Making Hydrogel with Crosslinked Reactions between Chitosan and

Dialdehyide Cellulose from Coconut Fiber as Wound Healers

Firman Sebayang

1*

, Rumondang Bulan

1

, Emma Zaidar Nasution

1,2

,

M. Zulham Efendi Sinaga

1,2

and Windi Anggara Putri

1

1

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara,

Medan, 20155, Indonesia

2

Pusat Unggulan IPTEK (PUI) Kitosan dan Material Maju Universitas Sumatera Utara, Indonesia

Keywords: α-Cellulose, Hydrogel, Chitosan, Dialdehyde Cellulose, Cross-linking.

Abstract: Making hydrogels from crosslinked reactions between cellulose oxidized with chitosan through Schiff base

formation reaction has been investigated as a wound healing drug in vivo. α-Cellulose obtained from the

isolation of coconut fiber by 14.24 g. α-Cellulose is oxidized by using KIO

4

to be dialdehyde cellulose. The

degree of oxidation of cellulose dialdehyde is 86%. Hydrogels were made by schiff base crosslinking

reaction between chitosan and dialdehyde cellulose with temperature variations of 75, 100, 125 and 150 oC.

The optimum temperature in hydrogel synthesis is 100 oC. the formation of a hydrogel is supported by the

presence of FTIR Spectrophotometer where the spectrum of 1643.35 cm-1 is formed where the group -

C=N- which shows the formation of a Schiff base reaction. The hydrogel that is obtained has a good

swelling ability of more than 1000%. Invivo analysis was carried out for 7 days in mice and as a result, the

injured mice have recovered and have not left a mark.

1 INTRODUCTION

Coconut coir is one of the biomass that is easily

obtained and is a by-product of agriculture. The coir

composition in coconuts is about 35% of the overall

weight of the coconut fruit. Coconut coir consists of

fiber (fiber) and cork (pitch) which connects one

fiber to another fiber. Coconut coir consists of 75%

fiber and 25% cork. Coconut coir fibers contain

lignin (35% - 45%) and cellulose (23% -43%)

(Carrijo, et al., 2002).

Cellulose is a linear condensed polymer

composed of D-anhydroglucopiranose units bound

by β-1,4-glycosidic bonds (Kalia, 2011). Cellulose

has one reducing group containing a non-substituted

hemiacetal, and one non-reducing group containing

an additional hydroxy group in C4. There are 2 main

crystalline cellulose arrangements, namely cellulose

I and cellulose II. Almost all initial cellulose consists

of cellulose I. Cellulose which has been dissolved

and deposited (regenerated) or through treatment

with concentrated alkaline solution and rinsed with

water (mercerized) consists of cellulose II. The

change in cellulose I to cellulose II is irreversible

(Wertz, 2010).

Chitosan is a natural polysaccharide obtained

from chitin deacetylation. If most of the acetyl

groups in chitin are substituted by hydrogen atoms

into amine groups by the addition of a strong high

concentration base solution, the result is called

deacetylated chitosan or chitin (Bastman, 1989).

Chitosan is one of the sources of amino natural

polysaccharides known as pH-sensitive properties

(Zhao, 2003).

Cellulose dialdehyde can be produced by

reacting cellulose with potassium periodate. Calcium

periodate is a selective oxidizer that will only break

the C2-C3 bonds so that 2 aldehyde groups are

formed (Höglund, 2015).

Hydrogels are essentially cross-linked polymers

which have the ability to absorb water thousands of

times from their dry weight, but are not soluble in

water due to the presence of a 3-dimensional

structure on the polymer network. Hydrogel is a very

interesting material because of its unique solubility

and water carrying capacity (Erizal, 2010).

The In vivo process is divided into three phases,

namely:

204

Sebayang, F., Bulan, R., Zaidar Nasution, E., Sinaga, M. and Putri, W.

Making Hydrogel with Crosslinked Reactions between Chitosan and Dialdehyide Cellulose from Coconut Fiber as Wound Healers.

