Electrolyte Membrane Composite from Modified Chitosan-Vanillin

and Zeolite Filler for Direct Methanol Fuel Cell Application

Anjas Badarani S.

1

, Gugus Handika

1

, Mochammad Purwanto

1

, Edi Pramono

2

, Cynthia Linaya R.

2

1

Institut Teknologi Kalimantan

2

Department of Chemistry, Bandung Institute of Technology, Bandung, Indonesia

cynthia@chem.itb.ac.id

Keywords: Fuel cell, Membrane, Chitosan-Vanillin, Zeolite

Abstract: Fossil fuels, which are the main fuels in the world has a negative impact on the environment and must be

replaced immediately with other fuels, DMFC is variant of fuel cell which works as portable to maintain daily

human activity and potential to replace fossil fuels as the main source of energy. DMFC regulates as similar

to an electrochemical cell in which favor of separator referred to as Polymer Electrolyte Membrane (PEM).

PEM shows the main feature, such as hindering the electrons and reactants from trespassing between the

electrodes while acting as a proton conductor. The main parameter of PEM for DMFC are good proton

conductivity and low methanol permeability. Chitosan-Vanillin (CV) was synthesized by reacting chitosan

and vanillin at 1: 2,5 wt ratio and stirred continuously to obtain the product. The membrane then cast by

mixing the CV with some variations of zeolite with the compositions of 1,5%, 3%, and 6% wt towards CV.

The membrane then cast into a petri dish and left it overnight. The resultant membrane then characterized

with FTIR, ATR, molecular weight, water and methanol uptake, ion exchange capacity, ionic conductivity,

and methanol permeability. The optimum membrane result was the 6% wt zeolite in the CV, in which ionic

conductivity reached 0,1 S/cm and 1,266 x 10-3 cm2/s for methanol permeability.

1 INTRODUCTION

Fossil fuels still dominating in the world, especially

in countries that still use transportation, which fossil

fuels as the main fuel. Fossil fuels have a large

negative impact on the environment. Fossil fuels had

82 percent of total global energy sources in 25 years,

although any efforts to reduce still requires a lot of

alternative energy because the percentage is still the

same (Republika, 2013). If fossil fuels still used

continuously, impacts such as acid rain and global

warming will occur. Therefore, the purpose of this

study is to replace the fossil fuels with fuel cells that

produce more energy and fewer emissions

Direct methanol fuel cell (DMFC) is a type of

PEMFC. DMFC provides good power density almost

as high as PEMFC but is safe and capable. One of the

main factors for this DMFC to work is electrolytes.

Electrolytes known as separators as selective barriers

to methanol and H+ ions pass through the membrane.

DMFC will provide more energy and fewer

emissions. Nafion is famous for commercial

electrolytes used in PEMFC because of high

conductivity and excellent chemical stability.

Although the excellent performance of Nafion has

made it a good choice of electrolytes, methanol

permeability still occurs. Such permeability affects

the efficiency of methanol in DMFC. Therefore,

several developments have been made to overcome

this problem.

Chitosan is a biopolymer in crustacean animals.

Chitosan functions as a good biocompatibility

composite and a good polycationic ability to provide

chemical stability. Another feature of chitosan is that

OH and NH2 backbones can be modified, so chitosan

acts as a flexible matrix for any application. In

electrolyte membranes for DMFC applications,

parameters such as proton conductivity and methanol

permeability must be considered. So, to modify

chitosan, several methods are offered, such as

modifying chitosan, whether inside and outside the

matrix. This research was conducted by combining

these methods. Vanillin is used for reagent polymers

and inorganic silica materials such as zeolites as

modifications outside the matrix. Both of these

ingredients enhance chitosan as a DMFC electrolyte,

94

S., A., Handika, G., Purwanto, M., Pramono, E. and Linaya R., C.

Electrolyte Membrane Composite from Modified Chitosan-Vanillin and Zeolite Filler for Direct Methanol Fuel Cell Application.

DOI: 10.5220/0009406100940099

In Proceedings of the 1st International Conference on Industrial Technology (ICONIT 2019), pages 94-99

ISBN: 978-989-758-434-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

which is suitable in terms of proton 2 experimental

methods. Zeolite was chosen because it has good

results, specifically decreased water uptake,

decreased methanol uptake, and reduced methanol

permeability. Whereas, vanillin was chosen as an

anti-bacterial.

