Simulation of Wind Turbines with Variation of Number of Blades

and Blades Angle on Turbine Performance

Achmat Hidayat, Andi Idhil Ismail

Institut Teknologi Kalimantan

Keywords: Cross-flow, Power Coefficient, Tip Speed Ratio, Torque Coefficient, Wind Turbine, Turbine Performance.

Abstract: Crossflow wind turbines are known because of the advantages of producing maximum torque in a low tip

speed ratio also as a self-starting wind turbine. Therefore, it is an ideal wind turbine type for application as a

power generator in rural areas that have low wind speed between 2-5 m/s. The design parameter of cross-

flow wind turbines is required in order to improve turbine performance. This work investigates the influence

of blades number and blades angle on the performance of cross-flow wind turbines. Furthermore, to

investigate the effect of blades number and blades angle on crossflow wind turbine performance. Crossflow

wind turbines designed using 18 and 20 blades on 45˚, 60˚, and 75˚ blades angle on 0.68 aspect ratio

diameter. Based on the results obtained, cross-flow wind turbines with 18 number of blades and 45˚ blades

angle showed the best result.

1 INTRODUCTION

Crossflow type wind turbines are ideal turbines for

remote areas because crossflow type turbines can

produce large torque when a small tip speed ratio.

Crossflow wind turbines can effectively capture

wind when the wind conditions are in poor

condition.

If considering the limits of the type of classic

wind turbines, crossflow type wind turbines should

be a solution for areas that have poor wind

conditions and low speeds of 2-5 m / s [1].

At present, there is a lot of follow-up research on

crossflow type wind turbines. The efficiency

produced by crossflow wind turbines is high because

energy is produced from two sides of the turbine;

first, when the wind enters and pushes the front

turbine, the two come out of the turbine and push

back the backside of the wind turbine [2].

The purpose of the study was to measure the

performance of a crossflow type wind turbine with

variations in the number of blades and blade angle.

So that it can be seen the turbine design with the best

performing variation of research.

Turbine performance analysis is done with

Computational Fluid Dynamics (CFD). The design

made is 1 x 1 m2 outer diameter and 0.68 x 0.68 m2

in diameter with a ratio of aspect ratios of 0.68 with

two variations in the number of blades as much as

18 blades and 20 blades and also three variations of

blade angle 45 sudut, 60˚, and 75˚. Based on the

results of the study, the design of a crossflow type

wind turbine with 18 blades and a slope angle of 45˚

produced the highest Cp value of 0.45.

2 LITERATURE REVIEW

Computational Fluid Dynamics (CFD) is used to

help calculate the output value, CFD uses the

continuity equation as follows:

⍴/ ⍴/ (1)

Taking into account the conditions are ideal

conditions, the incompressible Navier-Stokes

calculation formula is used as follows:

⍴/ . Τ f. (2)

Kinetic energy is transferred to the rotor, and the

wind leaves the turbine. The actual power of the

turbine is efficiency or known as Cp. Thus, the Cp

value can be searched by comparing the actual

power and wind power available by:

Hidayat, A. and Ismail, A.

Simulation of Wind Turbines with Variation of Number of Blades and Blades Angle on Turbine Performance.

DOI: 10.5220/0009423101150118

In Proceedings of the 1st International Conference on Industrial Technology (ICONIT 2019), pages 115-118

ISBN: 978-989-758-434-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

115

Cp=

⍴

(1)

Where Pt is the turbine output power, the Cp

value can depend on the type of blade, a number of

blades, blade settings, and others.

Ct=

⍴

(2)

Where Tt is motor torque. Tip Speed Ratio

(TSR) can be defined between turbine speed and

wind speed.

=

(3)

The maximum Tip Speed Ratio (TSR) value is

directly proportional to the value of turbine

efficiency [1].

