Analysis of Physical Properties and Chemical Contents in

Eucalyptus citriodora PT. Toba Pulp Lestari, Tbk

Zul Alfian

1

, Muhammad Taufik

1*

, Sovia Lenny

1

, Chintya Cahaya

2

, Rizky Hidayati

2

,

Simon Sidabuke

3

, E. Manullang

3

and Jeremi Sitohang

1

1

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara,

Jl. Bioteknologi No. 1, Medan 20155, Indonesia

2

Postgraduate Chemistry Study Program, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Jl.

Bioteknologi No. 1 Kampus USU, Medan, Indonesia

3

PT Toba Pulp Lestari, Tbk., Indonesia

rizkyhidayati12345@gmail.com, legal_tpl@tobapulp.com, sitohangyeremia@gmail.com

Keywords: Eucalyptus, GCMS, Acidity, Ester Number, Stahl.

Abstract: Eucalyptus citriodora is one type of eucalyptus that has the potential to be developed. This plant originates

from Australia, which is one of the most popular eucalyptus trees that grows in almost all of Australia, and

is now found to grow in almost all tropical regions of the world including Indonesia. Content Analysis and

determination of sineol Content in Eucalyptus citriodora leaf essential oil from PT. Toba Pulp Lestari Tbk

has been carried out by the GCMS method. Eucalyptus leaves have been used for medicine, industry and

perfume as well as Eucalyptus oil. The purpose of this study was to determine the compound content and

levels of cineol in Eucalyptus citriodora leaves. The abundance of sineol levels 55-65% can be used as

perfume, medicines and Eucalyptus oil. Stahl distillation was developed to produce The Eucalyptus oil.

There are eleven compounds in Eucalyptus citriodora leaves, including α-Pinene, 1-Limone, 1.5

Cyclooctadiene, 1.8 Sineol, 1-P-Menthen-8-YL-Acetate, 3- Cycloheksane, 1-Methanol, α-Terpinyl Acetate,

Phenol, Butylhidroxytoluena, Trans-Methyl-dihydrojasmonate, ISO - Cytronellate, ISO - Propyl Myristat,

Propyltetradekanoate, Octadecanoic Acid. The mximum abundance is 1,8-cineol (60.29% v/v). The physical

properties was obtained used titrimetric method yields of acidity and ester numbers respectively 2.8025 and

12.0 (T= 26.010C).

1 INTRODUCTION

Eucalyptus citriodora plant is one of the essential

oils producing plants that are important for the

essential oil industry in Indonesia. The main

products produced from this plant are Eucalyptus oil

obtained from the distillation of leaves. The total

production of Eucalyptus oil produced in Java in

2018 is 300 tons (Mukriz Damanik, 2009)

PT.Toba Pulp Lestari Tbk is one of the Industrial

Plantation Forest companies in Indonesia, especially

the North Sumatra province which is the Industrial

Plantation Forest with the largest area in North

Sumatra where the total area reaches 188,055 Ha

and the main commodity developed is the

Eucalyptus Plant (Eucalyptus spp) Eucalyptus

belongs to fast-growing plants or better known as

Fast Growing Species (Beyranvand, 2015). Besides

that, Eucalyptus is also a plant that has better

benefits in terms of stems, branches, and leaves

(Mahmoud and Ali, 2015).

PT Toba Pulp Lestari Tbk has developed

Eucalyptus plants to be used as paper raw materials

(Anders et al., 2018). However, now what is still

used from Eucalyptus plants is still in the wood and

branches while the leaves are not utilized or just left

alone (Han Roliadi, Dulsalam, 2010). Some previous

studies have also analyzed the content of essential

oils from Eucalyptus leaves (Technology, 2013).

The quality of raw materials of eucalyptus

leaves, especially in Java, is still low, only having a

yield of 0.6% - 1.0%. While from the results of the

study (Muyassaroh, 2016) with steam and water

distillation methods the range of eucalyptus oil

yields ranged from 0.84% to 1.21% (Abed, 2018).

Alfian, Z., Taufik, M., Lenny, S., Cahaya, C., Hidayati, R., Sidabuke, S., Manullang, E. and Sitohang, J.

Analysis of Physical Properties and Chemical Contents in Eucalyptus citriodora PT. Toba Pulp Lestari, Tbk.