2 MATERIALS

Dried shrimp shells of Penaeus monodon as chitosan

sources. Vanillin powder purchased from PT Subur

Kimia Jaya. Zeolite purchased from PT Bratacho

Chemica. Sodium hydroxide (NaOH), hydrochloric

acid (HCl), methanol (MeOH), acetic acid, hydrogen

peroxide (H2O2), sulfuric acid (H2SO4), toluene,

ethanol (EtOH), phenolphthalein indicator, and

sodium chloride in the pure analytical grade were

purchased from Merck.

2.1 Chitosan Preparation

Chitosan preparation has three steps deproteinized,

demineralized, and deacetylated. The first step is

deproteinized, shrimp shells that have been prepared

ground into a powder and then stir it at 60-70C in

NaOH 3,5% wt solution by the composition 1:10 (gr

powder/mL NaOH) for about 2 hours. The shells then

filtered from the solution, washed it by demineralized

water (aqua dest), and dried at 100C for about 4

hours. The shells then demineralized in HCl solution

at 60-70C by the composition 1:10 (gr powder/mL

HCl) for about 2 hours. The shells turned into chitin

this time and underwent the same procedure to get

dried chitin. Chitin then deacetylated in NaOH 50%

wt solution by the composition 1:10 (gr powder/mL

NaOH) for about 1 hour at 90-100C. Chitin was

degraded into chitosan, and lastly, the same procedure

is applied to get dried chitosan.

The dried chitosan underwent modification by

vanillin. Chitosan first diluted by 1% of acetic acid

(2% w/v ratio) and vanillin diluted by absolute

ethanol (1:2 ratio). Both diluted chitosan and vanillin

then mixed in one container with 1:2,5 of chitosan:

vanillin ratio for about a day at 35. The resultant

solution then filtered by using a vacuum filter flask to

get the chitosan powder. The product itself has a

brown-yellowish.

2.2 Membrane Preparation

The electrolyte membrane was prepared using the sol-

gel process. Initially, the experiments were performed

by preparing various concentrations (1,5%, 3%, and

6% wt zeolite) chitosan membrane. Chitosan and

desire filler were dissolved in acetic acid 2% v/v and

then stirred at room temperature for 24 h until the

solution formed a gel. The solution was placed into a

petri dish for 24 h. After the thin film was formed, the

membrane then poured with NaOH solution to faster

the peeling. The resultant membrane then washed and

dried at room temperature.

2.3 Chitosan and Chitosan-Vanillin

Characterization

Membrane characterization was used Fourier

Transport Infra-Red (FTIR) as instrumental analysis.

Chitin and chitosan functional groups was

identification by Fourier Transport Infra-Red (FTIR).

Samples are directly exposed to electromagnetic

radiation to obtain absorbance and then correlate

between absorbance and functional groups.

2.4 Water and Methanol Uptake

Water uptake and methanol uptake determine the

ability of the membrane absorbs the solution. The

membrane was weighed before soaked with methanol

or water for 12 hours. Then wet membranes are

weighed and can be applied to the following formula:

Uptake (%) = ((W

wet

–W

dry

)/W

dry

)x100% (3)

Where : W

wet

= Mass Membrane after immersion

aaaaaaaaaaaaaaaa(gram)

W

dry

= Mass Membrane before immersion

aaaaaaaaaaaaaaaa(gram)

2.5 Methanol Permeability

Methanol permeability to determine membrane

performance for methanol crossover. The membrane

is cut to the size of 1.6 X 1.6 cm and placed into the

diffusion cell compartment. Compartment A contains

1M methanol, and compartment B contains water.

Methanol concentration was measured using samples

in compartment B every 30 minutes for 2 hours.

Methanol concentration was measured using a

pycnometer and corrected with a calibration curve.

