Synthesis of Cross-linked Breadfruit Starch (Artocarpus communis)

using Epichlorohydrin

Cut Fatimah Zuhra

1,2*

, Mimpin Ginting

1

and Desi Sonya Siregar

1

,

1

Departement of Chemistry, Faculty Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan,

North Sumatera , Indonesia

2

Pusat Unggulan Iptek Kitosan dan Material Maju

Keywords: Breadfruit Starch, Epichlorohydrin, Cross-linked Starch, Degree of Substitution.

Abstract: Synthesis of cross-linked starch has been successfully carried out by crosslinking reaction between breadfruit

starch (Artocarpus communis) and epichlorohydrin with variation of epichlorohydrin 1%; 2%; and 3 %. The

result of cross-linked starch was characterized by FT-IR spectrophotometer and the degree of Substitution

(DS). The formation of cross-linked starch was confirmed by FT-IR spectra data with the appearance of

stretching vibrational of C-O-C at 1018.41-1242.16 cm

-1

. The value of DS for variations of epichlorohydrin

1%; 2%; 3% are 0.0552; 0.0701; 0.0613, respectively. The cross-linked starch with variation 2% of

epichlorohydrin has the highest DS and then it was characterized using SEM and determined the swelling

degree. The results of the swelling degree test with a variation of absorption time of 6 hours, 24 hours, 36

hours, 72 hours were 0.9925%, 1.4611%, 1.8054%, 2.0049%, 3.0124%, respectively.

1 INTRODUCTION

Starch is one of important source of food ingredients.

Starch can be found in grains, tubers and fruit from

plant which has shape like granules (Sauyana, 2014).

The application of starch as a raw material for

industry is very broad, including in the food, textile,

cosmetics and paper industries. The need of starch

tends to increase both for domestic consumption and

exports. Considering the need of starch is quite large,

many reseacher were interested to find the alternative

source of starch from other crops other than the

source of starch as well as we know such as cassava,

potatoes and corn (Hartati and Prana, 2003).

Breadfruit is one source of starch and intensively

cultivated in Indonesia. Breadfruit has high

carbohydrates contain so that breadfruit is a

promising source of starch. The isolation starch from

breadfruit produced 18.5g/100g which have 98.86%

of purity with amylose and amylopectin content of

27.68% and 72.32%, respectively (Rincón and

Padilla, 2004).

Natural starches such as tapioca, corn starch, sago

have problems if used as raw material for food and

non-food industries. If we cooked starch takes a long

time (until it needs high energy), also the pasta that is

formed hard and not clear. Besides that it is too sticky.

These constraints cause natural starch to have limited

use in the industry. Even though the source and

production of starch in our country is very abundant,

which consists of cassava starch, sago starch, rice

starch, and many other sources of starch that have not

been produced commercially. The development of

technology in the field of starch processing, starch

can be modified according to the properties that we

needed (Zuhra, et al, 2018).

Modified starch is starch that hydroxyl group has

been altered through a reaction or by modifying its

original structure. Pati is given certain treatment with

the aim of producing better properties to improve the

previous properties so that they can be used in

accordance with industrial needs (Wijayatiningrum,

2009).

Crosslinking method is one of method to modify

starch. The principle of this method is the way to

replace the OH group of starch and replaced it with

other functional group such as an ether, ester, or

phosphate group (Stevens, 1989). The advantages of

using crosslinking method can produce starch with

lower swelling capacity, furthermore its impact to

strengthen starch granules and make the starch more

resistant to acidic and hot media so that it does not

218

Zuhra, C., Ginting, M. and Siregar, D.

Synthesis of Cross-linked Breadfruit Starch (Artocarpus communis) using Epichlorohydrin.

DOI: 10.5220/0008878902180222

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 218-222

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

break easily during heating process. In addition,

crosslinking methods can improve texture and

viscosity of starch. However, this method has

disadvantages such as decreasing of the solubility,

precipitation, volume and stability of starch (Raina et

al., 2006).

The crosslinking of carboxymethyl starch from

rice was made by reaction between rice starch and

epichlorohydrin at concentrations (0.1-15% w/w).

The crosslinking reaction of carboxymethylation

directly using methanol as a solvent, the degree of

carboxymethylation substitution was between 0.24-

0.26 w/w with lower the content of amylose. The

resultof SEM showed a small changes on the surface

of the granule. Absorption of water volume and

swelling capacity of crosslinked starch increased

significantly as a result of modification

(Kittipongpatana and Kittipongpatana, 2013).

