Proximate and Physical Characteristics of Cookies Made of Cassava

Starch and Wheat Flour Blends Containing Soymilk Waste Powder

Basuki Wirjosentono*, Tamrin, Amir Hamzah Siregar, Diana Adnanda Nasution

and Paula Netti Sihombing

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan 20155,

Sumatera Utara, Indonesia

Keywords: Cassava Starch, Soymilk Waste Powder, Gelatinization, Cookies Dough.

Abstract: Blends of cassava starch (CS) and wheat flour (WF) containing soymilk waste powder (SWP) were prepared

using gelatinization process for cookies dough, and then baked in the presence of 10% margarine, 1% cane

sugar, and 0.1% table salt. It was found that after cookies baking, optimum composition of cookies possesses

comparable disintegration time with that of control (fresh wheat flour) was obtained when used weight ratio

of CS/WF/SWP = 60/40/20. It was also found that increase fibre and protein as well as other nutrition contents

in the cookies dough have been revealed when compared to that of standard cookies using fresh wheat four.

DSC analysis of cookies sample containing SWP showed addition of exothermic temperature peak due to

decomposition of SWP. SEM micrograph of cookies sample containing SWP showed bigger granules due to

aglomeration of SWP covered with CS/WF matrix.

1 INTRODUCTION

Cookies are food products that are baked and made of

flour, sugar, fat, and eggs with a moisture content less

than 4% and can be stored for a long time, (4-6

months). Cookies have a small shape and will run out

in two bites, usually used as snacks, and its texture is

less dense, dry, and crispy. Flour as main ingredient

of cookies can be varied using various source of

natural flours, but quality of the cookies depends on

type of flour used (Saeed et al., 2012). Before baking

process all ingredients of cookies are blended as a

dough with addition of various enzymes (Panghal et

al., 2011). Cookies ingredients, such as flour and egg

have been replaced with gluten free replacers and

affecting physicochemical and sensory properties of

the cookies (Julianti et al., 2016).

Cassava (Manihot Esculenta Crantz), has been long

cultivated in Indonesia but not been used intensively as

main and staple foods, due to its lower preference and

considered as cheap and low quality of food products.

However, nutritional content of cassava has been

reported suitable for various food products

(Oluwaseun et al., 2015). Budijanto and Yuliana

(2015) have reported food diversification in Indonesia

to reduce imported food raw materials. Whereas

Anggraini, et al., have characterised blends of casava

flour, red sweet potato and carrot powders for

alternative food raw materials (Anggraini et al, 2016).

On the other hand, soybean powder has been

utilised as alternative staple food ingredient to improve

protein content (Tharise et al., 2014). In this, work,

cassava starch (CS) and wheat flour (WF) with

addition of soymilk waste powder (SWP) have been

blended as dough for cookies products. Main

objectives of this works is utilised cassava starch (CS)

and soymilk waste powder (SWP) to reduce use of

imported wheat flour (WF) as well as to improve

nutrition (protein and fibre contents) for alternative

cookies dough.

2 METHOD

In this works soymilk waste powder (SWP) were

collected from soymilk home industries in Percut Sei

Tuan, Deli Serdang, Sumatera Utara, vacuum dried,

milled and shieved to 80 mesh powder size. Preparation

of cookies samples was based on gelatinisation process

reported by previous researchers (Julianti et al., 2016;

Panghal et al., 2011; Saeed et al., 2012). Whereas further

blending of the cookies dough were carried out in a

Wirjosentono, B., Tamrin, ., Hamzah Siregar, A., Adnanda Nasution, D. and Netti Sihombing, P.

Proximate and Physical Characteristics of Cookies Made of Cassava Starch and Wheat Flour Blends Containing Soymilk Waste Powder.

DOI: 10.5220/0009005403390342

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 339-342

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

339

single screw extruder similar to that used for blending

of thermoplastic materials (Ismail et al., 2002 and

Wirjosentono et al., 2004), at constant temperature of

80

o

C. Whereas Mishra, et.al. (2012) have used extrusion

technology for preparation of rice analogous. Weight

ratio of casava starch and wheat flour was maintained

constant at (CS/WF = 60/40), whereas loading of SWP

were varied (0, 15, 20, and 25 phm: per hundred matrix),

in the presence of margarine, cane sugar, and table salt

(10, 1, and 0.1 phm, respectively). Moreover, cookies

samples and control were prepared by baking the related

dough in a constant temperature oven at 150

o

C, for 15

minutes. Optimum composition of cookies sample was

taken from its disintegration time in water and boiling

water (30, and 100

o

C), compared to that of control

without SWP. Proximate analysis of cookies includes

water (%), fat (%), fibre (%), carbohydrate (%), and

protein (%) contents. Thermal and morphological

characteristics of cookies samples were carried out

using differential scanning calorimeter and scanning

electron microscopy (DSC and SEM).