DOI: 10.5220/0008869402040210

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 204-210

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

The inflammatory phase lasts from the time of

the wound until the third day. Broken blood vessels

in the wound cause bleeding and the body will try to

stop it with vasoconstriction. Hemostasis occurs

because platelets that come out of blood vessels

stick together and together with fibrin formed

freezes blood coming out of blood vessels.

The proliferation phase is also called fibroplation

because what stands out is the process of fibroblast

proliferation. In this phase the fiber is formed and

destroyed again to adjust to the stress on the wound

that tends to constrict. This property, together with

the contractile properties of miofibroblasts, causes

attraction to the edges of the wound. At the end of

this phase the wound strain strength reaches 25% of

normal tissue. Later, in the process of increasing the

strength of collagen fibers increases due to

intramolecular bonds and between molecules. In this

fibroplasias phase, the wound is filled with

fibroblasts and collagen which forms a reddish

colored tissue with a fine-grained surface called

granulation tissue. The wound edge epithelium

consisting of basal cells is released from the base

and moves to fill the wound surface. The place is

then filled with new cells formed from the mitotic

process. The migration process can only occur in a

lower or flat direction, because the epithelium

cannot migrate in a higher direction. This process

only stops after the epithelium touches and closes

the entire wound surface. With the closed surface of

the wound, the process of fibroplasia with the

formation of granulation tissue will also stop and the

maturation process begins in the phase of

completion.

In this phase there is a maturation process that

consists of excessive tissue reabsorption, shrinkage

and finally new tissue is formed. The body tries to

normalize everything that is abnormal because of the

healing process. During this process, the scar tissue

is pale, thin and weak and easily moved from the

bottom. Maximum shrinkage is seen in wounds. At

the end of this phase, skin wound healing can

withstand stretches of approximately 80% of normal

skin ability (Moenadjat, 2003).

2 MATERIALS AND METHODS

2.1 Tools

The tools used in this study include: glassware,

beaker glass, sieve, petri dish, reaction tube,

analytical balance, oven, hot plate stirrer,

thermometer, desiccator, incubator, Fisher

Scientific, vacuum device, universal indicator,

Aluminum foil, Thermometer , pH meter, Alcohol

Meter, FTIR, SEM.

2.2 Materials

The materials that used in this study include:

Coconut coir, Chitosan, Water, Aquadest, HNO

3

,

NaNO

2

, NaOH, Na

2

SO

3

, NaOCl, H

2

O

2

, KIO

4

,

Acetate buffer, KMnO

4.

Chitosan powder (1, 2, 3 and 4 g) was dissolved

in a 100 ml acetic acid 0.2 M solution at 60 ºC and

600 rpm to produce chitosan solution. Agar powder

(5 g) was dissolved in a 100 ml deionized water at

95 ºC and 600 rpm for 60 minutes. An amount of

20% of glycerol was added to the agar and chitosan

solution as plasticizer. The agar-chitosan film was

fabricated by mixing chitosan solution (1, 2, 3 and 4

g/100 mL) and agar solution (5 g/100 ml) with a

ratio of 1:1. The mixture was stirred at 60 ºC and

600 rpm for 60 minutes. An amount of film solution

was distributed into the template for drying and

casting for 24 hours at 40 ºC. The films were stored

in a desiccator.

2.3 Research Procedure

2.3.1 Preparation of Coconut Fiber Powder

Coconut coir is separated from the outer skin. Then

the fiber is washed with running water. Then the

clean coconut fiber is dried in the sun for 1 day. Dry

coconut coir is cut into smaller pieces and then in a

blender. Then the coconut husk that has been finely

filtered uses an 80 mesh sieve.

2.3.2 Isolation of α-Cellulose from Coconut

Coir

Weighed as much as 75 grams of coconut fiber

powder is put into a glass beaker, then added 2000

ml of 3,5% HNO

3

and 10 mg NaNO

2

then heated

at 90 ℃ for 2 hours while stirring on a hot plate.

Filtered and washed residue until neutral filtrate.