Original (unmodified) rice starch has rarely use in

industrial processes so modification of starch is

needed to reach the standard of food products. Rice

starch is cross-linked with epichlorohydrin with

various different concentrations (0.5%, 0.7%, 0.9% w

/ w, based on dry weight). Hydrolyzed rice starch by

α-amylase and hydrolyzed rice cross-linked starch

showed that the degree of amylase hydrolysis is

lower than hydrolyzed rice starch (Xiao et al., 2012).

The crosslinking agent used in this study were

epichlorohydrin. Epichlorohydrin is the best of

crosslinking agent if we compared to other monomers

such as POCl

3

and Sodium Trimetaphospate (STMP)

because its has small molecular weight (Rodríguez

and Nunez, 2008). The crosslinking bond that formed

between carbohydrate and epichlorohydrin generaly

were ether which bridges or connects of two hydroxyl

groups or more glucose units from starch molecules

(Wurzburg, 2010).

Based on the background, the researcher is

interested to synthesis cross-linked starch by

crosslinking reaction betweeen starch that isolated

from breadfruit and various concentration of

epichlorohydrin.

2 MATERIALS AND METHODS

2.1 Materials and Equipment

Breadfruit starch is isolated from ripe breadfruit.

Chemical used, which is sodium carboxymethyl

cellulose and aluminum sulfate octadecahydrate are

purchased from Merck & Co.

2.1.1 Material

The materials used in this study are: Starch

Breadfruit, Epichlorohydrin, NaOH, HCl, NaCl,

Aquadest, Phenolphtalein Indicator.

2.1.2 Equipment

The tools used in this study were: FT-IR Shimadzu

Spectrophotometer, Scanning Electron Microscope

Hitachi, Blender, Desiccator, Analytical Balance,

Oven Blower, Burette, Beaker Glass, Pumpkin

Measure, Measuring Cup, Hotplate Stirer, Universal

Indicator, Funnel, Desiccator , Magnetic stirrer, Statif

and clamp.

2.2 Methods

2.2.1 Isolation of Starch from Breadfruit

Breadfruit was peeled, cut into small piece, and then

washed using water to remove the gum and other

impurities. The resulted breadfruit was added with

enough water and then mashed using a blender.

Furthermore, the result was then pricipitated after

filtered using gauze. The precipitation was washed

frequently until the washed water waste was

transparent. The obtained starch was dried in the oven

at 45

0

C for 24 hours. This step aims to prevent starch

becoming charred and gelatinized. Crude starch was

then milled and sieved with a size of 115 mesh

(Merdikasari et al., 2009). Finally, the starch was

analyzed using FT-IR and SEM.

2.2.2 Synthesis of the Cross-linked Starch

Synthesis of cross-linked starch was carried out based

on the (Xiao et al., 2012) method with a slight

modification, namely crosslinking of starch with

epichlorohydrin. 30 gram of breadfruit were mixed

with 45 ml aquadest until a suspension was formed

and then 3 grams of NaCl, 1% epichlorohydrin was

added successively and stirred. The mixture was

made into pH = 10 by dripping 1 M NaOH while

stirring and then stirred for 3 hours at 30

o

C.

Subsequently, the starch pulp obtained was

neutralized to pH 6.0-6.5 with 1 M HCl and washed

thoroughly. The starch was dried at 45

0

C for 24 hours.

Crude crosslinked starch was milled and sifted. The

same procedure was carried out for variation 2% and

3% Epichlorohydrin. Finally, the cross-linked starch

were analyzed using FT-IR and SEM, and also

determined the degree of substitution (DS) and the

degree of swelling capacity.

Synthesis of Cross-linked Breadfruit Starch (Artocarpus communis) using Epichlorohydrin

219

2.3 Characterization

2.3.1 Determination the Degree of

Substitution (DS)

The Degree of Substitution (DS) of cross-linked

starch was determined by titration method. Weighed

as much as 0.1 grams of starch, dissolved in 5 mL

NaOH 0.5 N and stirred for 30 minutes. Then 3 drops

of phenolphthalein indicator were added and titrated

with 0.5 N HCl until it reached the equivalent point.

