Acidic and Basic Amino Acids Gasification Characteristics under

Supercritical Water Conditions

Thachanan Samanmuly

1,*

and Yukihiko Matsumura

2

1

Department of Chemical Engineering, Faculty of Engineering, King Mongkut’s Institute of Technology Ladkrabang,

Chalongkrung Road, Ladkrabang, Bangkok 10520 Thailand

2

Division of Energy and Environmental Engineering, Institute of Engineering, Hiroshima University, 1-4-1 Kagamiyama,

Higashi-Hiroshima, 739-8527 Japan

Keywords: Amino acids, Hydrothermal, Supercritical water, Gasification, Biomass

Abstract: Animal biomass wastes and aquatic biomass are alternative biomass materials for renewable energy

production which are contained low or no lignocellulosic. Protein is one of major contents in food waste,

animal matter, and algae. The 2 selected amino acids, glutamic acid and arginine, were chosen to determine

the gasification characteristics. Aqueous solution 1.0 wt% of those two amino acids was gasified under

supercritical water conditions by using a tubular flow reactor. Reaction temperatures were varied ranging

between 500 and 650 oC and pressure was fixed at 25 MPa. Aqueous feedstock flow rate also fixed at 2.0

g/mL for a residence time of 86-119 s. Identification and quantification of the gas products were examined

by gas chromatography (GC). The aqueous phase product was also determined the dissolved carbon by the

total organic carbon (TOC) analyzer. An increasing reaction temperature improved the carbon gasification

efficiency. The gasification rate of glutamic acid and arginine follow Arrhenius behaviors and are

explained well by the first order kinetics equation. Gasification characteristics of glutamic acid and arginine

were also compared to those of glycine and alanine. The effect of the functional group in arginine is an

increasing alkalinity that made pH of liquid products are above 9.

1 INTRODUCTION

Nowadays, the world energy consumption is

tendency rises with the rising of fossil fuel depletion

and the global environmental problem. Then,

renewable energy such as biomass-derived energy

becomes an attractive issue to reduce the fossil fuel

production and develop to be a sustainable energy

resource. Generally, organic compounds in biomass

cannot be dissolved in normal conditions water due

to they are non-polar molecules. Under supercritical

conditions (Tc = 647 K or 374

o

C, Pc = 22.1 MPa),

supercritical water became a better solvent more

than a normal conditions water that behaves like an

organic solvent. Supercritical water dissolved

organic compounds, the lignocellulosic compounds,

polysaccharide, and protein, which presented in

biomass and hydrolyzed to form glucose, xylose,

amino acids, and organic acids which are further

utilized as feedstocks of bio-ethanol or bio-

chemicals or bio-fuel productions. Then,

supercritical water gasification has excellent

reactivity, which makes it a very promising reaction

medium for converting various types of biomass into

value-added fuel products. Furthermore,

supercritical water gasification has been developed

not only to solve the problem of tar and char

formation which initiated low conversion efficiency

and reactor plugging but also increases gasification

efficiency (Antal et al., 2000).

Many works have studied and revealed that

supercritical water gasification technology is an

innovative thermochemical methodology for

converting wet biomass and organic waste into

combustible gases, such as hydrogen and methane

(Matsumura et al., 2013). A wide variety of model

biomass compounds have been separately gasified in

supercritical water in order to investigate the

gasification characteristics of substantial biomass

species as the representative of real biomass

containing these compounds. But, the gasification

rate of specific feedstocks is still miserable to

Samanmuly, T. and Matsumura, Y.

Acidic and Basic Amino Acids Gasification Characteristics under Supercritical Water Conditions.

DOI: 10.5220/0008652500170022

In Proceedings of the International Conference on Future Environment Pollution and Prevention (ICFEPP 2019), pages 17-22

ISBN: 978-989-758-394-0

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

17

predict. There are not much known about the

gasification characteristics of non-lignocellulosic

biomass which has low or no cellulose,

hemicellulose and lignin content. Protein, which is

non-lignocellulosic, is a common important

component of biomass, organic waste, food waste,

animal matter, and algae which are usually wet

biomass. Then, protein gasification characteristics is

important to study that its molecule is different from

carbohydrate and has N-containing. Amino acids

are good representative model compounds of protein

due to they are produced by the hydrolysis of

protein. So far, glycine, alanine, valine, leucine, and

proline have been studied their gasification

characteristics (Samanmulya et al., 2014). These

employed amino acids showed the different

gasification behavior but only the gasification rate of

glycine and alanine are practically identical, and

they were considered to be a standard for

determining amino acid gasification. By the

different stability of the bond between the carboxyl

group and amino group and functional group, the

other three amino acids behave variously from the

standard amino acids and the different sensitivity of

the produced radicals also affect to their gasification

characteristics. Then, more gasification

characteristics data is required to be able to predict

the gasification characteristics of amino acids.

