfur

levels of 22,95%, and could reduce energy consumption to 65%.

1 INTRODUCTION

Garlic (Allium sativum) is used in most Indonesian

cuisine. The Ministry of Agriculture’s self-

sufficiency roadmap in 2017 showed the estimated

production in 2018 increased by 199,565 tons and

estimated production in 2019 by 603,281 tons

(Kementrian Pertanian, 2017). The abundance of

garlic production causes the selling price to be quite

low at only Rp. 18,000/kg. While out of the harvest

season, the price can reach Rp. 58,000/kg. The

fluctuating prices cause farmers to lose, especially

garlic, which cannot be stored for a long time.

Besides that, peeling garlic for too long will cause a

hot sensation on hands caused by the organosulfur

content (allicin) in garlic, and it's also time-

consuming when cooking (Hernawan, 2003).

Therefore, it is necessary to innovate the processing

of garlic by extracting the garlic oil that can be used

for cooking and can increase farmer’s incomes.

The process of extracting garlic oil has been

developed in various methods. Previous research

was conducted by Valle (2006) using the Extraction

of Garlic with Supercritical CO2 method. From this

research, the highest yield was obtained at 0.9% at

50oC and a pressure of 400 bars. However, this

method used very complex technology with a long

extraction time and high energy consumption (Valle,

2006). Then, Yang (2012) conducted a study using a

simple method with relatively faster extraction time

so that the energy consumption was low by using the

Microwaves-Assisted Extraction (MAE) method at a

temperature of 30-45oC for 1 to 2 hours and 0.478%

yield was obtained (Yang, 2012). However, the

disadvantage of this method is that it had a lower

yield compared to the Extraction of Galic with

Supercritical CO2 method.

In this research, extraction of garlic oil was

conducted by using the MAE method with the

addition of ultrasonic waves, and it's called

Microwaves Ultrasonic Assisted Extraction

(MUAE) to obtain a more efficient extraction

process with lower energy consumption and higher

yield.

