The Quick Design Method for the Big and Complex Products based

on Function Disassembling

Xianying Yang

1, a

, Weizhan Li

1, b

1

Chongqing Jiaotong University, Art Design Collage, Chongqing 400074,China

Keywords:

Modularity, Disassembling, Concept Design, Industrial Design.

Abstract: This paper gave out an analyst the condition, disassembling and unfold principle of module concept with the

function planning and relationship, developed the process with the sample of leveling machine. It got the

idea plan of the product, put forward the action of function disassembling and transit into the design by the

quick industrial design sketch and rendering method, improved the efficiency of concept design. It get

conclusion the modularity and disassembling method will guiding the designer and give a reference on the

large and complex product function defining and design.

1 BACKGROUND

Simplified conceptual design is usually adopted to

start the creative process first in the early stage of

product development, because of massive

components of big and complex products. These

products are characterized by large size, complex

design, high technical standard, and strict

requirements for the adaptability in actual working

environment (Jungmin Yoo, Minjung Park, 2016). In

simplified methods, the modular design concept is

universal in this kind of products design, and it is the

study object of traditional design. Previously, the

team of foreign scholars Browning. T.R and Wei XP

proposed multi-level evolutionary design theories

and methods for complex products to improve the

intelligence of complex product design, aiming at

the multidisciplinary coupling integration of

complex product design. Liu FY studied the key

technologies of complex customized products

development and design. Lin ZQ studied the digital

design of complex equipment. Zhang SY studied the

theory and method of engineering semantic

expression, transmission and driving in product

design based on fuzzy interaction modeling

technology for product design information of

engineering semantics. Feng YX researched the

principles, methods and applications of complex

mechanical product design intent (Lei Zhang,

Xuening Chu, Deyi Xue, 2019; CHEN Mengyue,

et.al, 2016). Based on the above methods, this paper

put forward research on the product form design

from further function disassembling and unfolding

process of modularity, to obtain a creative method

that is easier for designers to control.

2 DEFINING MODULES BY

PRODUCT FUNCTION

Module is a relatively independent and replaceable

component in a product system or service system,

which is also a function unit of modular system. In

mechanical products system, module is a group of

combined elements with the same function. Modular

design is a way of disassembling and reorganization.

It is a method of integrating and innovating based on

product system design by exchanging and

transplanting innovative ideas. The purpose is to

improve the demand of system diversity, plurality,

economy and standardization. According to the

relevant demand information of the product system,

considering the correlation between the product

modules, the product function re-design module can

be identified according to the output efficiency of

product core function, after determining the

importance of each module by using QFD (Quality

Function Deployment) matrix and fuzzy evaluation

method (CHEN Mengyue, et.al, 2016, Chen, L., A.

Macwan, and S. Li, 2007). In the module

construction and combination of ideas, the module is

Yang, X. and Li, W.

The Quick Design Method for the Big and Complex Products based on Function Disassembling.

DOI: 10.5220/0008849501870191

In Proceedings of 5th International Conference on Vehicle, Mechanical and Electrical Engineering (ICVMEE 2019), pages 187-191

ISBN: 978-989-758-412-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

187

a bit fuzzy, which needs to be sorted and determined

according to the design goals and research methods.

