Lead (II) Nitrate Catalyzed Esterification Palmitic Acid with Alcohols

Nimpan Bangun

1*

, Justaman Karo-Karo

2

, Hamonangan Nainggolan

1

, Slamet Silaban

1

,

Nia Erisa Tarigan

1

, Rahmad Ramadan

1

1

Department of Chemistry, Universitas Sumatera Utara, Jl. Bioteknologi No. 1 Kampus USU, Medan,

North Sumatera, Indonesia

2

BARISTAND, Medan, Indonesia

niaerisa7@gmil.com, rahmadramadhan32@gmail.com

Keywords: Lead Nitrate, Fatty Acid, Alcohols, Esters.

Abstract: Esters has been long known in some applications that has been attempted to prepare in many fashion

methods. Several catalysts used based on acid either solid or liquid has been known popular. A transition

salt also has been intensively reported catalyzes esterification. Very few catalysts from Group A metal

shown activities esterification catalysis. Lead (II) nitrate shown a good catalyst performance in esterification

long chain fatty acid reacts with primary and secondary alcohol. Palmitic acid reacts with alcohols, glycerol,

1,2-propane diol as well as stearyl alcohol gives high yield ester respectively. All ester has been

characterized in FT-IR, 1H NMR and 13C NMR spectrophotometer shown the yield was 90-97%.

1 INTRODUCTION

Oleochemical industry is still growing sustainable

due to the product is needed in daily living. Esters

for example have high demand as fuel, plasticizers,

fragrance, adhesive and also as lubricants (Joseph,

2005; Mbaraka, 2006; Krause 2009; Martinez 2009).

Catalysis esterification reactions can be performed

in several manner catalyst such as, homogeneous

acid include AlCl

3

, HF, H2SO4. Although those

catalysts bring high environmental risk and the cost

inefficiency, this is still used in production industrial

esters (Ziarani, 2013). Part of research to improve

the environmental risk, then the heterogeneous

catalyst has been developed. This catalyst system

can be allowed to recovery, recycle and then reused

(Gupta, 2007). Parallels to the chemical process

environmentally, sulfonates acid functional was

modified, by grafting with silica gel (Davison, 2008)

anchoring to silica mesoporous (Keppelera, 2011),

inorganic solid supported (Vijaykumar, 2012) that

can be less toxic. Attempt to apply in chemical

process esterification long chain acid, fatty acid with

glycerol (alcohol multivalent), a sulfonate catalyst

was used in a high condition (240

0

C) (Sari, 2017).

In a relative new esterification catalyst

development such as Barnstead acid salt, Sn (II) and

Sn (IV) performs reaction long chain acid with

alcohols to be esters. The key reaction is a forming

bonding Sn-OR (Cardoso, 2009; da Silva, 2011;

Ferreira, 2012). However the report is still limited

on a simple alcohols. Due to Lead has a very similar

chemistry to Tin, then it has been shown catalytic

activity in esterification palmitic acid toward stearyl

alcohol, diol and also triol as reported here.

2 MATERIALS AND METHODS

2.1 Materials

Materials used in this research Pb(NO

3

)

2

, 1,2-

propane diol, 1, glycerol, octadecyl alcohol (stearyl

alcohol), palmitic acid and m-xylene were purchased

from Merck and used without pretreatment.

2.2 Analysis Method

1

H NMR and

13

C NMR spectra were recorded at 500

MHz on Agilent spectrometer. Wave number of

carbonyl were recorded on spectrometer FT IR.

Bangun, N., Karo-Karo, J., Nainggolan, H., Silaban, S., Tarigan, N. and Ramadan, R.

Lead (II) Nitrate Catalyzed Esterification Palmitic Acid with Alcohols.

DOI: 10.5220/0008857901330135

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 133-135

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

133

2.3 Esterification Reaction

Into a round bottle flask provided a hotplate stirrer, a

bar magnetic and a condensor, a mixture of xylene

30 ml; glycerol (1.84 g; 0.02 mol), palmitic acid

(15.384 g; 0.06 mol) and lead (II) nitrate (0.02 g;

6x10

-5

mol). The system was heated at 140

0

C for 8

hours. The product mixture was distilled to free

xylene, then extracted with n-hexane 2x 50 mL. The

solution was washed with water 50 mL followed by

addition with ethanol- water 30 mL. Finally the n-

hexane fraction was dry with Na

2

SO

4

anhydrous 5 g.

After filtration, then the solution was evaporated and

dried in vacuum, gave a solid was 14.526 g; 90%

yield. Glyceryl tripalmitate was characterized with

spectroscopy FT-IR and

1

H NMR (CDCl

3

).

A similar work was done by change the alcohol,

1,2-propane diol (1.58 g ; 0.02 mol and stearyl

alcohol (5.41 g; 0.02 mol) reacts toward palmitic

acid (10.256 g; 0.04 mol) and (5.12g; 0.02 mol)

respectively producing 1,2-propanyl dipalmitate

(11.244 g; 95%) and stearyl palmitate (10.21 g;

97%).