2 METHOD

2.1 Equipment and Materials

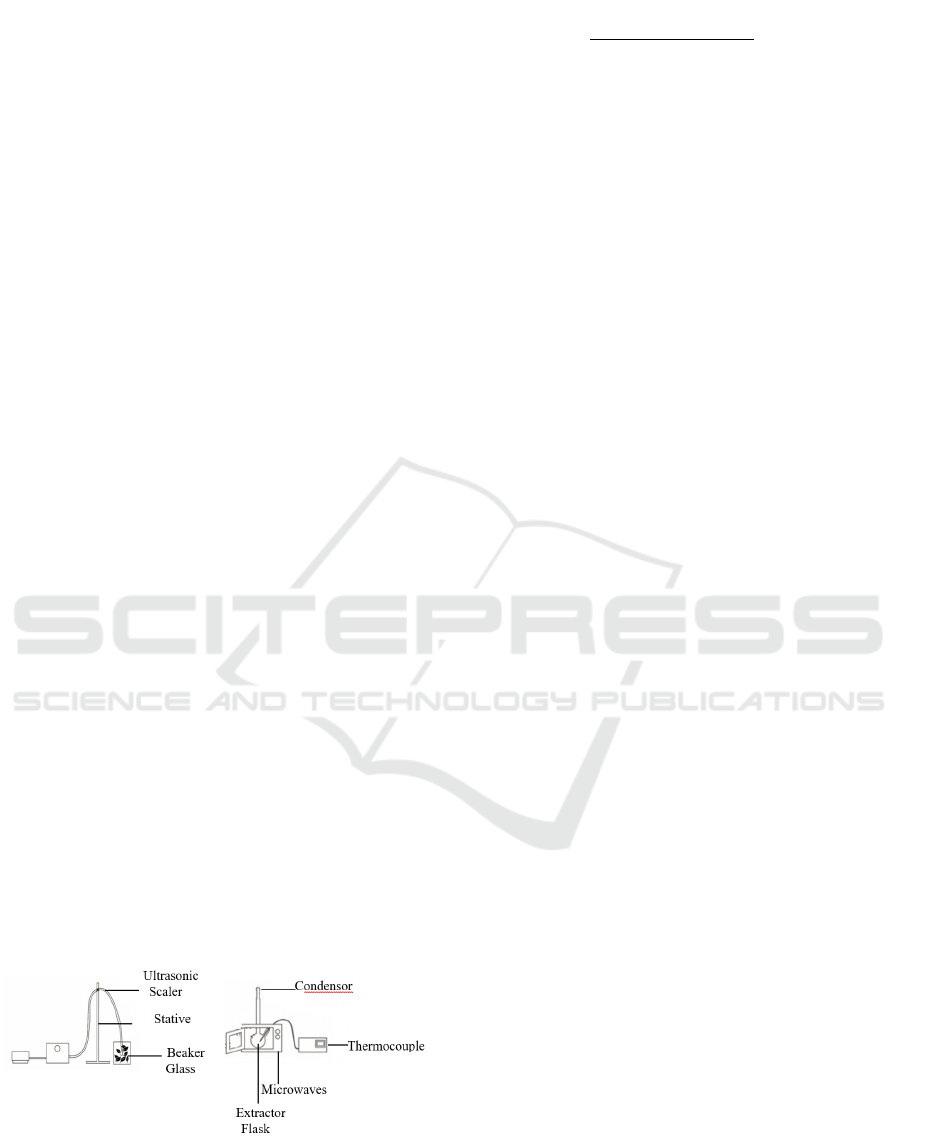

The equipment used in this research were Electrolux

EMM2308X Microwave, Ultrasonic Sonode

Woodpecler USD-J, Type K Thermocouple, Stative,

and Clamp, Condensor, Hotplate, Extractor Flask,

and Erlenmeyer. The materials used were Garlic

(Allium sativum L.) and ethanol 96%.

Putra, A., Nabila, N. and Salsabila, S.

Extraction of Garlic Oil using Microwave Ultrasonic Assisted Extraction Method.

DOI: 10.5220/0009445402330236

In Proceedings of the 1st International Conference on Industrial Technology (ICONIT 2019), pages 233-236

ISBN: 978-989-758-434-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

233

Yield =

Mass of Garlic Oil

Mass of Garlic

2.2 Pretreatment

Pretreatment of raw materials began with peeling

and cutting garlic into small pieces to expand the

garlic’s surface so that optimal oil could be

produced. Then Garlic that had been sliced was

weighed as much as 100 grams.

2.2.1 Microwave-Assisted Extraction (MAE)

Method

At this step, 100 grams of garlic had been weighed

in the pretreatment step was placed into the extractor

flask then 300 ml of ethanol was added. The next

step was the maceration process for 30 minutes.

After the maceration process was completed, the

extractor flask containing garlic and ethanol solvent

was put into the microwaves, which functioned as

the heater. The extraction process took place at the

temperature of 40oC and pressure of 1 atm, then

after the extraction process was completed in

accordance with the time variable, the separation of

garlic oil with ethanol solvent was done by

evaporating ethanol at 50-55oC for 12 hours to

obtain garlic oil.

2.2.2 Microwave Ultrasonic Assisted

Extraction (MUAE) Method

MUAE method had the same treatment with MAE

method, but in the maceration process of MUAE

method, ultrasonic waves were added for 30

minutes. These ultrasonic waves were generated by

a transducer. This equipment can change a form of

energy into another form of energy. Ultrasonic

application has several advantages, including

reducing the solvent used and accelerating the

extraction process compared to conventional

extraction. Moreover, this ultrasonic method is safer,

shorter, and suitable for the extraction of compounds

that are thermolabile (Mukhriani, 2014) (Chen,

2008).

Figure 1. Set of Equipment of Microwaves Ultrasonic

Assisted Extraction (MUAE) method

2.2.3 Analysis of Garlic Oil Yield

Garlic oil that had been produced in MAE and

MUAE methods was calculated to compare the yield

of garlic oil produced from the two methods. The

calculation of garlic oil yield is written in the

following formula.

2.2.4 Analysis of Garlic Oil Compound

Analysis of garlic oil components was used to

determine the composition of garlic oil produced

from both methods. Analysis of garlic oil

components used GCMS quantitatively.

