Effect Croslinking on Characteristics of Silica Chitosan Composite

from Vulcanic Ash of Sinabung Mount and Shrimp Husk by Sol Gel

Method

Lisnawaty Simatupang

1,2

, Manihar Situmorang

2

, Rikson Siburian

3

, Basuki Wirjosentono

3*

1

Chemistry Postgraduate Study Programs, Universitas Sumatera Utara, Medan 20155, Indonesia

2

Department of Chemistry, Universitas Negeri Medan, Jl. Willem Iskandar Psr. V Medan Estate 20371, Indonesia

3

Department of Chemistry, Universitas Sumatera Utara, Medan 20155, Indonesia

Keywords: composit material, cross-link, glutaraldehyde, precursor, sol gel

Abstract: This research was carried out to determine the effect of glutaraldehyd croslinking on the synthesis of silica

chitosan composites from the Na

2

SiO

3

precursor of volcanic ash of Sinabung and chitosan from shrimp husk

by sol gel method. The synthesis of the silica-chitosan composite by mixing the 20 mL Na

2

SiO

3

precursors

with (2% : 3%) (w/v) chitosan in the aid of glutaraldehyde as crosslinking agent and without glutaraldehyde.

Modifications with sol gel is done because it is more simple and rapid progress as well as the binding

reaction of the ligands mobilized. Prepared Silica Chitosan Composit using glutaraldehyd labeled (Si-g-

ChC) and Silica Chitosan Composit without glutaraldehyd labeled (SiChC) . The characteristic of the

composit material (Si-g-ChC) and (SiChC) used by FTIR and XRD.

1 INTRODUCTION

The volcanic ash of Sinabung mount has the main

content of Silica (SiO

2

) which is very abundant

based on previous research (Barasa et al., 2013;

Kusmartini et al., 2017; Simatupang et al., 2016).

This potential SiO

2

content can be used as a basic

ingredient in making silica-based adsorbents (Barasa

et al., 2013). Silica can be used as an absorben

because of its high porosity, high mechanical

strength, high thermal stability, high pore surface

area, stable surface in acidic medium, non-fluffy,

resistant to microbes and low prices. Previous

research shows that the silica gel be successful

synthesized by using of volcanic ash base on

Sinabung mount. The silica gel consists of –OH

from Si-OH and Si-O from Si-O-Si. The silica gel is

well generated on this research is amorphous,

average pore radius of 1.5469x10

-1

Å, the surface

area of silica gel is 374,994 m²/g which is it possible

to be applied as an adsorbent (Simatupang et al.,

2018). The susceptibility of using silica gel is the

low ability of its surface to interact with heavy metal

ions so that silica gel is unable to function as an

effective adsorbent for heavy metal ions (Astuti et

al., 2012).

Abundant shrimp husk waste can be used as a

basis for making chitosan. Chitosan can be used in

the adsorption process because it is rich in amino

and hydroxyl groups as chelating, biocompability,

biodegradation and high adhesion power

(Kolodynska D,. 2011; Budnyak ТM, et al., 2013; Li

et al., 2009; Hu et al., 2018; Li et al., 2018; Badwan

et al., 2015). Chitosan without modification has low

mechanical strength and low solubility in acidic

medium. The amine groups in chitosan are unstable

in acidic conditions and cause protonation.

Therefore chitosan in original form generally does

not have specific selectivity for certain types of

heavy metals such as complex pollutants in water or

wastewater, even though the chitosan has high

content of amine and hydroxyl groups. The

modification of silica surface with chitosan by sol

gel method will produce silica chitosan composite

adsorbent in the development of technical

Simatupang, L., Situmorang, M., Siburian, R. and Wirjosentono, B.

Effect Croslinking on Characteristics of Silica Chitosan Composite from Vulcanic Ash of Sinabung Mount and Shrimp Husk by Sol Gel Method.

DOI: 10.5220/0008875902110214

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 211-214

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

211

nanomaterials, due to performance benefits such as

ease of synthesis, reduction in size, weight, and

multifunction. The sol-gel process provides many

advantages such as reaction conditions at room

temperature, easy and simple, high purity and

homogen, uniform and small size due to the binding

process going on simultaneously ( Zhao et al., 2017;

Budnyak et al., 2015; Budnyak et al., 2016). The

improvement effectivity of silica-organic polymer-

based materials because it combines the hardness

properties of silica and the functional properties of

chitosan polymers (Shchipunov et al., 2004). The

purpose of this research was study the effect of the

use of glutaraldehyd croslinking on the formation of

composite materials and their characteristics.