DOI: 10.5220/0008920302570261

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 257-261

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

257

Distillation of Eucalyptus leaves to obtain

Eucalyptus oil uses a principle based on the

properties of essential oils that can evaporate if

heated with hot steam (Muyassaroh, 2016). The flow

of steam will carry essential oils contained in the

leaves and when the steam comes into contact with

cold media, changes will occur into moisture so that

water and oil will be obtained in a separate state. In

distillation by using direct steam there is a process of

transporting essential oils from the ingredients

together with hot steam which is blown directly

(Beyranvand, 2015). This method is similar to the

steamed method but water is not filled in the

distillation kettle. The hot steam produced from the

boiler is flowed through a porous steam pipe located

above the filter in the tank or distillation kettle

(Hadji et al., 2017). Several factors affect the

amount of oil that evaporates together with water

vapor, namely: the amount of vapor pressure used,

the molecular weight of each component in the oil

and the speed of oil coming out of the material. In

distillation of steam at atmospheric pressure, the

distillation temperature is slightly above or below

100

0

C, which depends on whether the saturated

vapor pressure or steam through each distillation

process can be adjusted so that it runs below 100

0

C,

provided that the pressure is 1 atmosphere

(Ghasemian, 2018).

Mukriz Damanik, (2009) has compared the yield

of oil and the quality of oil from the same type of

Eucalyptus, Europhylia based on differences in plant

age. And it was obtained that the older the plant age,

the more oil yield will be obtained, but the oil quality

will decrease. Oil is obtained from steam distillation

and obtained low levels of cineol, 30-35% and 40-

45%. At harvest time in industrial plantations requires

fast growing both for wood and also for the quality of

oil in the leaves. Sunanto., 2003, the optimum length

of eucalyptus oil refining is 3-4 hours. The factors that

influence the operational steam are as low as possible,

even though the production speed is determined by

the temperature of the amount of water that is in

direct contact with the distilled material. Use the least

amount of water that can be connected or in direct

contact with plant material. The size of the material,

by chopping the plant material before distillation, is

attempted so that the filling into the kettle is as

homogeneous as possible (Kumar Tyagi et al., 2014).

In this work, we want to analyze the chemical

content, physico-chemical properties of acid

numbers, esters and determination of cineol levels to

be able to utilize leaf waste from Eucalyptus

Citriodora plants in the PT. Toba Pulp Lestari Tbk

area. analysis of chemical content and determination

of cineol levels using the GC-MS method. Then a

study was conducted to determine the physico-

chemical properties of acid numbers, Esters. and the

content analysis is carried out at the beginning to see

the main compound. Then the determination of the

level is done as a comparison that Eucalyptus

Cittriodora has the potential as eucalyptus oil and

also the highest% content obtained based on

retention time.

2 MATERIALS AND METHODS

2.1 Collecting Sample

The process of collecting samples (Eucalyptus

Citriodora fresh leaves) is taken directly from the

PT. Toba Pulp Lestari located on Jl. Indorayon Desa

Dolok Nauli, Kecamatan Parmaksian, Toba Samosir

Regency, North Sumatra Province. Identification of

Eucalyptus Cittredora leaves at the FMIPA - USU

Herbarium Medanense (MEDA) Laboratory. Oil

distillation from Eucalyptus Citriodora leaves was

carried out with the Stahl Distillation at the FMIPA -

USU Organic Chemistry Laboratory. Content

Analysis and Determination of Sineol Levels were

carried out at the Organic Chemistry Laboratory of

FMIPA - UGM using GCMS method.

2.2 Extraction Process

100 grams of Eucalyptus citriodora leaves that have

been cut into small pieces and put into a 1000mL

bottom flask, then added enough aquadest until the

entire sample is submerged, connected to a Stahl

distiller, and boiled for ± 5-6 hours at ± 100 ° C to

produce oil and distillation is terminated when the

distillate that comes out is clear yellow. The

essential oil obtained is accommodated in

erlenmeyer. The distillate obtained is a mixture of

oil and water. Then CaCl

2

anhydrous layer of oil is

added to bind water which may still be mixed with

essential oil, the oil layer is decanted and put into

vial bottles, then the essential oil is stored in the

refrigerator in a bottle and tightly closed.

The essential oils obtained were analyzed for

their contents and determined by the level of cineol

using GCMS tools.

2.3 Physical Properties Analysis

The physical properties analysis used titrimetri

method (acidity and ester numbers).

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

258

2.4 Gcms Analysis

The Specifications Instrument GC-MS QP 2010S

Shimadzu, using Column 5MS with type of ion

source Electron Impact, Injector Temperature:

300

0

C, Carrier Temperature: 50

0

C, Carrier: Helium,

Gas flow rate of carrier: 1.0 mL / min, Temperature

oven: 500C for 5 minutes then 2400C for 7 minutes.,

Ionization electron: 70 ev.