Then added 375 ml of 2% NaOH and 375 ml of 2%

Na2SO3, heated at 50 ℃ for 1 hour while stirring on

the hot plate then filtered and washed away until

neutral filtrate. Then it was bleached with 500 ml of

1.75% NaOCl solution, heated at 70℃ for 30

minutes while stirring on a hot plate. Filtered and

washed residue until neutral filtrate. Then added

with 500 ml of 17.5% NaOH and then heated at

80℃ for 30 minutes while stirring on a hot plate.

Filtered and washed residue until neutral filtrate.

Making Hydrogel with Crosslinked Reactions between Chitosan and Dialdehyide Cellulose from Coconut Fiber as Wound Healers

205

Then added with 250 ml of 10% H

2

O

2

, heated at

60℃ for 15 minutes while stirring on a hot plate.

Filtered and washed residue with aquadest until the

filtrate is neutral. Dried the residue in the oven at

60℃ then stored in the desiccator. (Ohwoavworhua,

2009)

2.3.3 α-Cellulose Oxidation with Potassium

Periodate (KIO

4

)

1 gr of isolated cellulose was immersed in a mixture

of KIO

4

solution and 0.1 M acetate buffer, with a

ratio of KIO

4

and acetate buffer 1: 100 (b / v) and

variation of KIO4 concentration of 0.2; 0.4; 0.6; 0.8;

1.0 mg / ml. Then stir it slowly without light and the

reaction conditions pH 4.5 and temperature 40o C

for 60 minutes. After oxidation, it is washed with

aquadest. The oxidized cellulose is characterized by

FT-IR. (Liu, 2004)

2.3.4 Determination of the Degree of

Oxidation (D.O) of Cellulose

A total of 0.1 grams of sample was dissolved with

10 ml of aquadest. Then added with 10 mL of NaOH

0.1 N. The solution is then heated to complete

dissolution. After that, the solution is cooled. Added

to the 10 mL 0.15 N HCl solution to the pH of the

solution <7. Then add aquadest as much as the

volume decreases during the first heating. The

solution is reheated for 1 minute, then the PP

indicator 2 drops is added. Titrated with 0.1 N

NaOH solution, and observed color changes.

Determination of the degree of oxidation can be

determined through the following equation:

%DO=((C

NaOH

× V

NaOH

)-(C

HCl

× V

HCl

))

/(m/162)×100%

2.3.5 Crosslinking between Oxidized

Chitosan and Cellulose

Chitosan solution was made by: as much as 8.0

grams of chitosan were put into 400 ml of acetic

acid solution 2% (v / v) with constant stirring for 1

hour at 60oC then oxidized cellulose was immersed

in chitosan solution with stirring for 15 minutes at

sushu 60

o

C so that a thick brownish yellow solution

is formed. Then poured into a glass beaker and dried

at a temperature variation of 75, 100, 125 and 150

o

C for 2 hours. (Pratama, A 2018)

2.3.6 Characterization of Hydorgels

Chitosan-dialdehyde Cellulose

FT-IR Analysis.

The sample is prepared in the form of pulp. Porridge

is examined in a thin film placed between flat plates

of salt. The test is done by clamping the mixed film

on the sample site. Then the film is placed on the

plate in the direction of infrared light. The results

will be recorded periodic paper in the form of a

wave flow curve 4000-200 cm-1 to the intensity.

Test of Water Absorption Percentage.

Testing the percentage of water absorption was

carried out by determining the percent swelling ratio

by measuring the initial weight (Wd) of the sample

which was then immersed in distilled water for 24

hours. The soaked samples are then filtered using

filter paper and measured the final weight (Ws).

Measuring the percentage of water absorption in the

hydrogel can be determined by the following

formula (Muthoharoh, 2012):

% S=(Ws-Wd)/Wd x100 % (1)

Where :

% S = Percentage of water absorption (%) (g/g)

Ws = Swollen hydrogel weight (g)

Wd = Dry weight of hydrogel (g)

Cross-linking Test.

The percentage value of crosslinking can be done by

determining the crosslink percent percent where the

dry weight of the resulting hydrogel is weighed.