The sampled concentrations were regressed to get its

slope. Methanol permeability formula as follows :

P = [ΔCB/Δt] * [L*VB/(A*CA)] (4)

Where :

P = methanol permeability (cm2/s)

ΔCB/Δt = slope determined by function of time

(mol/L.s)

Electrolyte Membrane Composite from Modified Chitosan-Vanillin and Zeolite Filler for Direct Methanol Fuel Cell Application

95

L = membrane thickness (cm)

VB = volume of water in compartment (cm3)

A = membrane surface area (cm2)

CA = methanol concentration in compartment

(mol/L)

2.6 Ion Exchange Capacity (IEC)

IEC is used to determine the movement of protons in

membrane. Membrane is immersed into HCL for 1

hour as protonate. Then the membrane was immersed

in NaCl as a second protonate for 24 hours.

membrane has been titrated using 0.01 M NaOH with

phenoptalein indicator as a titer after protonation.

Titration data can be used in the following formula:

IEC (meq) = [V*C/m] (5)

Where :

V = Volume of titer used to netralize the NaCl

solution (mL)

C = NaOH concentration (M)

m = Dry weight of the membrane (gram)

2.7 Proton Conductivity

Proton conductivity is the main parameter to find out

membrane quality to delivering protons. Zdata could

be found from the LCR meter. Zview will be

implemented Zdata to get the Rbulk value. Then

Rbulk can be used into the formula :

Ϭ = L/(R*A) (6)

Where :

Ϭ = Conductivity (S/cm))

R = Bulk resistance (ohm)

L = Membrane thickness (cm)

A = Area of the membrane (cm2).

3 RESULTS AND DISCUSSION

3.1 Membrane Structure

3.1.1 Chitosan-Vanillin Structure

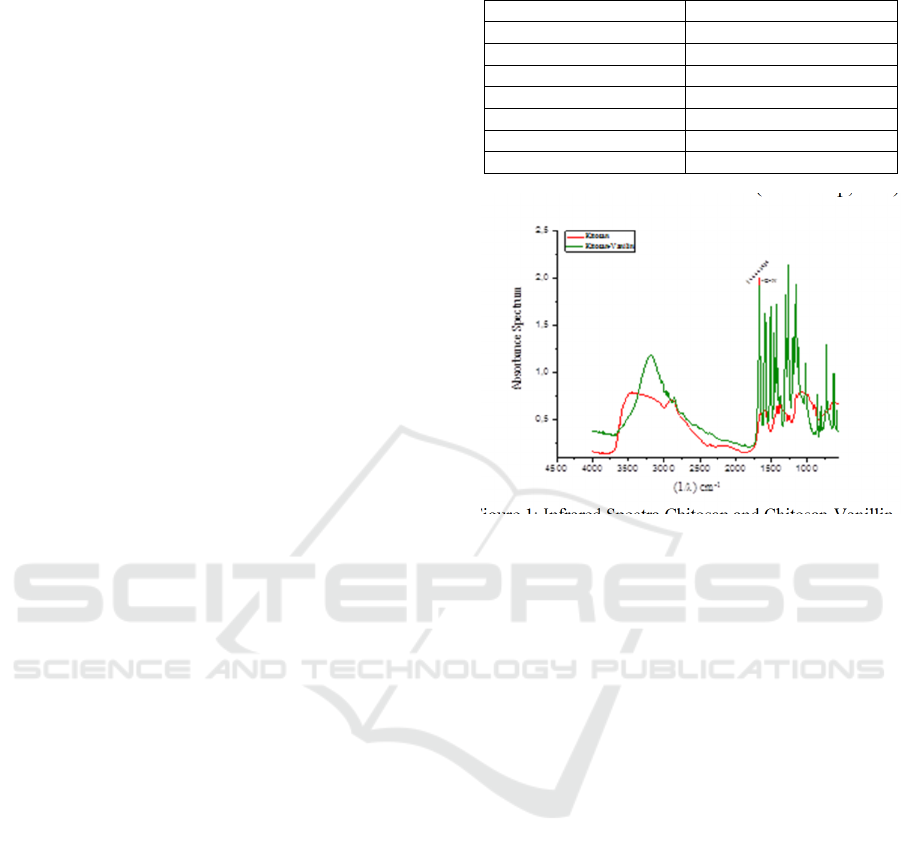

FTIR assessments were to determine the group

functionality of chitosan and chitosan-vanilline.

