Modification and Characterization Starch Nanoparticles of

Mangrove Fruit using Chemical-mechanical Method and Application

as Basic Materials Making Hydrogel

Gimelliya Saragih

1,3

, Tamrin

2*

, Marpongahtun

2

and Darwin Yunus Nasution

2

1

Postgraduate Chemistry Study Program, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara,

Jl. Bioteknologi No. 1 Kampus USU, Medan, Indonesia

2

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan, Indonesia

3

Department of Chemical Engineering, Politeknik Teknologi Kimia Industri, Medan, Indonesia

Keywords: Mangrove Starch, Chemical-mechanical Methods, Nanoparticles, Hydrogel, FTIR, PSA, SEM, XRD, DSC.

Abstract: Mangroves are plants that function as protectors of the land from ocean waves. Mangroves are a source of

starch that has not been explored. To expand the application, the starch needs to be modified. Natural starch

is made using wet extraction. Natural starch is synthesized into nanoparticle starch by chemical-mechanical

methods. Modified Mangrove Fruit Starch can be used as a base for making hydrogels. Characterization of

starch and starch nanoparticles includes proxy analysis, functional groups using the Fourier Transform

Infrared Spectroscopy (FTIR). Test the PSA (Partiicle size analyzer) to find out the particle size. Crystallinity

test of starch nanoparticles using X-Ray Diffraction (XRD). The morphological analysis of nanoparticles was

carried out using the Scanning Electron Microscopy (SEM) instrument. Thermal test using Differential

scanning calorimeter (DSC). The results showed that mangrove starch had a yield of 29.60% and particle size

of mangrove nanoparticles of 38.79 nm.

1 INTRODUCTION

Starch is a natural biopolymer used in the food,

chemical, pharmaceutical / biomedical, paper, textile

and so on industries. Starch is renewable, non-toxic,

edible and inexpensive and easy to obtain. Natural

starch has several disadvantages that need to be

modified so that it has the appropriate characteristics

as industrial ingredients.

Desirable important properties of modified starch

include higher brightness, lower viscosity, clearer gel

formed, easier starch granules to rupture, higher

gelatinization time and temperature (Koswara, 2009).

Modification of several types of starch namely

tapioca, sago can produce nanoparticle starch which

serves as a matrix binding to herbal active ingredients

and lactic acid bacteria (Sunarti, et al, 2015).

There are still many sources of starch that have not

been developed, among others, mangrove fruit starch

besides functioning as a protector of land from large

ocean waves (Irwanto, 2006), rhizophora mucronata

plants. also is one type of mangrove that can be used

as a new food source. This is because this species

contains high carbohydrates.

Nanotechnology has great potential to produce

new composites. One application is nanocomposite in

biomedicine. Nanocomposite can be done by

inserting nanoparticles into the matrix. The

nanoparticles commonly used for nanocomposites

include carbon nanotubes, cellulose, silica, and chitin.

Nanocomposite is generally used to improve

mechanical properties and packaging properties

(barrier properties) (Azeredo, 2009). Starch in the

form of nanoparticles has several advantages

including low suspension viscosity even though the

concentration is relatively high, and has a high

binding strength (Gularte and Rosell, 2011).

There are several previous studies that have been

carried out to isolate starch and synthesis of starch

nanoparticles. Among them are chemical methods of

hydrolysis with strong acids H

2

SO

4

(Wei, et al, 2014),

dissolution methods and non-solvent precipitation

(Saari, et al, 2017), ionic gelation methods (Yang, et

al, 2015). Enzymatic method of enzyme hydrolysis

using alpha amylase enzyme (Rahmawati and

Saragih, G., Tamrin, ., Marpongahtun, . and Nasution, D.

Modification and Characterization Starch Nanoparticles of Mangrove Fruit using Chemical-mechanical Method and Application as Basic Materials Making Hydrogel.

DOI: 10.5220/0008868501910196

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 191-196

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

191

Yunianta, 2014). Combined method of enzyme

hydrolysis and acid (LeCorre, et al, 2012). The

mechanical method uses ultrasonication (Haaj, et al,

2013). From several studies on starch making it is

known that chemical-mechanical methods have

proven effective for isolating starch and reducing its

size to starch nanoparticles (Kim, et al, 2013).