2.3.2 Determination of Swelling Capacity

The degree of swelling capacity determined by

(Zuhra, et al, 2018) method, the starch were weighed

at 2-3 grams, then placed on a dry cup whose weight

was known, then stored in a desiccator which had

been saturated with K2SO4 or KCl solution and

observed weight gain. Samples were weighed over a

period of 6, 12, 24 48, 72 hours.

2.3.3 Fourier Transform Infra Red (FT-IR)

Spectroscopy

The Fourier transform infrared (FTIR) spectra were

recorded with Shimadzu-IR Pretige 21 Spectrometer

were recorded in the transmittance mode in region

400-4000 cm

-1

at 16 cm

-1

resolution. Samples were

mixed with KBr powder and examined using IR

spectrometers.

2.3.4 Scanning Electron Microscope (SEM)

The morphology of the surface of samples were

discovered by using Scanning electron microscope

(SEM) Hitachi and operated at 20 kV. Sample were

recorded at magnification between 1000 to 10000

times their original sizes.

3 RESULT AND DISCUSSION

3.1 Isolation of Breadfruit Starch

The result of isolation of breadfruit starch

(Artocarpus communis) from 10 kg of breadfruit was

obtained as much as 680 g (6.8%) mass of starch. The

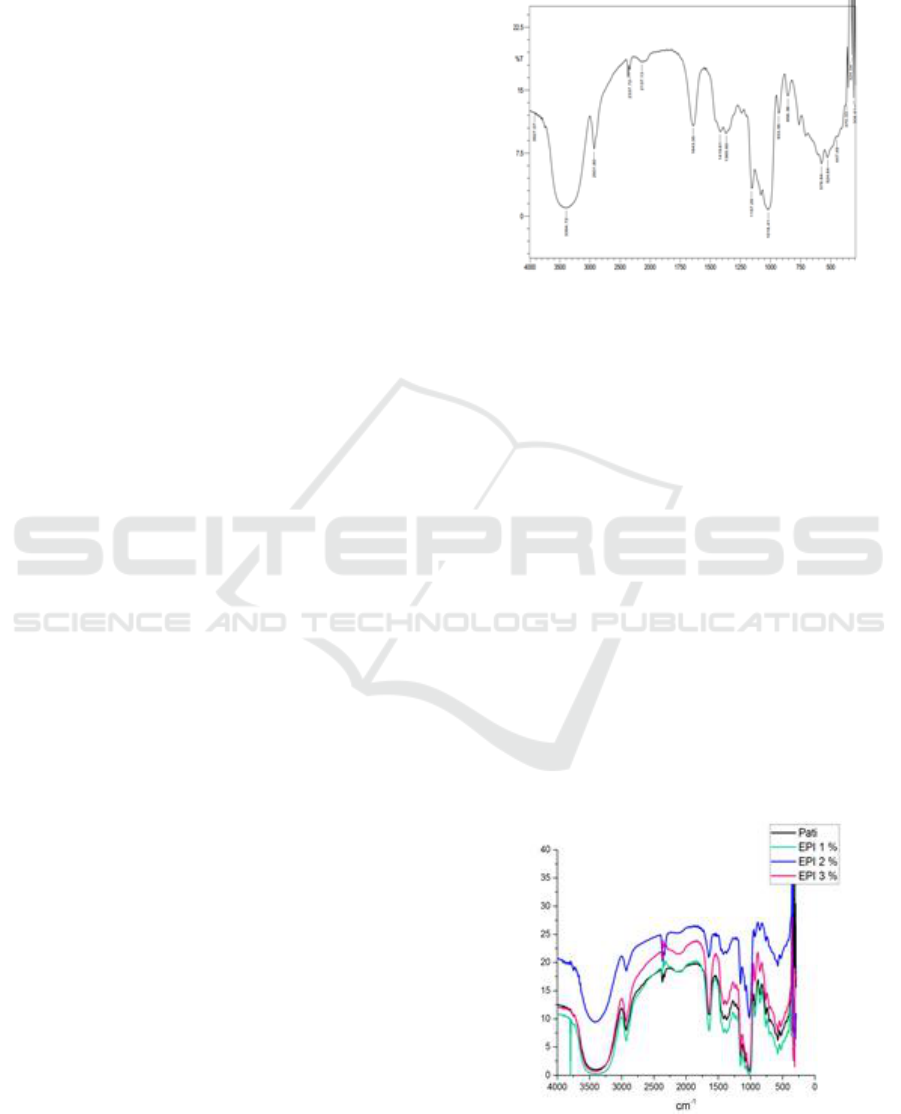

data of FTIR spectrum of fruitbread starch displayed

in Figure 3.1. the characteristic vibrations that

confirm of breadfruit starch appeared at the wave

number area 3387cm

-1

; 2931 cm

-1

; 1643 cm

-1

; 1157

cm

-1

. The broad and intense peak at 3387 cm

-1

attributed to O-H stretching vibration and the peak at

2931 cm

-1

corresponded to C-H stretching and also

the peak at 1157 cm

-1

indicated as C-O-C functional

group.