Numerous wavelengths were caught in the FTIR

spectrum. There is numerous vibration of functional

groups as informed in the table below:

Table 1: Functional group vibrations of chitosan

Functional Group Absorbance Spectrum

-O-H 3550-3100

-N-H (COCH3) 1680-1630

-N-H 1650-1580

-C-H 3000-2850

-C-N 1250-1020

-C=O 1650

-C-O (Eter) 1150-1085

(Beuchamp,1981)

Figure 1: Infrared Spectra Chitosan and Chitosan-Vanillin

Deacetylation by compare amide absorption

against water absorption. As a result, the best DD

obtained of 92%. Later, the substitution of imine

groups' appearance in CV was determined in

wavenumber 1690-1640 cm-1. As depicted in figure

1, the –C=N group was in 1666,65484 cm-1, which

indicating CV was successfully synthesized. As

explained by Pramono (2014), FTIR analysis of

vanillin chitosan showed peaks in the area of 1641

cm-1, including the formation of an imine (C = N) or

schif base bond.

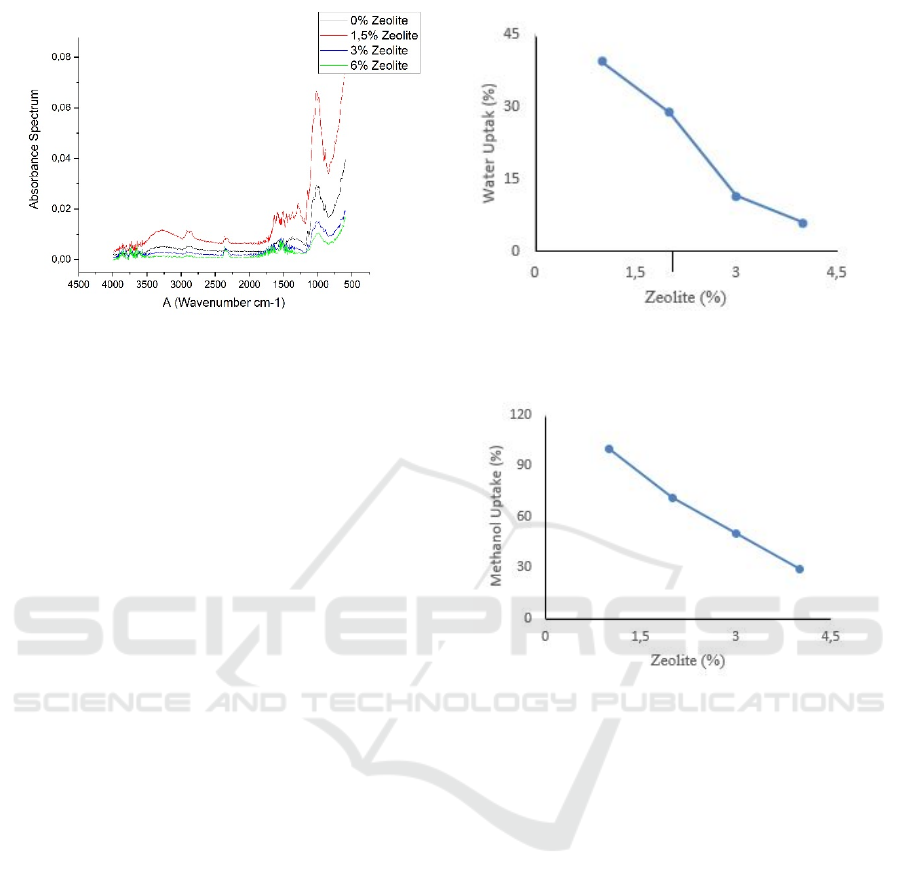

3.1.2 Chitosan-Vanillin Filler Zeolite

Structure

The filler membrane was also be examined to

determine the substitution of functional groups

between CV and zeolite. When the chitosan

membrane is modified with zeolite, the adhesion

strength between the polymer and zeolite particles

will increase and reducing the void space on the

membrane (Fitri, 2016).

From figure 2, chitosan-vanillin successfully

binds to the zeolite. It is proved by the vibrations peak

at range 1100-980 cm-1 dan 1000-500 cm-1. This

vibration is functional group Al-O and Si-O, which is

chitosan-vanillin filler zeolite bonding comparable

with Saikia (2010). But the highest vibrations peak at

1,5% zeolite because mixing didn’t go properly.