Taking automotive products as an example, the

body structure is a large and complex system. Soon

after the birth of the first production line, Ford

Motor faced consumer demand to cars

diversification, and thus produced a variety of

models by determining the core modules. Toyota

launched a global framework to improve the

common use of component layers whose versatile

rate increased from around 20% to 80%. In addition,

domestic and foreign automobile enterprise

introduced different types of modular platforms such

as MLB, MMB, UKL, MFA and MRA to improve

the common use of design and increase differential

controllability. At the same time, the platforms

number of cars were reduced by modular design. For

example, the number of Ford Motor car platforms

was reduced from 27 to 8, and its utilization rate of

core modules was greatly increased. In today's

highly competitive marketplace, the development

team of automotive manufacture enterprises

introduce modular design ideas in automotive

construction system, to reduce production risks and

costs, increase production flexibility, and improve

production acumen. The car body is divided into

several modules according to the specific function,

and the module is disassembled hierarchically from

the model, the body, the units, the components, the

parts, etc. And then the modules are combined

according to the produced models. The production

adaptability and R&D production efficiency are

greatly improved by this form of production

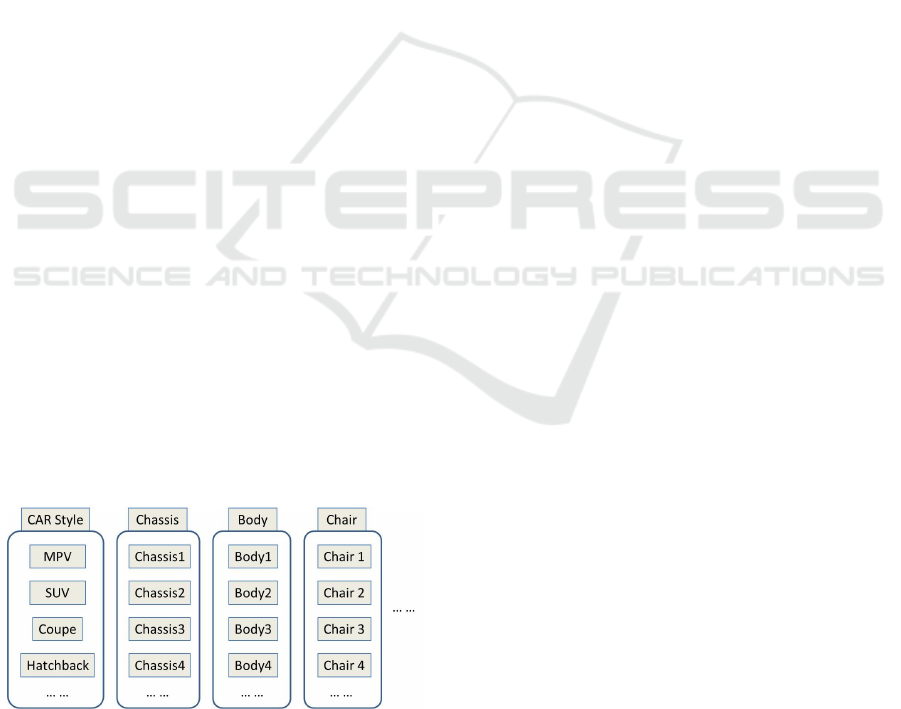

organization. As shown in Figure. 1, from left to

right is the module layer subdivision of automobiles.

Automobile companies form a variety of models

through multi-layer module combination, which

meets the needs of consumers' meticulousness and

greatly improves the efficiency of supporting

production.

Figure 1. The Module Layer of Car Body.

3 PRODUCTS MODULARITY

FUNCTION DEPARTING

3.1 The Condition and Demand

Modular design is a special design idea and the

designers need to consider factors such as using

conditions, economy, and necessity of demand. The

design team analyzes the system factors such as the

conditions and requirements of the design object,

and understands the modular advantages of the

design object function. Through the analysis and

evaluation, the modular design method is

determined.

The design conditions and requirements of the

modular design are often the requirement of multi-

function, multi-purpose, and variable function, such

as the space variability requirements of product

combination, requirements for high frequency

switching of storage and placement functions, multi-

function requirements for both home and outing.

To determine the use time and condition of modular

product design, we can observe the product's

operating conditions, core functional components,

and maintenance needs, it can be observed in terms

of product use conditions, core function

components, and maintenance requirements.

3.2 Function Layer Disassembling

The modular concept facilitates the complex product

functions disassembling. The function output of the

product system can be disassembled into constituent

units to determine the core modules and non-core

modules of the modular layout. Module functions

can be disassembled from the following layers:

3.2.1 The Whole Product

This layer mainly focuses on products serialization

and product group differentiation. The serialization

of products is targeted at the function disassembling

of modules. Take construction machinery - leveling

machine as an example, product group and system

composition layers can be classified from the

function requirements. The core function module

can be divided into four basic modules: power unit,

operation unit, cockpit and frame platform (Chen,

L., A. Macwan, and S. Li, 2007). By product

modules disassembling, the multiple combinations

of product serialization extension are provided, as

shown in Figure. 2 below.

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

188

Figure 2. The Product Model of Leveling Machine.

3.2.2 Parts Layer

Components are independent modules that make up

a product, which is also the layer of the most

common modular design applications. Different

configurations can be obtained by modularizing the

components, with obvious modular design traces and

visual elements. The structural connection between

the component modules affects the basic direction of

the exterior form design. According to the algorithm

of module division under design structure matrix

(DSM) architectural constraints, Wei et al. adopted

the modularity

Q

function as the optimization

target of module division (Wang, Y., Cho, H, 2012).