Then the hydrogel is soaked with a solvent

(chloroform) for 24 hours. After immersion, the

hydrogel is heated at a temperature of 60oC to dry

for 3 hours. The dry weight of the hydrogel after

immersion is determined by weighing using an

analytical balance. The degree of crosslinking can be

determined by the following formula (Muthoharoh,

2012):

% DC= Wg/(Wo ) x 100 (2)

Where,

% DC = degree of crosslinking

Wg = Dry weight of hydrogel (g)

Wo = Swollen hydrogel weight (g)

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

206

Morphological Analysis using Scanning Electron

Microscope (SEM).

The microscopic observation process using SEM

begins with glueing the sample with a stick made of

older metal specimens. Then the sample is cleaned

with a blower, then the sample is coated with gold

and palladium with a dionspater machine

pressurized 1492x10

-2

atm. The sample is then put

into a special room and then illuminated with 10

Kvolt-powered electrons so that the sample emits

secondary electrons and the electrons are detected by

a scientor detector which is then amplified by an

electric circuit that causes a chatode ray tube (CRT)

image. Shooting is done after selecting a specific

part of the object (sample) and the desired

magnification so that a clear photo is obtained

(Negulescu, 2004).

Antimicrobial Activity.

Antimicrobial activity of hydrogels was performed

on two types of microbes, i.e., S. Aureus and E.

Coli. The microbes culture were diluted in

accordance with the standards McFarland, each

inoculated into petri dishes containing Mueller

Hinton agar. Then the disc was inserted into the

blends of dialdehyde cellulose/chitosan in a petri

dish aseptically. The petri dish then put in an

incubator at 35 °C for 24 h. After 24 h, the

antimicrobial zone (clear zone) was observed and

measured in diameter by using a caliper.

In Vivo.

Before cutting, the hair around the femur was shaved

and anesthetized using lidocaine 0.2 cc in 2 cc

aquadest, then injured. The injury is done at the

femur of the mouse by making an incision with a

length of 20.0 mm and a width of 1.8 mm using a

sterile scalpel then handled. Handling is done twice

a day, before giving the sample to the wound,

always clean it first using distilled water. Giving the

sample is done by applying it to the part of the

wound on the femur of the mice, ie in the morning

and evening, for 7 days after induction of the wound

using a cotton bud. As a comparison, negative

controls and positive controls were used using

Salticin Gentamicin Sulfate.

3 RESULTS AND DISCUSSIONS

In this study α-Cellulose can be isolated from

coconut fiber waste. Where from 75 grams of

coconut coir powder isolated 14.24 grams of pure

cellulose were obtained or about 18.98% of the

initial mass of coconut husk samples used

α-Cellulose is oxidized using potassium periodate

which is a selective oxidizer. Potassium periodate

will break the C2-C3 bond which has a secondary

alcohol group so that it becomes 2 aldehyde groups.