ICONIT 2019 - International Conference on Industrial Technology

96

Figure 2: Infrared Spectra Chitosan-Vanillin Filler Zeolite

3.2 Water and Methanol Uptake

Chitosan generally has hydrophilic and hydrophobic

properties. Evidenced by the measurement of water

contact angel membrane with range 100-115

prominent in hydrophobic properties but has

hydrophilic properties also. Water contact angles

below 90 and hydrophobic 90-180 (Dwivedi,

2017).Water molecules in chitosan increase the

mobility of ions, but higher intensity water can be

damaging membrane structure. Therefore a water

uptake measurement is necessary to determine the

results of the addition zeolite filler to the chitosan

membrane because zeolite has hydrophobic

properties. Methanol uptake measurements to

determine the selectivity of the membrane against

methanol as the main fuel in the direct methanol fuel

cell because higher methanol uptake can affect the

chemical reaction of the direct methanol fuel cell. As

depicted from the figure below, the water uptake and

methanol uptake of chitosan were determined.

Figure 3 showed water uptake decreased, and new

molecular bonds decrease the membrane's ability to

absorb water molecules from the solvent (Wang,

2010). Zeolite filler has silica molecules that increase

hydrophobic properties. Further, in figure 4, methanol

uptake decreased. It has two possibilities, methanol

structure similar to the fenolic group, so it has a high

affinity (Antony, 2019) or methanol density smaller

than water molecules. This makes it easy for

methanol molecules to pass through the membrane

based on particle size.