3 RESULTS AND DISCUSSION

3.1 Preparation of Cookies Made of

Cassava Starch (CS) and Wheat

Flour (WF) with Various Loading

of Soymilk Waste Powder (SWP)

Results of disintegration time of cookies samples

measured in cold water (30

o

C) and boiling water

(100

o

C) were shown in Table 1. It was shown that

addition of cassava starch in wheat flour blends

increased disintegration times of cookies samples

both in cold and boiling waters, which due to

formation of cassava starch gelatin. However, when

the blends were added with SWP their disintegration

times were decreased again because of that the SWP

absorbs more water than the CS/WF blends do.

Therefore optimum composition of cookies sample

possesses comparable disintegration time with that of

control cookies (made of 100 % WF) is that made of

CS/WF/SWP: 60/40/20, (Cookies sample B).

3.2 Proximate Analysis of Cookies

Samples

Data of proximate analysis of cookies samples

(CS/WF/SWP) containing various loading of SWP: 0,

15, 20, and 2 phm) were shown in Table 2.

Table 1: Composition of cookies dough samples (phm unit:

per hundred matrix) at various loading of SWP (soymilk

waste powder: 0, 15, 20, 1nd 25 phm).

No

Cookies Sample

Disintegration time (min)

Cold water

(s)

Boiling

water (s)

1

Control

CS/WF/SWP

0/100/0

36

16

2

Cookies A

CS/WF/SWP

60/40/15

49

29

3

Cookies B

CS/WF/SWP

60/40/20

37

17

4

Cookies C

CS/WF/SWP

60/40/25

25

11

It was shown that their water contents were improved

(from 3.2 – 5.9%) when loading of SWP was

increased, which may be due to that the SWP

contribute to high water absorption capacity

compared to other ingredients. In the case of fat

content, however, did not show any considerable

changes due to the SWP also did not possesses high

fat content. Interestingly, carbohydrate contents of

cookies samples decreased (from 9.6 – 4.2 %)

although the fibre contents also decreased slightly

(from 85.08 – 80.97 %), whereas the protein

increased significantly (from 1.9 – 8.7 %). Therefore,

it is revealed that addition of soymilk waste powder

(SWP) as raw material for cookies samples has

improved nutrition contents of the cookies samples.

Table 2: Proximate analysis data (water, fat, carbohydrate,

fibre and protein contents) of cookies samples at various

loading of soymilk waste powder (SWP: 0, 15, 20, 25 phm).

Code

Carbohydrate

(%)

Fat

(%)

Protein

(%)

Fibre

(%)