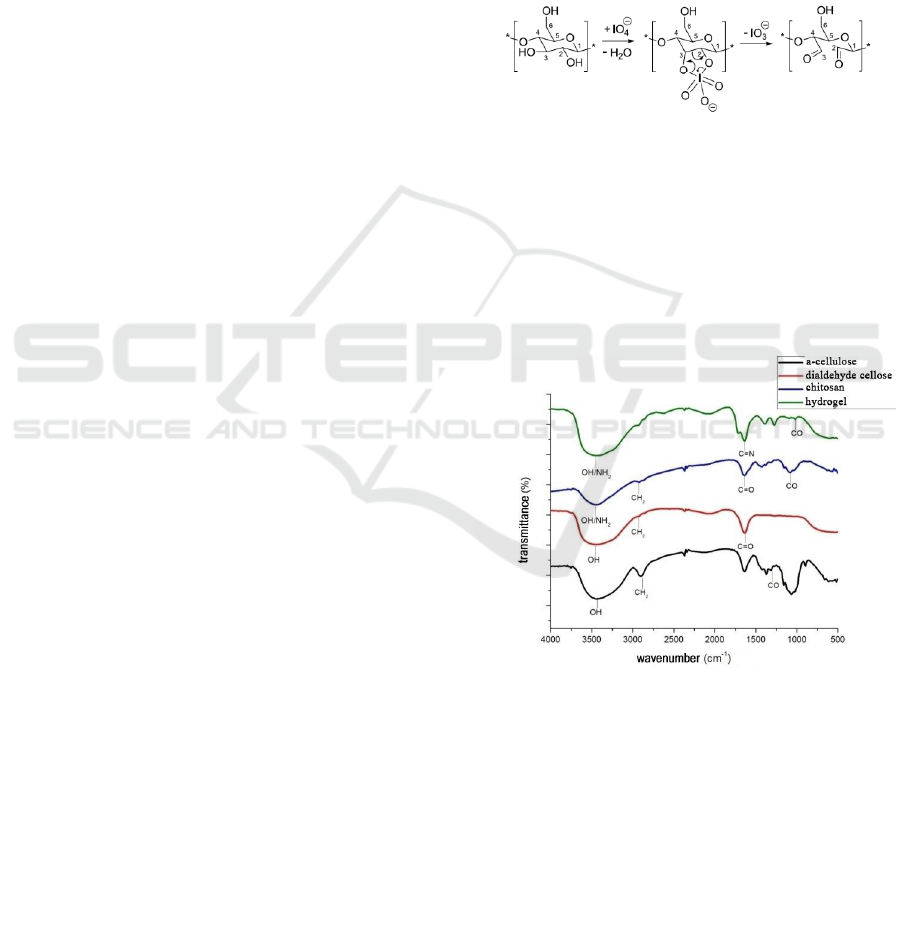

Figure 1: Cellulose Oxidation Reaction with Periodate.

The reaction between watershed and chitosan is

an imine group formation reaction (Schiff base),

where the primary amine group in chitosan will react

with carbonyl aldehyde groups found in the

watershed to form an imine group (R-C = N-).

3.1 FT-IR Analysis

Figure 2: Spectrum FT-IR α-Cellulose, DAS, Chitosan,

Hydrogel.

The results of the analysis of the α-cellulose

functional group used for the study showed that the

absorption of wavelengths of 3448.72 cm

-1

showed

the presence of a bound -OH group found in α-

cellulose compounds, the absorption of a wavelength

of 2900.94cm

-1

indicated the presence of a group -

CH sp3 and the absorption of wavelengths of

1064.71cm

-1

indicates the presence of -CO- groups.

Making Hydrogel with Crosslinked Reactions between Chitosan and Dialdehyide Cellulose from Coconut Fiber as Wound Healers

207

The results of the analysis of the cellulose

dialdehyde (DAS) functional group used for the

study showed that the wavelength absorption of

3441.01cm

-1

showed the presence of a bound -OH

group found in cellulose dialdehyde compound

(DAS), with wavelength uptake of 2924.09cm

-1

shows the presence of -CH sp3 group and the

presence of wavelength uptake of 1026.15cm

-1

shows the presence of -CO- group and at wavelength

absorption of 1635.64cm

-1

indicates the presence of

–C = O-.

In the FTIR spectrum of chitosan powder, there

was an absorption peak at wave number 3448.72 cm

-

1

which showed the free peak absorption of O-H and

nitrogen amine (-NH

2

). With the presence of N-H

absorption peaks, it is the main characteristic of

chitosan structure. In addition, the presence of

absorption peaks in wave numbers can also be

referred to as marking N-H stretching primary

aliphatic amines (Rohman A, 2014). According to

(Fessenden and Fesssenden, 1982) if there are two

hydrogens on a nitrogen amine (-NH

2

), absorption of

N-H appears as a twin peak. This is not proven by

the results of the FTIR spectrum of chitosan powder

analyzed showing that there were no twin peaks on

the absorption band around 3000 - 3700 cm

-1

. In

addition there is an absorption peak at wave number

2924.09 cm

-1

indicating the presence of –C-H sp3

bond. Furthermore, the absorption peak at wave

number 1265.30 cm

-1

indicates the presence of C-O

and C-N groups. The absorption bands of C-O and

C-N groups are usually not easy to identify in the

fingerprint area because this spectrum area often

contains many peaks that overlap and are difficult to

identify (Fessenden and Fesssenden, 1982). But on

the results of the spectrum analysis of chitosan

powder used for research, CO and CN fingerprint

areas are easy to identify. One of the factors that

supports this convenience is that chitosan powder

used in the study can be categorized as pure. In

addition, where this CN group is also a characteristic

typical functional groups found in chitosan

molecules. From the description above, it can be

seen that the results of functional group analysis

using FTIR spectrophotometer on chitosan powder

have no changes in the functional groups composed

of chitosan chemical molecules or there are no other

groups that absorb infrared absorption from FTIR

spectrophotometers so that chitosan powder used in

research is pure chitosan compound.