Figure 3: Water Uptake

Figure 4: Methanol Uptake

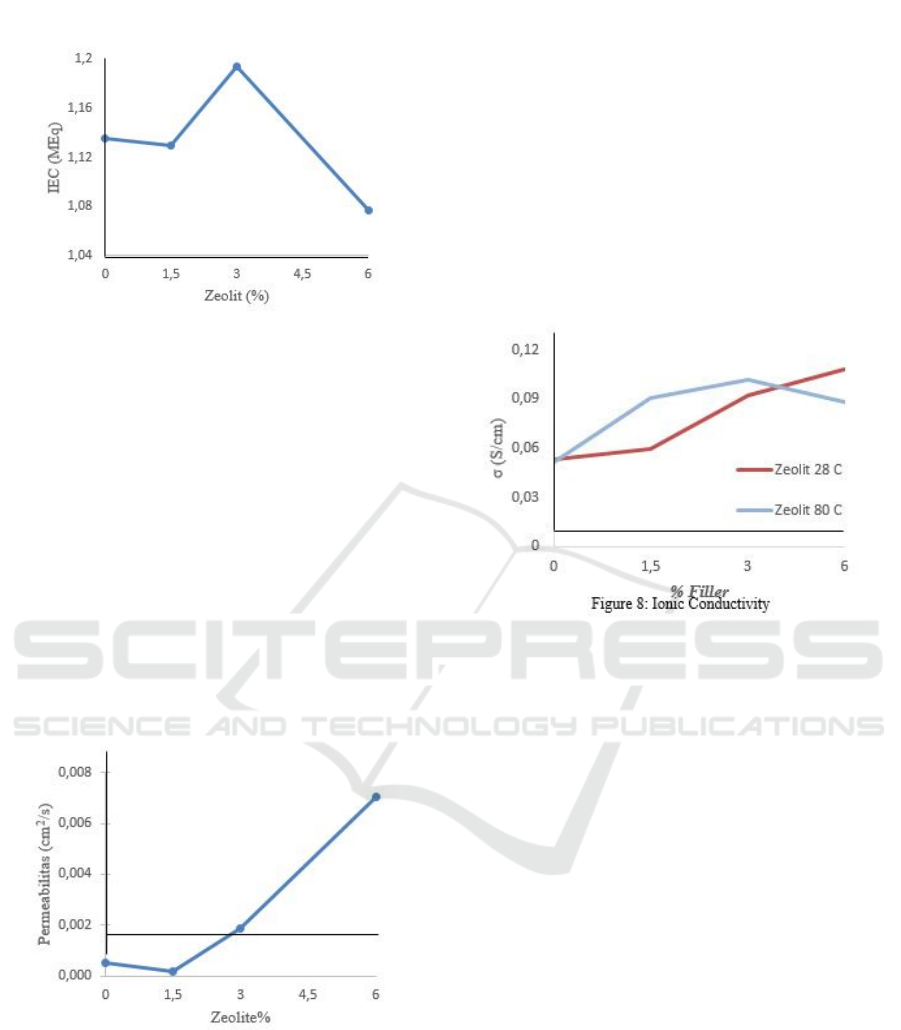

3.3 Ion Exchange Capacity

Ion exchange capacity was conducted to determine

the delivery of ions on the membrane. Therefore, an

ion exchange capacity measurements are performed

to compare ion delivery each variable of zeolite.

Figure 5 showed the chitosan-vanillin membrane

with zeolite filler increase ion exchange capacity at

concentration 3% with a value ion exchange capacity

is 1,1935 milliequivalent and then decreased at a

concentration of 6% of zeolite. Chitosan-vanillin

filler zeolite bond makes new proton pathways.

However, the silica content of zeolite reduced water

molecules causes a lack of proton transport — vehicle

mechanism which one requires water molecules to

formed H3O+ for delivering a proton (Wang 2008).

Electrolyte Membrane Composite from Modified Chitosan-Vanillin and Zeolite Filler for Direct Methanol Fuel Cell Application

97

Figure 5: Ion Exchange Capacity

3.4 Methanol Permeability

This membrane will be applied for direct methanol

fuel cells that methanol as the main fuel. The low

permeability of methanol generates high fuel

efficiency and reduce fuel loss. And methanol

permeability is expected to be low and does not

interfere with membrane performance.

Methanol permeability test can be linked with

methanol uptake. The results were not enough to

outrun the Nafion's. From figure 6, the best result was

only 1,875, E-04 cm2/s by CV-Z 3%. Comparable

with Wang (2010), high zeolite content can be

affected by zeolite molecules because it has a low

affinity for each other enlarges membrane pores.

Figure 6: Methanol Permeability

Such a membrane could absorb the amount of

methanol that would make this membrane-less

efficient. Also, from IR spectra result was also

affecting the result. These results concluded that the

addition of silica content was one method to reduce

the permeability of the membrane. Despite this

successfully reducing methanol permeability, the

optimization should be conducted for later research.

3.5 Ionic Conductivity

This membrane will be applied to direct methanol

fuel cells, which are used as methanol to produce

electrical energy. The membrane functions as a

conduit of H+, which will then react with O2 and

produce H2O. So, the proton conductivity test is

needed to determine the ability of the membrane to

deliver H+.

Figure 7: Ionic Conductivity

As shown in figure 7, at 28C ionic conductivity

increased along with zeolite concentration additional.

Zeolites provide hydroxyl groups as pathways proton

jumping mechanism. Higher temperature causes the

polymer chain to fluctuate, causing a movement to the

electrolyte group (Salman, 2018). Especially

hydroxyl and phenolic groups in the membrane

matrix. This movement causes the transferring proton

at 80C is better than 28C. However, at 80C,

with a 6% zeolite concentration, ion conductivity was

decreased because high temperature is the main

problem for water content at the membrane. Proton

delivery in-vehicle mechanism requires water

molecules to delivers protons. This phenomenon was

previously known by the measurement of ion

exchange capacity. It has a connection to the delivery

of protons.

4 CONCLUSIONS

Chitosan-Vanillin with zeolite membrane for fuel cell

application was prepared with the addition of zeolite

content. The best composition for this research for

water uptake at CV-Z 1.5% with 28.834%, methanol

uptake at CV-Z 6% with 29.03226%, ion exchange

ICONIT 2019 - International Conference on Industrial Technology

98

capacity at CV-Z 3% with 1.1935 MEq, proton

conductivity at KV-Z 6% with 0.088474546 S / cm,

and permeability of 3% KV-Z methanol with 1,875 X

10-4 cm2 / S. The best composition in this research

are methanol uptake and water uptake because the

parameter decreases the point near 30% as the best

composition. But needs optimization, especially in

methanol permeability, because it is still higher than

Nafion, which is one essential parameter for the fuel

cell.