Control

9.6

0.22

1.9

85.08

A

7.1

0.28

4.4

83.92

B

6.6

0.24

7.3

80.36

C

4.2

0.26

8.7

80.94

3.3 Differential Scanning Calorimetry

(DSC) Analysis

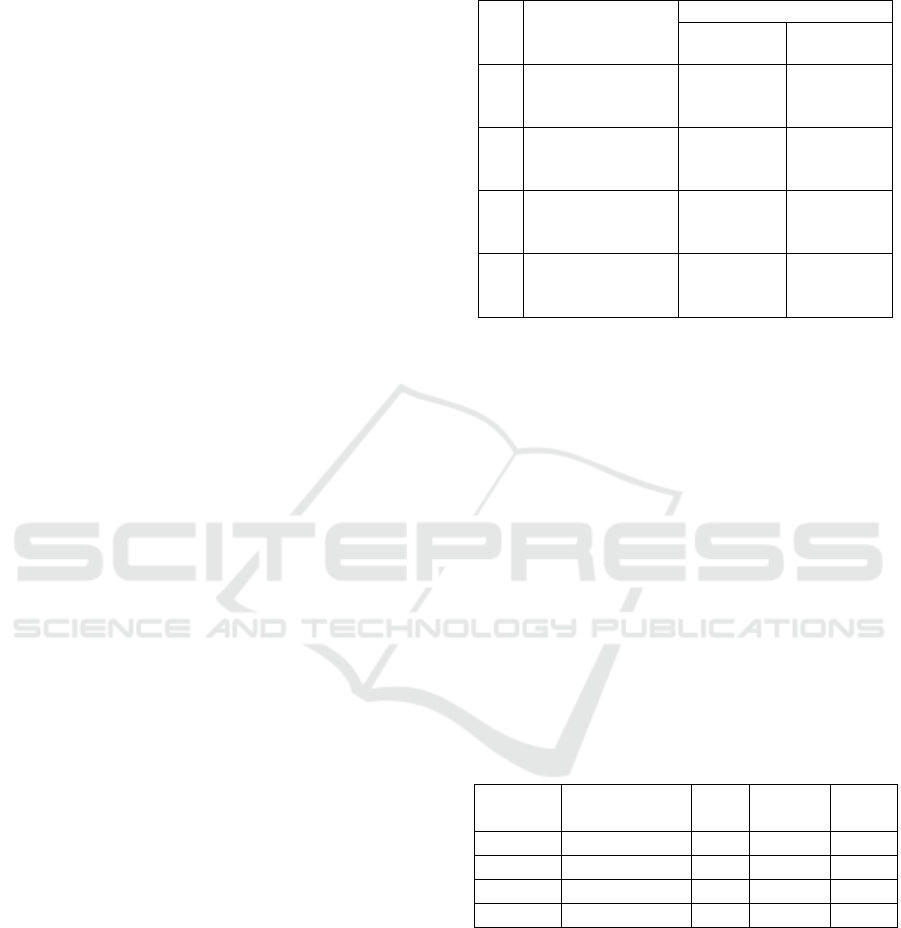

Figure 1 is DSC thermogram of cookies sample

containing (CS/WF/SWP: 60/40/20, Sample B),

which showed endothermic peak of water

evaporation at 108.41

o

C (peak start at 67.82

o

C and

end at 154.25

o

C). In addition, the thermogram also

showed two exothermic peaks of thermal

decomposition of the cookies sample at, (start at

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

340

270.46

o

C end at 287.59

o

C) and at peak 302.06

o

C

(start at 275.07

o

C end at 319.64

o

C). The first

exothermic peak (275.07

o

C) representing

decomposition of CS/WF blend, whereas the later

(302.06

o

C) is due to decomposition of SWP, and in

which at 319.64

o

C all the cookies constituents have

been burnt completely.

Figure 1: DSC thermogram of cookies sample containing

(CS/WF/SWP: 60/40/20, Sample B).

When compared to that of cookies control made

of (WF only) he DSC thermogram (Figure 2) also

exhibited endothermic peak at 108.41

o

C (start at

67.82

o

C and end at 154.25

o

C) due to evaporation of

its water content. In this case single exothermic peak

was observed at 269.73

o

C (starts at 262.47

o

C, end at

271.51

o

C), which represents decomposition of the

CS/WF blend.

Figure 2: DSC thermogram of cookies control made of

wheat flour only.

