Simulation of a Proportional-Integral-Derivative Control for

Continuous Bioreactor

Rudy Agustriyanto, Puguh Setyopratomo, Akbarningrum Fatmawati

Faculty of Engineering, The University of Surabaya, Jl. Raya Kalirungkut, Surabaya, Indonesia

Keywords: Bioprocess control, simulation, PID controller, bioreactor.

Abstract: In a continuous bioreactor, feed is added, and the product flow is removed at a constant rate. The objective is

to maintain the system at a steady state with high product formation. This can produce a very productive

process, with a low operating cost. However, there are operational challenges, especially on an industrial

scale, because they require tightly controlled conditions and strong monitoring methods. For long operation,

the system suffers a higher risk of contamination. This paper investigated the PID (Proportional integral

Derivative) control strategy of a continuous bioreactor. Several tuning methods of PID controller were used

for controller parameters determination (i.e., Direct Synthesis, Ziegler-Nichols (Z-N), and Tyreus-Luyben

(TLC)). The results of the closed-loop simulation for servo (setpoint tracking) problems are presented in this

paper for each method and compared. The results showed that the three method works well qualitatively.

However, the process model of the system needs to be modified by introducing 5 hrs time delay, which is

useful in obtaining cross over frequency and to make PID possible in the Direct Synthesis method.

1 INTRODUCTION

An important aspect of bioprocess control is to lay

down real-time operations that are stable, less

susceptible to various disturbances, close to certain

circumstances, or desired profiles compatible with an

optimal operating condition (Dochain, 2008).

Bioprocess control itself can be defined as providing

an environment that is close to optimal so that

microorganisms can grow to reproduce and produce

the desired product. This includes providing the right

concentration of nutrients (e.g., carbon, nitrogen,

oxygen, phosphorus, sulfur, minerals), eliminating

toxic metabolic products (e.g., CO2), and controlling

important parameters (e.g., pH, temperature).

The dynamics model for a bioreactor system has

been available (Riggs and Karim, 2006). Based on

this model, Agustriyanto (2015) obtained the first-

order transfer function in the Laplace domain, which

then successfully controlled by the Proportional

Integral (PI) controller (2016). Simulation results of a

closed-loop system with PI controller tuned by direct

synthesis method have been presented (Agustriyanto,

2016).

The objective of this paper is to investigate the

Proportional Integral Derivative (PID) control

strategy of the above continuous bioreactor.

In the next section (Method), the system being

studied (continuous bioreactor) will be explained

first, followed by its open-loop transfer function in

the Laplace domain. PID control of the bioreactor

system will also be discussed and followed by several

tuning methods (Direct Synthesis, Ziegler Nichol,

and Tyreus Luyben).

Section 3 (Results and Discussion) mainly

presenting controller parameters and their closed-

loop simulation results.

