Consideration of the Different Pile Length Due to Soil Stress and Inner

Forces of the Nailed-slab Pavement System under Concentric Load

Anas Puri

1

, Roza Mildawati

1

and Muhammad Solihin

2

1

Department of Civil Engineering, Universitas Islam Riau, Pekanbaru, Indonesia

2

Undergraduate Student Department of Civil Engineering, Universitas Islam Riau, Pekanbaru, Indonesia

Keywords:

Inner Forces, Lateral Deflection, Stress Distribution, Longer Piles, Soft Clay, Soil Stress.

Abstract:

Concentric loading on the Nailed-slab Pavement System causes stress in the soil and the inner forces in

structural elements. The load stress is transferred to the soil by the structural elements tends to concentrate in

the centerline area under the system. Since load stress is concentrated in the center line area, the soil stress and

inner forces can be higher in the center of the system. To reduce the soil stress and inner forces of structural

elements, the longer pile can be put in the center area of the system. This research is aimed to learn the

soil stress and inner forces behavior of the Nailed-slab Pavement System in case putting the longer pile in the

center area of the system. The maximum double wheel load was taken 50 kN which transfer to the slab surface

by contact pressure. Wheel load was loaded in the center of the slab. The Nailed-slab materials properties and

soft clay properties were taken from the previous researcher. The piles in the center area of the Nailed-slab

were longer 33.3% than others. Results show that the Nailed-slab by longer piles in the center area can reduce

the soil stress significantly for maximum shear stress up to 28%. The inner forces were also reduced by about

43% to 46% and caused the reducing in lateral deflection of pile tip about 37%. It can be concluded that the

increasing pile length in the central area of the system can reduce soil stress and inner forces of the system.

1 INTRODUCTION

The uniform pile length in bearing the vertical

loadings on the Nailed-slab Pavement System was

used by the previous researchers. Such as the research

by Hardiyatmo (2011), (Puri et al., 2011a; Puri et al.,

2011b; Puri et al., 2012; Puri et al., 2013; Puri et al.,

2014; Puri et al., 2015; Puri and Mildawati, 2019)

and (Puri et al., 2015; Puri, 2016) for Nailed-slab

System on the soft clay. The distribution of soil stress

will be experienced a maximum settlement due to the

load position. A maximum settlement on the center of

the Nailed-slab can be occurred due to the concentric

load. The soil stress and inner forces analysis can be

done by the finite element method of Plaxis software

(Puri et al., 2015; Puri, 2016; Puri and Mildawati,

2019; WARUWU, 2018). Inner forces analysis of

Nailed-slab can be also done by the finite element

method of SAP2000 (Puri et al., 2015; Somantri,

2013) and Abaqus (Syarif et al., 2018; Diana, 2017).

This research is aimed to investigate the effect of

different pile length due to the soil stress and inner

forces behavior of the Nailed-slab Pavement System.

