Distillation of Agarwood Oil (Aquillaria sp) using

Photovoltaic Methods

Nelly Safitri

1

, Teuku Rihayat

2

, Suryani

2

, Shafira Riskina

2

, Rudi Saputra

1

, Aida Safitri

2

,

Tjut Yayang Risqatia Hasnah

2

, Kiki Yolanda Putri

3

and Yuhanis Yunus

3

1

Departement of Electrical Engineering, Politeknik Negeri Lhokseumawe, 24301, Aceh Indonesia

2

Department of Chemical Engineering, Politeknik Negeri Lhokseumawe, 24301, Aceh Indonesia

3

Department of Civil Engineering, Politeknik Negeri Lhokseumawe, 24301, Aceh Indonesia

rudi.syahputra75@gmail.com, aidasafitri853@gmail.com, tjutyayang.risqatia07@gmail.com,

kikiyolanda956@gmail.com, yunusyuhanis@gmail.com

Keywords: Agarwood, Solar Cell, Water Content, Hydro Distillation.

Abstract: The use of solar light is currently used as one of the renewable energy by utilizing sunlight, or commonly

called photovoltaic (PV). One of the technologies related to the application of solar panels to energy by

converting sunlight into electricity is called photovoltaic. The amount of solar energy that can be absorbed

depends on the cell size and absorption of solar cells on sunlight. Solar panels are known as WP (Watt peak)

where this amount is the maximum power produced by each panel unit with a capacity of 100 watts/hour, size

1200 mm x 550 mm with a thickness of 35 mm. The battery used is 12 Volt 200 Ah, and the heater used is

2000 Watt. Agarwood crust is obtained from the Aquillaria malaccensis tree, which is then soaked for 14, 16,

18, 20 and 22 days respectively. The best results of soaking are at 14 days, during which the immersion

process has expanded and finally broken, so that water enters the cell wall through diffusion and increases

turgor pressure. Soaking water becomes more acidic over time and damages the cell wall. This causes the

process of increasing cell wall destruction. However, a longer immersion time causes more oil content to be

wasted into soaking water. It was concluded that the most suitable immersion time for extracting agarwood

oil was 14 days. The results showed that high oil yield was obtained from oil extracted with a 10 hour hydro

distillation sample (0.44% analysis water content). Analysis of chemical compounds using GC-MS showed a

typical compound of agarwood namely Guaiol with the highest value 4.10% (GC-FID) and 1.95% (GC-MS).

Guaiol was used as a parameter to determine the quality of essential oils produced from the distillation process

that has been carried out because the area produced from the test results has an area greater than other

components contained in essential oils.

1 INTRODUCTION

Energy is the ability to do work. Energy is a force that

can be used to carry out various processes of activities

using mechanical energy, heat, and others. Therefore,

almost everyone in the world, based on energy

sources. There is some natural energy as alternative

energy that is not polluted, safe and collected not

limited to what is known as renewable energy [1].

New energy sources and resources that are renewed

in the future will increasingly have a very important

role in meeting energy needs. This is due to the use of

fossil fuels for conventional power plants for a long

time to drain oil, gas and coal sources whose reserves

are depleting [2].

In Indonesia, which is located in the tropics it

actually has a considerable advantage, namely

receiving continuous sunlight throughout the year.

Unfortunately, energy seems to be left in vain only

for natural needs [3]. In addition, solar energy can be

utilized with the help of other equipment, namely by

converting solar radiation to other forms. There are

two kinds of ways to convert solar radiation into other

energy, namely through solar cells and collectors [4].

There is no doubt that solar energy is an

environmentally friendly energy source and is very

promising in the future because there is no pollution

produced during the energy conversion process, and

also many energy sources available in nature [5].

Safitri, N., Rihayat, T., Suryani, ., Riskina, S., Saputra, R., Safitri, A., Risqatia Hasnah, T., Putri, K. and Yunus, Y.

Distillation of Agarwood Oil (Aquillaria sp) using Photovoltaic Methods.