The solution of each 1 μL standard sineol series

was inserted into the syringer to be injected into the

GCMS. Only the conditions adjusted to the

conditions of each piece of equipment and then

observed Mass Chromatogram data generated

interpreted data. Obtained data then in Perform

calculations to get the calibration curve and do the

determination of levels through the equation.

3 RESULTS AND DISCUSSIONS

The result of identification shows that eucalyptus

leaf is eucalyptus of Robusta species with plant

taxonomy as follows: Kingdom: lantae, Clade:

Angiosperms, Clade: Eudicots, Order: Myrtales

Family: Myrtaceae, Genus: Eucalyptus, Species:

Eucalyptus grandis W. Hill ex Maiden

Based on the research result, Eucalyptus grandis

leaf essential oil of distillation with stahl tool is 1.8

mL with leaves of 450 grams and the percentage is

0.4%. Eucalyptus Oil Quality Requirements

According to SNI 06-3954-2006 as Table 1.

Table 1: Eucalyptus Oil Quality Requirements

(According to SNI 06-3954-2006).

No

Type of test

Unit

Terms

1

Condition

1.1

colour

-

Clear until

greenish yellow

1.2

odor

-

typical Eucalyptus

2

density

-

0,900 – 0,930

3

Refractive index

-

1,450 – 1,470

4

Solubility in

Ethanol

-

1:1 up to 1:10 clear

5

Rotary optic

-

-4̊ up to 0̊

6

Cineole Content

%

50 – 65

Table 1 showed that then in terms of physical

properties, the color of essential oil leaves

Eucalyptus grandis was obtained a clear yellow

solution of weak yellow. Compared to Table 1

above, the essential oils are in accordance with

Eucalyptus oil requirements. The odor produced by

the essential oil is almost the same as the smell of

Eucalyptus oil that has a spicy, fresh and breathable

scent. The smell of essential oils in accordance with

the requirements of Eucalyptus oil. The weight of

the essential oil is 0.9143. The refractive index was

obtained 1.4653. Cineole content of essential oil is

0.08827 g or 8.827% v / v, with a percentage area of

36.55%. Based on SNI No. 06-3954-2006, cineole

content is 50% - 65%. Cineole in volatile oil is one

of the main constituent compounds alfa - Pinene as

the main compound. In this study the method used is

the distillation of water with stahl equipment which

is a very simple method and has a weakness less

vacuum so it can cause evaporation on essential oils

during the process that allows evaporate cineole.

The essential oil of Eucalyptus citriodoras leaf

obtained from the study was analyzed by using GC-

MS to determine the chemical content contained

therein, the results were adjusted with Library Wiley

229 and NIST Library 12, the chemical content of

Eucalyptus grandis leaf contained twelve

compounds in guess, that is : 𝛼-Pinene (45.21%),

Camphene ( 1.38%), 𝛽-Pinene (1.11%), Camphogen

( 0.74%), 1,8-Cineole (36.55%), 𝛼-Campholene

Aldehyde ( 0.73% ), Pinocarvone (0.83%), 𝛼-

Terpineol (8.87%), 𝛽-Caryophyllene ( 1.72% ),

Spathulenol (0.84% ), Elemol (0.85% ), 1–

Nonadecene ( 1.17% ).

The titrimeric method was done to analysed of

the physical properties. This method yields of

acidity and ester numbers respectively 2.8025 and

12.0 (T= 26.010C).