Based on this background, the authors are

interested in conducting research on the modification

and characterization of starch from mangrove

nanoparticles with chemical-mechanical methods and

their application as a basis for making hydrogels

2 MATERIALS AND METHODS

2.1 Materials

The materials used in this study are Mangrove Fruit,

Aquadest, 2% Sodium Hydroxide (NaOH), Sulfuric

Acid (H

2

SO

4

) 98% (E.Merck), Na-metabisulfite

(E.Merck), Sodium Chloride (NaCl), Ethanol (E.

Merck).

2.2 Extraction of Mangrove Starch

Extraction of mangrove starch was carried out by

referring to the method developed by Wijayanti et al.

(Wijayanti, et al, 2010). Mangrove fruit obtained

from the coast in Aceh Tamiang Regency, mangrove

fruit weighed 1 kg and then peeled and then washed

into a 4% NaCl solution in 3 liters of water

(comparison 1: 3). To find out the net weight, the

peeled skin is weighed so that it gets clean weight.

Then soaked with 0.075% Na-metabisulfite with a

ratio of 1: 3. Then the tubers are washed with tap

water, shredded and filtered while being given water.

Then leave it to settle for 1 night, the filtrate is

removed and the sediment is taken. The precipitate is

dried at 40

o

C, then milled and sifted with a 100 mesh

sieve.

2.3 Characterization of Mangrove

Fruit Starch

2.3.1 Proximate Analysis

Mangrove starch obtained by proximate analysis of

the AOAC Method, 2006 (AOAC, 2006).

2.3.2 Fourier Transform Infrared

Spectroscopy (FTIR)

Analysis of mangrove starch functional groups using

the Fourier Transform Infrared Spectroscopy (FTIR)

tool. The FTIR spectrum of the sample was recorded

using the Bruker OPUS 7.5.18 infrared spectrometer

(Bruker, Germany) at wavelengths from 400 to 4000

cm

-1

at a speed of 20 cm

-1

.

2.4 Isolation of Nanoparticles of

Mangrove Starch

Starch nanoparticles are prepared using a

modification of the procedure described by Angellier,

et al (2004). Briefly, mangrove fruit starch (44.07 g,

dry solid) was dispersed in an acidic solution of

H

2

SO

4

(3.16 M, 300 ml), and the dispersion was

stirred with a magnetic stirrer (200 rpm) at 40 ° C.

After various periods of hydrolysis, the sample taken

and neutralized with NaOH (1 M) to neutral pH and

centrifuged at 3500 rpm for 10 minutes. Added

deionized water (300 ml) into the precipitate, and the

mixture stirred for 30 minutes at room temperature.

This washing process is repeated twice to remove the

remaining salt. Next, the starch was deposited, and

the suspension was centrifuged at 500 rpm for 10

minutes to separate the solids in the supernatant. Then

it was ultrasonified at the highest amplitude (90%) for

15-30 minutes. Then freeze drying was used to obtain

starch nanoparticle powder.

2.5 Characterization of Mangrove

Starch Nanoparticles

2.5.1 Proximate Analysis

Particle size was characterized using Particle Size

Analyzer (PSA) nanoq cordouan v2.0.0.1

2.5.2 X-Ray Diffraction (XRD) Analysis

Analysis of crystallinity of mangrove starch using X-

Ray Diffraction (XRD) was operated at 40 kV and

current of 30 mA of electricity using Cu Kα radiation

at 1.5418 A wavelength and scanned from 0.0050 (2

Ɵ / s).

2.5.3 Scanning Electron Microscopy (SEM)

Analysis

The surface morphology of mangrove starch

nanoparticles was characterized using SEM (DX

EVO MA 10 Carl Zeiss, Germany).

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

192

2.5.4 Differential Scanning Calorimeter

(DSC) Analysis

Thermal properties of nanoparticle starch using

Differential scanning calorimeter (Shimadzu). This

analysis is carried out to measure the energy absorbed

or emitted by a sample which gives measurements of

calorimetry and transition energy at a certain

temperature.

3 RESULTS AND DISCUSSION

3.1 Extraction of Mangrove Starch

Making mangrove starch is done by wet extraction.

The yield of mangrove fruit starch was 29.60%. The

high rendeman of large-potential mangrove fruit

starch is developed into a starch source and

alternatively becomes a new food source (Kardiman,

et al, 2017). The resulting mangrove fruit is brownish

white. The results of extracting mangrove fruit can be

seen in Figure 1.

Figure 1: Mangrove Fruit Starch.