2.2.5 Analysis of Energy Consumption

Energy consumption analysis was used to determine

the economic value of the two methods, which were

not only seen from the yield and extract yield levels

but also the calculation of the energy needed during

the process. The calculation of energy consumption

can be written in the following formula.

Energy

Consumption

=

Total Power Input x Time

of Extraction

3 RESULTS AND DISCUSSION

3.1 Analysis of the Effect of the

Addition on Ultrasonic Waves on

the MAE Method to Garlic Oil

Yield

This research used two extraction methods,

Microwaves-Assisted Extraction (MAE), which used

a microwave heating system and microwave

Ultrasonic Assisted Extraction (MUAE), which was

an innovation of MAE method by adding of

ultrasonic waves.

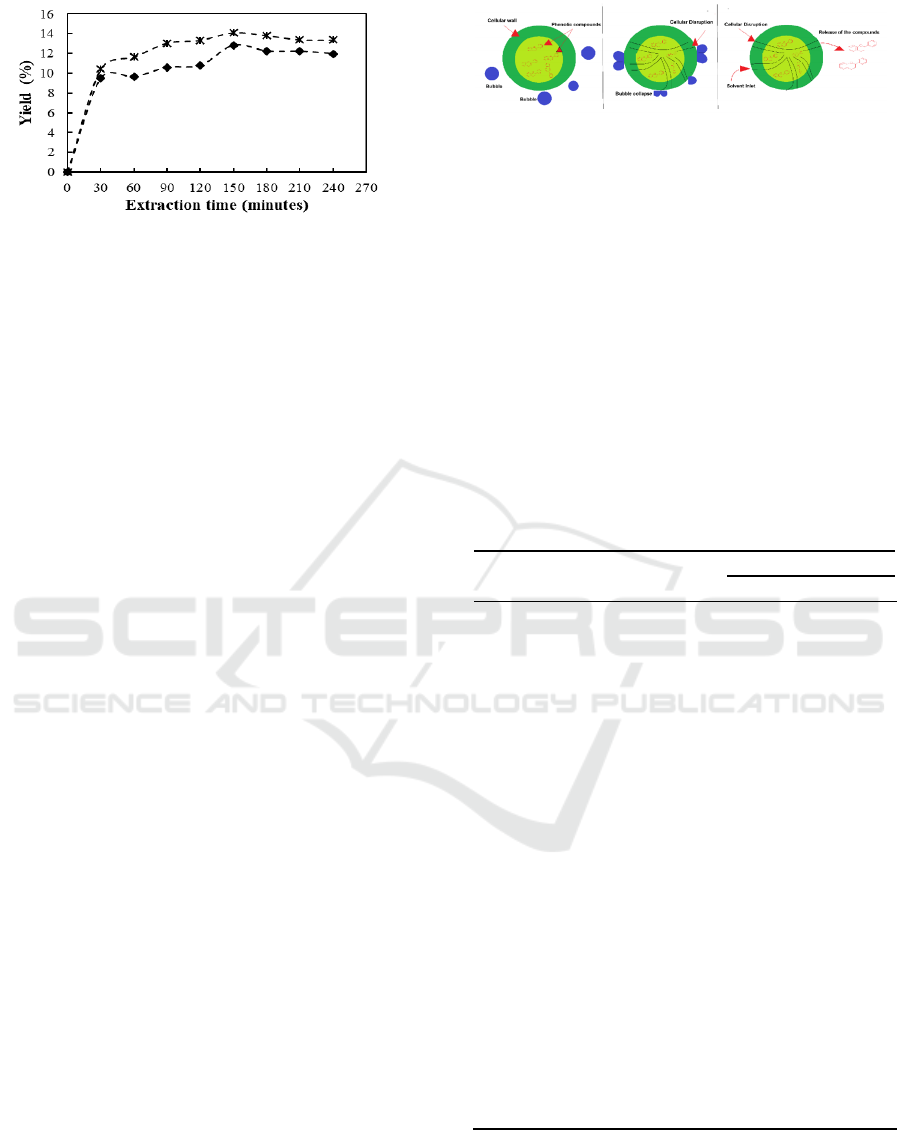

The effect of ultrasonic addition in MAE method

on garlic oil yield, it is illustrated in Figure 2

(1)X 100%

(2)

ICONIT 2019 - International Conference on Industrial Technology

234

Figure 2. The yield of Garlic Oil using MAE and MUAE

Methods

Based on the data in Figure 2, it can be seen that

the longer the extraction, the yield of garlic oil

obtained in the MAE and MUAE methods tends to

increase. However, after 150 minutes, the yield

produced in both methods also tends to decrease.