3 METHODOLOGY

In this study, cross-flow wind turbines were carried

out using the 2D method. Cross-flow wind turbines

with D1 = 1 m and D2 = 0.68 m are placed in

modeling with a length of 15 m with a width of 7.5

m, and the distance between inlets to wind turbines

is 2.5 m. The domain of modeling can be seen in

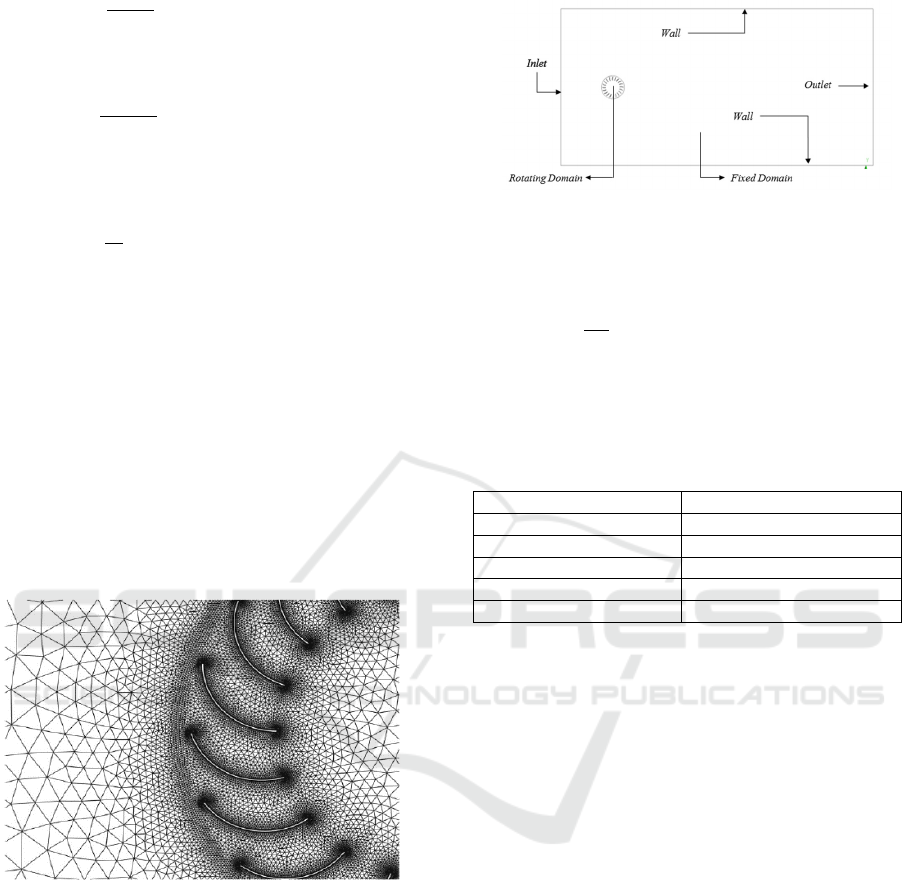

Figure 1.

Figure 1 Meshing Quality

The computational domain is divided into two

subdomains, namely fixed domain and rotating

domain. The inlet is where the wind enters and is

modeled with a wind speed of 2 m / s. Meanwhile,

the right side is modeled as a pressure outlet with a

relatively static pressure of 0 Pa. The upper and

lower sides of the turbine are boundary walls as the

upper and lower limits of the wind turbine.

Figure 2 Computational Domain

Value Tip Speed Ratio (TSR) for the simulation

in Computational Fluid Dynamics (CFD) can be

defined by the equation as follows:

4

Where is the angular speed of the cross-flow

wind turbine and R = D1 / 2, which is the outer

diameter, and v is the air velocity modeled in the

simulation.

Table 1 Tip Speed Ratio (TSR)

(rad/s)

0 0

0.1 0.4

0.2 0.8

0.3 1.2

0.4 1.6

The meshing used is the Triangular Meshing

model used in all parts of the cross-flow wind

turbine domain. The quality of the meshing results in

the study shows that 0.78, where the meshing results

belong to the category of good meshing, which

makes meshing can be used to continue the research

(Wikantyoso, 2017). The following are the results of

meshing.