2 RESEARCH METHODS

2.1 Materials

The Na2SiO3 solution precursor from volcanic ash

of Sinabung mount and shrimp husk were obtained

on previous research. Reagents consist of HNO

3

,

NaOH, HCl, CH

3

COOH, etanol, and glutaraldehyd

25% were Analytical Grade (AR) from E-Merck..

.

2.2 Instrumentations

Equipment includes: analytic balance, mortar, 200

mesh sieve, desiccator, filter paper whatman 42,

magnetic strirer, universal indicator, buchner funnel,

glassware and plastic glass container. The

measurements was made by using a Fourier

Transform Infra Red (FTIR) Bruker spectrometer

equipped with a Digitec detector (Shimadzu),

Rigaku ZSX X- Ray Difraction (XRD) (Shimadzu

XRD 6000).

2.3 Procedure

2.3.1 Synthesis of Precursor Na

2

SiO

3

Solution

The volcanic ash as much as 20 g was soaked into

120 mL HNO

3

for 24 hours. Dried on the oven at T

= 120°C for 6 hours and then weight was recorded.

Subsequently, the volcanic ash was destructed with

156 mL NaOH 4M until the viscous on the furnace

at T = 500 °C during 30 minutes. After that, it was

added 200 mL water for 24 hours. Finally the

solution was filtered as Na-Silicat (Na

2

SiO

3

)

(Simatupang et al., 2018).

2.3.2 Synthesis of Silica-based Chitosan

Composite

The Na

2

SiO

3

solution as much as 20 mL put into a

plastic glass containers. The other plastic glass

containers were put (0.2; 0.3) g chitosan and

dissolved in 10 ml of acetic acid (2%, v / v) and then

stirred for 1 hour to form (2%, 3% ) w/v chitosan

solution. The glutaraldehyde of 5% as much as 1

mL was put into a chitosan solution (2%, 3%) and

stirred vigorously for 5 minutes and in another

plastic glass containers (2%, 3%) chitosan solution

without glutaraldehyde. Then the mixture of

chitosan and glutaraldehyde is poured into a sodium

silicate solution while stirring with a magnetic

stirrer. Chitosan solution without glutaraldehyde is

added to the other Na

2

SiO

3

solution. Gel formation

is done by adding 3M HCl drops to pH 7. The gel is

left overnight, filtered, washed with distilled water.

The obtained gel is dried at 70° with the use of a

vacuum pump. The obtained gel was sieved with a

200 mesh sieve. The end product is named as silica

chitosan composite material. Silica chitosan

composite are labelled based on the composition of

the chitosan, successively the composites material

prepared from 20 mL of Na

2

SiO

3

with 2% chitosan

used glutaraldehyd as crosslinking is labeled as

composite S-g-ChC1, with 3% chitosan is composite

S-g-ChC2. While 20 mL of Na

2

SiO

3

and 2%

chitosan without glutaraldehyd is labeled as SChC1,

and 3% chitosan without glutaraldehyd as SChC2.

Characterizations of Silica Chitosan

Composit

The methods for silica chitosan composit research

are versatile. X-Ray Diffraction (XRD) data at room

temperature using an X-ray diffractometer (Siemens

D 500) with copper anticathode radiation

(λCuKα=1.541838

Å) at 2θ from 7 to 70°. Fourier

Transform Infrared (FTIR) spectra were obtained on

a Vertex 70 spectrometer equipped with a digital

detector, via the conventional KBr pellet method.

The samples were scanned in transmission mode

with 2 and 4 cm

-1

resolution, at the range of 4000 to

400 cm

-1

.