ACKNOWLEDGMENTS

The authors gratefully acknowledge for LPPM

Kalimantan Institute of Technology for supporting

this research. We also regard the Bandung Institute of

Technology for funding and facilities provided.

REFERENCES

Antony,R., Arun, T., dan Theodore, D. M. S. (2019), A

Review On Applications of Chitosan-Based Schiff

Bases, International Journal of Biological

Macromolecules vol. 159, hal. 615-633.

Beauchamp, J.L., dan Wight, C.A. (1981), Infrared Spectra

of Gas-Phase Ions and Their Use inElucidating

Reaction Mechanisms. Identification of C7H7-

Structural Isomers by Multiphoton Electron

Detachment Using a Low-Power Infrared Laser,

Journal of American Chemical Society vol.21, hal.

6499-6501.

Dwivedi C , Pandey I, Pandey H, et al., Electrospun

Nanofibrous Scaffold as a Potential Carrier of

Antimicrobial Therapeutics for Diabetic Wound

Healing and Tissue Regeneration, Elsevier, Chapter 9

Fitri Kurnia S, W. Nurul, (2016), Penambahan Polieteriida

pada Membran Komposit kitosan/zeolit-A untuk

meningkatkan kinerja membran PEMFC, Fakultas

Kimia dan Ilmu Pengetahuan Alam, Institut Teknologi

Sepuluh November.

Komi, Daniel, E.A., dan Hambiln, M.R. (2016), Chitin and

Chitosan: Production and Application of Versatile

Biomedical Nanomaterials, Int J Adv Res (Indore), vol.

4, issue 3, hal. 411–427.

Pramono, E, Prabowo, A, Purnawan, C. (2012), Pembuatan

Dan Karakterisasi Kitosan Vanilin Sebagai Membran

Polimer Elektrolit, Jurnal penelitian kimia, vol. 8, no. 1,

hal. 70-78.

Pramono, E., Purnawan, C., Hidayat, Y., Wulansari, J., dan

Wahyuningsih, S. (2014), Komposit Kitosan

Vanilin/Polistirena Tersulfonasi Sebagai Membran

Polimer Elektrolit: Kapasitas Tukar Kation, Derajat

Pengembangan Dan Sifat Termal, ALCHEMY jurnal

penelitian kimia, vol. 10, no. 2, hal.116-129.

Purwanto, Atmaja et.al, (2016), Biopolymer-based

electrolyte membranes from chitosan incorporated with

montmorillonite-crosslinked GPTMS for direct

methanol fuel cell, Journal RSC Advances, 2314-2315.

Republika. (2013). IEA: Penggunaan Bahan Bakar Fosil

Global Tetap Dominan . Dikutip 8 Agustus 2019 dari

Republika.c.id:https://www.republika.co.id/berita/eko

nomi/bisnis-global/13/11/14/mw8f2s-iea-penggunaan-

bahan-bakar-fosil-global-tetap-dominan

Saikia, G. Parthasarathy, (2010), Fourier Transform

Infrared Spectroscopic Characterization of Kaolinite

from Assam and Meghalaya, Journal Scientidic

Research, 206-210.

Salman, Y. A. K., Abdullah, O.G., Rawad R. H., dan

Shujahadeen B. A. (2018), Conductivity and Electrical

Properties of Chitosan -Methylcellulose Blend

Biopolymer Electrolyte Incorporated with Lithium

Tetrafluoroborate, International Journal

Electrochemical Science., vol. 13, hal. 3185 – 3199.

Se-Kwon, (2011), Chitin, Chitosan, Oligosaccharides and

Their Derivatives, CRC Press.

Wang Y, Jiang Z, Li H, (2010), Chitosan membranes filled

by GPTMS-modified zeolite beta particle with low

methanol permeability for DMFC, Elsevier, 278-285.

Wang Y, Yang D, Zheng X, Yi Z, Li ., (2008), Zeolite beta-

filled chitosan membrane with low methanol

permeability for direct methanol fuel cell, Elsevier,

454-463.

Electrolyte Membrane Composite from Modified Chitosan-Vanillin and Zeolite Filler for Direct Methanol Fuel Cell Application

99