Application of Grey Linear Regression Combined Model in

Predicting the Motor Oil Wear Particles for Passenger Cars

Chunjiang Bao

1, a, *

, Zhikuan Wang

1, b

, Lipeng Xu

1, c

1

College of Mechanical and Automotive Engineering, Liaocheng University, Liaocheng Shandong, China

Keywords: Passenger car, engine oil, particle content, grey linear regression combination model.

Abstract: A new model is established by combining the grey model and the linear regression model to synthesize the

advantages of the two models, and then the number of oil wear particles in passenger cars is predicted. The

three models are used to predict and compare the particle content of different levels of passenger car oil.

The prediction results of wear particles in the SJ oil for No.1 passenger car show that the prediction

accuracy of the grey linear regression combined model are higher than the linear regression model

(1.85%) and the grey model (0.29%), and for the SL oil are 1.34% and 0.45%, respectively. For No.2

passenger car, the prediction accuracy is increased by 2.86% in SJ oil and 1.28% in SL oil for the linear

regression model, and 0.12% in SJ oil and 2.62% in SL oil for the grey model. The results indicated that the

combined model has better prediction effect, and it can be applied to the prediction of oil wear particles in

passenger cars. Through the prediction of combined model and the judgment of cleanliness grade, it can

provide the basis for automobile to replacement oil by quality.

1 INTRODUCTION

As a result of the relative movement between the

friction pairs during operation, the oxidation

products produced by oil oxidation and the entry of

external gravel will accelerate the wear of the engine,

resulting in an increase in the number of wear

particles in the oil, which will accelerate the

deterioration of oil quality. In addition, oil

replacement prematurely will cause oil waste, and

oil replacement too late will make the number of

wear particles in the oil exceeding the standard,

accelerating the deterioration of oil quality. The

deterioration of oil has a great harm to the engine of

passenger cars, and the use of degraded oil for a long

time will accelerate the corrosion and wear of engine

parts, leading to serious mechanical faults, so the

problem of oil replacement according to the quality

has been widely concerned by people.

At present, there are many models currently used

for prediction, mainly including grey models, linear

regression models, time series models, and various

combined models. (Y. Wang, et al, 2013) adopted the

combined models based on the variance reciprocal

and the optimal weighting are applied to optimize

the forecasting model. The accuracy of forecast

models on passenger and freight traffic volume has

been improved, which provides a reasonable basis

for the planning and development of the

transportation system. (S.Z. Chen, et al, 2019).

Unbiased model and sliding GM (1, 1) model were

combined with BP neural network optimized by

genetic algorithm (GA), and a combined forecasting

model of GA-grey neural network was obtained,

which took into account the advantages of grey

theory, genetic algorithm and BP neural network.

Finally, the effectiveness of the proposed

combination model was verified with specific

examples. (H. Hao, et al, 2018). Presented a

combined prediction model consisting of a grey

model, exponential smoothing and an artificial

neural network optimized by the particle swarm

optimization (PSO) algorithm. The prediction of the

number of end-of-life vehicles to be recycled in this

paper will support the end-of-life vehicle recycling

industry in terms of recycling management and

investment decision-making and provide a reference

for the formulation and implementation of policies

relating to end-of-life vehicles. (Tobita, Mikio, et al,

2016)l combined the logarithmic and exponential

decay functions and developed methods for

obtaining global solutions using nonlinear least

squares calculations for such complex functions.

38

Bao, C., Wang, Z. and Xu, L.

Application of Grey Linear Regression Combined Model in Predicting the Motor Oil Wear Particles for Passenger Cars.

DOI: 10.5220/0008850800380049

In Proceedings of 5th International Conference on Vehicle, Mechanical and Electrical Engineering (ICVMEE 2019), pages 38-49

ISBN: 978-989-758-412-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Their models significantly improved the fitting

performance of the postseismic time series and the

prediction performance of the evolution of

postseismic deformation. (F.L. Ren, et al, 2018)

adopted the optimized multiple linear regression

model and grey GM(1,1)model to forecast the power

demands of Shaanxi Province in recent years and

obvioused that the prediction model has the high

accuracy. To improve the prediction accuracy of

bridge structure deformation. (J.Z. Xin, et al, 2018)

based on data mining and to accurately evaluate the

time-varying characteristics of bridge structure

performance evolution, this paper proposes a new

method for bridge structure deformation prediction,

which integrates the Kalman filter, Autoregressive

Integrated Moving Average Model (ARIMA), and

Generalized Autoregressive Conditional

Heteroskedasticity (GARCH). Finally, this paper

provides a new way for structural behavior

prediction based on data processing, which can lay a

foundation for the early warning of bridge health

monitoring system based on sensor data using

sensing technology. (Y. Han, 2016) used grey

prediction theory to construct the grey model GM (1,

1) and linear regression weighted combination

model, used to predict the settlement of subgrade.

The studies show that the model has a certain

practical application value and provides a new way

for the study of subgrade settlement prediction. (D.

Liang, et.al, 2014) verified the feasibility of this

combination model is verified through the example.

It can obtain higher prediction accuracy by

collecting relative little data. The combination model

has a lot of advantages in the machine tool sales

forecast. (K.P. Bi, et al, 2016) verified the gray-linear

regression combined model is proved to be valid and

more accurate forecasting method compare with

single forecasting model through practical example.