Moreover, the correlation between kinetic rate and

temperature are useful to hypothesize and

understand the reaction mechanism of supercritical

water gasification of biomass (Promdej and

Matsumura, 2011). The reactions between

intermediates were differentiated to be radical and

ionic reactions by their compatibility to Arrhenius

behavior (Yong and Matsumura, 2013). Therefore,

Arrhenius rate law has attracted attention to

determine supercritical water gasification

characteristics of amino acids.

Glutamic acid and arginine are of interest

because they are mostly found in a variety of foods

including animal source and plant source. They are

classified in different category which are acidic and

basic, respectively, and moreover, their gasification

characteristics have not much been studied yet.

This study purpose is to determine the effect of two

carboxyl groups, guanidine functional group, acidity

and alkalinity on supercritical water gasification.

Furthermore, the obtained reaction products were

evaluated based on qualitative and quantitative, and

the kinetics parameters were also elucidated for the

reaction rate of glutamic acid and arginine

gasification.

2 EXPERIMENTAL SECTION

2.1 Experimental Procedure

All gasification experiments were performed using

the tubular flow reactor which was schematically

illustrated in our previous study (Samanmulya et al.,

2014). Briefly, a SS316 steel tube with a length of

12 m and an inner diameter of 2.17mm was used as

the reactor. The reaction temperature was varied

from 500 to 650

o

C (residence times in a range of

86–119 s) and reaction pressure was fixed at 25

MPa. Before the addition of the feedstock, the

reactor pressure was maintained at 25 MPa by

feeding only deionized water and controlled by

back-pressure regulator, and the reactor temperature

was reached the desired temperature. Glutamic acid

and arginine, obtained from Nacalai Tesque with

purity >98%, aqueous solutions of 1.0 wt% were

prepared by dilution in deionized water and fed into

the reactor at a feedstock flow rate of 2 g/min. After

passing through the reactor, the effluent was cooled

down in a heat exchanger, depressurized by a back-

pressure regulator, and then sampled.

2.2 Analytical Methods

The rate of gas generation was measured using a

water displacement method in which we measured

the time required for the effluent gas to fill a vial of

known volume. The gaseous product was

characterized and quantified using gas

chromatography (GC). Carbon dioxide and carbon

monoxide were detected by GC with a thermal

conductivity detector (GC-TCD) using helium as the

carrier gas. Methane, ethene, and ethane were

detected using GC with a flame ionization detector

(GC-FID) using helium as the carrier gas. Hydrogen

was detected by GC-TCD with nitrogen as the

carrier gas.

The liquid product was quantified the amounts of

carbon in the liquid product (non-purgeable organic

carbon, NPOC) and the dissolved carbon gas

product (inorganic carbon, IC) by a total organic

carbon (TOC) analyzer.

Although, gasification of nitrogen contained

molecule that can produce syngas with NOx but N-

containing molecule is finally converted to N

2

via

intermediate compound of NH

3

generation in

supercritical water gasification system and no NOx

is occurred (Goto et al., 1998 and Yakaboylu et al.,

2013).

ICFEPP 2019 - International conference on Future Environment Pollution and Prevention

18

3 RESULTS AND DISCUSSION

3.1 Glutamic Acid Gasification

Based on the previous studies, decomposition

schematic of glutamic acid was proposed as shown

in Figure 1. The schematic has been adapted from

previous work (Samanmulya et al., 2014). The bond

between the carboxyl group and the other parts

(amino group and functional group) is likely to be

cleaved first; considering the instability of the

radicals produced in the following stage, this can be

expected to be the rate determining step for the

gasification. Decomposition of glutamic acid leaves

propionic radical (CH

2

CH

2

COOH) which is rather

unstable. It further decomposes and produces

ethylene and carboxyl radical which are gasified

easily.

Figure 1: The proposed decomposition schematic pathway

of glutamic acids under supercritical water conditions.

Figure 2: Effect of temperature on the product gas

composition of glutamic acid gasification.

The effect of reaction temperature on product gas

composition is shown in Figure 2. A fraction of

ethylene is evident in gas composition, which is

explained by the production of ethylene from

decomposition of propionic radical

(CH

2

CH

2

COOH). Ethylene is further consumed to

produce other gases at later stages, which leads to a

lower ethylene fraction at higher temperatures, while

methane fraction is increased.