On the results of the hydrogel functional group

analysis used for the study, the wavelength uptake of

3441.01 cm

-1

showed the presence of a bound -OH

group found in the hydrogel compound, the

wavelength absorption of 2924.09 cm

-1

indicated the

presence of the -CH sp3 group . In the crosslinking

reaction between α-cellulose with chitosan, an imine

bridge (Bases Shiff) is formed as a change that links

between chitosan compounds and α-cellulose. The C

= N group causes vibrations on wavelength

absorption of 1643.35 cm

-1

but unlike chitosan

uptake in the previous FTIR results, the absorption

of these wavelengths does not form a twin peak

because there is no hydrogen group in the nitrogen

atomic bond chain, replaced by a bond duplicate

between the carbon chain on cellulose dialdehyde

and nitrogen in chitosan compounds. The occurrence

of crosslinking process is also reinforced by the

formation of uptake at a wavelength of 1273.02 as

an amplifier of carbon atoms in the chitosan group

still bound to nitrogen as from chitosan compounds.

Similar to the results of the previous functional

analysis, there was an absorption peak of 3441.01

nm as the absorption peak of the OH group, 2924.09

nm and 2854.65 nm as the absorption peak of the C-

H sp3 and 1064.71 groups as the peak C-O-H

absorption.

3.2 Percentage of Water Absorption

In making the hydrogel, the crosslinking reaction

works well. With the ability to expand well, the air

will be absorbed in crosslinked molecules between

cellulose dialdehyde and chitosan. On heating 75

o

C

produces a percentage of water absorption below

from heating 100

o

C which is 3.91% g / g. This is

evidenced by the destruction of the hydrogel into a

cluster of fine grains proving that the crosslinking

reaction between cellulose and chitosan dialdehyde

has not been fully formed because the temperature

of the crosslinking has not been fully formed. At an

increase of 125

o

C, and 150

o

C, the percentage of air

absorbency was lower than that of making hydrogels

with an increase of 100

o

C while the percentage of

overall air absorption reached 800.73% g / g and

198.26% g / g. This shows a high increase. A perfect

crosslinking occurs at 100

o

C. It has started to repair

or cut off the crossing. Because with cross bonding

between polymers, it will allow bond bonding with

the polymer where the air is absorbed in the

hydrogel crosslinked polymer polymer. With the

ability to absorb air, the results of this research

hydrogel can be used as a media to store drugs,

namely hydrogels as a healing agent for wound

healing and even wound healing agents.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

208

3.3 Percentage Crosslink Degree

On the results of the crosslinked degree test, the

highest percentage of crosslinking was at 150

o

C

heating. This is very inversely proportional to the

percentage of water absorption. Where a good

hydrogel is a hydrogel with the ability to absorb

water high due to the optimum crosslinking and does

not make the shape of the hydrogel hard and stiff so

that good cross-linking capability will increase the

ability of high water absorption.

At 75

o

C heating, the ability of crosslinking is the

lowest because an imperfect crosslinking process

occurs reinforced in the explanation of the ability of

the absorption of water on the heating. With the

modification of the polymer chain extension,

chloroform as an extracting agent for polymeric

materials is not able to extract hydrogel material

with good cross-linking ability. Whereas at 75

o

C

heating, the ability of low water absorption makes

the average percentage of crosslinking at 18.94% g /

g. The ability of chloroform to extract the remaining

ingredients of the formula for making hydrogels,

resulted in the shape of the hydrogel after extracting

it with chloroform not decreasing its shape and

weight after extracting it from its initial weight or

dry weight. This is indicated by the results of

crosslinking in the middle of the average percentage

of cross-linking at 100

o

C heating which is 78.32%

g/g. This shows that every gram of hydrogel formed,

the crosslinking ability is in the range of 78.32%

which is successfully cross-linked in the formula for

making it.