(B. Zeng, et al, 2013) used the inverse accumulation

generator of the original sequence, the non-

homogeneous exponential incremental sequence is

transformed into homogeneous exponential

incremental sequence, and then a DGM (1, 1) model

is established using the new sequence. Finally, two

examples are given to illustrate the simplicity,

practicability and operability of the model. (N. Tian,

Y. Wei. 2018) Based on the direct modeling of the

approximate non-homogeneous exponential discrete

grey model, this paper constructs a new grey

forecasting model, which not only improves the

modeling accuracy of approximate non-

homogeneous exponential sequences, but also

extends the application scope to such cases as the

combination of the increasing-decreasing sequence.

Finally, examples are employed to verify the

effectiveness and feasibility of the proposed method.

(Y.X. Jiang, Q.S. Zhang, 2015) Based on the recursive

solution to unbiased GM (1, 1) model, proposed the

method of time series piecewise representation. The

results show that the recursive model has higher

fitting precision, and also verify the effectiveness

and the practicability of the representation method of

time series based on the grey forecasting model.

(H.R.Zhao, X.Y.Han, S.Guo, 2018) presented a hybrid

annual peak load forecasting model (MVO-DGM (1,

1). The model uses the latest optimization algorithm

MVO (multi verse optimizer) to determine the two

parameters of DGM (1, 1) model, and then uses the

optimized DGM (1, 1) model to predict the annual

peak load. Taking the annual peak load of Shandong

Province from 2005 to 2014 as an example, the

analysis results show that the DGM (1, 1) model

parameter determination method based on MVO

algorithm has significant advantages over the least

square estimation method, particle swarm

optimization and Drosophila optimization algorithm.

In this paper, the CSI 5200 Three Vector Oil

Analyzer is used to detect and analyze the oil of

passenger cars of different grades, and the number of

wear particles in the oil is obtained, and then the

degree of deterioration of engine oil quality and the

wear condition of the engine are judged according to

the cleanliness grade. Because the analysis cost of

deterioration degree of passenger locomotive oil is

higher, the analysis period is longer, and the data

obtained is relatively less, the grey model is selected

to predict the deterioration degree of passenger

locomotive oil. The grey model is suitable for data

prediction in exponential form, which is not

consistent with the linear rule of actual data.

Therefore, this paper chooses the combination of

grey model and linear regression model to form a

new combination model for forecasting and analysis,

which can not only make up for the lack of linear

law in grey model, but also give full play to the

advantages of grey model, thus improving the

limitations of single model and improving the

accuracy of forecasting (J.F. Jing, K.C. Li, F.K. Deng,

et al, 2015). Due to the different temperatures, loads

and rotational speeds, the chemical composition of

the wear particles is likely to be not the same, which

also has an impact on the number of wear particles.

In this paper, the prediction of wear particles is

carried out under the same wear mechanism.

Application of Grey Linear Regression Combined Model in Predicting the Motor Oil Wear Particles for Passenger Cars

39

2 EXPERIMENTAL METHOD

2.1 Experimental Materials and

Instruments

The three vector oil analyzer (CSI 5200) is used to

detect and analyze the SVW71612BS type Shanghai

Volkswagen new santana sedan, which can quickly

obtain the number of wear particles in the oil. CSI

5200 three vector oil analyzer can carry out viscosity

measurement, dielectric constant measurement,

moisture measurement and particle count. Two

passenger cars (No.1 and No.2) equipped with CPD

engines are selected, and the oil selected by the

engines of the two passenger cars is the oil with a

viscosity rating of SAE 15W/40, a performance

rating of API SJ, a viscosity rating of SAE 10W/40,

and a performance rating of API SL. Two passenger

cars are in good condition and the road conditions

are flat. As the passenger cars used to take on the

driving training task, so the engine working

conditions are relatively bad. Typically, drivers of

passenger cars replace oil when their passenger car

mileage reaches about 5000 km. The passenger car

uses a special sampler to extract oil once per 1000

km of travel, and adds the same amount of new oil

to the same model. During the experiment, the oil is

heated to 40°C and the number of particles in the oil

is measured using the CSI 5200 three vector oil

analyzer.