3.2.3 Components Layer

Part modularization is the basic module element

layer division in product design category. The

modules are combined from the basic functions, and

then the overall form is designed, based on the

consideration of product serialization. According to

the modular design idea of the leveling machine

structure described above, the chassis components

are further subdivided into basic component module

elements (Smith, S., G. Smith, and Y. T. Shen,

2012), such as transmission, frame and suspension,

to form a new combination scheme. Then, the

holistic design of the new combination is made.

The module elements are divided from the

perspective of function flow disassembling of the

components level. The form of function flow is

divided into material flow, energy flow and

information flow. The disassembling or aggregation

of product functions is made by the module division

based on function flow, through materials, energy

and information flow. And then, the product module

is qualitatively divided. Through the static and

dynamic relation between components, the

correlation between function input and output is

established, such as the input-output relation matrix

of a certain parameter. Where, each matrix element

(, )

ki j

s

IO

is the correlation degree of the j function

input to the i function output when the k parameter

is considered. If the input and output functions are

listed separately,

1

()

k

sI

is the input function and

1

()

k

sO

is the output function. When observing the

correlation degree, it is assumed that there are

correlation degree indexes of M categories of

indicators and parameters for analyzing functions.

Among them, the influence coefficient of the

correlation degree of category k parameter on the

total correlation degree is

k

W

. Since the sum of

product functions is set by the goal, the sum of the

influence coefficients of various parameters is equal

to 1, as shown in equation (1).

1

1

M

k

k

W

(1)