3 RESULTS AND DISSCUSION

The preparation of silica chitosan composite (S-g-

ChC) was done by mixing 20 mL of Na

2

SiO

3

and

chitosan with variation (20 mL: 2%), (20 mL: 3%)

using glutaraldehyde as crosslinker, and silica

chitosan composite without glutaraldehyd (SChC)

with variation (20 mL: 2%), (20 mL, 3%). The

modification of the silica surface was done using sol

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

212

gel method. Chitosan has a high affinity to the

surface due to the interaction between part of

protonated amino groups of polymer and dissociated

hydroxyl groups of silica.

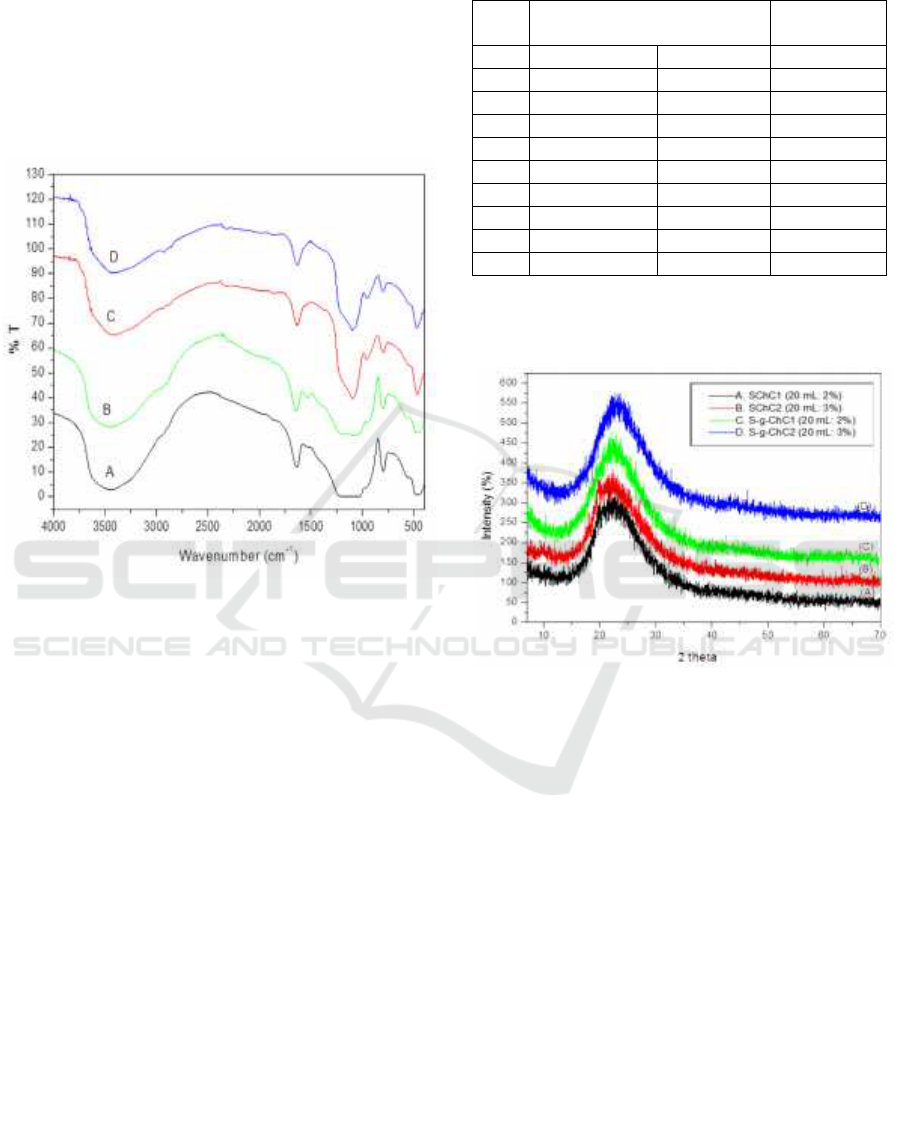

The FTIR spectrum of the synthesized silica

chitosan composit with glutaraldehyd as

crosslinking (S-g-ChC) show fig 1(A) and (B),

without glutaraldehyd (SChC) show fig 1 (C) and

(D) .

Figure 1: The FTIR spectra of: (A) S-g-ChC1 (20

mL:2%), (B) S-g-ChC2 (20 mL:3%), (C) SChC1 (20

mL:2%), and (D) SChC2 (20 mL:3%).