2.2 Selection of Experimental Data

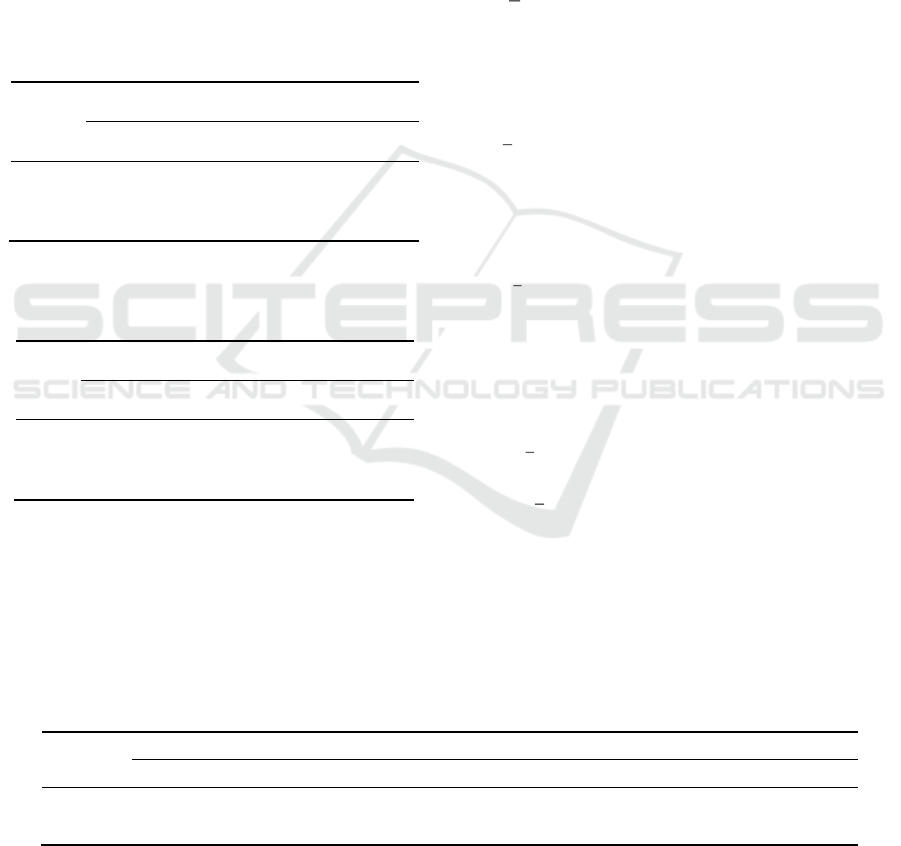

The trend of change in the number of 5~15μm wear

particles per milliliter in the oil of the No.1 and No.2

passenger cars measured by the experiment is shown

in Figure1.

In the process of oil circulation, large wear

particles will be filtered out by the oil filter, and

small particles will continue to flow with the oil,

when the number of particles increased to a certain

extent, it is necessary to replace the oil, otherwise

the oil passage will be blocked, leading to serious

accidents. As can be seen from Figure1a and

Figure1b, the change in the number of 5~15μm wear

particles per milliliter in No.1 and No.2 passenger

cars is more obvious, to some extent, which can

reflect the degree of deterioration of the engine oil

quality and the condition of engine wear. Therefore,

taking the number of 5~15μm wear particles per

milliliter in passenger car oil of two different grades,

SJ Grade and SL Grade as an example, the grey

linear regression combined model is used to predict

the deterioration degree of the engine oil quality.

(a) Passenger car No.1

(b) Passenger car No.2

Figure 1. Number of particles 5~15μm per milliliter in

different grades of engine oil.

2.3 Oil Cleanliness Analysis

Clean lubricating oil can extend the service life of

mechanical equipment, improve the operating

efficiency of equipment, different equipment have

different requirements on the cleaning degree of

lubricating oil, steam turbines and hydraulic systems

require high cleanliness of lubricants, while the

internal Combustion engines require relatively low

requirements. The relationship between the degree

of lubricating oil cleanliness required by different

equipment and the ISO 4406 cleanliness level is

shown in Table 1 (B. Chen, J.G. Wang , 2012;X. Xiao,

H. Guo, S. Mao, 2014). As the mileage of passenger

cars increases, changes in the ISO 4406 cleanliness

level for No.1 and No.2 passenger cars oil are shown

in Table 2 and Table 3.

20000

25000

30000

35000

40000

1000 2000 3000 4000 5000

Number of particles

/mL

Driven distance /km

SJ grade engine oil

SL grade engine oil

25000

30000

35000

40000

1000 2000 3000 4000 5000

Number of particles

/mL

Driven distance /km

SJ grade engine oil

SL grade engine oil

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

40

Table 1. Relationship between the cleaning degree of

lubricating oil required by different equipment and the

ISO 4406 cleanliness level.

Oil

product

Turbine

oil

Hydraulic

oil

Gear

oil

Internal

combustion

engine oil

12/9

very

clean

very

clean

-

-

14/11

very

clean

very

clean

very

clean

-

16/13

clean

clean

very

clean

very clean

18/15

dirty

dirty

very

clean

very clean

20/17

dirty

dirty

dirty

clean

22/19

dirty

dirty

dirty

dirty

24/21

dirty

dirty

dirty

dirty

Note: 22/19 means that if the number of particles

larger than 5 μm is within 20000~40000 per

milliliter of oil, the grade is 22; more than 15μm. If

the number is within 2500~5000, the rating is 19

Table 2. ISO 4406 cleanliness level for different grade

passenger car oils for passenger car No.1.

Grade

Driven distance /km

0

1000

2000

3000

4000

5000

SJ

grade

19/16

22/16

22/16

22/15

22/15

22/16

SL

grade

18/15

22/15

22/15

22/15

22/15

22/15

Table 3. ISO 4406 cleanliness level for different grade

passenger car oils for passenger car No.2

Grade

Driven distance/km

0

1000

2000

3000

4000

5000

SJ

grade

19/16

22/16

22/16

22/15

22/15

22/16

SL

grade

19/15

22/15

22/15

22/15

22/16

22/16

As can be seen from Table 2 and Table 3, the

cleanliness level of the new oil is between

18/15~20/17, indicating that the new oil is clean.

With the increase in mileage of No. 1 and No. 2

passenger cars, the ISO 4406 grade of two grades of

passenger car oil is between 18/15~22/19, and

according to the cleanliness level required by the

internal combustion engine, it is indicated that no

replacement oil is required when the passenger car

mileage reaches 5000km. According to Tables 1, 2

and 3, as well as the cleanliness grade, two different

grades of oil contain a large amount of wear

particles of about 5μm, which easily lead to engine

lubrication system blockage and siltation. This

means that when the oil flows through the oil filter,

some of the large particles will be filtered out and

the small particles will flow with the oil. When the

cleaning level of oil reaches 22/19, the oil should be

replaced in time.