3.2 Characterization of Mangrove

Starch

3.2.1 Analysis Proximate

For the results of a preliminary analysis of mangrove

starch following the procedure of the Association of

Official Analytical Chemist (AOAC), 2006, it can be

seen in Table 1 below. Proximate analysis result

showed that starch mangrove fruit is a surce of high

carbohydrate.

Table 1: Test Results Mangrove Fruit Starch Proximate.

Proximate Components

Content (%)

Protein

4.26

Crude fiber

36.98

Starch

56.61

Crude fat

0.76

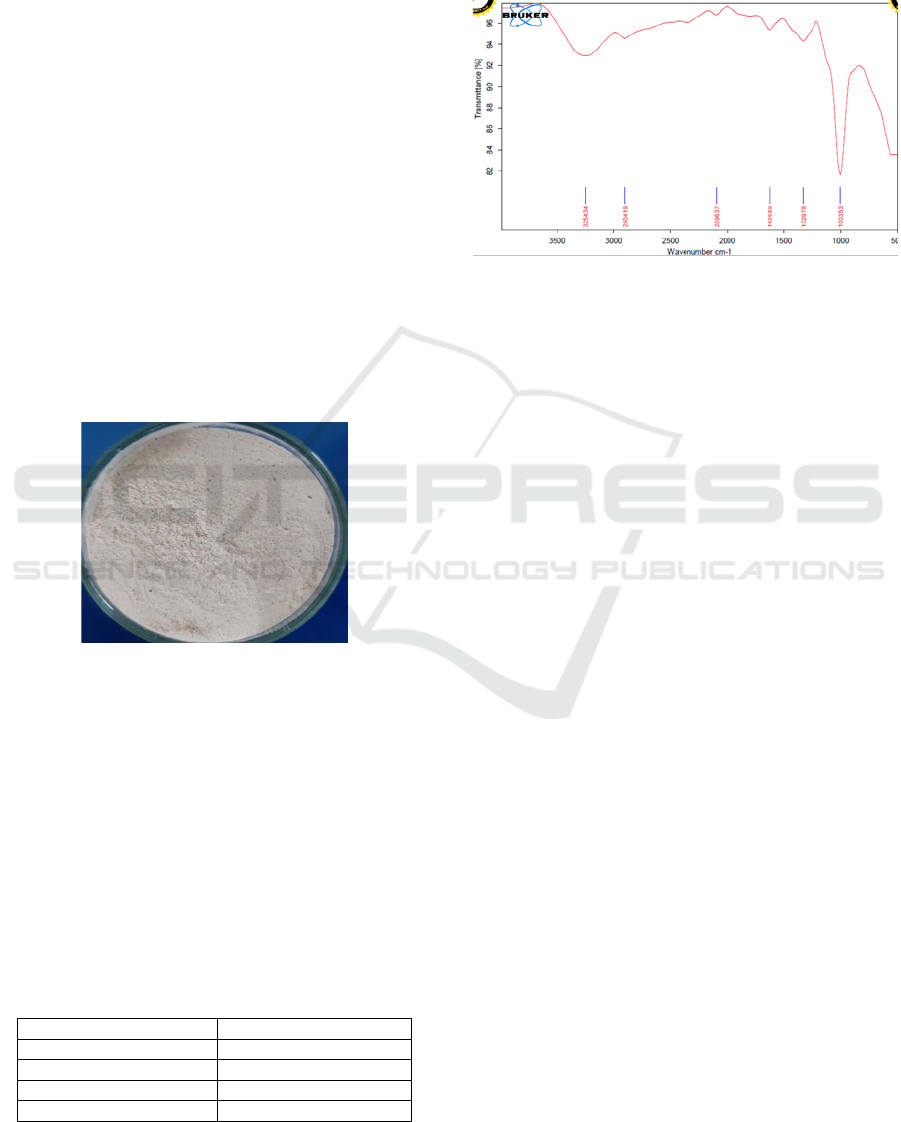

3.2.2 Analysis Fourier Transform Infrared

Spectroscopy (FTIR)

FTIR spectrum from mangrove starch nanoparticles

can be seen in Figure 2.

Figure 2: FTIR spectrum of mangrove starch.

The shape of the widening peak is seen in the absorption

area of 3000 - 3600 cm

-1

. This vibration shows the vibration

of the stretching region of hydrogen with O-H bonds

(carboxylic acids). The vibrational peak in the area of 2850

- 2960 cm

-1

and vibration in the area of 1340 - 1470 cm

-1

,

this stretch shows the vibration of the aliphatic C-H bond.