4 FUNCTION PLANING

After the decomposition of modularization, a

preliminary layout plan can be obtained through the

graphic arrangement of functional layout, that is, the

function modules are simplified into blocks to show

the basic construction system of modular design and

the basic logic relationship of the product is

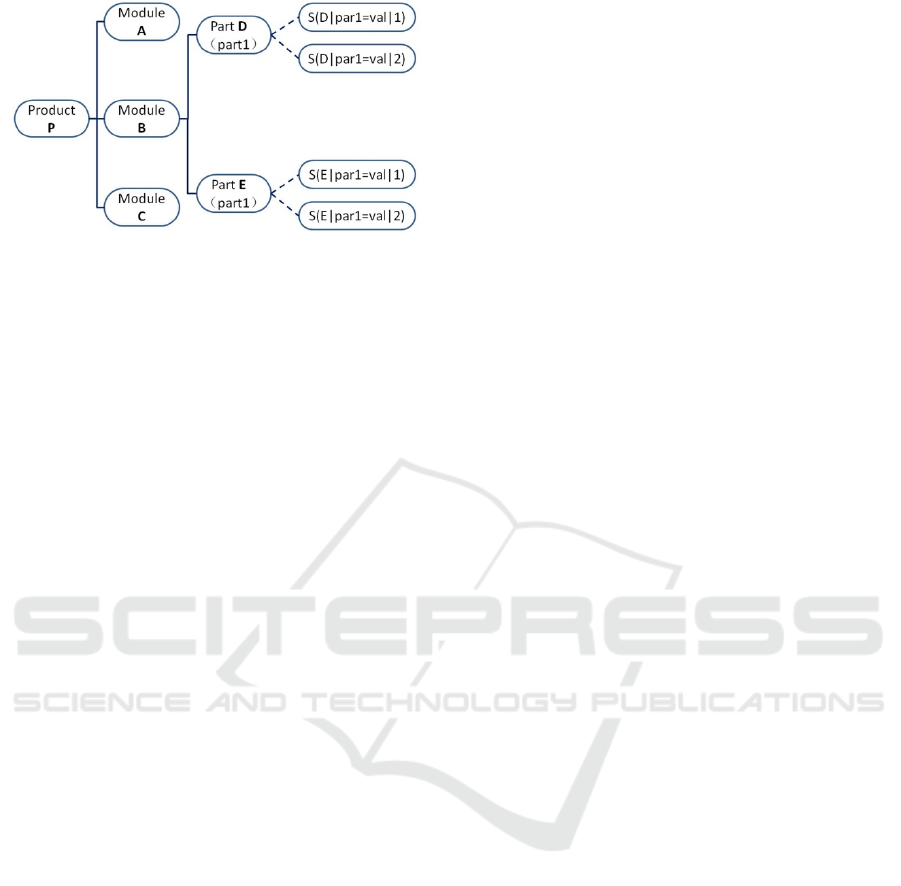

expanded. For example, the function modules of a

product are divided into four parts: P1, P2, P3 and

P4, among which P1 is determined to be the core

module and cannot be replaced, while the other three

modules can be replaced according to the

application. The basic combination scheme of P1+

P2+ P3+ P4. It can also be divided into P1+( P2+

P3)+ P4 combination scheme according to the

function application frequency. In addition, it can be

divided into P1+( P2+ P3+ P4) combination scheme,

that is, P1 is the core module, P2, P3, P4 is the

component or part module, can be replaced, as

shown in the lower part of Figure. 3. By dividing in

this way, different combinations are formed. After

the basic plan is determined, differential exploration

of the detailed modeling for the certain plan is

obtained, such as the differential combination of the

basic combination scheme. Then the detailed

decomposition form is obtained, thereby forming

different structure prototypes and appearances.

The Quick Design Method for the Big and Complex Products based on Function Disassembling

189

5 QUICK CREATIVE DESIGN

PROCESS

In this paper, a large-scale engineering equipment -

leveling machine is taken as a design object for

modular design process analysis and industrial

design process study (Minjung Park, Jungmin Yoo,

2018; Daie P, Li S, 2016).

5.1 Function Decomposition and

Developing

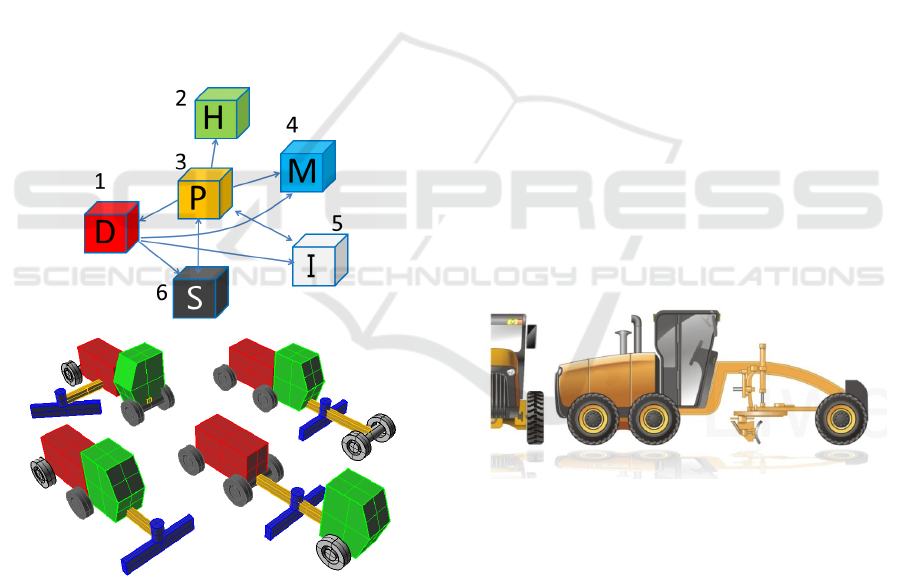

According to the previous function division

principle, the following main function modules are

determined: ① D engine cabin (Driving, red); ② H

cockpit (Human, green); ③ P chassis and frame

(Planning, orange); ④ M flat shovel module

(Moving, blue); ⑤ I guide wheel set (Index, gray);

⑥ S supporting wheel set (Supporting, black),as the

Figure3.

Figure 3. The Image of Function Relationship.

It can be seen that the chassis and frame are the

main body supporting the engineering vehicle, and

its shape is variable, according to the principle of

function decomposition and interrelation. P supports

and links each of the other modules, from the

function input and output relationship. H cockpit is

supported by the chassis and is not directly related to

other modules. In the design process of it, care must

be taken to maintain the open view of the cockpit. In

the design process, it is necessary to ensure the wide

operation vision of the cockpit. D engine cabin

module is supported by P, outputting power to M, S,

I and other modules, and the product function

expansion is shown in Figure. 3. There are 8

unidirectional or mutual output - input relationships

among the 6 basic modules of the leveling machine.

At the same time, the M, S, and I modules must

touch the ground at the same time, according to the

body supporting and operation requirements.

Through logical relationship analysis, creatives

compile function relationship and use system

software to rationally combine ideas.

5.2 Quick Creative and Rendering

According to the above combinations, the paper

created a preliminary creative plan by divergent

thinking and discussion. We evaluated and filtered

the design schemes, according to the requirements of

the engineering machinery products in the practical

application, such as the operating range, the stability

of the car, the steering stability, the passivity, the

work efficiency, etc. Then, they obtained the more

specific design schemes and drew detailed sketches.