Whereas the heating of 125

o

C and 150

o

C has a

high percentage of crosslinking capacity, namely

91.61% g / g and 92.93% g / g. The high percentage

of crosslinking does not indicate that the hydrogel is

in a good shape. In fact, the hydrogel is rubbed on

each side so it is possible that the hydrogel has been

crystallized so that it is difficult to extract by

chloroform.

3.4 Sem Analysis

Figure 3: Results of morphological analysis of hydrogels

using SEM with magnifications of 1000 and 2000 time.

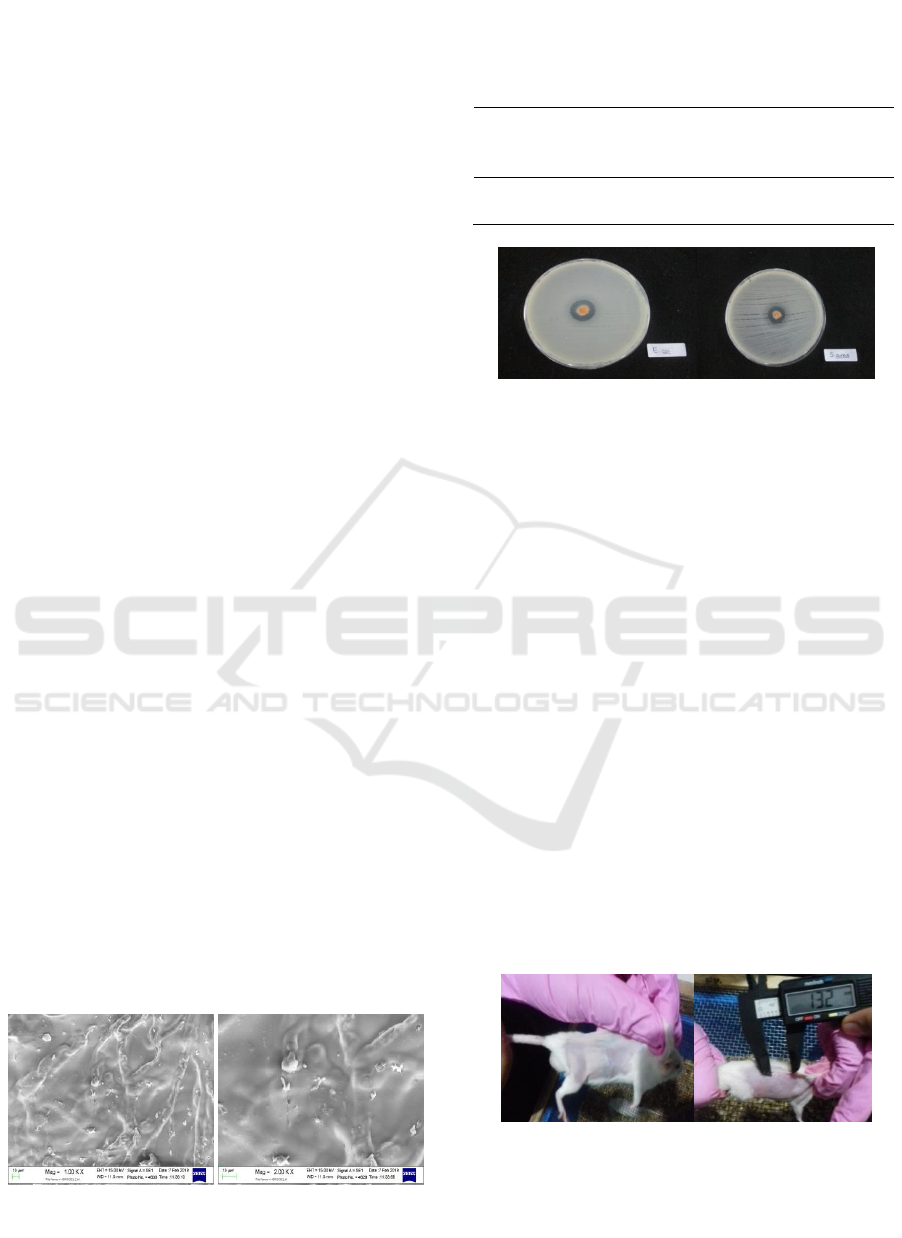

3.5 Anti Bacterial Test Results with

Hydrogels

Table 1: Antibacterial Test Results for Hydrogels.

Diameter of

hydrogel

(mm)

Diameter of

inhibition zone

(mm)

E. coli

6.5

17.45

S. aureus

6.5

15.20

(a) (b)

Figure 4: observations of clear zones (a) Escherichia coli,

(b) Staphylococcus aureus.

From Figure 4 it can be seen that hydrogels made

from crosslinked reactions between chitosan and

watershed have good antimicrobial activity against

Escherichia coli bacteria as gram negative bacteria

and Staphylococcus aureus bacteria as gram-positive

bacteria.

3.6 In Vivo

Inflammatory phase is the phase where bleeding

occurs and freezing or cessation of bleeding due to

contraction of smooth muscle walls of blood vessels

that are open and blood clots by thrombin and fibrin.

The results showed that the inflammatory phase for

control (-), hydrogel samples and control (+) had

different healing phases. For control (-) takes more

than 7 days, the control treatment (+) takes 7 days to

heal but leaves a mark and not all mice tested

recovered, while the treatment for hydrogel samples

only takes 7 days to heal and does not leave made an

impression.

(a) (b)

Figure 5: (a) Heal (without trace), (b) Heal (with trace).

Making Hydrogel with Crosslinked Reactions between Chitosan and Dialdehyide Cellulose from Coconut Fiber as Wound Healers

209

4 CONCLUSIONS

From the results of the research that has been done,