Meshing results will affect the accuracy of the

research conducted. Therefore, triangle meshing is

used because it has a sufficient level of accuracy.

4 RESULTS

The turbulence modeling k- is widely used to carry

out crossflow type wind turbine simulations because

the application is complex and is very suitable for

rotation so that the resulting results can approach the

results of experimental studies.

ICONIT 2019 - International Conference on Industrial Technology

116

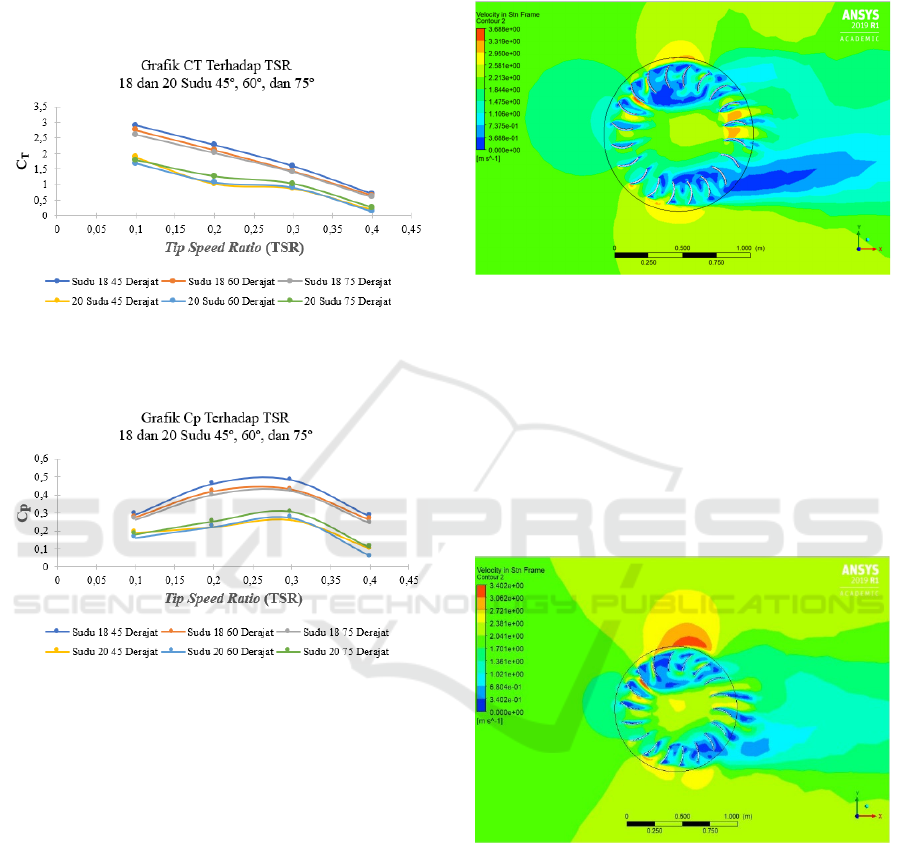

It can be seen that the trend of the torque

coefficient value (ct) decreases as the value of the

Tip Speed Ratio (TSR) increases because this value

of Ct is not directly proportional to the TSR value.

The highest Ct value is found when the TSR is 0.1,

and the lowest TSR value is at TSR 0.4

Figure 4 Grafik Cp

The highest Cp value is found in blade 18 with a

blade angle of 45˚ on TSR 0.3. This proves that

there are differences in performance with blades 18

and blade 20. Power Coefficient (Cp) generated

from wind turbines is directly proportional to the

actual power value produced by the turbine. Cp

value forms a parabolic pattern where when the

value reaches the maximum value, the value of Cp

will decrease after reaching the maximum point.

This is caused by when the value of Cp reaching the

maximum value will decrease directly proportional

to the value of TSR.