2 METHODOLOGY

This research used the soil and Nailed-slab structural

data from Puri (2015). The soft soil geometry was

set with thickness 10 m. There was the dense

sand layer below the soft clay which neglected in

the analysis. The considered load 50 kN was a

concentric load on the pavement slab. The boundary

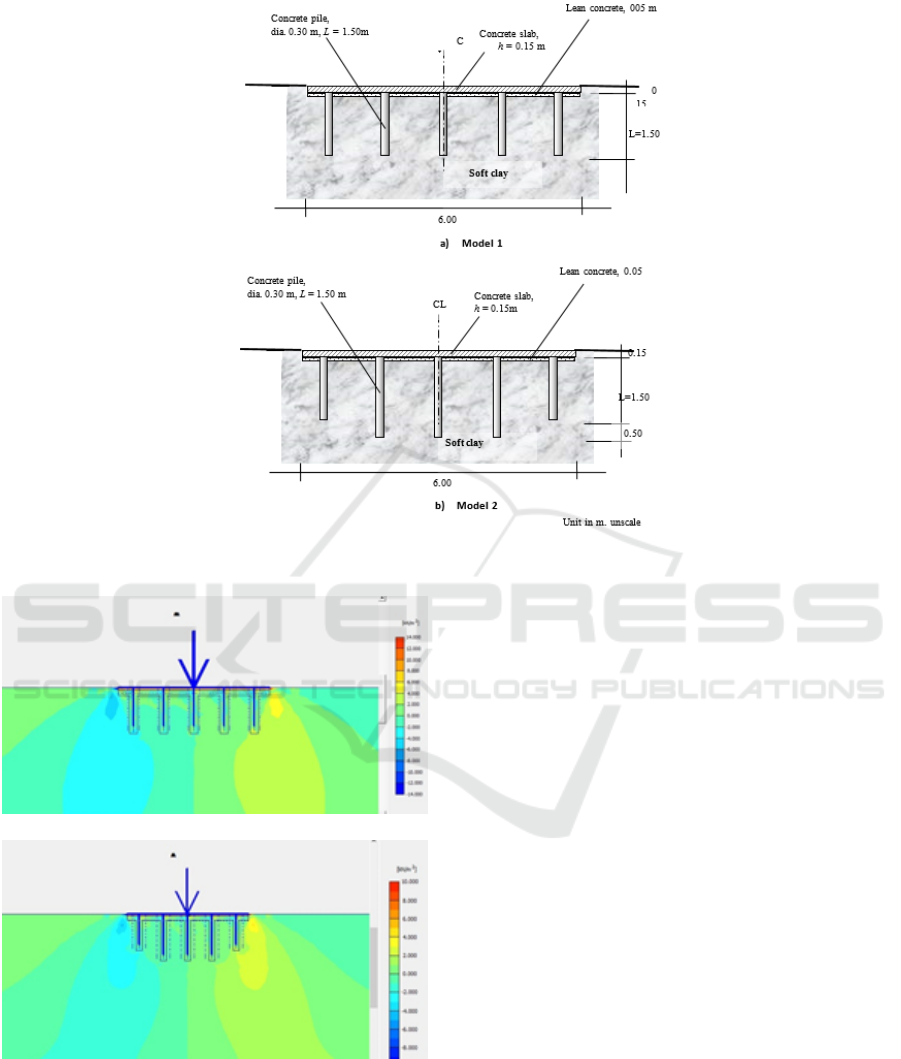

condition of the soil is shown in Figure 1. Figure 1a

shows the Model 1 which used uniform pile length

and Figure 1b for different pile length (piles in the

center area longer 33.3% the edge piles). (Somantri,

2013) analyzed full-scale Nailed-slab model by using

soil properties from experimental project. (Puri and

Mildawati, 2019) simulated the effect of dimensions

of Nailed-slab by using soil and structural properties

from full-scale test.

The dimension of Nailed-slab model was 6.0 m

x 3.6 m and 0.15 m slab thickness. The slab is

supported by 5 piles. Pile diameter was 0.30 m. Pile

spacing was 1.20 m. The pile-slab connections were

monolithically. The pile length for model 1 was 1.50

m and for model 2 was 1.50 m for edge piles and

2.00 m for piles in the center area of the slab. The

Puri, A., Mildawati, R. and Solihin, M.

Consideration of the Different Pile Length Due to Soil Stress and Inner Forces of the Nailed-slab Pavement System under Concentric Load.

DOI: 10.5220/0009364903110314

In Proceedings of the Second International Conference on Science, Engineering and Technology (ICoSET 2019), pages 311-314

ISBN: 978-989-758-463-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reser ved

311

Table 1: Model and parameters of soil.

Parameters Name/ Notation Soft clay Unit

Material model Model Mohr-Coulomb -

Material behavior Type Un-drained -

Saturated density γsat 16.30 kN/m

3

Dry density γd 10.90 kN/m

3

Young’s Modulus E 1,790.00 kPa

Poisson’s ratio ν 0.45 -

Un-drained cohesion cu 20.00 kPa

Internal friction angle φ 1.00 o

Dilatancy angle ψ 0.00 o

Initial void ratio e0 1.19 -

Interface strength ratio R 0.80

Table 2: Model and parameters of structural elements in

FEM 2D plain strain.