The optimum time for both methods of extracting

garlic oil was 150 minutes. The yield on the MAE

method was 12.82%, and on the MUAE method

amounted to 14,09%.

An increase in the extraction process time from

30 minutes to 150 minutes caused an increase of

garlic oil yield because the length of extraction time

made the protective membrane of material soft,

which then facilitated the penetration of the solvent

into the raw material (Pratiwi, 2016). The solubility

of the components of garlic oil ran slowly in

accordance with the increase in time. However, if

the extraction time was too long, it caused the

components in the garlic oil to be degraded so that

the garlic oil yield decreased, which could also be

caused by the limited ability of the solvent used to

dissolve the existing material (Lin, 2010).

The difference of MAE and MUAE methods

existed in the addition of ultrasonic waves at the

maceration stage of the material with 96% ethanol.

The MUAE method produced higher oil yields than

the MAE method. The increase in yield in the

MUAE method was due to the addition of ultrasonic

waves at the maceration stage. The use of ultrasonic

waves caused the pores of plant cells to open due to

the cavitation bubbles, which maximized the

penetration of solvents into the solute, and increased

the diffusion process. Thus this would increase the

process of mass transfer. High pressure and high

temperatures can destroy the cell of the garlic, and

the content in garlic cells can be released into the

surface so as to increase the yield product (Bilgin,

2013) (Khan, 2010).

Figure 3. Mechanism of Ultrasound Waves

3.2 Effect of MAE and MUAE

Methods to Garlic Oil Quality

Analysis of the quality of garlic oil obtained is an

important determinant to determine a good method

for extracting garlic oil. The quality of garlic oil can

be determined from various parameters, one of

which is the levels present in garlic oil. To

determine the levels of compounds in garlic oil, Gas

Chromatography-Mass Spectrometry (GC-MS) test

was performed.

The following are GC-MS test results on garlic

oil with MAE and MUAE methods.

Table 1. Results of Organosulphur Compound Analysis in

Garlic Oil by using GC-MS

No Compound

%

MAE MUAE

1 1-Propene, 3,3-thiobis- 3,34 2,78

2 Formyltrimenthyl-urea 1,29 0,99

3 Disulfide, methyl 2-

propenyl

1,61 2,75

4 Phenyl acetaldehyde 1,33 0,97

5 Disulfide, di-2-propenyl 7,89 11,24

6 3-Piperidinol 0,39 2,72

7 Trisulfide, methyl 2-

propenyl

2,64 5,99

8 Hydrazinecarbodithioic

acid, 1-methyl-, methyl

ester

1,50 6,08

9 2-Furancarboxaldehyde,

5-(hydroxymethyl)

1,99 1,24

10 o-Methylisourea

hydrogen sulfate

3,28 0,81

11 Trisulfide, di-2-propenyl 7,12 2,97

12 1,2,4,6-Tetrathiepane 2,87 6,67

13 Cyclopentanol 33,48 22,00

14 Piperidine 8,54 12,00

15 Quinoline 1,80 2,00

16 Propanoic acid 4,09 4,32

17 4H-Pyran-4-one, 2,6-

dimethyl

3,72 0,91

The GC-MS results in Table 1 show that most of

the garlic oil obtained by the MAE and MUAE

methods are organosulfur compounds (disulfide,

trisulfide, tetrasulfide). The percentage of

Extraction of Garlic Oil using Microwave Ultrasonic Assisted Extraction Method

235

organosulfur content produced in MAE and MUAE

methods has the difference. The percentage of

organosulphur content in the MAE method was

disulphide methyl 2-propenyl (1,61%), disulphide

di-2-propenyl (7,89%), trisulfide methyl 2-propenyl

(2,64%), trisulfide di-2-propenyl (7,12%). Whereas

in the MUAE method, the percentage content of

organosulphur produced is disulphide methyl 2-

propenyl (2,75%), disulphide di-2-propenyl

(11,24%), trisulfide methyl 2-propenyl (5,99%),

trisulfide di-2-propenyl (2,97%). If the organosulfur

compound is totaled, the percentage obtained is

19,26% for the MAE method and 22,95% for the

MUAE method. Therefore, additions of ultrasonic

waves on garlic oil extraction with the MAE method

are able to increase the organosulphur content

obtained.