3 GREY LINEAR REGRESSION

COMBIMATION MODEL

In 1982, Professor Deng proposed a new system

theory method for studying the problem of less data

and uncertainty of poor information, which is the

grey system theory (J.S. Wang, 2015). The core of

Grey system theory is grey model, and the grey

model is suitable for the prediction of the

development trend of the original series with

exponential growth, without considering the actual

situation with linear law, the prediction effect is

often poor. Linear regression model is only a linear

description of the future development trend, for the

change of large data prediction results are quite

different. The new model, which combines the grey

model with the linear regression model, is called the

grey linear regression combined model (Y.B. Zhou,

L.F. Jiao, 2008). The linear regression model is

combined with the grey model to avoid the

disadvantage of a single model and to draw on each

other's strengths, which can improve the prediction

accuracy of the model.

3.1 Model Establishment

The process of establishing a grey linear regression

combination model is as follows:

The original number be listed as:

))(,),2(),1((

000

0

nxxxX

(1)

Perform an accumulation of the original series

0

X

to get a new series:

))(,),2(),1((

1111

nxxxX

(2)

Wherein:

k

i

nkiXkX

1

01

),,2,1(),()(

,

Finding the first-order differential equation for the

new series:

bax

dt

dx

1

1

(3)

Application of Grey Linear Regression Combined Model in Predicting the Motor Oil Wear Particles for Passenger Cars

41

Among them, 𝑎 is he development coefficient,

which 𝑏 is the amount of grey action. When 𝑡

represents the unit time, the differential form of the

differential equation is equal to the differential form,

that is:

)()()1(

011

1

txtxtx

dt

dx

(4)

Therefore, the differential equation of the

)1,1(GM

model can be expressed as:

btaxtx )()(

10

(5)

The formula (5) is called the original form of the

)1,1(GM

model.

Find the solution of (3):

a

b

e

a

b

xtx

at

))1(()(

11

(6)

For convenience, record as:

21

1

)1(

ˆ

cectx

t

(7)

Linear regression equations such as

baxy

and exponential equations such as

x

cey

are used

to fit the cumulative sequence

)(

1

tX

, thus, a new

model sequence is generated, and seek its

undetermined coefficients. The new sequence is:

321

1

)(

ˆ

ctcectx

t

(8)

Wherein, c1, c2, c3 is the undetermined

coefficient. In order to obtain the parameters, the

sequence of parameters is:

11

( 1)

1 2 3 1 2 3

( ) ( 1) ( ) ( 1)

t

Z t X t X t ce c t c c e t c t c

21

)1( ceec

t

(9)

Wherein:

1,,2,1 nt

.And assume that:

1 1 1 1

ˆ ˆ

( ) ( ) ( 1) ( ) ( 1) ( )

m

X Z t m Z t X t m X t m X t X t

)1)(1(

1

eeec

mt

(10)

Transform equation (10):

)1)(1(

)1)(1(

)(

)1(

1

)1(

1

eeec

eeec

tX

tX

mt

mt

m

m

e

(11)

In order to obtain the solution

, the two sides

are derived:

)(

)1(

ln

tX

tX

m

m

(12)

When

m

takes different values, the

corresponding

value will be obtained, find the

average value of

of

, and use

as the

estimated value of

, thereby improving the

precision of

. The steps are as follows:

)1()2(2)3()1()2()1(

111

1

XXXZZX

1 1 1

1

1 1 1

1

(2) (3) (2) (4) 2 (3) (2)

( ) ( 1) ( ) ( 2) 2 ( 1) ( )

X Z Z X X X

X m Z m Z m X m X m X m

Determined by (12):

)1()1(

11

m

)2()1(

22

m

)3()1(

33

m

)1(

1m

The average value is obtained:

)1(

)(2

1

1

mm

j

m

i

im

j

i

(13)

Wherein: m=n-2. If

)exp( tL

t

, the equation (8)

can be transformed:

321

1

ˆ

ctcLcX

t

(14)

Using the least squares method, the estimated

values of

321

,, ccc

are obtained.

1

1

1

1

2

3

1

(1)

(1) 1 1

(2) 2 1

(2)

,,

( ) 1

()

x

L

c

L

x

X C c A

c

L n n

xn

(15)

Then

ACX

1

, the values of c1, c2, c3 are

obtained using the least squares method. Bring it

into equation (8) and get the prediction formula for

the combined model:

321

1

)( ctcectX

t

(16)

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

42

Wherein, c1, c2, c3 are the undetermined

coefficients.

3.2 Model Test

The combined model residuals is:

)(

ˆ

)()(

10

ixixiq

(17)

The Relative error is:

)(

)(

)(

0

ix

iq

i

(18)

The average relative error is:

n

i

i

n

avg

2

)(

1

1

)(

(19)

The model accuracy is:

%100))(1( avgp

(20)

It is generally believed that when

%90p

, the

accuracy is acceptable, that is, the model can be used.

The accuracy level is shown in Table 4 (

Y Zhou, Y

Luo, SM Jia, et al, 2014)

.

Table 4. Predictive model accuracy division.

Predictive model accuracy

level

P value

First grade

99%

Two grade

95%p99%

Three grade

90%p95%

Four grade

90%

4 APPLICATION OF GREY

LINEAR REGRESSION

COMBIMED MODEL

4.1 Linear Regression Model

Prediction

The linear regression model is an equation of the

form

baxy

. From the experimental data, the

prediction equations for the number of wear particles

of 5~15μm per milliliter in the different grades of

the No.1 passenger cars are:

1

3.77444 19193.08

SJ

yx

(21)

1

2.8827 24540

SL

yx

(22)

Similarly, the prediction equations for the

number of 5~15μm wear particles per milliliter in

different grades of the No.2 passenger car are:

2

SJ

0.9811 2499.60yx

(23)

2

0.4288 20496.19

SL

yx

(24)

The results of predicting the number of 5~15μm

particles per milliliter in different grades of oil

through the above equations are shown in Tables 5

and 6.