In the absorption area with wave number 1636 cm

-1

, this

vibration shows the vibration of the C = C bond. This peak

shows the vibration of the area which is cyclic or aromatic

ring and in the absorption area of 1050 - 1300 cm

-1

This

vibration shows the vibration of the stretching region of

hydrogen with the C-O bond). The results of FTIR

spectroscopic analysis showed that the mangrove starch

provides a spectrum that describes the structure of starch.

3.3 Synthetic Mangroveti Fruit Starch

Nanoparticles

The making of mangrove starch nanoparticles

consists of several stages, namely: the acid hydrolysis

stage, the neutralization stage of the mechanical stage

and the phase of separation or often called the

chemical-mechanical method.

In this study, the hydrolysis of mangrove starch

was dispersed in an acid solution of 3.16 M H

2

SO

4

,

the use of sulfuric acid was too concentrated to

convert starch to glucose and the dispersion was

stirred with a magnetic stirrer (200 rpm) at 40 ° C.

After various periods of hydrolysis, samples were

taken and neutralized with NaOH (1 M) to neutral pH

and centrifuged at 3500 rpm for 10 minutes. Added

deionized water (300 ml) into the precipitate, and the

mixture stirred for 30 minutes at room temperature.

This washing process is repeated twice to remove the

remaining salt. Next, the starch was deposited, and

the suspension was centrifuged at 500 rpm for 10

Modification and Characterization Starch Nanoparticles of Mangrove Fruit using Chemical-mechanical Method and Application as Basic

Materials Making Hydrogel

193

minutes to separate the solids in the supernatant. Then

it was ultrasonified at the highest amplitude (90%) for

15-30 minutes. Then freeze drying was used to obtain

starch nanoparticle powder.

The point of Hee-Young Kim et al., (2013) the

chemical treatment aims to degrade amorphous

regions in starch granules. Mechanical treatment is

carried out such as homogenization by ultrasonication

in starch that has undergone chemical treatment

before. During the hydrolysis process, starch

nanoparticles continue to be produced because starch

granules are fragmented by acid but producing starch

nanoparticles may tend to form aggregates that are

easily deposited as microparticles. To inhibit

aggregation or to separate nanoparticles, ultrasonic

treatment is applied to starch dispersion, and changes

in the size distribution of starch particles are

examined by dynamic light scattering. Mild acid

hydrolysis combined with ultrasonication can

effectively produce starch nanoparticles.

Ultrasonication plays an important role in separating

the aggregates of nanoparticles that can form during

hydrolysis, thus effectively increasing the yield of

starch nanoparticles. However, starch nanoparticles

which are processed by ultrasonication can reduce the

crystallinity of starch.

3.4 Characterization of Starch

Nanoparticles

3.4.1 Results of Particle Size Analyzer (PSA)

Analysis

Particle Size Analyzer (PSA) is a characterization that

can be used to determine particle size and distribution

in a solution.

This method uses the principle of light scattering.

In this study wet method was used for the particle size

testing process. In the wet method using dispersion

media to disperse the test material. So that the starch

nanoparticles to be tested are dissolved in distilled

water for 4 hours at room temperature while the

stirring process is carried out so that the particles do

not agglomerate (clump) each other. Thus the

measured particle size is the size of a single particle.

Besides the measurement results in the form of

distribution, the measurement results can be assumed

to have described the overall condition of the sample.