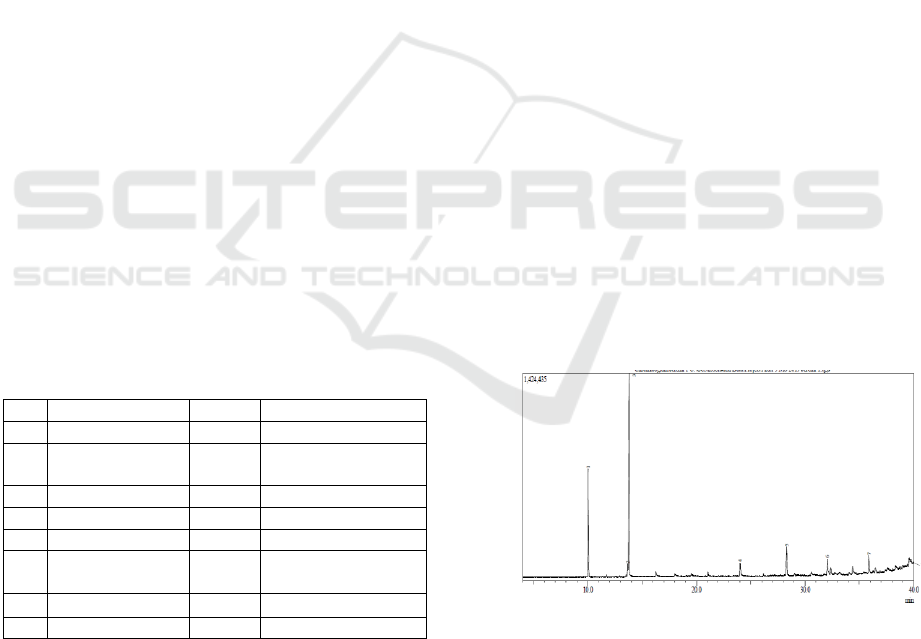

Based on the analysis with GC-MS that has been

adapted to Library Wiley 229, the 1.8-Cineole

spectrum is shown in Figure 1 below:

Figure 1: Chromatogram 1,8 sineol.

Peak Chromatogram with a retention time of

15.266 minutes is a compound with the formula

C

10

H

18

O molecule. The spectrum shows the

molecular ion peak at m / e 154 followed by

fragments at m / e 154, 139, 125, 108, 84, 81, 69, 43,

41, 27. By comparing the spectrum obtained with

the standard spectrum data library, which allows is

Analysis of Physical Properties and Chemical Contents in Eucalyptus citriodora PT. Toba Pulp Lestari, Tbk

259

1.8 - Cineole as much as 36.55% with the wake

formula as in Figure 2 follows:

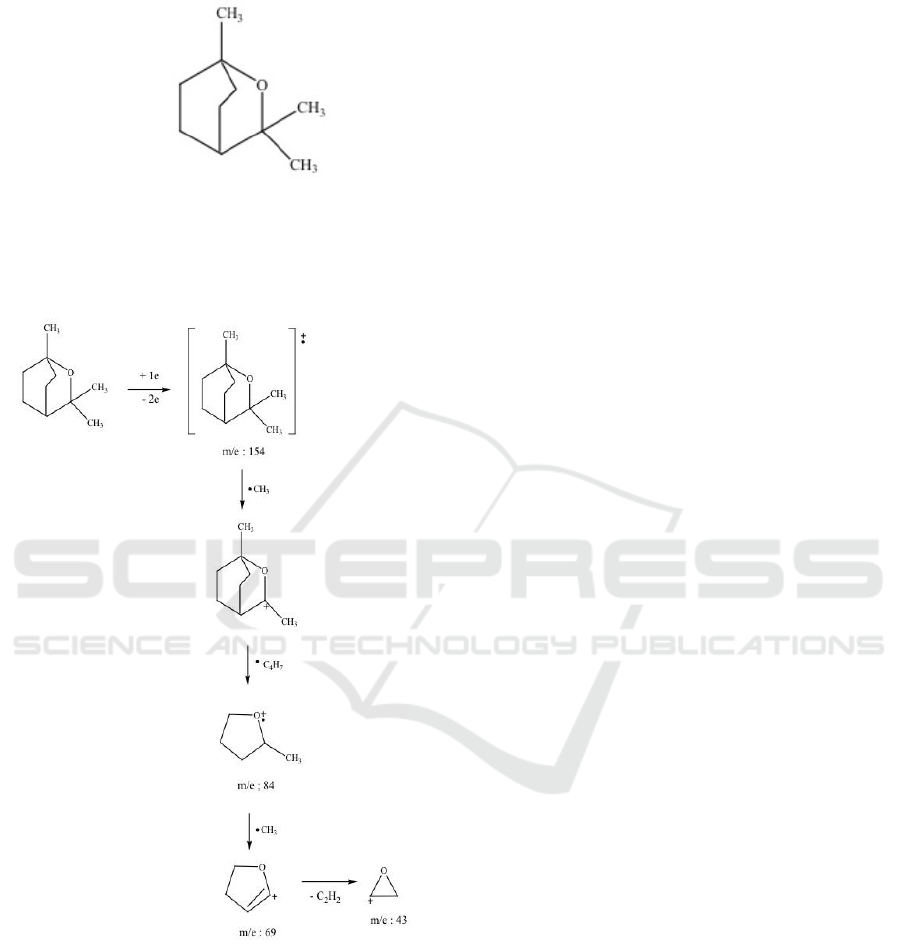

Figure 2: Structure of 1,8 – Cineole.

The fragmentation pattern of the 1.8 - Cineole

compounds is most likely as shown in Figure. 3

below:

Figure 3: Fragmentation Pattern of 1,8 – Cineole.

4 CONCLUSIONS

Eucalyptus citriodora is plant originates from

Australia, which is one of the most popular in

Australia. Determination of sineol content in

Eucalyptus citriodora leaf essential oil from PT.