2 METHOD

2.1 Continuous Bioreactor

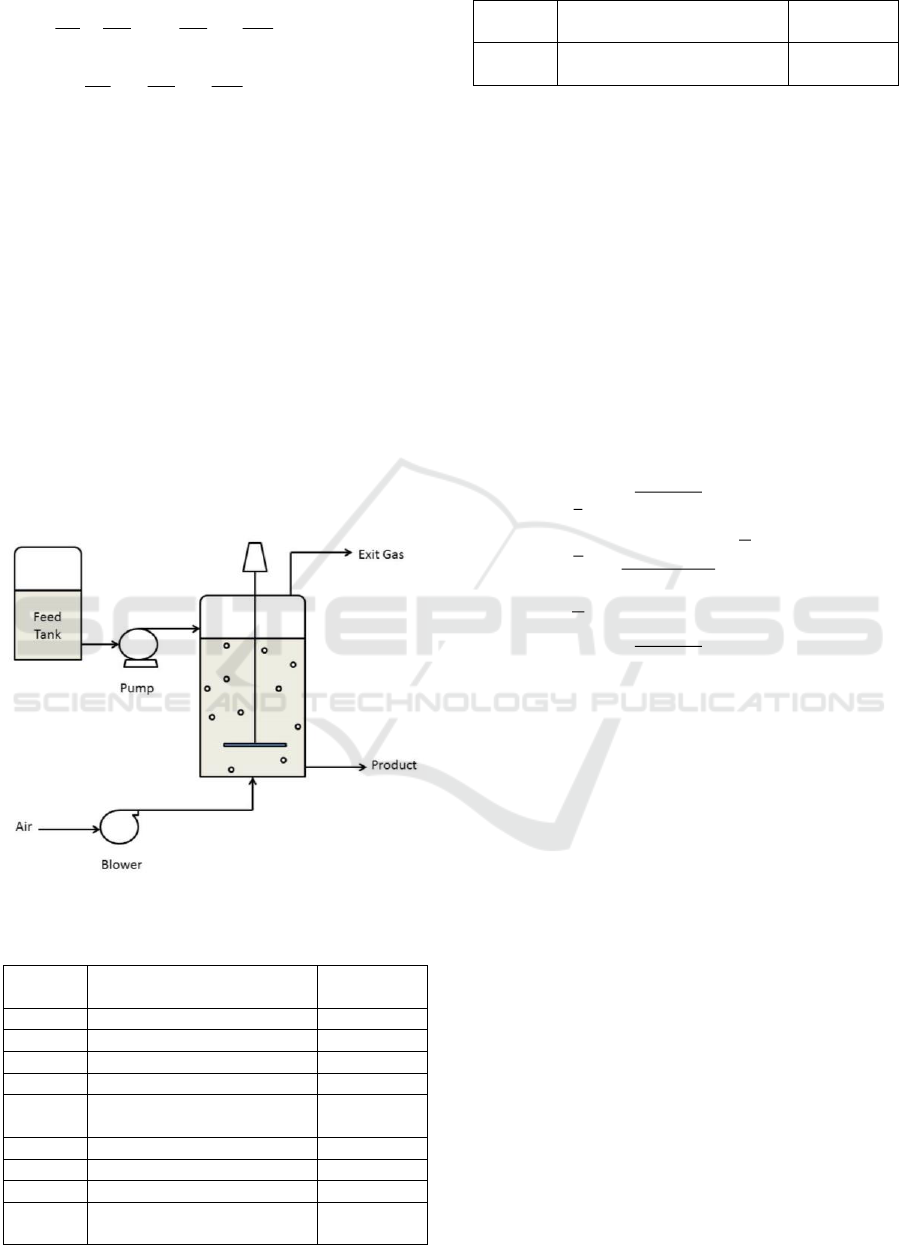

The continuous bioreactor being studied is presented

in Figure 1 (Riggs and Karim, 2006). The model

based on first principle (mass conservation) for this

system is presented as follows:

xx

V

F

dt

dx

V

max

+−=

(1)

Agustriyanto, R., Setyopratomo, P. and Fatmawati, A.

Simulation of a Proportional-Integral-Derivative Control for Continuous Bioreactor.

DOI: 10.5220/0009423201190123

In Proceedings of the 1st International Conference on Industrial Technology (ICONIT 2019), pages 119-123

ISBN: 978-989-758-434-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

119

x

Y

S

V

F

S

V

F

dt

dS

xS

V

F

V

max

1

−−=

(2)

x

Y

P

V

F

dt

dP

xP

V

max

1

+−=

(3)

The cells consumed most of the substrate, and it

was assumed that the cell growth followed Monod

kinetics. The process variables and parameters for

this bioreactor model were given in Table 1.

The feed contains sugar as a substrate (S) from

grains (such as wheat, barley, corn, rice, etc.) and

nutritional salts to support cell growth (x). Cells (x)

consume substrate (S) and produce product (P) and

CO2. The air blower provides oxygen to cells. The

exit gas consists mainly of nitrogen from the air,

oxygen that is not consumed, and carbon dioxide

produced by cells from sugar consumption. Cell

concentration was measured with a turbidity meter,

and substrate concentration was measured by an

online HPLC analyzer. In industrial bio-processes,

filters are normally used for all inlet and outlet flow

to keep sterile conditions even though it is not shown

in Figure 1.