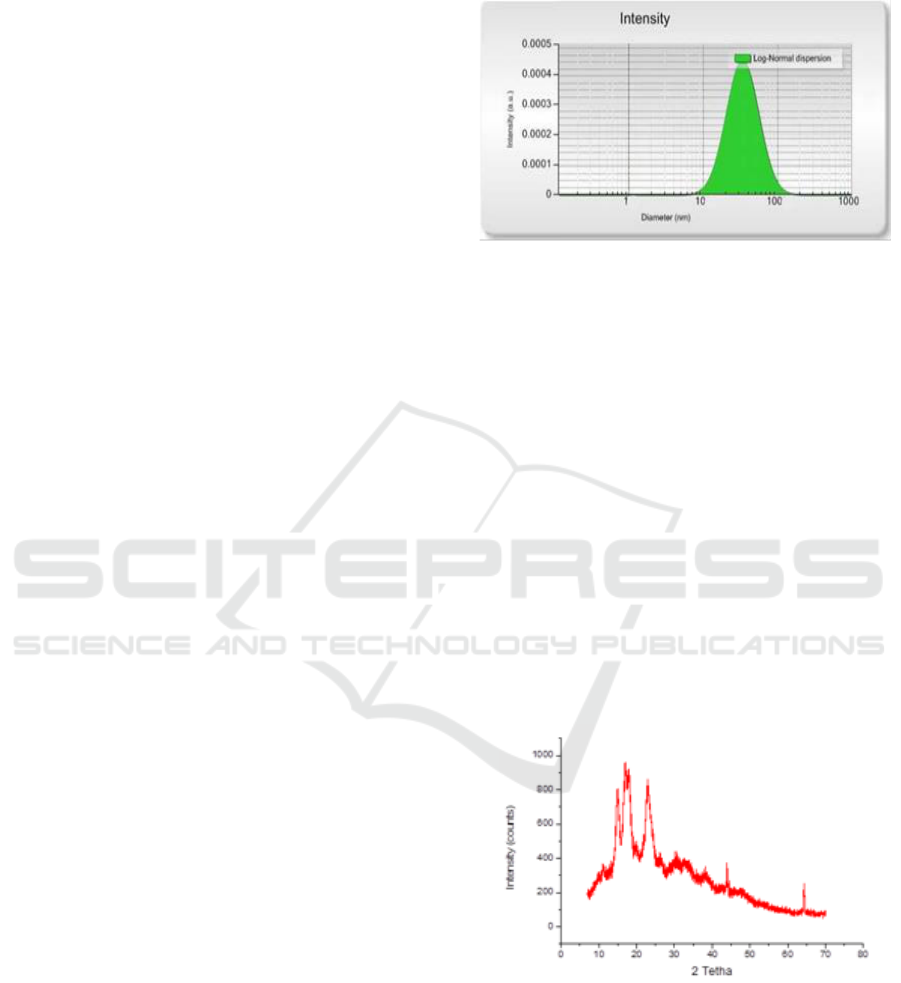

Based on Figure 3, there is a symmetrical peak

which indicates the particle size distribution is evenly

distributed in all parts. The peak appears in an area

with an average particle size of 38.79 nm. The size

and distribution of the particles produced reflects or

represents the size of the particle diameter in its bulk

state.

Figure 3: Distribution curve for the size of the Mangrove

Starch Nanoparticles.

3.4.2 Results of Particle Size Analyzer (PSA)

Analysis

Determination of the crystallinity of mangrove fruit

nanoparticles was done by XRD, which is by placing

samples of mangrove fruit nanoparticles in a place so

that they can rotate on one axis. Then irradiate the

sample with X-rays, so the field devices in the crystal

reflect the X-ray beam. Then the beam is received by

the detector, so that the diffractogram is obtained. The

diffractogram of the polymer samples produced

contained crystalline and amorphous regions which

mixed randomly. The diffractogram of X-ray

crystalline polymers has a sharp peak, while

amorphous polymers have a wide peak. For the XRD

analysis of mangrove fruit starch nanoparticles can be

seen in Figure 4 below.

Figure 4: Distribution curve for the size of the Mangrove

Starch Nanoparticles.

The highest mangrove starch nanoparticle peaks were

formed at 150 and 230, indicating that mangrove fruit

nanoparticles were successfully synthesized.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