Figure 1: FTIR Spectrum of Breadfruit Fruit Starch.

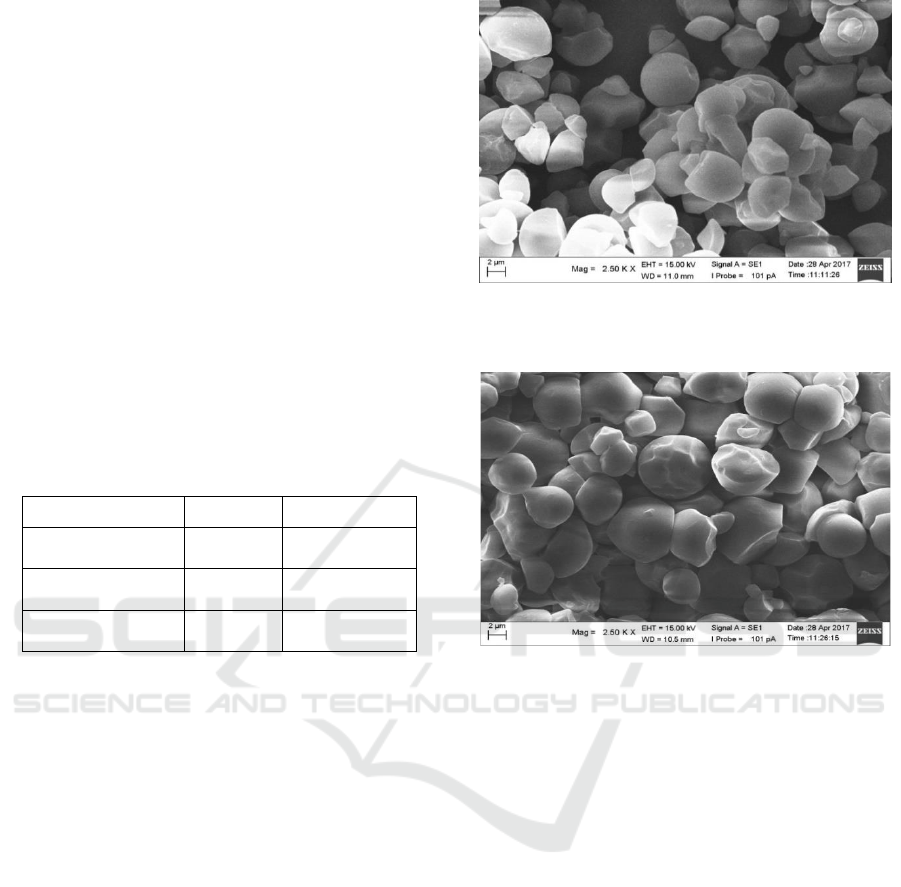

3.2 Synthesis of Cross-Linked Starch

The cross-linked starch was obtained by crosslinking

reaction between starch and epichlorohydrin with

addition of NaOH as catalysts. The data of FTIR

spectrum of cross-linked starch displayed in Figure

3.2. The formation of cross-linked starch with

variation 1%,2%,3% of epichlorohydrin was showed

by FT-IR spectra data with appearance of the range

wave number at 3000-3500 cm

-1

, 1630-1650 cm

-1

,

1010-1160 cm

-1

.

The increasing variation weight of

epichlorohydrin reduced the intensity of vibration

peak at 3387 cm

-1

and the appearance of a vibration

peak in the area at 1018 -1242 cm

-1

corresponded to

C-O-C functional group. The peak at 1018 cm

-1

showed intramolecular hydrogen bonds, it was

confirmed with breadfruit starch peak at 1018 - 1242

cm

-1

more intense than cross-linked starch. This

implied that hydrogen bonds have been severed (Xiao

et al., 2012).