Based on Albert Betz's theory that the maximum

CP value that can be owned by a crossflow type

wind turbine is 0.59 because the air that hits the

turbine will pass the distance between one turbine to

another. Inner vortex increases at TSR 0.4 and TSR

0.5, causing a decrease in crossflow wind turbine

performance. Where the higher TSR values given to

variations will affect the performance of crossflow

type wind turbines. The performance of the wind

turbine reaches a peak at the point of TSR 0.2 and

TSR 0.3, which has a maximum CP value of 0.45.

Figure 5 Contour Velocity 18 Blades 45˚ Blades Angle

The velocity contour of blade 18 and 45 blade

angles show that there is an inner vortex that occurs

around the turbine blades. Inner vortex is backflow

from the wind that passes through the turbine so that

it disturbs the flow of air that passes through the

turbine blade. Inner vortex has an effect on the Cp

value generated by the turbine, the more there is an

inner vortex, the more resistance to airflow in the

turbine so that the turbine does not function

optimally.

Figure 6 Velocity Contour 20 blades

If we compare inner vortex in the number of

blades 18 and the number of blades 20, it can be

seen that the number of blades 20 has inner vortex

which is more because the number of blades 20 has

too many blades in the crossflow wind turbine

resulting in broken wind through the blade which

causes a lot of inner vortex occurred in the crossflow

wind turbine caused the flow of the wind can’t reach

its optimum level, so based on figure 5 the value of

Cp blade 20 is not optimal compared to the value of

Cp blade 18.

Figure 3 CT

Simulation of Wind Turbines with Variation of Number of Blades and Blades Angle on Turbine Performance