The formation of silica chitosan composites

occurs because silanol groups on the surface of silica

take hold of important role in the modification of

chitosan copolymers. FTIR results show a

significant difference in wave numbers between

silica chitosan composites using crosslinking

glutaraldehydes S-g-ChC and without crosslinking

glutaraldehydes (SChC). At S-g-ChC, the wave

number for O-H, C-H, and C-O group stretch

vibrations appears to shift to a higher wave number

compared to SChC. The wave number shift is due to

the cross link formed between the chitosan polymer

and silica. When silica gel is introduced into

chitosan copolymers, the number of hydroxyl groups

(Si-OH) increases which results in an increase in

hydrogen interactions between the copolymer matrix

and silica gel (Nithya et al., 2016). This cross

linking causes the movement of molecules to be

more limited, so that more energy is needed to

conduct vibrations (Bin et al., 2013)

Table 1: Analysis of S-g-ChC and SChC function groups

based on FTIR spectrum.

No

Wave number

Streaching

vibration

1

S-g-ChC1

SChC1

3447,44

3421,72

-OH

2928,57

2927,94

-CH

1637.71

1631.78

-C=N

1099.42

1095.57

-Si-O

2

S-g-ChC2

SChC2

3436,05

3421.72

-OH

2927,35

2927.94

-CH

1639,48

1631.78

-C=N

1095,10

1091.71

-Si-O

This result was further supported by the XRD.

The XRD of SChC and S-g-ChC show Fig 2.

Figure 2: The XRD pattern of: (A) and (B) komposit silika

chitosan without crosslinking glutaraldehyde (SChC); (C)

and (D) komposit silika chitosan wih crosslinking

glutaraldehyde S-g-ChC

Figure 2 that silica chitosan composites with

various variations of chitosan have a peak pattern

widened which represent a low degree of

crystallization (amorphous). The decrease in

chitosan crystallinity evidence the conjugation

between chitosan and silica polymer chains so that it

suppresses crystallinity to a certain extent. The silica

and chitosan polymer chains are well mixed at the

molecular level wherein that the peak of SChC is

more lowest than S-g-ChC (Gandhi et al., 2012).

There is also a 2θ difference between SChC and S-g-

ChC where SChC at 2θ = 20-22 while S-g-ChC at 2θ

= 22-23. This is due the silica chitosan composite S-

g-ChC has greater conjugation of silica and chitosan

compared to SChC. This can occur because the

glutaraldehyde as cross-linker on the composit S-g-

ChC will cause a higher density form so that the

Effect Croslinking on Characteristics of Silica Chitosan Composite from Vulcanic Ash of Sinabung Mount and Shrimp Husk by Sol Gel

Method

213

chemical bond will be much stronger compared to

SChC which has a lower density.

4 CONCLUSIONS

The silica chitosan composites from precursors of

sodium silicate (Na

2

SiO

3

) from volcanic ash of

Sinabung mount and chitosan from shrimp husk

combined with glutaraldehyde crosslink (S-g-ChC)

and without cronsslink glutaraldehyde (SChC) by

sol gel method have been successfull. The results of

the FTIR and XRD analysis showed differences in

the characteristics of the two composites due to the

glutaraldehyde crosslink effect.

ACKNOWLEDGEMENTS

Acknowledgment our sincere thanks to BOPTN

Universitas Negeri Medan for their support and

funds provided for the completion of this work,

Rector of Universitas Negeri Medan and Head of

Unimed Research Institute and other peoples who

helped a lot in this research.

REFERENCES

Astuti, M. D., Nurmasari, R., Mujiyanti DR., 2012.

Imobilisasi 1,8 Dihidroxyanthraquinon Pada Silika

Gel Melalui Proses Sol-Gel. Sains dan Terapan Kimia.

6(1), 25-34.

Badwan, A.A., Rashid, I., Al Omari, M.M.H. and Darras,

F.H. 2015. Chitin and Chitosan as Direct Compression

Excipients in Pharmaceutical Applications. Mar.

Drugs. 13, 1519-1547.

Li, B., Shan, C.L., Zhou, Q., Fang, Y., Wang, Y.L., Xu,

F., Han, L.R., Ibrahim, M., Guo, L.B., Xie, G.L.,

2013. Synthesis, characterization, and antibacterial

activity of cross-linked chitosan-glutaraldehyde. Mar.