3.3 Effect of MAE and MUAE

Methods to Energy Consumption

The energy consumption factor during the process

needs to be calculated to determine the economic

value of the method used. Here is a table about the

comparison of energy consumption between the

MAE and MUAE methods.

Table 2. Energy Consumption by Using MAE and MUAE

Methods

Parameters

Method

MAE MUAE

Yield (%) 10,4 10,58

Extraction Time (min) 90 30

Power Input (Watt) 1250 1285

Energy (kWh) 1,87 0,64

From Table 1. it can be seen that at different

extraction times, the yield is almost the same. MAE

method with 90 minutes of extraction time has

10.4% yields. Whereas the MUAE method with 30

minutes of extraction time produces a yield of

10.58%. The energy needed to perform the MAE

and MUAE methods is 1.87kWh and 0.64 kWh,

respectively. Therefore it can be concluded that the

MUAE method can reduce energy consumption by

65% when compared to the MAE method.

4 CONCLUSIONS

From the results of the research conducted, the

following conclusions are obtained:

1. The addition of ultrasonic waves can increase

the yield of garlic oil. In the MUAE method

yields a yield of 14.09%, while the MAE

method produces a yield of 12.82%. This

proves that the yield on the MUAE method is

higher than the MAE method with the same

time ratio.

2. The effect of the addition of ultrasonic waves

can increase organosulfur levels of garlic oil

from 19,26% (MAE method) to 22,95%

(MUAE method).

3. The addition of ultrasonic waves can reduce

energy consumption. This is proven from

energy consumption, which decreased from

1.87 kWh (MAE method) to 0.64 kWh

(MUAE method), which means that it can

reduce energy consumption by 65%.

REFERENCES

Bilgin, M., & Sahin, S. “Effect of Geograhical Origin and

Extract Methods on Total Phenolic Yield of Olive

Tree (Olea uropea) Leave”. Journal of the Taiwan

Institute of Chemical Enginees. 2013

Chen, D., Sharma, S. K., & Mudhoo, A. “Handbook on

Applications of Ultrasound Sonochemistry for

Sustainability (I es.)”. New York: CRC Press. 2008

J. d. Valle. “Extraction of Garlic with Supercritical CO2

and Conventional Organic Solvents”. Brazilian

Journal of Chemical Engineering. 2006

Kementerian Pertanian. “Pusat Data dan Sistem Informasi

Pertanian Kementerian Pertanian Republik Indonesia”.

Statistik Pertanian. 2017

Khan, M. K., Vian, M. A., Tixier, A. S., Chemat, F., &

Dangles, O. (2010). Ultrasound-Assisted Extraction of

Polyphenols (Flavanone Glycosides) from Orange

(Citrus sinensis L.) Peel. Food Chemistry, 851-858.

L. Yang. “Microwave-Assisted Extraction of Garlic

Essential Oil from Garlic”. Applied Mechanics and

Materials. 2012

Lin, C. M., Sheu, S. R., Hsu, S. C., & Tsai, Y. H.

”Determination of Bactericidal Efficacy of Essential

Oil Extracted from Orange Peel on the Food Contact

Surfaces”. Food Control. 2010

Mukhriani “Ekstraksi Pemisahan Senyawa dan Identifikasi

Senyawa Aktif”. Jurnal Kesehatan Vol VII No.2. 2014

Pratiwi, L., Rachman, S., & Hidayati, N. “Ekstraksi

Minyak Atsiri sari Bunga Cengkeh dengan Pelarut

Etanol dan N-Hexane”. The 3rd University Research

Colloquium. 2016

U. E. Hernawan. “Senyawa Organosulfur Bawang Putih

(Allium sativum L.) dan Aktivitas Biologinya.

Biofarmasi, 65-76. 2003.

ICONIT 2019 - International Conference on Industrial Technology

236