117

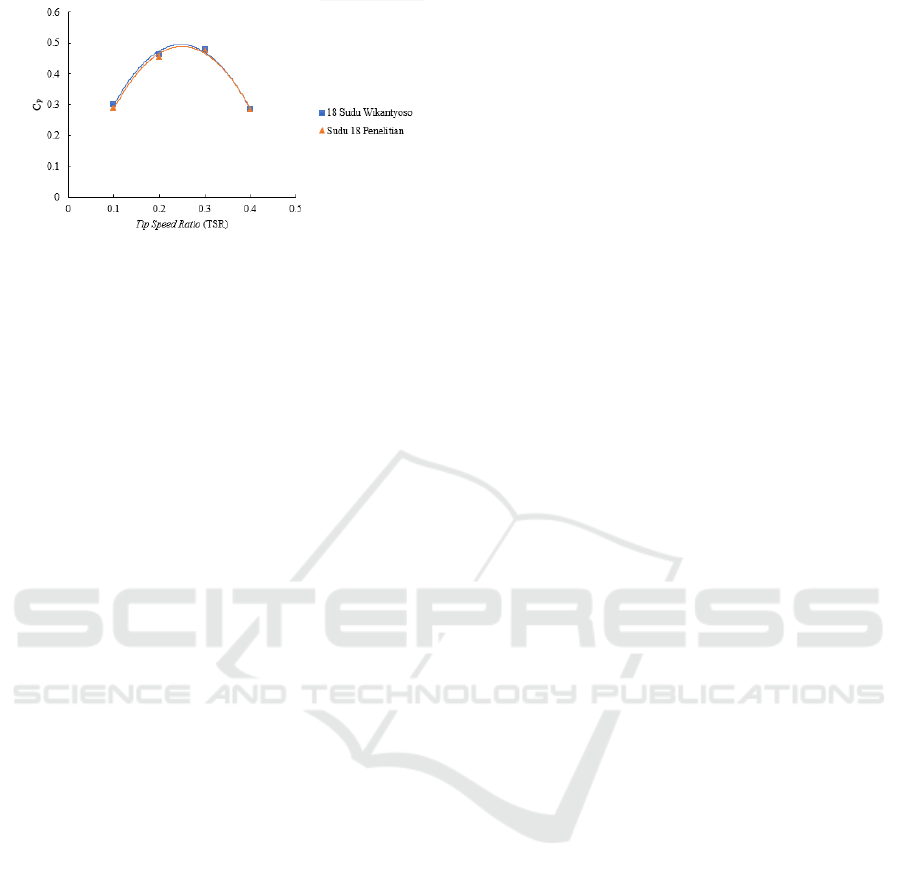

Figure 7 Results Comparation

The highest CP performance occurs at a TSR

blade 0.3. The highest CP value is due to the

variation of blade thickness of 10 mm, which has an

influence on the CP research results. The thickness

of the blade of 10 mm influences the speed of the

incoming winds, which hit the first level wind

turbine so that the speed of the incoming wind and

the speed of the outgoing wind. Blades can affect the

incoming wind, in research conducted the number of

recommended blades for wind turbines is blade 18 to

blade 22 if it exceeds the wind will split and cannot

enter the maximum

Based on figure 7, the value of the power

coefficient will increase maximally at Tip Speed

Ratio (TSR) 0.3 and decrease at TSR 0.4. This is

caused after the turbine reaches a maximum point at

TSR 0.3 after which the turbine will decrease after

reaching the maximum point. The maximum point

of a crossflow wind turbine is at a low Tip Speed

Ratio (TSR) of 0.3, and this makes a crossflow wind

turbine an excellent turbine for low wind speeds. If

using a TSR value of 0.5 to TSR of 0.6, the results

of the performance of a cross-flow wind turbine will

experience a decrease so that the value of the power

coefficient can experience a minus. The comparison

of CP values can reach 0.5 very high when

compared with the Beltz momentum theory.

5 CONCLUSIONS

Based on the results of the analysis after conducting

research, it is suggested that the turbine can only

operate with a maximum Tip Speed Ratio (TSR) at

0.4, the higher the TSR value, the maximum turbine

drop will occur after reaching the maximum value

on TSR 0.3. And a comparison with experimental

research is needed to ensure the simulation results

with experimental research in the real world.

Furthermore, based on the results of the contour

speed analysis it is recommended to use symmetrical

casing to make the wind direction more regular and

can change the direction of the wind so that it can

make the wind direction more convergent which

causes a little backflow which makes the Cp value of

the turbine more leverage. For 1 x 1 m turbine size,

it is recommended to use blade 18 because, based on

the results of the study, it produces a value that is

more optimal when compared to blade 20.

REFERENCES

Al Maaitah, A., 1993. The design of the Banki wind

turbine and its testing in real wind conditions.

Pergamon Press Ltd, Volume 3, p. 1.

Dragomirescu, A., 2010. Performance assessment of a

small wind turbine with crossflow runner by numerical

simulations. Elsevier Ltd, pp. 2-9.

Hau, E., 2005. Wind Turbines: Fundamentals,

Technologies, Application,. 2nd penyunt. s.l.:Springer.

Jain, P., 2011. Wind Energy Engineering. United States:

McGraww-Hill.

Kurniawati, D. M., 2018. Eksperimen Pengaruh Aspek

Rasio Diameter Terhadap Tinggi dan Jumlah Sudu

Terhadap Performa Turbin Angin Cross flow. AIP

Publishing, pp. 1-6.

Mathew, S., 2006. Wind Energy Fundamentals, Resource

Analysis, and Economics. Malapuram: Springer.

Natayuda, G., 2017. Analisa Termodinamika dan Kinerja

Turbin Angin Tipe Sumbu Horizontal Menggunakan

Computational Fluid Dynamics. Universitas Jenderal

Achmad Yani.

Permadi, M. F. W. & Siregar, I. H., 2018. Uji

Eksperimental Turbin Angin Sumbu Vertikal Jenis

Crossflow Dengan Variasi Jumlah Sudu.

JTM.unesa.ac.id, Volume 06, pp. 15-31.

Shigemitsu, T., 2016. Performance and Flow Condition of

Cross-Flow Wind Turbine with a Symmetrical Casing

Having Side Boards. International Journal of Fluid

Machinery and Systems, Volume IX, p. 171.

Wikantyoso, M. F., 2017. Studi Pengaruh Ketebalan dan

Jumlah Sudu. digilib.uns.ac.id, pp. 45-46.

ICONIT 2019 - International Conference on Industrial Technology

118