Toba Pulp Lestari Tbk has been carried out used

GCMS method. There are eleven compounds in

Eucalyptus citriodora leaves, including α-Pinene, 1-

Limone, 1.5 Cyclooctadiene, 1.8 Sineol, 1-P-

Menthen-8-YL-Acetate, 3- Cycloheksane, 1-

Methanol, α-Terpinyl Acetate, Phenol,

Butylhidroxytoluena, Trans-Methyl-

dihydrojasmonate, ISO - Cytronellate, ISO - Propyl

Myristat, Propyltetradekanoate, Octadecanoic Acid.

The mximum abundance is 1,8-cineol (60.29% v/v).

The physical properties was obtained used titrimetric

method yields of acidity and ester numbers

respectively 2.8025 and 12.0 (T= 26.010C).

ACKNOWLEDGEMENTS

The authors gratefully acknowledge

Kemenristekdikti of Republik Indonesia for the

financial support via DRPM Project 2019

REFERENCES

Abed, K.M., 2018. Extraction of Essential Oil from Iraqi

Eucalyptus Camadulensis Leaves by Water

Distillation Methods Extraction of Essential Oil from

Iraqi Eucalyptus Camadulensis Leaves by Water

Distillation Methods. IOP Conf. Ser. Mater. Sci. Eng.

https://doi.org/10.1088/1757-899X/454/1/012163

Anders, M., Rodrigues, R.A.F., Alberto, L., Soares, L.,

2018. Quantification of the components in commercial

essential oil of Eucalyptus globulus labill . by gas

chromatography-GC-FID and GC-MS Quantification

of the components in commercial essential oil of

Eucalyptus globulus labill . by gas chromatography –

GC-FID. Drug Anal. Res. 01, 9–14.

Beyranvand, K., 2015. Identification and comparison of

the yield and composition of essential oil constituents

of four Eucalyptus species adapted to the climatic

conditions of Khorramabad. J. HerbMed Pharmacol. J.

J HerbMed Pharmacol 4, 25–28.

Ghasemian, M., 2018. Journal of Fisheries & Eucalyptus

camaldulensis Extract as a Preventive to the Vibriosis

in Western White Shrimp ( Litopenaeus vannamei ) in

Bushehr Province. J. Fish. Livest. Prod. 6, 2–6.

https://doi.org/10.4172/2332-2608.1000268

Hadji, E., Ndiaye, B., Gueye, M.T., Ndiaye, I., Diop, M.,

Diop, M.B., Fauconnier, M. -l., 2017. Chemical

composition of essential oils and hydrosols of three

Eucalyptus species from Senegal : Eucalyptus alba

Renv , Eucalyptus camaldulensis Dehnh and

Eucalyptus tereticornis Hook. Am. J. Essent. Oils Nat.

Prod. 5, 1–7.

Han Roliadi, Dulsalam, D.A., 2010. Penentuan daur teknis

optimal dan faktor eksploitasi kayu hutan tanaman

jenis Eucalyptus hbrid sebagai bahan baku pulp kertas.

J. Litbang Pertan. 1, 1–20.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

260

Kumar Tyagi, A., Bukvicki, D., Gottardi, D., Tabanelli,

G., Montanari, C., Malik, A., Guerzoni, M.E., 2014.

Eucalyptus Essential Oil as a Natural Food

Preservative: In Vivo and In Vitro Antiyeast Potential.

Biomed Res. Int. 2014, 1–9.

https://doi.org/10.1155/2014/969143

Mahmoud, K., Ali, S.I., 2015. International Journal of

Pharma and Bio Sciences ISSN Antioxidant ,

Antiproliferated Activities and Gc / Ms Analysis Of

Eucalyptus Camaldulensis Essential Oil. Int. J. Pharma

Bio Sci. 6, 883–892.

Mukriz Damanik, 2009. Kajian Minyak Atsiri Pada

Ekaliptus (Eucalyptus Urophylla) Umur 4 Tahun Di Pt

Toba Pulp Lestari, Tbk.

Muyassaroh, 2016. Steam Destillation Eucalyptus Trees

To The Variation Of Operating Pressure And

Treatment Materialsto Optimize Sineol Content In

Eucalyptus Oil. J. Tek. Kim. 10, 36–41.

Technology, M.O.F., 2013. Extraction of Essential Oil

from Eucalyptus Leaves Using Solar Distillation

Method.

Analysis of Physical Properties and Chemical Contents in Eucalyptus citriodora PT. Toba Pulp Lestari, Tbk

261