3.2 Arginine Gasification

Decomposition of amino acids leads to the

production of radicals (Samanmulya et al., 2014).

Figure 3 shows a schematic of the proposed

decomposition pathways of arginine, the employed

amino acids. This schematic has been adapted from

previous work (Samanmulya et al., 2014). The same

hypothesis as mentioned in glutamic acid

gasification, propyl-guanidine may produce from

arginine decomposition and it is a big molecule that

should stay longer than small radicals. Propyl-

guanidine will further decompose to produce small

molecules and product gas leaving ammonia in

liquid phase. Water gas shift reaction will be

promoted by this alkalinity. The carbon monoxide

reducing is evident in gas composition when the

reaction temperature increased. Moreover, we had

observed the pH of liquid products which were

above 9.

The composition of generated gases from the

arginine gasification as a function of reaction

temperature is shown in Figure 4. Arginine

gasification results in an increased methane fraction

with increasing reaction temperature while carbon

monoxide was decreased. This can be explained as

methanation. At low reaction temperature, we also

observe a carbon monoxide fraction in the product

gas, possibly owing to incomplete gasification.

However, this fraction reduces with increasing

reaction temperature. At 650

o

C, the fraction of

carbon monoxide was reduced while those of carbon

Acidic and Basic Amino Acids Gasification Characteristics under Supercritical Water Conditions

19

dioxide and hydrogen were increased, owing to the

promotion of the water-gas shift reaction at high

reaction temperature. Ethylene fraction is evident in

product gas composition which supports the

proposed arginine decomposition schematic as

shown in Figure 3.

Figure 3: The proposed decomposition schematic pathway

of arginine under supercritical water conditions.

Figure 4: Effect of temperature on the product gas

composition of arginine gasification.

3.3 Reaction Rate of Glutamic Acid and

Arginine Gasification

Carbon gas product yield or carbon gasification

efficiency (CGE) is defined as the ratio of the

amount of carbon basis in the gas product to that in

the feedstock solution.

(1)

where

0C

n

denote the initial amount of carbon

[mol],

Cg

n

denote the amount of gasified carbon

[mol],

Cgas

n

denote the total amount of carbon in

gaseous product obtained from GC [mol],

CIC

n

denote the total amount of inorganic carbon in liquid

product [mol], and

CGE

denote carbon gasification

efficiency [-].

Assuming the Arrhenius rate law that the

gasification reaction is first order in terms of the

feedstock carbon content, the following equation is

obtained:

(2)

which leads to

t

RT

E

knnn

a

CCgC

expexp

000

(3)

t

RT

E

k

n

n

CGE

a

C

Cg

expexp1

0

0

(4)

ICFEPP 2019 - International conference on Future Environment Pollution and Prevention

20

where

0

k

= pre-exponential factor [s-1],

a

E

=

activation energy [J mol-1],

R

= gas constant [J

mol-1 K-1],

T

= Temperature [K], and

t

= time

[s].

The experimental data of carbon gasification

efficiency was fitted to Eq. (4) and the parameters

were determined.