Parameters Name/Notation Lean concrete

Structural elements

Unit

Slab Pile

Material Model Model Volume element Plate Plate -

Material behavior Type Elastic Elastic Elastic -

Normal stiffness EA - 4,554,000 738,528 kN/m

Flexural rigidity EI - 8,539 5,649.74 kNm

2

/m

Equivalent thickness d - 0.15 0.3 m

Weight w - 3.60 0.9 kNm/m

Poisson’s ratio v 0.2 0.15 0.20 -

Unit weight γ 22 24 24 kN/m

3

Young’s modulus E 17,900 25,300 19,600 MN/m

2

Interface

strength ratio

R 0.80 0.80 0.80

models were analyzed by 2D finite element method

(FEM). In 2D FEM plain strain analysis, the soft

clay was modeled by Mohr-Coulomb in un-drained

condition. All structural elements were modeled

by plate element in linear-elastic behavior. Lean

concrete was modeled by soil with the linear-elastic

non-porous material. Soil parameters and idealization

of structural elements are presented in Table 1 and 2

respectively.

3 RESULTS AND DISCUSSIONS

Results are shown in Tabel 3, 4 and Figure 2.

The loaded Nailed-slab caused soil and structural

movements and stresses.

3.1 Soil Stress

Table 3 shows the results of the effects of different

pile length due to soil stresses. The soil effective shear

stresses are shown in Figure 2. The soil effective

shear stresses for Model 2 has a similar shape to

Model 1. Maximum shear stress, effective stress,

and maximum excess pore pressure tend to decrease

(Table 3). That was beneficial for the soil. While

the maximum excess pore water pressure under the

central pile tip tends to increase about 12%. The

distribution of the effective shear stress in the soil is

shown in Figure 2. Model 2 can significantly reduce

the maximum effective shear stress and maximum

excess pore water pressure 37% and 32% respectively.

While the maximum excess pore water pressure under

the central pile tip a little bit increase about 12% and

effective stress of soil insignificantly decrease. Model

2 also has a better stress distribution because it has

wider stress distribution.

Table 3: The stresses in the soil

Description Unit

Model

1

Model

2

Maximum shear stress,

τ

xy−max

kN/m

2

-15.31 -9.69

Effective stress, σ kN/m

2

65.33 64.27

Max. excess pore water

pressure, U

kN/m2 107,49 72,93

Max. excess pore water

pressure under the central

pile tip, U

kN/m2 -11.00 -12.31

3.2 Inner Forces of Structural

Table 4 shows the inner forces in the structural

elements. The slab has a negative bending moment in

the area of the slab center similar to other researchers

(Puri et al., 2015; Puri, 2016; Diana, 2017; Puri and

Mildawati, 2019). Using the longer pile in the center

area of the slab were result in the good effects. All

inner forces decreased by using the longer pile, except

for bending moment on the pile head was relatively

constant. Model 2 can significantly decrease the

bending moment of slab of about 46%. Otherwise,

it can also decrease the bending moment and axial

force of pile 46% and 43% respectively. Decreasing

the inner forces in the structural elements is very

beneficial for this system. In the case of lateral

deformation of pile head, Model 2 can significantly

reduce it about 37%.

Table 4: The extreme inner forces in the structural elements.

Description Unit

Model

1

Model

2

Bending moment of

slab, M

s

kNm/m -42.62 -22.78

Bending moment of

pile, M

p

kNm/m 2.94 2.95

The axial force of

pile, P

kN 12.33 6.61

The shear force of

pile, H

kN 15.33 8.72

Lateral deflection

of pile tip, U

x

mm -7.53 -4.73

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

312

Figure 1: Variation of the model in the analysis.

Model 1, τ

xy−max

= 15.31 kN/m

2

Model 2, τ

xy−max

= 9.69 kN/m

2

Figure 2: Distribution of effective shear stress of soil.