DOI: 10.5220/0008853300570062

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 57-62

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

57

The sun is a potential energy source for human

needs, where energy can be obtained from heat that

moves to the surface of the earth, or light that falls to

the surface of the earth. From several studies

mentioned that by changing sunlight, especially the

intensity of the sun with PV can be used as a source

of electrical energy for human consumption. The

choice of renewable energy sources is very

reasonable considering the supply of solar energy

from sunlight received by the earth's surface reaches

3 x 1024 joules per year [6]. The amount of energy is

equivalent to 10,000 times the energy consumption in

the world today. In Indonesia, the abundance of

sunlight distributed evenly and can be captured

throughout the Indonesian archipelago for most of the

year is a potential source of electrical energy[7].

Renewable energy has a very important role in

meeting energy needs, given the abundant source [8].

This problem because the use of fuel for conventional

power plants over a long period of time will deplete

oil, gas, and coal sources which are running low and

can also cause environmental pollution. Wrong the

only effort that has been developed is the Solar Power

Plant (PLTS).

Solar energy can be applied to produce heat

energy through solar heat collectors (SC) and produce

electrical energy through PV collectors. At present, it

is common practice to install it in two separate solar

collectors, one for solar thermal collectors and one for

photovoltaic modules[9]. Thermal photovoltaic /

hybrid (PV / T) systems are the integration of

photovoltaic and solar thermal components. This

produces electricity and heat from a combined system

[10]. It consists of a conventional heat collector with

an absorbent which is covered by a layer of PV. PV

modules produce electricity, and simultaneously the

heat energy absorbed is transported by the working

fluid [11].

In the industrial world, distillates of essential oils

are known as perfume seeds. The process of

extracting and refining essential oils requires

equipment at very expensive prices, so that essential

oils do not become a household industry with a small

scale of production. This essential oil is used in food,

medicine, and cosmetics, etc. So for this reason, it is

necessary to develop alternatives to develop PV

technology that is environmentally friendly in the

process of refining essential oils. This PV installation

has many advantages, said to be an overall increase in

efficiency, lower production and installation costs,

and less space requirements[12].

Therefore, the purpose of this study is to improve

the extraction efficiency of oil obtained from different

extraction methods and to identify optimal

parameters of agarwood extraction. The stages

carried out in this study were materials and tools,

refining techniques, photovoltaic methods, and

chemical analysis using Gas Chromatography-Flame

Ionization Detector (GC-FID) and Gas

chromatography with Mass Spectrometry (GC-MS).

2 MATERIALS AND METHOD

2.1 Plant Material

Agarwood crust from the Aquillaria malaccensis

stem used in this study was obtained from Keuramat,

North Aceh intersection, water, and a set of hydro

distillation devices.

2.2 Optimization Technique

The technique used in this distillation process is

hydro distillation process. In this case, the sample size

and immersion time as a control to get the maximum

value from the optimal parameters. Agarwood

samples are initially ground into powder using a

grinding machine (FRITSCH). Agarwood samples

were immersed in 1 liter glass with sample variations

of 14, 16, 18, 20 and 22 days respectively. Samples

were distilled using photovoltaic technology for

approximately 6 hours a day.

Hydro distillation: 15-liter distilled water is

poured into the kettle. 1000 g of agarwood powder is

put in the kettle. Turn on the heater until it reaches

100

o

C. After the distillation time is complete, the

process is stopped. Water and essential oils from

separate funnels. After the water and oil are separated

1 hour apart, the essential oil is taken above the

separating funnel. Extraction is done in triplicate and

the average oil is calculated. The oil is then stored in

a closed container under the coolant before being

analysed by chromatography.

2.3 Photovoltaic Methods

Solar panels used for distillation of essential oils are

1000 WP (peak watts) in this case 6 panels are

needed. The battery capacity is 15 Volt 200 Ah, the

number of batteries used for this essential oil

distillation process is 11 batteries. A 2,000-watt

power heater is used as a heater to agarwood oil

distillation. Then an inverter (AC-DC current

converter) is needed with a capacity greater than 2125

watts [13].