Drugs. 11, 1534–1552.

Barasa RF, Rauf A, Sembiring M., 2013. Dampak Debu

Vulkanik Letusan Gunung Sinabung Terhadap Kadar

Cu, Pb, Dan B Tanah Di Kabupaten Karo. Jurnal

Online Agroekoteknologi. 1(4), 1288-1297.

Budnyak, ТM., Tetykh, VА., Yanovska, ES., 2013.

Chitosan and its Derivatives as Sorbents for Effective

Removal of Metal Ions. Surface. Suppl, 20, 118–34.

Budnyak, TM., Pylypchuket, LV., Tertykh, VA.,

Yanovska, ES., Kolodynska, D., 2015. Synthesis and

adsorption properties of chitosan-silica nanocomposite

prepared by sol-gel method. Nanoscale Research

Letters. 10, 87.

Budnyak, T.M., Yanovska, E.S., Kichkiruk, O.Y., Sternik,

D., and Tertykh, V.A., 2016. Natural Minerals Coated

by Biopolymer Chitosan: Synthesis, Physicochemical,

and Adsorption Properties. Nanoscale Research

Letters. 11, 492.

Gandhi, MR., Meenakshi., 2012. Preparation and

Characterization of Silica Gel/Chitosan Composite For

the Removal of Cu(II) and Pb(II). International

Journal of Biological Macromolecules. 50(3), 650–

657.

Hu, Z., Zhang, D.Y., Lu, S.T., Li, P.W., and Li, S.D.,

2018. Chitosan-Based Composite Materials for

Prospective Hemostatic Applications, Mar. Drugs. 16,

273.

Kolodynska, D., 2011. Chitosan as an Effective Low-Cost

Sorbent of Heavy Metal Complexes with the

Polyaspartic Acid. Chem Eng J., 173:520–9.

Kusmartini, I., Syahfitri, W.Y.N., Kurniawati, S., Lestiani,

D.D., M. Santoso, M., 2017. Journal of Physics:

Conf. Series. 860.

Li C, Champagne P., 2009. Fixed-Bed Column Study for

the Removal of Cadmium (II) and Nickel (II) Ions

from Aqueous Solutions Using Peat and Mollusk

Shells. Journal of Hazardous Materials. 171, 872.

Li, J., Cai, C., Li, J., Li, J., Li, J., Sun, T., Wang, L., Wu,

H., and Yu, G., 2018. Chitosan-Based Nanomaterials

for Drug Delivery, Molecules. 23, 2661.

Nithyaa. R., Gomathi, T., Sudha, P.N., Venkatesan, J.,

Anil. S., Kim, S.K., 2016. Removal of Cr(VI) from

aqueous solution using chitosan-g-

poly(butylacrylate)/silica gel nanocomposite,

International Journal of Biological Macromolecules.

87, 545-554,

Shchipunov, A.Y., Karpenko, Y.T, Bakunina, Y.I,

Burtseva, V.Y, Zvyagintseva, N.T., 2004. A New

Precursor for the Immobilization of Enzymes Inside

Sol–Gel-Derived Hybrid Silica Nanocomposites

Containing Polysaccharides, J. Biochem. Biophys

Methods. 58, 25–38.

Simatupang L., Devi., 2016. The preparation and

characterization of Sinabung volcanic ash as silica

based adsorbent. Jurnal Pendidikan Kimia, 8(3), 9-13.

Simatupang, L., Siburian, R., Sitanggang, P., Doloksaribu,

M., Situmorang, M., Marpaung, M., 2018. Synthesis

and Application of Silica Gel Base on Mount

Sinabung’s Fly Ash For Cd(II) Removal With Fixed

Bed Column. Rasayan J.Chem. 11(2), 819-827.

Zhou, D., Qi, C., Chen, Y.X., Zhu, Y.J., Sun, T.W., Chen,

F., and Zhang, C.Q., 2017. Comparative study of

porous hydroxyapatite/ chitosan and

whitlockite/chitosan scaffolds for bone regeneration in

calvarial defects. International Journal of

Nanomedicine. 12, 2673–268.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

214