Figure 1. Continuous bioreactor system

Table 1: Process variables and parameters

Symbol

Variables & Parameters

Values &

Units

Fv

Feed rate

1 m3/h

Ks

Monod’s constant

0.1 g/L

P

Concentration of product

1.25 g/L

S

Concentration of substrate

25 g/L

SF

Substrate concentration in

the feed

50 g/L

t

Time

h

V

Bioreactor volume

5 m3

x

Concentration of cell

0.25 g/L

YxP

Yield factor

0.2 g-cells/

g-product

YxS

Yield coefficient

0.01 g-cells/

g-substrate

μmax

The maximum specific

growth rate

0.2/h

2.2 Process Transfer Function

First-order transfer function in Laplace domain for

this bioreactor system has been published before

(Agustriyanto, 2015) by solving the model equation

(i.e Equation (1) to (3)) subject to the steady-state

parameters and values are given in Table 1 using DEE

(Differential Equation Editor) in Matlab. The results

were re-identified using the System Identification

Toolbox. This method was previously explained in

Agustriyanto and Fatmawati (2013) and Agustriyanto

(2014). The results are as follows (where the mark bar

indicates that the variables are in the form of

deviation):

P

S

x

=

+

−

+

+

−

1100

025.0

1663.96

54813.0

1100

005.0

s

s

s

v

F

(4)