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

58

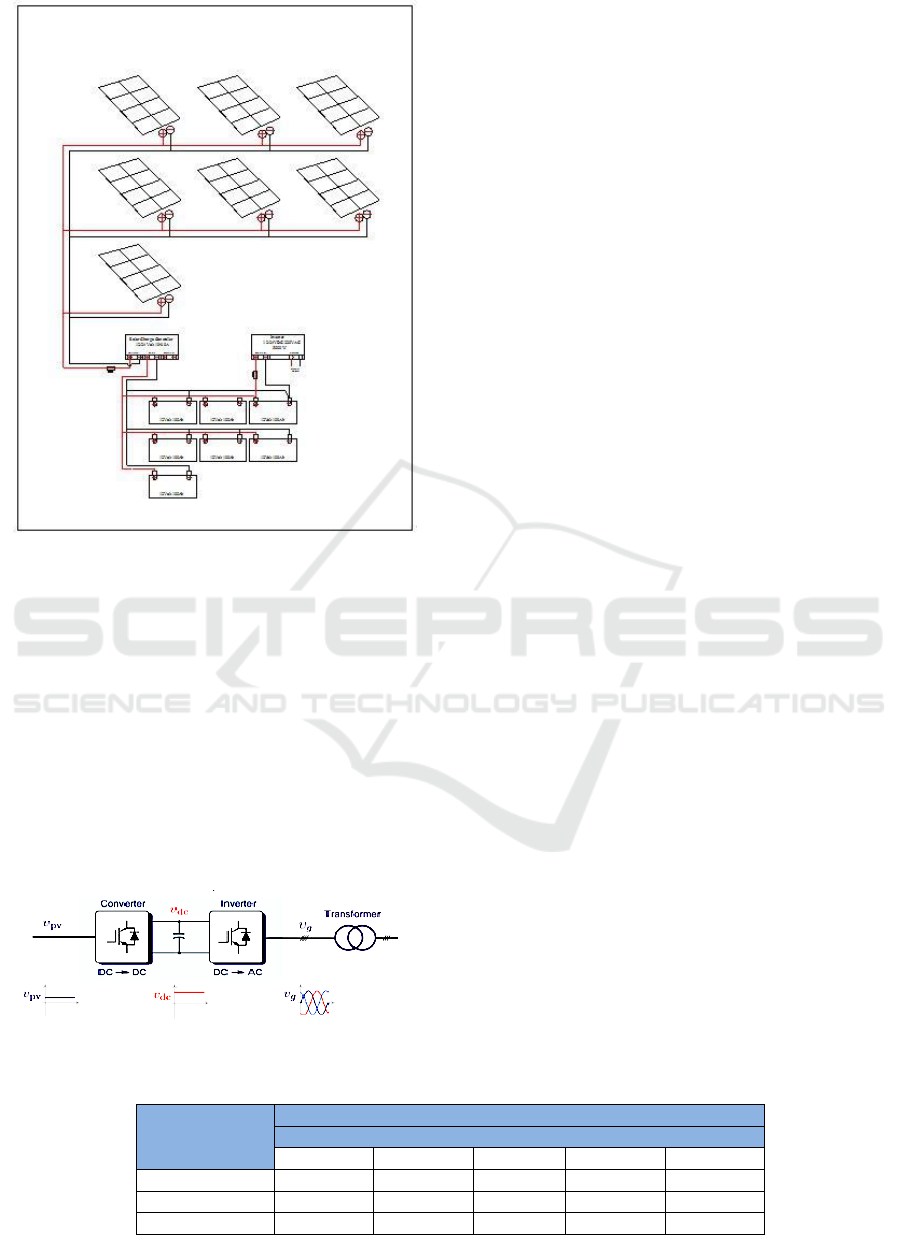

Figure 1: Photovoltaic design.

PV designs is arranged in series and is not connected

to the grid. This system is installed on the rooftop of

the house, PV takes energy from the sun and the

inverter converts it into electrical energy. The energy

is used to run equipment or charge the battery. When

solar panels do not produce energy, then the battery

can be used.

Grid-connected PV is a smart grid system, which

includes PE, such as a DC / DC converter that can

guarantee maximum solar energy harvested through

maximum power point tracking control (MPPT), and

converters used to connect PV to the network [14].

Figure 2: PE through grid-connected PV system.

Figure 1 illustrates the PE that commonly used for the

grid-connected PV system. The inverter extracts as

much DC voltage as possible from the PV array and

converts it into clean mains AC voltage at the right

frequency for feeding into the grid or for supplying

domestic loads at the customer sides[15].