Table 5. Number of particles 5~15μm per milliliter in

different grades of motor oil on the 1st passenger car

(pieces).

Grade

Driven distance /km

1000

2000

3000

4000

5000

SJ

grade

22968

26742

30516

34291

38065

SL

grade

27422

30305

33188

36071

38954

Table 6. Number of particles 5~15μm per milliliter in

different grades of motor oil on the 2nd passenger car

(pieces).

Grade

Driven distance /km

1000

2000

3000

4000

5000

SJ

grade

25640

27655

29631

31572

35408

SL

grade

27988

30740

32344

34408

36719

4.2 Grey Model Prediction

The equation of the form

baey

x

is the grey

model equation. Using MATLAB for data fitting,

the prediction equations of the number of 5~15μm

wear particles per milliliter in different grades of oil

in No.1 passenger car are:

1 0.875

58374.5645 35142.4821

t

SJ

ye

(25)

1 0.684

45862.8695 19849.2547

t

SL

ye

(26)

Application of Grey Linear Regression Combined Model in Predicting the Motor Oil Wear Particles for Passenger Cars

43

Similarly, the prediction equations for the

number of wear particles per milliliter of 5~15μm in

the different grades of the No.2 passenger car are:

2 0.578

42178.75 17298.215

t

SJ

ye

(27)

2 0.854

53117.296 28832.795

t

SL

ye

(28)

Through the above formula, the number of

particles of 5~15μm per milliliter in different grades

of oil is predicted, and the results are shown in Table

7 and Table 8.

Table 7. Number of particles 5~15μm per milliliter in

different grades of motor oil on the 1st passenger car

(pieces).

Grade

Driven distance /km

1000

2000

3000

4000

5000

SJ

grade

23227

27008

30453

33561

36333

SL

grade

26991

29723

32858

36274

39042

Table 8. Number of particles 5~15μm per milliliter in

different grades of motor oil on the 1st passenger car

(pieces).

Grade

Driven distance /km

1000

2000

3000

4000

5000

SJ

grade

25740

27685

30421

32894

36841

SL

grade

25482

28156

31856

34258

38563

4.3 Combined Model Prediction

(1) Model establishment

The grey linear regression combined model is

established by using the number of 5~15μm particles

per milliliter in the SJ grade oil of No. 1 passenger

car as the original series:

3630435132319112549323742

0

X

After a cumulative increase:

152582116278811464923523742

1

X

When

1m

:

1

(1) (2) (1) 6418X Z Z

1

(2) (3) (2) 3221X Z Z

1

(3) (4) (3) 1172X Z Z

The solution:

01.1)2(,69.0)1(

11

.

When

2m

, Similarly, it can be obtained that:

1172)2(,3221)1(

22

XX

. From the formula, it

can be obtained that:

69.0

2

. It can be obtained

that

9.0

. From MATLAB, it can be obtained

that:

]89.3075486.201528.27521[C

The prediction formula for the number of

5~15μm particles per milliliter in the SJ grade oil of

No.1 passenger car can be obtained:

1 0.9

( ) 27521.28 2015.86 30754.89

t

SJ

X t e t

(29)

Similarly, the prediction formula for the number

of 5~15μm particles per milliliter in SL grade Oil of

No. 1 passenger car is:

1 0.6035

( ) 18963.41 5241.25 28756.95

t

SL

X t e t

(30)

According to the derivation of the above formula,

the prediction formulas for the number of particles

of 5~15 μm per milliliter in the different grades of

the passenger car of No. 2 passenger car are:

2 0.75

SJ

( ) 35274.52 4625 15247.12

t

X t e t

(31)

2 0.81

( ) 25874 3589 8952.86

t

SL

X t e t

(32)

From the prediction formulas (29),(30) and

formulas (31), (31), the number of particles of 5~15

μm per milliliter in different grades of oil can be

obtained. The results are shown in Table 9 and Table

10.

Table 9. Number of particles 5~15 μm per milliliter in different grades of motor oil on the 1st passenger car (pieces).

Grade

Driven distance /km

1000

2000

3000

4000

5000

SJ grade

23576

26788

30942

34789

36567

SL grade

25785

28952

32245

35365

37154

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

44

Table10. Number of particles 5~15 μm per milliliter in different grades of motor oil on the 1st passenger car (pieces).

Grade

Driven distance /km

1000

2000

3000

4000

5000

SJ grade

25425

27523

30425

33986

37425

SL grade

26895

28452

30487

33721

35154

(2) Model test

According to Table 9 and Table 10 and formulas

(17) and (18), the residuals and relative errors of the

5~15μm particles per milliliter and the predicted

values of the grey linear regression combination

model are obtained. The results are shown in Table

11 and Table 12.

From the data in equations (19), (20) and Table

11 and Table 12, the average errors of the grey linear

regression combined model of No.1 passenger car

are 2.1% and 4.61% respectively, and the accuracy

are 97.99%, 95.38%. The average errors of the grey

linear regression combined model of No.2 passenger

car are 1.3%, 2.08% respectively, and the accuracy

is 98.7%, 97.92%, respectively. According to the

classification of prediction accuracy in Table 3, the

prediction accuracy level of the number of 5~15μm

particles per milliliter in different grades of oil using

the combined model is level-2. The grey linear

regression combined model can be applied to the

prediction of oil wear particles in passenger cars.