194

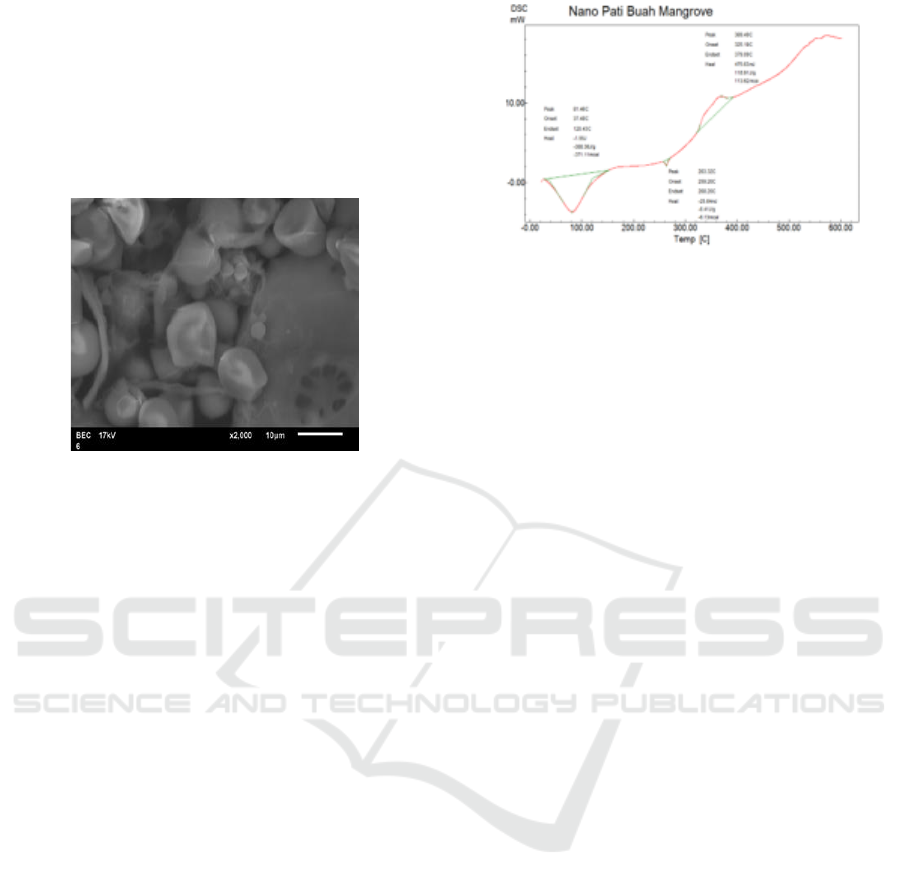

3.4.3 Results of Scanning Electron

Microscopy (SEM) Analysis

Morphological analysis was carried out to see the

pore size of the hydrogel with variations in the

addition of mangrove starch nanoparticles in this case

using the Scanning Electron Microscopy (SEM) tool.

For SEM photos can be seen in Figure 5 below.

Figure 5: Results of SEM of Mangrove Fruit Starch

Nanoparticles.

The treatment of acidic and mechanical hydrolysis

during the precipitation process can cause the

formation of smaller particles when starch is

degraded. This mechanical treatment causes the

cutting of bonds between amylose and amylopectin

molecules when starch is degraded so that the shape

and size of the particles of starch do not return to their

original conditions, this indicates that the structure of

starch has been modified. Based on morpholytic

analysis of starch using SEM, it was seen that the

starch particles after precipitation were still not

completely separated and still combined to form

pores. This porous structure can affect the functional

characteristics of nanocrystalline starch.

3.4.4 Results of Analysis of Mangrove

Starch DSC Analysis

Differential Scanning Calorimetry (DSC) is a thermal

property analysis technique where the function is

measured. DSC is used to study thermal properties

and phase changes in calorimetry of a material. DSC

analysis has been conducted on mangrove starch

samples which can be seen in Figure 6.

Figure 6: Graph of Analysis Results of DSC Nanoparticles

of Mangrove Starch.

In Graph 5 shows changes in endothermic reactions

and exothermic reactions of mangrove starch

nanoparticles. At temperatures of 81.46

o

C showed the

temperature of the endothermic reaction (heat

absorbing), at temperatures of 369.49

o

C showed the

exothermic reaction temperature, which stated that

the material had been degraded (damaged), this meant

that mangrove starch nanoparticles could be used

below the degraded temperature which was below

369.49

o

C.

4 CONCLUSIONS

Mangrove starch nanoparticles were successfully

isolated by chemical-mechanical methods, through

three stages of using acid hydrolysis stage, H2SO4

3.16 M, mechanical phase neutralizing with NaOH

(1M) using centrifugation at 500 rpm for 10 minutes

and ultrasonication at highest amplitude (90% ) for

15-30 minutes. FTIR Characterization Results of

mangrove starch nanoparticles provide a spectrum

that describes the structure of starch, the highest peak

of mangrove starch nanoparticles formed at 150 and

230, This shows that mangrove fruit nanoparticles

were successfully synthesized and the size of starch

nanoparticles obtained was 38.79 nm.

ACKNOWLEDGEMENTS

The authors are grateful to the Pusdiklat Industri

Kementerian Perindustrian who has supported the

funding of this research, Politeknik Teknologi Kimia

Industri medan, Department of Chemistry, University

of Sumatera Utara, Medan for its support in the use of

laboratories, and not forgetting my promoters who

have provide useful guidance and advice in

conducting this research.