2.4 Chemical Analysis

Chemical constituents of agarwood oil were obtained

by two GC-FID chromatographic techniques (Agilent

7890A) and GC-MS (Agilent 7890A). GC-MS was

attached to a mass spectrometer (Agilent 5975C)

using a DB-1MS capillary column (30 x 0.25 mm ID

film thickness of 0.25μm). Both chromatographic

techniques are the same in operating conditions. The

temperature of the injector and detector was

determined at 250°C. The temperature of the oven

was programmed at 60°C for 3 minutes, increasing at

3°C / minute to 240°C and then increasing for 10

minutes. Helium as a gas carrier is determined at a

flow rate of 1.2 mL / minute. The sample volume

injected was 1.0μL. Components are supported by

retention indices and mass spectra with disputed data

[16] and are in accordance with the library of the

National Standard Technology Institute (NIST). The

GC-FID instrument is equipped with a flame

ionization detector (FID) and detector in full scanning

mode under ionization of electron concentration (EI,

70eV) used in GC-MS [17].

3 RESULT AND DISCUSSION

Pre-treatment process in extracting essential oil is an

important step. Previous studies showed several

methods for pre-treatment of plant samples before

extraction such as immersion in water, chemical

treatments, sonication, and microwave treatments [9].

This research continues the previous research that has

been done. In this study, the immersion process of

agarwood powder was carried out with time

variations of 14,16,18,20 and 22 days and distillation

times of 8, 9 and 10 hours respectively, so that the

water obtained can be seen in table 1.