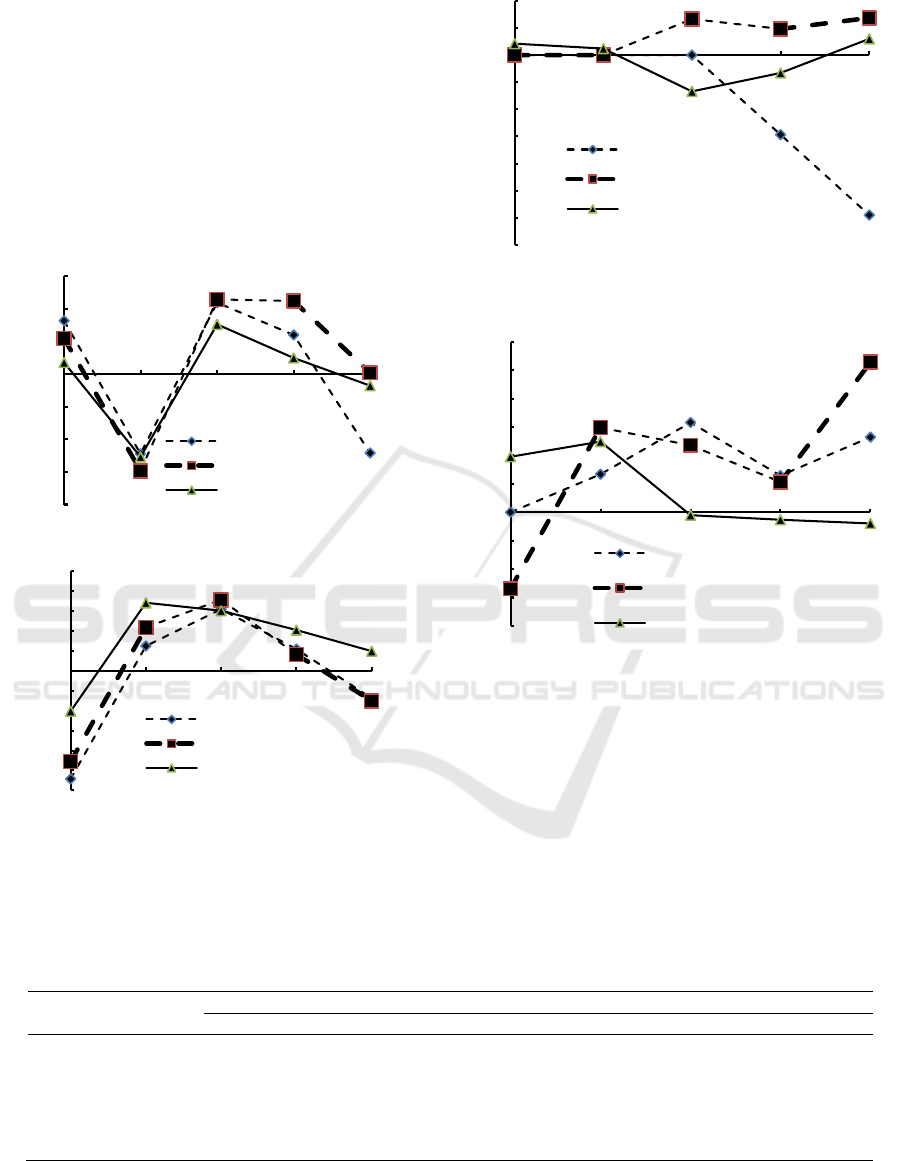

4.4 Model Comparison

Through the prediction of three models, it can be

found that the prediction value of 5~15μm particles

per milliliter of different grades in passenger car oil

is obtained. Compared with the measured values, the

trend of the number of 5~15μm particles per

milliliter of different grades in No.1 and No.2

passenger cars is obtained, which is shown in Figure

2 and Figure 3.

Table 11. Residual and relative error of predicted values of passenger car combination model No.1.

Driven distance /km

1000

2000

3000

4000

5000

SJ

grade

Measured value

23742

25493

31911

31911

31911

Predictive value

23576

26788

30942

34789

36567

Residual

166

-1295

969

343

-263

Eerror/%

0.7

-5.08

3.04

0.98

-0.72

SL

grade

Measured value

24739

31084

35391

36882

37910

Predictive value

25785

28952

33245

35365

37154

Residual

-1000

2132

3146

1517

756

Error/%

-4.04

6.86

6.06

4.11

1.99

Table 12. Residual and relative error of predicted values of passenger car combination model No.2.

Driven distance /km

1000

2000

3000

4000

5000

SJ

grade

Measured value

25640

27655

29632

33542

37879

Predictive value

25425

27523

30425

33986

37425

Residual

215

132

-793

-444

454

Error/%

0.84

0.48

-2.68

-1.32

1.20

SL

grade

Measured value

27988

29940

30424

33542

34879

Predictive value

26895

28452

30487

33721

35154

Residual

1093

1488

-63

-179

-275

Error/%

3.91

4.97

-0.21

-0.53

0.79

Application of Grey Linear Regression Combined Model in Predicting the Motor Oil Wear Particles for Passenger Cars

45

(a) SJ grade engine oil

(b) SJ grade engine oil

Figure 2. Comparison of predicted values of 5~15μm particles per milliliter in different grades of passenger car No.1.