3 RESULT AND DISCUSSION

3.1 Esterification Process

Reaction alcohols to palmitic acid catalyzed by lead

(II) nitrate has been successfully to form esters.

However the reaction took place in a consuming

time. This is may be needed the evaluation catalyst

amount to increase amount. Normally, the catalyst

amount is proportional to speed of reaction. The end

of the reaction shown that the catalyst turn to black

powder more soluble in ethanol rather the product

that allowable easy to separated from the ester

product in the reaction. The black powder is a future

challenge for investigated.

Based on the ratio product to catalyst, turn over

frequency catalyst found 300- 323 per second.

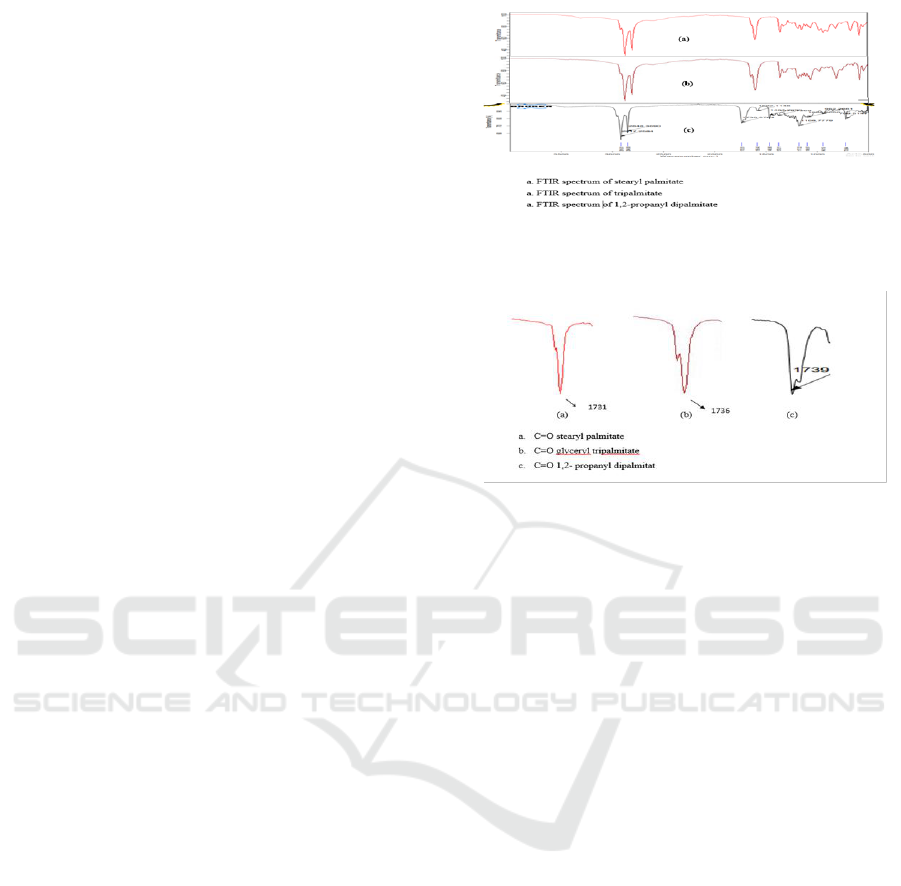

3.2 Spectroscopy FT- IR

Product glyceryl tripalmitate shows wave number (ν

C=Ocm-1) 1731, 1,2-propanyl dipalmitate 1739 and

strearyl palmitate 1736. Figure 1 shows feature of

FT IR spectrum of the esters.

Figure 1: FT-IR Spectrum of the Esters.

Figure 2: Carbonyl fashion on FT IR.

Spectrum FT IR shows on stearyl palmitate

perform a single band C=O) at 1731 cm

-1

with trace

band at 1735 cm

-1

(unknown) while in glyceryl

tripalmitate shows two bands C=O, 1740 cm

-1

(shoulder) and 1736 cm

-1

(strong band) may be

indicated two types of ester resulted 1 and 3 carbon

atom which are equal contribution to IR spectra and

the other one resulted from carbon atom 2 . The

similar mode has also been indicated on 1,2-

propanyl dipalmitate.

Analysis on

1

H NMR (500MHz, CDCl3) and

13

C

NMR (125 MHz, CDCl

3

). The data collected as

below:

a) Stearyl palmitate: 1H NMR δ (ppm) 0.86 -

0.90 (br m, 6H), δ 1.26 - 1.30 (br s, 54H), δ

1.57-1.65 (br m, 4H), δ 2.29 (t, 2H), δ 4.05

(t, 2H)

13

C NMR( 125 MHz, CDC

13

) δ (ppm)

13.98, 22.13, 24.53, 25.54, 28.57, 28.73,

28.77, 28.93, 29.00, 29.05, 31.32, 32.57,

33.70, 60.76, 174.53.

b) Glyceryl tripalmitate: 1H NMR δ (ppm)

0.86 - 0.90 (br m, 2H), δ 1.26 - 1.30 (br s,

78H), δ 2.32 (t, 2H), δ 4.32 (t, 1H), δ 5.25

(t, 2H)