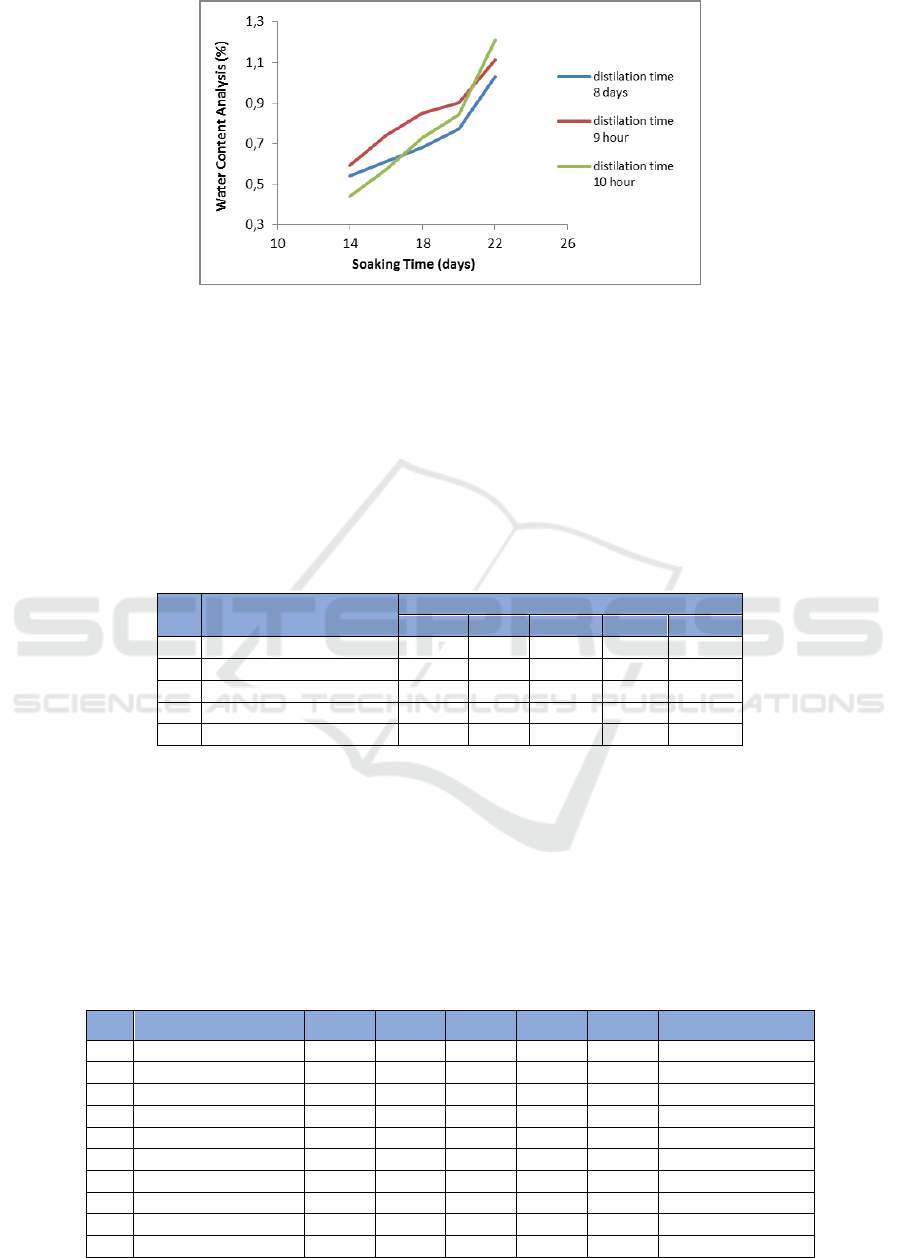

Table 1: Water content value of soaking agarwood oil.

Distilation

time (hours)

Water content analysis (%)

Soaking time (days)

14

16

18

20

22

8

0.54

0.61

0.68

0.77

1.03

9

0.59

0.74

0.85

0.9

1.11

10

0.44

0.57

0.73

0.84

1.21

Distillation of Agarwood Oil (Aquillaria sp) using Photovoltaic Methods

59

Figure 3: Graph Water Content Analysis.

From the analysis of water content shown in table

1, the highest water content was obtained at 10 hours

of soaking time with 22 days which was 1.21% which

identified the produced agarwood oil to be of Poor

quality, while the lowest water content in distillation

was 10 hours with 14 days immersion which is

0.44%. The following are the results of the graph plot

of the data of agarwood immersion water content

values.

During the immersion process, the cells have

expanded and eventually ruptured, releasing the

agarwood content into the soaking water[18]. Water

enters the cell wall through diffusion and increases

turgor pressure. Soaking water becomes more acidic

over time and damages the cell wall. This causes a

process of increasing cell wall damage. However, a

longer immersion time causes more oil content to be

wasted into soaking water[19].

Table 2: Chemical Components Abundances (%) From GC-MS Analysis.

No

Chemical Compounds

Abundances (%)

S14

S16

S18

S20

S22

1

α- Guaiene

5.8

9.79

3.49

4.41

2.8

2

β- Selinene

4.9

16.9

9.06

4.72

13.6

3

α-Muurolene

3.3

3.98

6.09

9.11

0.9

4

γ- Gurjunene

1.09

1.45

2.30

7.43

3.30

5

Guaiol

4.10

5.32

3.98

2.01

2.11

The table above is a tabulation of chemical

composition analysed using GC-MS tools in

agarwood oil samples using the photovoltaic method

with immersion times of 14,16,18,20 and 22 days,

respectively. Based on the results of analysis using

GC-MS it was found that there were 5 compounds

namely α- Guaiane, β-Selinene, α-Muurolene, γ-

Gurjunene and Guaiol as a significant chemical

composition for agarwood oil and could be used as

compound markers in classifying agarwood oil [18].

Based on the table, it can be seen that oil samples with

immersion times 14 days are more effective in

producing better oil quality.

Indicators that can be assessed from GC-MS

analysis can be seen in a line pattern that shows the

intensity of detected component compounds.

Table 3: Chemical Components From GC-MS Analysis.