(a) SJ grade engine oil

(b) SL grade engine oil

Figure 3. Comparison of predicted values of 5~15μm particles per milliliter in different grades of passenger car.

According to the prediction results and the

cleanliness grade analysis of the combined model,

the number of 5~15μm particles per milliliter of

different grades in passenger car oil does not exceed

40000. At this time the oil is clean and does not need

to be replaced. While if the number of 5~15μm

particles per milliliter in the oil exceeds 40000, the

oil cleanliness has exceeded the passenger car

22000

27000

32000

37000

1000 2000 3000 4000 5000

Number of particles

/mL

Driven distance/km

Measured value

Linear regression model predictive value

Grey model prediction

Combined model prediction

22000

24000

26000

28000

30000

32000

34000

36000

38000

40000

1000 2000 3000 4000 5000

Number of particles

/mL

Driven distance/km

Measured value

Linear regression model predictive value

Grey model prediction

Combined model prediction

22000

24000

26000

28000

30000

32000

34000

36000

38000

40000

1000 2000 3000 4000 5000

Number of particles

/mL

Driven distance/km

Measured value

Linear regression model predictive value

Grey model prediction

Combined model prediction

22000

24000

26000

28000

30000

32000

34000

36000

38000

40000

1000 2000 3000 4000 5000

Number of particles

/mL

Driven distance/km

Measured value

Linear regression model predictive value

Grey model prediction

Combined model prediction

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

46

engine requirements of the cleaning degree of oil.

There are too many impurities in the oil, and it can

not continue to use. Otherwise, it will accelerate the

deterioration of oil quality, resulting in engine wear

failure, and the oil should be replaced in time.

According to the experimental data and the

predicted values of three prediction models, the

relative error and average error of the predicted

value of 5~15μm particles per milliliter in different

grades of oil are obtained and shown in Table 8. The

changing trends of different relative errors are

shown in Figure 4 and Figure 5.

(a) SJ grade engine oil

(b) SL grade engine oil

Figure 4. Comparison of relative errors of predicted values

of 5~15 μm particles per millet in different grades of

motor oil of No.1 passenger car.

(a) SJ grade engine oil

(b)SL grade engine oil

Figure 5. Comparison of relative errors of predicted values

of 5~15μm particles per millet in different grades of motor

oil of No.2 passenger car.

Table 13. Relative error analysis of predicted values of 5~15μm particles per milliliter in different grades of passenger car

No.1.

Driven distance /km

SJ grade relative error/%

SL grade relative error/%

Linear

Grey

Combined

Linear

Grey

Combined

1000

3.26

2.17

0.70

-10.85

-9.10

-4.04

2000

-4.90

-5.94

-5.08

2.51

4.38

6.86

3000

4.37

4.57

3.04

6.22

7.16

6.06

4000

2.39

4.47

0.98

2.20

1.65

4.11

5000

-4.85

0.07

-0.72

-2.75

-2.99

1.99

Error/%

3.95

3.44

2.10

4.90

5.06

4.61

-8

-6

-4

-2

0

2

4

6

1000 2000 3000 4000 5000

Number of particles/mL

Driven distance/km

Linear regression model

Gray model

Combined model

-12

-10

-8

-6

-4

-2

0

2

4

6

8

10

1000 2000 3000 4000 5000

Number of particles/mL

Driven distance/km

Linear regression model

Gray model

Combined model

-14

-12

-10

-8

-6

-4

-2

0

2

4

1000 2000 3000 4000 5000

Number of particles/mL

Driven distance/km

Linear regression model

Gray model

Combined model

-8

-6

-4

-2

0

2

4

6

8

10

12

1000 2000 3000 4000 5000

Number of particles/mL

Driven distance/km

Linear regression model

Gray model

Combined model

Application of Grey Linear Regression Combined Model in Predicting the Motor Oil Wear Particles for Passenger Cars

47

Table 14. Relative error analysis of predicted values of 5~15 μm particles per milliliter in different grades of passenger car

No.2.

Driven

distance /km

SJ grade relative error/%

SL grade relative error/%

Linear

Grey

Combined

Linear

Grey

Combined

1000

0

0

0.84

0

-5.38

3.91

2000

0

0

0.48

2.67

5.96

4.97

3000

0

2.66

-2.68

6.31

4.71

-0.21

4000

-5.87

1.93

-1.32

2.58

2.13

-0.53

5000

-11.80

2.74

1.20

5.28

10.56

-0.79

Error/%

4.16

1.42

1.30

3.36

4.80

2.08

According to Table 13 and Table 14, it can be

found that the wear particles in the SJ oil for No.1

passenger car show that the prediction accuracy of

the grey linear regression combined model are

higher than the linear regression model (1.85 %) and

the grey model (0.29 %), and for the SL oil are

1.34 % and 0.45%, respectively. For No.2 passenger

car, the prediction accuracy is increased by 2.86% in

SJ oil and 1.28% in SL oil for the linear regression

model, and 0.12% in SJ oil and 2.62% in SL oil for

the grey model. According to the relative error

changes of the predicted values of each model, the

relative error of the predicted values of the

combined model are much smaller than those of the

grey model and the linear regression model. This

shows that the grey linear regression combined

model is better than the grey model and the linear

regression model. The grey linear regression

combined model can be applied to the prediction of

passenger car oil wear particles. According to Table

8 and the prediction of the grey linear regression

combination model, when the mileage of the

passenger car reaches 5000km, the number of

5~15μm particles per milliliter in the SJ grade and

SL grade oil does not exceed 40000, indicating that

the oil is clean at this time. The drivers of the

passenger cars generally perform oil replacement

when the passenger car's mileage reaches 5000km.