2.3 PID Control of Continuous

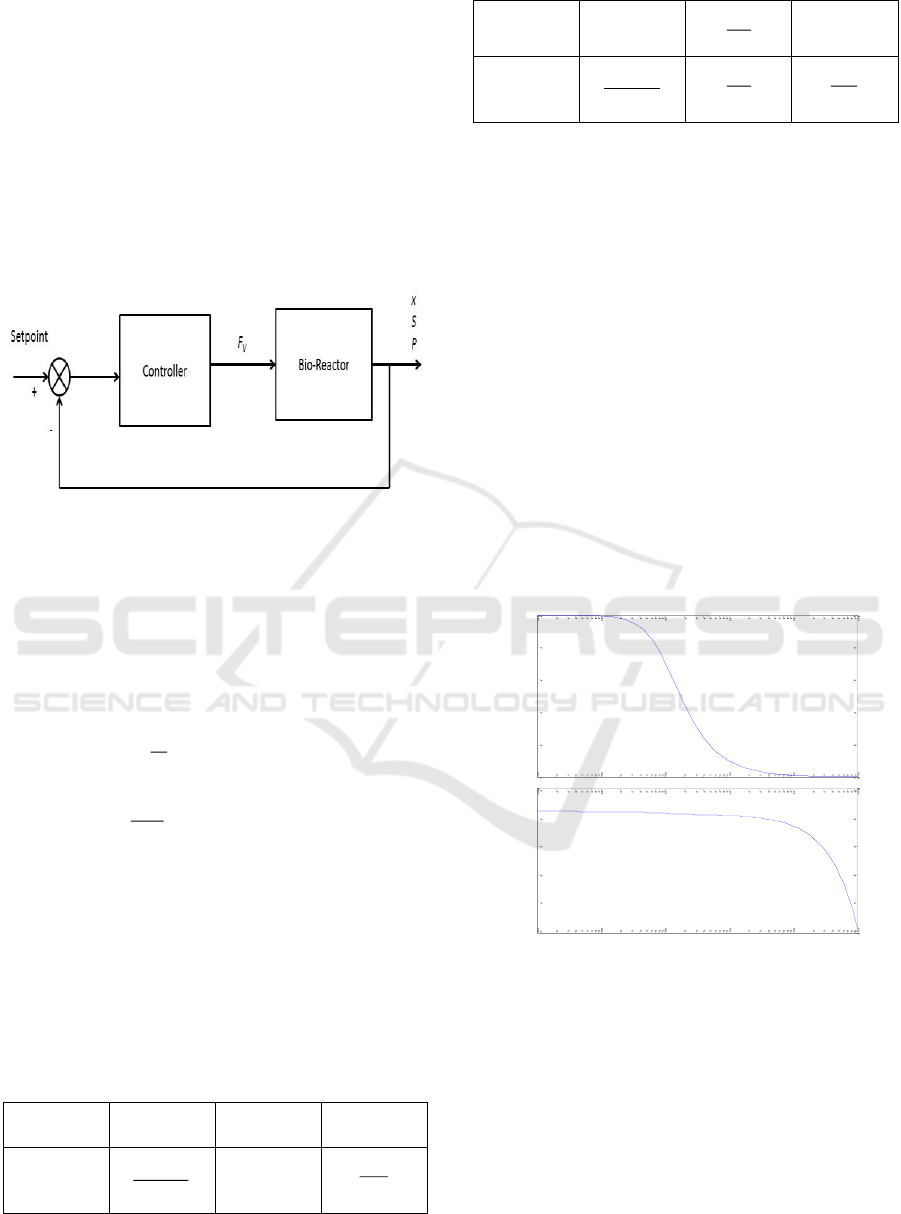

Bioreactor

Product (P) was chosen as the variable being

controlled, and the flow rate to the reactor (FV) as the

manipulating variable. Figure 2 shows the closed-

loop system for the continuous bioreactor. It was

assumed that the transfer function for the

measurement equipment and control valve are one, so

they were ignored in the figure.

PID mode was chosen for the controller, and as

the system transfer function is first order, the Direct

Synthesis tuning method (Seborg, 2010) or Ziegler-

Nichol and Tyreus-Luyben method can be applied. It

was assumed that there were 5 hrs time delay, and it

was used for tuning purposes only.

The reason for using the Direct Synthesis is that

we can specify the desired closed-loop transfer

function, which is in this case: servo problem (Chen

and Seborg, 2002). While Ziegler Nichol is a classical

method that is still widely used due to its simplicity

(Zalm, 2004).The Tyreus Luyben procedure is quite

similar to the Ziegler Nichol, but the final controller

setting is different.

ICONIT 2019 - International Conference on Industrial Technology

120

2.4 Direct Synthesis (DS) Controller

Tuning

Direct synthesis for a first-order process will lead to

a PI controller (Agustriyanto, 2016); therefore, for

this system, another approach will be used. Here,

FOPTD (First Order Process with Time Delay) is

used since it will give PID. The derivation to obtain a

PID setting can be found elsewhere, and the resulting

PID is shown in Table 2. (http://inside.mines.edu/

~jjechura/ProcessDynamics/14_DirectSynthesis.pdf)

. It was also assumed that the value of λ = 5 hrs.

Figure 2. Close loop of the bioreactor system

2.5 Ziegler Nichols (Z-N) Controller

Tuning

To use the Ziegler-Nichols method, first, we need to

plot the Bode diagram (Coughanowr, 2009). Table 2

shows that controller parameters are the function of

Ku and Pu.

A

K

u

1

=

= ultimate gain

(5)

co

u

P

2

=

= ultimate period

(6)

=A

amplitude ratio at the cross over

frequency

(7)

=A

amplitude ratio at the cross over

frequency

(7)

Table 2: Controller tuning formula

Direct

Synthesis

Ziegler

Nichols

Tyreus

Luyben

c

K

p

p

K

+

u

K6.0

2.2

u

K

I

+

p

2

u

P

u

P2.2

D

+

p

p

8

u

P

3.6

u

P

2.6 Tyreus Luyben (TLC) Controller

Tuning

Similar to the Ziegler-Nichols method, Tyreus-

Luyben controller parameters are also the functions

of Ku and Pu

(http://pages.mtu.edu/~tbco/cm416/zn.html). These

functions are shown in Table 2.

3 RESULTS AND DISCUSSION

Figure 3 shows the Bode Plot for the system being

studied. It was found the value of cross-over

frequency = 0.944 with the amplitude of 0.000266 at

cross-over. Therefore, by using Eq.(5) and (6):

3759=

u

K

(8)

6599,6=

u

P

(9)

Figure 3. Bode plot

Table 3 shows controller parameter values, which

are calculated according to the formula shown in

Table 2.