No

Compound

S14

S16

S18

S20

S22

Identification

1

β- maaliene

0.4

9.21

1.28

1.02

0.7

GC,FID

2

α- Guaiene

5.8

2.79

3.49

4.41

2.8

GC,FID

3

Aromsdendrene

-

3.90

2.11

3.56

0.9

GC,FID

4

Panasinsen

0.7

0.26

2.61

2.93

-

GC,FID

5

β- Selinene

4.9

6.9

9.06

4.72

13.6

GC,FID

6

α- Muurolene

3.3

2.98

6.09

9.11

0.9

GC,FID

7

γ- Guaiene

-

-

5.00

5.09

1.74

GC,FID

8

γ-Eudasmol

-

1.08

0.97

9.54

2.6

GC,FID

9

γ- Gurjunene

1.09

0.45

2.30

7.43

3.30

GC,FID

10

Guaiol

1.95

1.06

1.92

2.01

2.11

GC,FID

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

60

There are several compounds obtained through

GC-FID testing namely β-maaliene, α-Guaiane,

Aromadendrene, Panasinen, β-Selinene, α-

Muurolene, Gu-Guaiane, γ-Eudasmol, γ-Gurjunene

and Guaiol using GC-FID detectors. This fact shows

that the ionization detector contains more chemical

components than other methods. Soaking time in 14

days is more effective in producing better oil quality

than others. All the processes carried out,

photovoltaic technology was successfully carried out

on refining essential oils, one of which was agarwood

oil. Where data acquisition proved significant.

4 CONCLUSIONS

This study is can be concluded as follow, the best oil

is obtained from the results of immersion at 14 days,

which is 0.44% of the water content. Then through

the results of analysis using GC-MS and GC-FID

obtained 5 compounds namely α-Guaiane, β-

Selinene, α-Muurolene, γ-Gurjunene and Guaiol,

respectively, as a significant chemical composition

for agarwood oil and can be used as a marker of

compounds in classifying agarwood oil, whereas 14

days are more effective in producing better oil quality

than others. All the processes carried out, throughout

the photovoltaic technology was successfully carried

out on refining essential oils, one of which was

agarwood oil. Where data acquisition proved

significant.

ACKNOWLEDGEMENTS

The author would like to thank the Directorate of

Student Affairs and Education for Research and

Higher Education Technology in Indonesia and the

research and community center of Politeknik Negeri

Lhokseumawe.

REFERENCES

N. Katayama, S. Osawa, S. Matsumoto, T. Nakano, and M.

Sugiyama, “Solar Energy Materials and Solar Cells

Degradation and fault diagnosis of photovoltaic cells

using impedance spectroscopy,” Sol. Energy Mater.

Sol. Cells, vol. 194, no. January, pp. 130–136, 2019.

I. Mathews, S. N. Kantareddy, T. Buonassisi, and I. M.

Peters, “Technology and Market Perspective for Indoor

Photovoltaic Cells,” Joule, pp. 1–12, 2019.

L. Hernández-callejo, S. Gallardo-saavedra, and V. Alonso-

gómez, “A review of photovoltaic systems : Design ,

operation and maintenance,” Sol. Energy, vol. 188, no.

June, pp. 426–440, 2019.

H. Fu, G. Li, and F. Li, “Performance comparison of

photovoltaic / thermal solar water heating systems with

direct-coupled photovoltaic pump , traditional pump

and natural circulation,” Renew. Energy, vol. 136, pp.

463–472, 2019.

P. Gonçalves, V. Sampaio, M. Orestes, A. González, R.

Monteiro, D. Vasconcelos, M. Aylla, J. Carlos, D.

Toledo, J. Paulo, and P. Pereira, “Photovoltaic

technologies : Mapping from patent analysis,” Renew.

Sustain. Energy Rev., vol. 93, no. May 2017, pp. 215–

224, 2018.

I. Ierides, A. Zampetti, and F. Cacialli, “AC SC,” Curr.

Opin. Green Sustain. Chem., 2018.

E. Tatsi and G. Gri, “Solar Energy Materials and Solar

Cells Polymeric materials for photon management in

photovoltaics,” vol. 196, no. January, pp. 43–56, 2019.

A. Chauhan, V. V Tyagi, and S. Anand, “Futuristic

approach for thermal management in solar PV / thermal

systems with possible applications,” Energy Convers.

Manag., vol. 163, no. February, pp. 314–354, 2018.

H. Mahmoudi, S. A. Abdul-wahab, M. F. A. Goosen, and

S. S. Sablani, “Weather data and analysis of hybrid

photovoltaic – wind power generation systems adapted

to a seawater greenhouse desalination unit designed for

arid coastal countries,” vol. 222, pp. 119–127, 2008.