Figure 2: FTIR spectrum of cross-linked starch with various

concentration of epichlorohydrin (1%, 2%, 3%).

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

220

3.3 Degree of Substitution

In this study, the DS was obtained with ranged from

0.0552 - 0.0701 that can be seen in Table 3.1. The

cross-linked starch with addition 2% of

epichlorohydrin was the highest DS. In process of the

preparation of cross-linked starch influenced by the

number of crosslinking agents used and the length of

reaction time. In this study, the more epichlorohydrin

used, so that the more clusters can replace the OH

group. This is caused by the lenght of contact time

between epichlorohydrin and breadfruit starch. The

longer of contact time can weaken the hydrogen

bonds in starch. But the addition of 3%

epichlorohydrin, did not show improvement of the

DS but a decline of the DS if it was compared with

the value of the DS of cross-linked starch with

addition 2% of epichlorohydrin (Zuhra, et al, 2018).

Tabel 1: The value of DS of cross-linked starch with

various concentration of epichlorohydrin.

Concentration

% DS

DS

Epiklorohidrin 1%

0,33

0,0552

Epiklorohidrin 2 %

0,415

0,0701

Epiklorohidrin 3%

0,365

0,0613

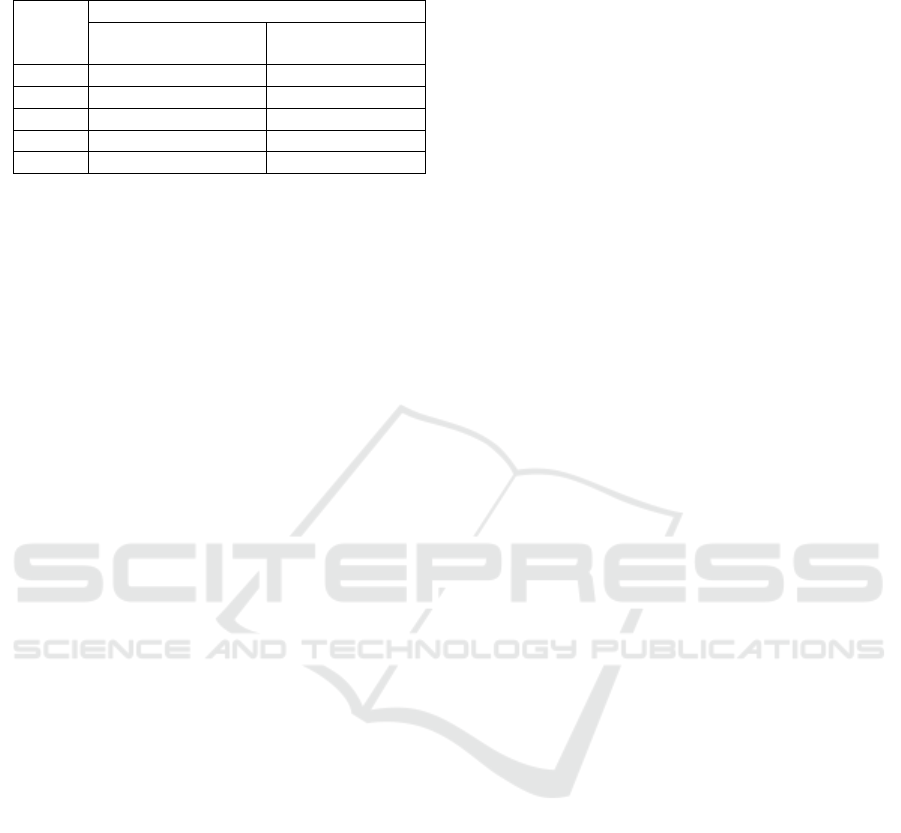

3.4 The Morphology Analysis

SEM analysis was performed to investigate the

surface morphology of the breadfruit starch and the

cross-linked starch with magnification 2500 times

that can be seen in Figure 3.3 and 3.4. In this research,

the SEM test only observed for the cross-linked starch

with addition 2% of epichlorohydrin that has the

higest value of DS. The shape of breadfruit starch and

cross-linked starch are both in the form of granules

but they have a little difference which is the surface

granule of breadfruit starch the surface of the granule

is more finer and the distance between the granules is

more tenuous while in the surface granule of cross-

linked starch is more coarse and the distance is more

tightly. This showed that the addition of

epichlorohydrin affects the shape of starch granules

(Zuhra et al., 2004).