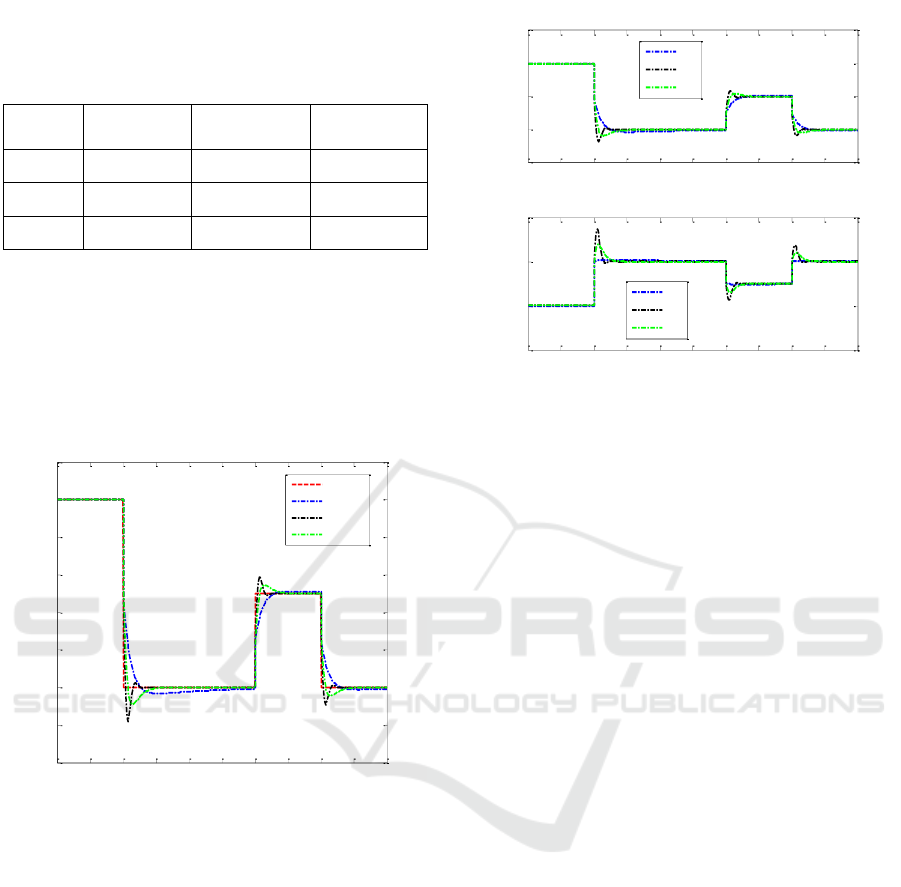

The product concentration was successfully

controlled using PID controller (Figure 4). This figure

shows the performance of the PID controller tuned by

three different methods (Direct Synthesis (DS),

Ziegler-Nichols (Z-N), and Tyreus Luybean (TLC)).

Here, the setpoint for product concentration was

changed from initial (i.e., 1.25 g/L) to 1.2 g/L at t=100

Bode Diagram

Frequency (rad/s)

10

-4

10

-3

10

-2

10

-1

10

0

10

1

-2880

-2160

-1440

-720

0

720

Phase (deg)

0

0.005

0.01

0.015

0.02

0.025

Magnitude (abs)

Simulation of a Proportional-Integral-Derivative Control for Continuous Bioreactor

121

hr, followed by a step up and down at t=300 hr and

400 hr to the value of 1.225 g/L and back to 1.2 g/L

Table 3: Controller tuning

Direct

Synthesis

Ziegler

Nichols

Tyreus

Luyben

c

K

-840

-2255.4

-1708.6

I

105

3.33

14.6518

D

4.7619

0.8325

1.0571

From simulation results shown in Figure 4, it can

be concluded that the Ziegler-Nichols (Z-N) method

of tuning will give the highest overshoot for step

changes in setpoint, followed by Tyreus Luyben

(TLC) and Direct Synthesis (DS). Therefore, Ziegler-

Nichols also fast in reaching its new steady-state

value as expected by the set point.