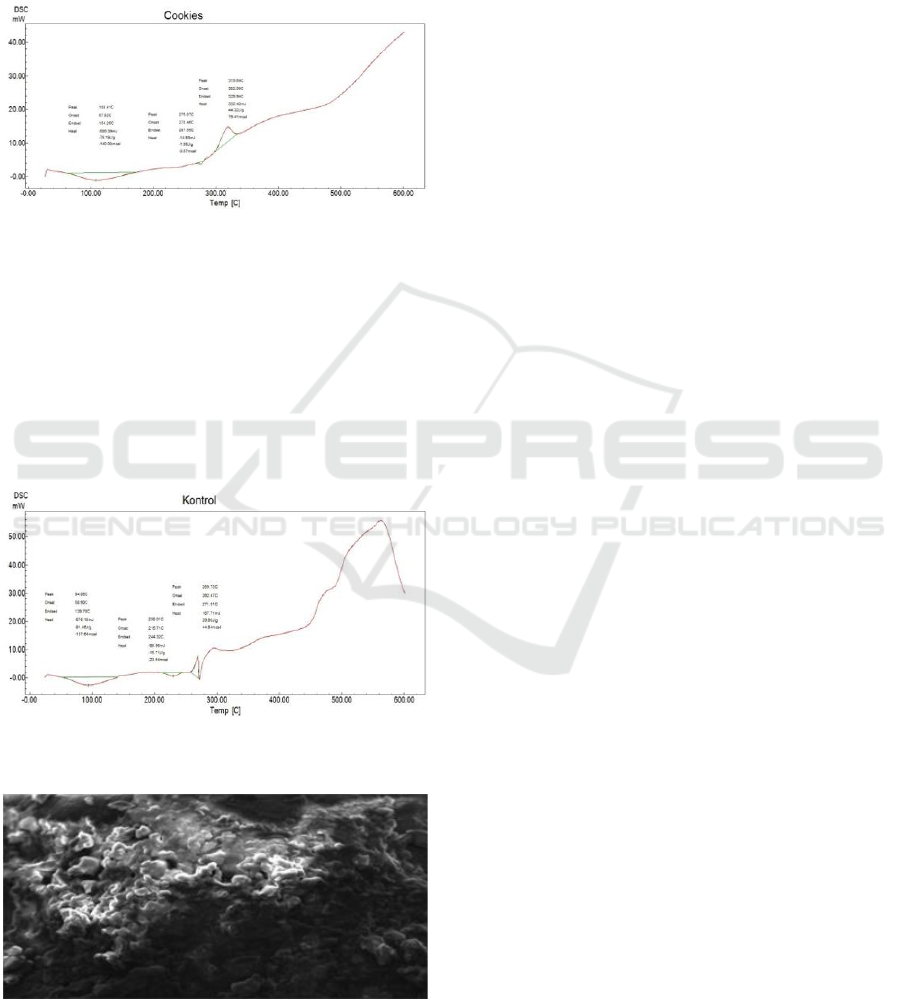

Figure 3: Surface SEM micrograph (magnification 1000x)

of cookies sample (CS/WF: 60/40) with the addition of

soymilk waste powder (SWP: 20phm).

4 CONCLUSIONS

Optimum composition of cookies sample posseses

comparable disintegration time with that of control

cookies (made of 100 % WF) is that made of

CS/WF/SWP: 60/40/20, (Cookies sample B).

Interestingly, optimum cookies sample has

improved nutrition cantents: carbohydrate contents

decreased (from 9.6 – 4.2 %) although the fibre

contents also decreased slightly (from 85.08 – 80.97

%), whereas the protein content increased

significantly (from 1.9 – 8.7 %). DSC thermograph

of the optimum cookies sample showed two

exothermic peaks, first at 275.07

o

C (representing

decomposition of CS/WF blend) and at 302.06

o

C

(due to decomposition of SWP). Surface SEM

micrograph of optimum sample showed bigger

granules due to SWP fibres interact well physically

and covered with the CS/WF matrix

ACKNOWLEDGEMENTS

The authors would like to thank to Universitas

Sumatera Utara for granting the research fund to

carry out this works through Professorship Research

Grant of TALENTA 2018

REFERENCES

Anggraini, T., Putri, V. J., Neswati, N., Yuliani, Y., (2016),

Characteristics of Red Sweet Potato (Ipomea batatas)

Analog Rice (SPAR) From The addition of Cassava

Flour (Manihot utillisima) and Carrot (Daucus carota),

International Journal on Advanced Science and

Engineering Information Technology, Vol. 6, N0.5,

ISSN: 2088-5334.

Budijanto, S., and Yuliana, N. D., (2015), Development of

Rice Analog as a Food Diversification Vehicle in

Indonesia, Journal of Developments in Sustainable

Agriculture, 10: 7-14.

Panghal, A., Navndhi, N., Singh, N., Khatkar, B. S., (2011),

Effect of enzymes on cookies quality, Anals. Agri-Bio

Research, 16(1), 75-78.

Ismail, H., Edyham, M. R., Wirjosentono, B., (2002),

Bamboo fibre filled natural rubber composites: The

effects of filler loading and bonding agent, Polymer

Testing, 21(2), pp. 139-144.

Julianti, E., Rusmarilin, H., Ridwansyah, R., Yusraini, E.,

2016, Effect of gluten free composite flour and egg

replacer on physicochemical and sensory properties of

cakes, International Food Research Journal 23(6):

2413-2418.

Proximate and Physical Characteristics of Cookies Made of Cassava Starch and Wheat Flour Blends Containing Soymilk Waste Powder

341

Mishra, A., Mishra, H. N., Rao, P. S. (2012), Preparation of

Rice Analogues Using Extrusion Technology,

International Journal of Food Science and Technology.

Oluwaseun, P., Bamidele, B., Mofoluwaso, B., Fasogbon,

F., Oladiran, D.A., Akande, E.O., 2015, Nutritional

composition of fufu analog fl our produced from

Cassava root (Manihot esculenta) and Cocoyam

(Colocasia esculenta) tuber, Food Science & Nutrition,

doi: 10.1002/fsn3.250.

Saeed, S., Ahmad, M.M., Kausar, H., Parveen, S., Masih,

S., and Salam, A., (2012), effect of sweet potato flour

on quality of cookies, J. Agric. Res., 50(4), 525-538.

Tharise, N., Julianti, E., and Nurminah, M., (2014),

Evaluation of physico-chemical and functional

properties of composite flour from cassava, rice, potato,

soybean and xanthan gum as alternative of wheat flour,

International Food Research Journal, 21(4): 1641-1649.

Wirjosentono, B., Guritno, P., Ismail, H., (2004), Oil palm

empty fruit bunch filled polypropylene composites,

International Journal of Polymeric Materials and

Polymeric Biomaterials, 53(4), pp. 295-306.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

342