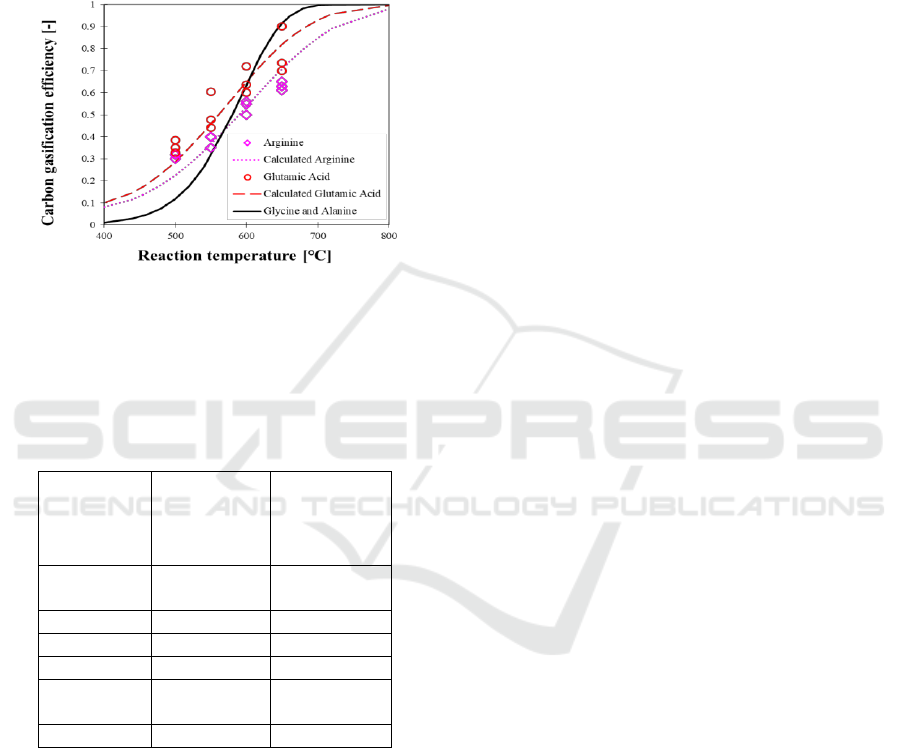

Figure 5: Gasification characteristics of the employed

amino acids relative to the reported results for glycine and

alanine.

Table 1: Reaction rate parameters of Supercritical Water

Gasification for Glycine, Alanine, Valine, Leucine,

Proline, Glutamic Acid and Arginine

Amino

acids

Pre-

exponential

factor [s

-1

]

Activation

Energy

[kJ/mol]

Glycine and

Alanine

7.37 ×10

5

131

Valine

6.97 ×10

1

70

Leucine

7.37 ×10

5

135

Proline

1.96 ×10

2

73

Glutamic

Acid

4.50 ×10

2

77

Arginine

2.50 ×10

2

75

Figure 5 shows the effect of reaction temperature

on carbon gasification efficiency of the employed

amino acids relative to the reported results for

glycine and alanine. Note that the gasification

characteristics of glycine and alanine are identical

and they are shown by a solid black line. The

gasification efficiency increased with reaction

temperature as was observed for glucose (Xu et al.,

1996), which implies the Arrhenius behavior. The

gasification efficiency of the employed amino acids

is consistent with Arrhenius behavior indicating by

the red dashed and pink dotted line in the figure.

The reaction parameters were pre-exponential factor

and activation energy which are shown in Table 1

including with those of glycine, alanine, valine,

leucine and proline for comparison purpose. The

fitting results using these parameters are also shown

in Figure 5. Gasification rate of arginine is slower

than that of glycine and alanine although the

activation energy is also lower. The calculated

results and experimental data are in a good

agreement. Experimental results and theoretical

results using the Arrhenius parameters from Table 1

showed good correlation.

4 CONCLUSION

The supercritical water gasification of glutamic acid

and arginine can be characterized by first order

kinetics with the Arrhenius equation rate constant,

and the reaction parameters were determined. The

gasification rate of the two selected amino acids

were lower than that of glycine and alanine, even the

activation energy is lower that of glycine and

alanine. Glutamic decomposition produces

propionic acid radical and it further decomposes and

produces ethylene and carboxyl radical which are

easily to gasify. Arginine decomposition leads to

produce propyl-guanidine and it will further

decompose to produce small compounds and

product gas, especially for ethylene that has evident

in product gas composition.

ACKNOWLEDGMENT

This study was supported by Thermal Engineering

Laboratory, Hiroshima University.

REFERENCES

Antal, Jr. M. J., Allen, S. G., Schulman, D., Xu, X.,

2000. Ind. Eng. Chem. Res. 39, 4040.

Goto, M., Nada, T., Ogata, A., Kodama, A., Hirose,

T., 1998. J. Supercrit. Fluids 13, 277.

Matsumura, Y., Hara, S., Kaminaka, K., Yamashita,

Y., Yoshida, T., Inoue, S., Kawai, Y., Minowa,

T., Noguchi, T., Shimizu, Y., 2013. J. Jpn.

Petrol. Inst. 56, 1.

Promdej, C., Matsumura, Y., 2011. Ind. Eng. Chem.

Res. 50, 8492.

Samanmulya, T., Inoue, S., Inoue, T., Kawai, Y.,

Kubota, H., Munetsuna, H., Noguchi, T.,

Acidic and Basic Amino Acids Gasification Characteristics under Supercritical Water Conditions

21

Matsumura, Y., 2014. J Jpn. Inst. Energy 93,

936.

Xu, X., Matsumura, Y., Stenberg, J., Antal, Jr. M. J.,

1996. Ind. Eng. Chem. Res. 35, 2522.

Yakaboylu, O., Harinck, J., Smit, K. G. G., Jong,

W.D., 2013. Biomass Bioenergy 59, 253.

Yong, T. L. K., Matsumura, Y., 2013. Ind. Eng.

Chem. Res. 52, 9048.

ICFEPP 2019 - International conference on Future Environment Pollution and Prevention

22