Combined with the predicted results, the oil is

replaced prematurely and the oil is still in a clean

state, resulting in a waste of oil. It is suggested that

when changing oil, the degree of deterioration of oil

quality should be considered, extend the oil

replacement period appropriately, realize the

replacement of oil according to quality, avoid the

waste of oil, and save the cost of use.

5 CONCLUSIONS

(1) With the increase of mileage in passenger cars,

the content of particles in oil also increases slowly.

The change trend of particle content of 5~15μm is

obvious and regular, which can be used as the main

index to monitor engine wear. If the cleanliness of

the oil reaches 22/19, the oil should be replaced.

(2) The grey linear regression combined model is

established by combining the grey model with the

linear regression model, which makes up for the

deficiency of the single model and improves the

prediction accuracy.

(3) The example shows that the prediction

accuracy of the grey linear regression combined

model is higher than the linear regression model and

the grey model. It indicated that the combined model

can be applied to the prediction of oil wear particles

in passenger cars.

(4) According to the cleanliness level, when the

mileage of passenger cars reaches 5000km, the oil

replacement is too early at this time and the oil is

still in a clean state. The oil replacement period

should be extended appropriately, and realizing the

replacement of oil according to quality.

ACKNOWLEDGEMENTS

This work was financially supported by the

Funding of National Science and Technology

Support Program (2015BAG02B01).

REFERENCES

B. Chen, J.G. Wang. Research on grey linear regression

combined model algorithm, Journal of Xi\'an

University of Arts and Science (Natural Science

Edition), 2012, 15(1): 82-85.

B. Zeng, S.F. Liu. Unbiased direct DGM (1, 1) model of

non-homogeneous exponential sequence and its

application in electric load forecasting. Statistics &

Information Forum, 2013,732-733.

D. Liang, Y.F. Hu, L.F. Ma, et al. Forecasting for Machine

Tool Sales Based on Grey Linear Regression Model.

Advanced Materials Research, 2014, 945: 2935-2938.

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

48

F.L. Ren, W.B. Li, T. He. Linear regression and grey

theory's application in the Power prediction, 2018.

H. Hao, Q. Zhang, Z.G. Wang, Forecasting the number of

end-of-life vehicles using a hybrid model based on

grey model and artificial neural network, Journal of

Cleaner Production, 2018, (202): 684-696.

H.R.Zhao, X.Y.Han, S.Guo. DGM (1, 1) model optimized

by MVO (multi-verse optimizer) for annual peak load

forecasting. Neural Computing and Applications,

2018, 30(6):1811–1825.

J.F. Jing, K.C. Li, F.K. Deng, et al. Grey line of corrosion

of oil and gas pipelines, Sexual regression combined

prediction model. Oil & Gas Storage and

Transportation, 2015, 34(12):1300-1304.

J.S. Wang. Standard of lubricating oil cleanliness and

detection of particulate pollution, Measurement and

testing technology, 2015, 42(5): 21-22.

J.Z. Xin, J.T. Zhou, S.X. Yang, Bridge structure

deformation prediction based on GNSS data using

Kalman-ARIMA-GARCH model, Sensors, 2018,

18(1) 298: 1-6.

K.P. Bi, G.H. Yan, H. Y. Zhang, et al, Research on

equipment failure rate forecasting based on gray-linear

regression combined model. 2016 Prognostics and

System Health Management Conference, 2016, 19-21.

N. Tian, Y. Wei Application Scope and extension of

approximate non-homogeneous exponential discrete

grey model. Statistics & Decision, 2018, 8: 126-132.

S.Z. Chen, S. Li, F. Xiao, Forecasting of asphalt pavement

performance based on GA-Grey neural network,

Journal of Chongqing Jiaotong University (Natural

Science), 2019, 159-164.

Tobita, Mikio. Combined logarithmic and exponential

function model for fitting postseismic GNSS time

series after 2011 Tohoku-Oki earthquake, Tobita

Earth, Planets and Space, 2016 68(41):1-12.

X. Xiao, H. Guo, S. Mao. The modeling mechanism

extension and optimization of grey GM (1, 1) model,

Applied Mathematical Modelling, 2014, 38(5): 1896-

1910.

Y.B. Zhou, L.F. Jiao. Standards and test methods of oil

cleanliness, Lubricating Oil, 2008, 23(1): 63-64.

Y. Han, Weighted grey linear regression combined model

and its application based on wavelet pretreatment,

Industrial Instrumentation & Automation, 2016, (06):

152-158.

Y. Wang, X.M. Chen, Y.H. Han. Forecast of passenger

and freight traffic volume based on elasticity

coefficient method and grey model, Procedia-Social

and Behavioral Sciences, 2013, (96): 136-147.

Y.X. Jiang, Q.S. Zhang. Recursive solution to

approximate non-homogeneous unbiased GM (1, 1)

model and its application. Control and Decision, 2015,

30(12):524-554.

Y Zhou, Y Luo, SM Jia, et al. Grey-linear regression

combination model for ritting and predicting layered

land subsidence in Beijing, Urban Geology, 2014,

9(4): 52-56.

Application of Grey Linear Regression Combined Model in Predicting the Motor Oil Wear Particles for Passenger Cars

49