Figure 3: The surface morphology of breadfruit starch with

magnification 2000x.

Figure 4: The surface morphology of cross-linked starch

with magnification 2000x.

3.5 Degree of Swelling Capacity

In this study, the determination degree of swelling

capacity was performed to breadfruit starch and the

cross-linked starch with addition 2% of

epichlorohydrin that has the highest value of DS. Its

can be seen in Table 3.2. The results showed that the

percentage of swelling capacity increased along with

the rising absorption time. Furthermore, the swelling

capacity decreased if it compared to breadfruit starch,

This is caused by crosslinking that are formed

between amylose molecules in starch granules, and

then causing swelling to be limited. This is also

influenced by the presence of cavities in the starch

that is formed by crosslinking reaction, so that water

molecules will be trapped to the cavity.

Synthesis of Cross-linked Breadfruit Starch (Artocarpus communis) using Epichlorohydrin

221

Table 2: Swelling capacity of breadfruit starch and cross-

linked starch.

Time

(hour)

W absorption (%)

Breadfruit starch

Cross-linked

starch

6

1.4842

0,9925

12

2.3358

1.4611

24

3.0032

1.8054

48

4.4974

2.0049

72

6.5195

3.0124

4 CONCLUSIONS

Synthesis of cross-linked starch has been

successfully carried out by crosslinking reaction

between breadfruit starch (Artocarpus communis)

and epichlorohydrin that were confirmed based on

FTIR spectrum. The FT-IR spectrum of cross-linked

starch showed C-O-C group that appears at wave

numbers 1018.41-1242.16 cm

-1

. The cross-linked

starch with addition 2% of epichlorohydrin were the

optimum condition that resulting the highest degree

of substitution at 0.0701%. The measurement of

degree of substitution from epichlorohydrin 1%; 2%;

3% were 0.0552%; 0.0701%; 0.0613%, respectively.

The SEM analysis of cross-linked starch is more

coarse and the distance between granules is more

tightly. Swelling capacity at absorption time of 6, 12,

24, 48, and 72 hours are 0.9925%; 1.4611%;

1.8054%; 2.0049%; 3.0124%, respectively.

ACKNOWLEDGEMENTS

Author would like to thank to Universitas Sumatera

Urara has facilitated all equipment until this journal

has been published successfully.

REFERENCES

Kittipongpatana, O.S., Kittipongpatana, N., 2013.

Physicochemical, in vitro digestibility and functional

properties of carboxymethyl rice starch cross-linked

with epichlorohydrin. Food Chem.

Merdikasari, Nurdjanah, S., Yulian, N., Lintang, N., 2009.

Amilografi Pasta Pati Sukun Termodifikasi

Menggunakan Sodium Tripolifosfat. Teknol. Ind. dan

Has. Pertan. 14, 173–177.

Raina, C.S., Singh, S., Bawa, A.S., Saxena, D.C., 2006.

Some characteristics of acetylated, cross-linked and

dual modified Indian rice starches. Eur. Food Res.

Technol.

Rincón, A.M., Padilla, F.C., 2004. Physicochemical

properties of Venezuelan breadfruit (Artocarpus altilis)

starch. Arch. Latinoam. Nutr.

Rodríguez, M., Nunez, S., 2008. Structural and rheological

characteristics of cross-linked banana starch with

different cross-linking agents. mexico 3–4.

Sauyana, Y., 2014. Produksi pati asetat dengan

menggunakan pati sagu nanokristalin. Dep.

IlmuPertanian FTP, IPB.

Wijayatiningrum, F.N.U.R., 2009. Makalah Seminar

Penelitian Modifikasi Cassava Starch Dengan Proses

Oksidasi Sodium Hypoclorite Untuk Industri Kertas,

Kimia, Jurusan Teknik Teknik, Fakultas Diponegoro,

Universitas Sudharto.

Wurzburg, O., 2010. Modified Starches. In: Food

Polysaccharides and Their Applications.

Xiao, H., Lin, Q., Liu, G.Q., 2012. Effect of cross-linking

and enzymatic hydrolysis composite modification on

the properties of rice starches. Molecules.

Zuhra, C.F., Ginting, M., Syufiatun, A., 2004. Modifikasi

Pati Sukun Dengan Metode Ikat Silang Menggunakan

Trinatrium Trimetafosfat. Chem. Nat. Acta 4, 142–146.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

222