it can be concluded as follows:

The synthesis of hydrogels from crosslinking

reactions between α-cellulose and chitosan tellah

was successfully carried out. The crosslinking

reaction forms an imine bridge (Schiff base) as a

change that links between chitosan compounds and

α-cellulose. This can be proven from the C = N

group formed which causes vibration on wavelength

absorption of 1643.35 and also has good water

absorption capability.

The results of the antibacterial activity of the

hydrogel showed good results for Gram-positive

bacteria Staphylococcus aureus and gram-negative

E. coli bacteria. This can be proven from the

formation of clear zones around the sample.

Hydrogels show better In vivo efficiency than

the healing drug Salticin Gentamicin Sulfate which

is within 7 days and leaves no trace.

REFERENCES

Carrijo, O. A., Liz, R. S., Makishima, N., 2002. Fiber of

Green Coconut shell as Agriculture substratum.

Brazilian Horticulture, 20, 533-535

Erizal. 2010. Synthesis and characterization of

superabsorbent hydrogels poly (acryl-amide-co-

acrylic acid) using radiation techniques. A Scientific

journal of application Isotopes and Radiation 6(2):

105-116.

Höglund E, 2015. Production of Dialdehyde Cellulose and

Periodate Regeneration: Towards Feasible Oxidation

Processes. Karlstads University

Kalia S, 2011. Cellulose Fibers: Bio- and Nano- Polymer

Composites. Springer-Verlag. London

Moenadjat Y, 2003. Burns Practical Clinic. Edition II.

Faculty of Medicine UI, Jakarta.

Pratama, A, 2018. Antibacterial Properties of Biofilm

Schiff Base Derived from Dialdehyde Cellulose and

Chitosan. Indones.J.Chem.

Wertz J, 2010. Cellulose Science and Technology. EPFL

Press. Italy

Zhao J, 2012. Chitosan-Based Gels For The Drug Delivery

System, in Yao K, Li J, Yao F, Yin F, (Ed), Chitosan-

Based Hydrogel; Functions And Applications, Taylor

&Francis Group, LLC,. New York.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

210