13

C NMR( 125 MHz, CDCl3) δ 14.26,

22.85, 24.84, 29.22, 29.28, 29.40, 29.44,

29.52, 29.59, 29.64, 29.75, 29.76, 29.80,

29.81, 29.83, 29.84, 29.85, 32.08, 34.21,

34.36, 62.15, 68.93, 180.21.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

134

c) 1,2-propanyl dipalmitate:

1

H NMR δ(ppm)

0.86 - 0.90 (t, 3H), δ 1.19- 1.30 (br s, 27H),

δ 1.57-1.65 (br m, 2H), δ 2.32-3.94 (t, 4H),

δ 4.11 (t, 2H), δ 4.96 (m, 2H), δ 5.14 (m,

1H)

(a)

(b)

(c)

a. Structure of stearyl palmitate

b. Structure of glyceryl tripalmitate

c. Structure of 1,2-propanyl dipalmitate

Figure 3: Chemical Structure of a,b and c.

3.3 Yield of Reaction

Influence of Alcohols with palmitic acid catalyzed

by Pb(NO

3

)

2

.

Stearyl palmitate (1-OH) 97%

Gyceryl tripalmitate ( 3-OH) 90%

1,2- propanyl dipalmitate (2-OH) 95%

The reaction alcohols in a same mole (0.02 mol)

mono, diol and triol with palmitic acid at

stoichiometric reaction gives a range of yield 97%,

95% and 90%. The alcohol might have steric effect

on the reaction that shown in triol less yield of ester

then the two others.

4 CONCLUSIONS

Lead (II) nitrate has a good catalyst esterification for

long chain acid with long chain, multivalent

alcohols. In future work, we need to show the

catalyst performance a simple acid esterfied with a

series alcohol chain.

REFERENCES

Cardoso, A. L; Neves, S C G; and da Silva, M. J., 2009.

Kinetic study of alcoholysis of the fatty acids

catalyzed by tin (II) chloride: an alternative catalyst

for biodiesel production,”Energy and Fuels. 23 (3):

1718–1722.

Da Silva, M J; Goncalves, C E and Laier, L O., 2011,

Novel esterification of glycerol catalysed by tin

chloride (II): a recyclable and less corrosive process

for production of bioadditives,” Catalysis Letters.

141(8): 1111–1117.

Ferreira,A B; Cardoso, A L and daSilva, M J., 2012. Tin-

Catalyzed Esterification and Transesterification

Reactions: A Review

G.M. Ziarani, A. Badiei, Z. Dashtianeh, P. Gholamzadeh,

N.H. Mohtasham., 2013. Application of SiO2–Pr–

SO3H as an efficient catalyst in the Ritter reaction.

Gupta, R; Paul, S; Gupta, R.,c2007. Covalently anchored

sulfonic acid onto silica as an efficient and recoverable

interphase catalyst for the synthesis of 3,4-

dihydropyrimidinones/thiones. Res. Chem. Intermed.

39, 3157– 3163.

J. Mol. Catal. A Chem. 266, 50–54.

Joseph, T., S. Sahoo and S. B. Halligudi (2005) Brönsted

acidic ionic liquids: A green, efficient and reusable

catalyst system and reaction medium for Fischer

esterification. Journal of Molecular Catalysis A:

Chemical, 234, 107-110, ISSN 13811169.

Krause, P., L. Hilterhaus, G. Fieg, A. Liese & U.

Bornscheuer., 2009. Chemically and enzymatically

catalyzed synthesis of C6-C10alkyl benzoates.

European Journal of Lipid Science and Technology,

111, 194-201, ISSN 14387697 14389312.

Martnez, M., R. Oliveros & J. Aracil., 2011. Synthesis of

Biosurfactants: Enzymatic Esterification of Diglycerol

and Oleic Acid. 1. Kinetic Modeling. Industrial &

Engineering Chemistry Research, 50, 6609-6614,

ISSN 0888-5885 1520-5045.

Mbaraka, I. K. & B. H. Shanks., 2006. Conversion of oils

and fats using advanced mesoporous heterogeneous

catalysts. Journal of the American Oil Chemists'

Society, 83, 79-91, ISSN 0003-021X.

Sari, V I; Hambali, E; Suryani, A and Permadi, P., 2017.

Esterification Reaction of Glycerol and Palm Oil Oleic

Acid Using Methyl Ester Sulfonate Acid Catalyst as

Drilling Fluid Formulation. IOP Conference Series:

Materials Science and Engineering, Volume 172, Issue

1, pp. 012062

Vijakumar, B; Mahadevaiah, N; Nagendrappa, G and

Prakash, J., 2012. Esterification of stearic acid with p-

cresol over modified Indian bentonite clay catalyst. J.

Porous Mater. 19: 201–210

C

15

H

31

C O C

17

H

35

O

C

15

H

31

C O CH

2

CH

CH

2

OCC

15

H

31

OCC

15

H

31

O

O

O

C

15

H

31

C O

H

C

H

CHO

CH

3

CC

15

H

31

O

O

Lead (II) Nitrate Catalyzed Esterification Palmitic Acid with Alcohols

135