Figure 4. The plot of Product Concentration (P) vs. Time

for PID Controller

Figure 5 shows the performance of uncontrolled

variables (i.e., x and S) vs. time. When the product set

point reduced to 1.2 g/L at t=100 hr, it can be seen

that cell concentration also reduced while the

substrate was increased. This is caused by different

signs in-process model gain for cell and substrate, as

indicated in Eq.(4).

Comparing to other published research (Husain et

al., 2014), these results agree that Tyreus Luyben

gave lower overshoot than Ziegler Nichols. While for

Direct Synthesis, we specify the output as desired

(i.e., no overshoot).

Figure 5. The plot of Cell and Substrate Concentration for

PID Controller

4 CONCLUSIONS

Simulation of a PID control strategy for a continuous

bioreactor system has been performed. Three

different tuning methods have been applied and work

well.

In implementing the method, the process model of

the system needs to be modified by introducing a 5

hrs time delay. This time delay should be small

enough compared to its time constant. Here we

choose about 5% of the time constant. This will help

in obtaining cross over frequency in Bode plot, as for

the first-order process without time delay will result

of none. This time delay also useful in obtaining the

PID parameter in the Direct Synthesis method as the

original process model will lead to the PI (not PID)

controller.

REFERENCES

Dochain, D. (2008). Bioprocess Control, John Wiley and

Sons, Inc.

Riggs, J.B., Karim, M.N. (2006). Chemical and Bioprocess

Control, Pearson Prentice Hall.

Agustriyanto, R. (2015). Simulation of Continuous Bio-

Reactor. In Proceedings of the Eight International

Conference of Chemical Engineering on Science and

Applications (ChESA), Banda Aceh, Indonesia.

Agustriyanto, R., Fatmawati, A. (2013). Bioprocess System

Identification of Continuous Fermentation, In

Proceedings of the 2nd International Conference of the

Indonesian Chemical Society, Yogyakarta, Indonesia

0 50 100 150 200 250 300 350 400 450 500

1.18

1.19

1.2

1.21

1.22

1.23

1.24

1.25

1.26

Time, [hrs]

Product Concentration, P, [g/L]

Set point

DS

Z-N

TLC

0 50 100 150 200 250 300 350 400 450 500

0.235

0.24

0.245

0.25

0.255

Time, [hrs]

Cell Concentration, x, [g/L]

DS

Z-N

TLC

0 50 100 150 200 250 300 350 400 450 500

24

25

26

27

Time [hrs]

Substrate Concentration, S, [g/L]

DS

Z-N

TLC

ICONIT 2019 - International Conference on Industrial Technology

122

Agustriyanto, R. (2014). Model Identification of

Continuous Fermentation under Noisy Measurements,

In Proceedings of the 3rd International Conference on

Computation for Science and Technology (ICCST-3),

Denpasar, Bali.

Agustriyanto, R. (2016). PI Control of a Continuous Bio-

reactor, In Proceedings of the 6th Annual International

Conference (AIC) of Syiah Kuala University, Banda

Aceh, Indonesia.

Seborg, D.E., Mellichamp, D.A., Edgar, T.F. (2010).

Process Dynamics and Control, John Wiley and Sons,

Inc.

Chen, D., Seborg, D.E. (2002). PI/PID Controller Design

Based on Direct Synthesis and Disturbance Rejection.

Ind. Eng. Chem. Res., 41, 4807-4822.

Zalm, G.M. (2004). Tuning of PI/PID Controllers:

Literature Overview.

https://pdfs.semanticscholar.org/b1a8/a78f2e8b0f64b2953

8b83e2859d8b6365b43.pdf

http://inside.mines.edu/~jjechura/ProcessDynamics/14_Di

rectSynthesis.pdf

Coughanowr, D.R., LeBlanc, S.E. (2009). Process Systems

Analysis and Control, McGraw-Hill’s.

http://pages.mtu.edu/~tbco/cm416/zn.html.

Hussain, K.M., Zepherin, R.A.R., Kumar, M.S. (2014).

Comparison of Tuning Methods of PID Controllers for

FOPTD System. International Journal of Innovative

Research in Electrical, Electronics, Instumentation and

Control Engineering, 2/3.

Simulation of a Proportional-Integral-Derivative Control for Continuous Bioreactor

123