Modification and Characterization Starch Nanoparticles of Mangrove Fruit using Chemical-mechanical Method and Application as Basic

Materials Making Hydrogel

195

REFERENCES

Angellier, H., Choisnard, L., Molina-Boisseau, S., Ozil, P.,

& Dufresne, A., 2004. Optimization of the preparation

of aqueous suspensions of waxy maize starch

nanocrystals using a response surface methodology.

Biomacromolecules, 5(4), 1545-1551.

AOAC Association of Official Analytical Chemists, 2006.

Official Methods of Analysis of The Association of

Official Agriculture Chemists 16th edition.

Azeredo, H. M., 2009. Betalains: properties, sources,

applications, and stability–a review. International

journal of food science & technology, 44(12), 2365-

2376.

Gularte, M. A., & Rosell, C. M., 2011. Physicochemical

properties and enzymatic hydrolysis of different

starches in the presence of hydrocolloids. Carbohydrate

Polymers, 85(1), 237-244.

Haaj, S. B., Magnin, A., Pétrier, C., & Boufi, S., 2013.

Starch nanoparticles formation via high power

ultrasonication. Carbohydrate polymers, 92(2), 1625-

1632.

Irwanto, 2006. Keanekaragaman Fauna Pada Habitat

mangrove. Yogyakarta www.irwantoshut.com. [20

Desember 2009]

Kardiman, K., Ridhwan, M., & Armi, A., 2017. Buah

Lindur (Bruguera gymnorrhyza) sebagai Makanan.

Serambi Saintia: Jurnal Sains dan Aplikasi, 5(2).

Kim, H. Y., Han, J. A., Kweon, D. K., Park, J. D., & Lim,

S. T., 2013. Effect of ultrasonic treatments on

nanoparticle preparation of acid-hydrolyzed waxy

maize starch. Carbohydrate polymers, 93(2), 582-588.

Kim, H. Y., Park, D. J., Kim, J. Y., & Lim, S. T., 2013.

Preparation of crystalline starch nanoparticles using

cold acid hydrolysis and ultrasonication. Carbohydrate

polymers, 98(1), 295-301.

Koswara, S., 2009. Teknologi modifikasi pati. Teknol.

Pangan, 1-32.

LeCorre, D., Bras, J., & Dufresne, A., 2012. Influence of

native starch's properties on starch nanocrystals thermal

properties. Carbohydrate Polymers, 87(1), 658-666.

Rahmawati, A., & Yunianta, Y., 2014. Hidrolisis Enzimatis

Pati Jahe Emprit (Zingiber officinale Var. Rubrum)

Dengan Enzim Αlfa Amilase (Kajian Pengaruh

Konsentrasi Enzim Dan Lama Inkubasi Terhadap Sifat

Fisik Dan Kimia Dekstrin) [In Press Juli 2015]. Jurnal

Pangan dan Agroindustri, 3(3).

Saari, H., Fuentes, C., Sjöö, M., Rayner, M., & Wahlgren,

M., 2017. Production of starch nanoparticles by

dissolution and non-solvent precipitation for use in

food-grade Pickering emulsions. Carbohydrate

polymers, 157, 558-566.

Sunarti, T.C., Mangunwidjaja, D., dan Richana, N., 2015.

Potensi Dan Aplikasi Pati Termodifikasi Sebagai

Bahan Matriks Enkapulasi Senyawa Bioaktif Herbal.

Balai Besar Penelitian dan Pengembangan Pascapanen

Pertanian, Bogor.

Wei, B., Xu, X., Jin, Z., & Tian, Y., 2014. Surface chemical

compositions and dispersity of starch nanocrystals

formed by sulfuric and hydrochloric acid hydrolysis.

PloS one, 9(2), e86024.

Wijayanti, R. E., Mulyati, A. H., & Winarti, C., 2010.

Modifikasi Pati Umbi Gembili (Dioscorea esculenta L.)

dan Gembolo (Dioscorea bulbifera) Sebagai Pati

Nanopartikel Melalui Hidrolisis Asam. Universitas

Pakuan. Bogor.

Yang, J., Han, S., Zheng, H., Dong, H., & Liu, J., 2015.

Preparation and application of micro/nanoparticles

based on natural polysaccharides. Carbohydrate

polymers, 123, 53-66.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

196