M. S. Elnozahy, “Technical Impacts of Grid-Connected

Photovoltaic Systems on Electrical Networks — A

Review Technical impacts of grid-connected

photovoltaic systems on electrical networks — A

review Additional information on J . Renewable

Sustainable Energy,” no. May, 2013.

S. Kumar, “Urban Climate Thermal – economic analysis of

a hybrid photovoltaic thermal ( PVT ) active solar

distillation system : Role of carbon credit,” Urban

Clim., vol. 5, pp. 112–124, 2013.

Y. Jia, G. Alva, and G. Fang, “Development and

applications of photovoltaic – thermal systems : A

review,” Renew. Sustain. Energy Rev., vol. 102, no.

December 2018, pp. 249–265, 2019.

N. Safitri, “Different Trends of Hybrid Solar And

Raindrops Energies to Generate Different Trends of

Hybrid Solar And Raindrops Energies to Generate

Photovoltaic,” 2019.

N. Safitri, F. Shahnia, and M. A. S. Masoum, “Stochastic

Analysis Results for Coordination of Single- Phase

Rooftop PVs in Unbalanced Residential Feeders,” no.

July 2018, 2015.

N. Safitri and F. Abdurrahman, “Integration of DC

Households System Generated by Single-Phase

Rooftop PVs into Unbalanced Three-Phase Residential

Feeder,” vol. 4, no. 2, 2017.

S. Seme, K. Sreden, Š. Bojan, and M. Had, “Analysis of the

performance of photovoltaic systems in Slovenia,” vol.

180, no. January, pp. 550–558, 2019.

Z. Zhang, M. Yao, X. Li, Q. Deng, Q. Peng, and J. Zhong,

“Solar Energy Materials and Solar Cells Simultaneous

functional and structural imaging for photovoltaic

Distillation of Agarwood Oil (Aquillaria sp) using Photovoltaic Methods

61

devices,” Sol. Energy Mater. Sol. Cells, vol. 193, no.

January, pp. 101–106, 2019.

T. Rihayat, “Composition on Essential Oil Extraction from

Lemongrass Fragrant by Microwave Air Hydro

Distillation Method to Perfume Dermatitis Production

Composition on Essential Oil Extraction from

Lemongrass Fragrant by Microwave Air Hydro

Distillation Method to Perfume Dermatitis Production,”

pp. 6–11, 2019.

H. Agusnar, B. Wirjosentono, S. Salim, T. Rihayat, and T.

Fauzi, “Synthesis and Characterization of Chitosan

with Addition of Patchouli Oil to Improve Mechanical

Properties Biofilm Synthesis and Characterization of

Chitosan with Addition of Patchouli Oil to Improve

Mechanical Properties Biofilm,” 2018.

Jaafar, Jamiluddin., Januar, P.S·, Mohd, B.M.P., Tezara, C.,

Sharmiza, A., Rihayat, T. "Influence of Selected

Treatment on Tensile Properties of Short Pineapple

Leaf Fiber Reinforced Tapioca Resin Biopolymer

Composites". Journal of Polymers and the

Environment. 2018.

Rihayat, T., Suryani, T. Fauzi., H.Agusnar., B.

Wirjosentono., Syafruddin., Helmi., Zulkifli., P..Alam.,

M.Sami. "Mechanical properties evaluation of single

and hybrid composites polyester reinforced bamboo,

PALF and coir fiber". IOP Conference Series: Materials

Science and Engineering. Vol.334. Pp 1-8, 2018.

T. Rihayat, M. Saari, M. H. Mahmood, W. M. Z. W. Yunus,

A. R. Suraya, K. Z. H. M. Dahlan, and S. M. Sapuan,

“Mechanical Characterisation of Polyurethane / Clay

Nanocomposites,” vol. 15, no. 8, pp. 647–652, 2007

T. Rihayat, J. P. Siregar, and M. Yunus, “Synthesis and

Characterization of North Aceh CEC Bentonite

Determination with Methylene Blue Method and

Increased D-Spacing after Addition of Surfactants

CTAB-SDS Synthesis and Characterization of North

Aceh CEC Bentonite Determination with Methylene

Blue Method and Increased D- Spacing after Addition

of Surfactants CTAB-SDS,” 2019.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

62