We continued to optimize the creative plans, and

used CAR (Computer Aided Rendering) to elaborate

the 2D plan design scheme and 3D data construction

(Computer Aided Design, CAD) , as shown in

Figure 4.

Figure 4. The CAD Picture of Leveling Machine.

5.3 Concept Evaluation

According to the 2D and 3D concept schemes

completed by designers, explicit visual evaluation

was made from the aspects of man-machine

interaction measure, function range, assembly

relation, maintainability and overall form. If detailed

evaluation is needed, in-depth evaluation can be

carried out based on 3D data, by methods of

computer-aided simulation, dynamic analysis,

structural performance, ergonomics, color survey

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

190

(Wei Wei, Xu Shaopeng, Liang He, 2016; Stone R

B, Wood K L, Crawford R H, 2000), etc.

6 DESIGN EVALUATION

The industrial design method needs to be quickly

evaluated in the conceptual design stage. Generally,

the design evaluation is carried out from several

aspects: the function realization effect, realizability,

maintainability, sustainability, and overall

appearance effect, which provides direction for later

optimization. The corresponding evaluation

mechanism and content should be established for

each index. For example, Minjung Park has

calculated the results of each evaluation index in the

modular design by FAHP (fuzzy analytic hierarchy

process). The design of color image has been studied

by Daie P et al. based on mathematical evaluation

for the evaluation of engineering machinery

products color.

7 CONCLUSION

The big and complex device products design is

meticulous, which is systemic and the link between

the steps will affect the progress and efficiency of

the next stage. Following the idea of modularity

disassembling and function unfolding principle with

a leveling machine as an example, this paper

explored and found out the intuitive results in

concept design stage by using the methods of

function disassembling, function relationship and

industrial design. The results would provide a

reference for industrial design and research on the

big and complex products. Due to the difference in

production level and innovation, the role of

industrial design in big and complex products needs

to be improved, and further exploration of it is

needed.

ACKNOWLEDGEMENTS

This paper was financially supported by Chongqing

Education Commission (KJ1500525) and

Chongqing Science and Technology Commission

(cstc2016jcyjA0467, cstc2017jcyjAX0248) in China

fund.

REFERENCES

Chen, L., A. Macwan, and S. Li. Model-based Rapid

Redesign Using Decomposition Patterns [J]. Journal

of Mechanical Design, 2007. 129 (3): 283–294.

CHEN Mengyue CHEN Dongping CHU Xuening. CHEN

Mengyue CHEN Dongping CHU Xuening [J].

Computer Integrated Manufacturing Systems, 2016,

11: 2522-2529.

Daie P, Li S. Matrix-based hierarchical clustering for

developing product architecture [J]. Concurrent

Engineering Research and Applications, 2016, 24(2):

139-152.

Lei Zhang, Xuening Chu, Deyi Xue. Identification of the

to-be-improved product features based on online

reviews for product redesign [J]. Taylor journal, 2019:

2464-2479.

Minjung Park a, Jungmin Yoo. Benefits of mass

customized products: moderating role of product

involvement and fashion innovativeness [J]. Heliyon,

2018, 4(2):1-25.

Smith, S., G. Smith, and Y. T. Shen. Redesign for Product

Innovation [J]. Design Studies, 2012, 33 (2):160–184.

Stone R B, Wood K L, Crawford R H. A heuristic method

for identifying modules for product architectures [J].

Design Studies, 2000, 21(1): 5-31.

The design structure system: A method for managing the

design of complex systems. Steward DV. IEEE

Transactions on Engineering Management. 1981

The effects of e-mass customization on consumer

perceived value, satisfaction, and loyalty toward

luxury brands [J]. Jungmin Yoo, Minjung Park.

Journal of Business Research. 2016 (12)

Wang, Y., Cho, H. The effect of fashion innovativeness on

consumer’s online apparel customization [J]. Int. J.

Ogan. Implant, 2012, 5 (2), 263e283.

Wei Wei, Xu Shaopeng, Liang He. A module partition

method of product platform based on environmental

resource factors [J]. Journal of Computer-Aided

Design & Computer Graphics, 2016, 28(2): 335-

344(in Chinese).

The Quick Design Method for the Big and Complex Products based on Function Disassembling

191