4 CONCLUSIONS

The results of this study prove that although the

JCI change pattern follows the changing pattern

of macroeconomic variables, but after it has been

proven by a series of statistical tests, none of the

macroeconomic variables affect JCI in the short run.

This might be caused by investors in Indonesia pay

more attention to the fundamental factors which are

the company’s financial performance. In addition,

stock indices in a country do have a tendency to

increase due to developments in a country’s Stock

Exchange.

REFERENCES

Diana, W. (2017). Behavior of Nailed-slab System on

Peat Soil. Dissertation, Universitas Gadjah Mada,

Indonesia (in Indonesian).

Puri, A. (2016). Behavior of uplift resistance of single

pile row nailed-slab pavement system on soft clay

sub grade. In Proceeding of the 3rd Asia Future

Conference (AFC).

Puri, A., Hardiyatmo, C., Suhendro, B., and Rifa’i, A.

(2011a). Experimental study on deflection of slab

which reinforced by short friction piles in soft clay. In

Proc. of 14 th Annual Scientific Meeting (PIT) HATTI,

pages 10–11.

Puri, A., Hardiyatmo, H., Suhendro, B., and Rifa’i, A.

(2011b). Contribution of wall barrier to reduce the

deflection of nailed-slab system in soft clay. In Proc.

of 9th Indonesian Geotech. Conf. and 15th Annual

Consideration of the Different Pile Length Due to Soil Stress and Inner Forces of the Nailed-slab Pavement System under Concentric Load

313

Scientific Meeting (KOGEI IX & PIT XV) HATTI,

pages 299–306.

Puri, A., Hardiyatmo, H., Suhendro, B., and Rifa’i,

A. (2013). Application of method of nailed-slab

deflection analysis on full scale model and

comparison to loading test. In Proc. the 7 th National

Conference of Civil Engineering (KoNTekS7), pages

G201–G211.

Puri, A., Hardiyatmo, H. C., Suhendro, B., and Rifa’i,

A. (2012). Determining additional modulus of

subgrade reaction based on tolerable settlement for the

nailed-slab system resting on soft clay. International

Journal of Civil and Environmental Engineering

IJCEE-IJENS, 12(03):32–40.

Puri, A., Hardiyatmo, H. C., Suhendro, B., and Rifa’i, A.

(2014). Behavior of nailed-slab system on soft clay

due to repetitive loadings by conducting full scale

test. In Proc. 17thIntrntl. Symp. FSTPT, University

of Jember, pages 739–750.

Puri, A., Hardiyatmo, H. C., Suhendro, B., and Rifa’i, A.

(2015). Pull out test of single pile row nailed-slab

system on soft clay. In Proc. The 14th International

Conference on Quality in Research (QiR), Universitas

Indonesia, Lombok, pages 63–68.

Puri, A. and Mildawati, R. (2019). Investigasi numerik

perkerasan jalan sistem pelat terpaku terhadap variasi

dimensi struktur. BENTANG: Jurnal Teoritis dan

Terapan Bidang Rekayasa Sipil, 7(1):1–7.

Somantri, A. K. (2013). KAJIAN LENDUTAN SISTEM

PELAT TERPAKU PADA TANAH PASIR DENGAN

MENGGUNAKAN METODE BEAM on ELASTIC

FOUNDATIONS (BoEF) DAN METODE ELEMEN

HINGGA. PhD thesis, Universitas Gadjah Mada.

Syarif, F., Adi, A. D., and Saputra, A. (2018). Studi

karakteristik fondasi pelat tipis dengan pengaku tiang

“+” pada tanah granuler melalui uji eksperimen dan

analisis pemodelan menggunakan software abaqus.

JURNAL SAINTIS, 17(2):66–78.

WARUWU, A. (2018). PERILAKU PEMAMPATAN

TANAH GAMBUT AKIBAT BEBAN TIMBUNAN

YANG DIDUKUNG SISTEM PELAT TERPAKU. PhD

thesis, Universitas Gadjah Mada.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

314