Study of Making Clay-based Ceramic Membranes with Additional

Rice Husk and Sawdust to Reduce Water Turbidity

Netti Herlina, Marheni Saragih and Hafizhah Mawarni

Environmental Engineering, Faculty of Engineering, University of Sumatra Utara

Jl. Almamater, Medan 20155, North Sumatra, Indonesia

Keywords: Turbidity, Ceramic Membrane, Rice Husk, Sawdust, Clay.

Abstract: There are still many people in the banks of the river in the city of Medan, especially in the Deli river, which

uses river water for their daily needs. This study was conducted to reduce the water turbidity of the Deli River

by using a ceramic membrane made from clay. The ceramic membrane was made by analyzing the effect of

the composition and the size of the additional ingredients of rice husks and sawdust to the reduction of water

turbidity in the Deli River. This ceramic membrane is made in the form of a pot (pot filter) with the height of

18 cm and the diameter of 21 cm which is burned at the temperature of 850

o

C - 900

o

C for 8 hours.Variations

in the size of the material used are range from 35-50, 50-60 and 60-100 mesh with a comparison of the

composition of materials (80%: 20%), (85%: 15%) and ( 90%: 10%). The result of the research on clay

ceramic membranes with the additional turbidity reduction efficiency is equal to 90.36%. Whereas, clay

ceramic membranes with the addition of rice husk showed a decrease in turbidity with an efficiency of

88.76%.

1 INTRODUCTION

Water is one of the main requirements that must be

met for the life of all living beings in order to survive

and to continue living. Potable water will be

decreased along with the increasing population

(Furqoni et al., 2016). Increased human needs for

natural resources lead to various negative impacts

such as pollution and environmental damage. Various

activities such as household activities, tourism,

mining, and industry also contribute to water

pollution (Yuniarti, 2007).

Deli River is one of the main rivers in

Belawan/Belumai/Ular River Basin Unit with five

tributaries. The river has an important function in

various aspects of life, namely, as a source of raw

materials for drinking water, bathing, irrigation,

tourism and industry in Medan City. Seventy percent

of pollution along the Deli River caused by solid and

liquid waste from domestic activities (Dinas

lingkungan hidup sumut provinsi, 2014).

Deli river is generally used by the community for

household water needs. However, in the upstream

area, the community in Karo and Deli Serdang

Regency commonly used it for agricultural and

fisheries activities.

Meanwhile, in the middle and downstream area of

the Deli river, it cannot be utilized optimally due to

contaminated water conditions and a decline in water

quality (Bapedaldasu, 2007). The occurrence of water

pollution has a risk of a waterborne disease for people

who depend on these water resources (Slamet, 2000).

The decline in water quality can be indicated by

an increase in the measured levels of physical

parameters. For instance, an increasing level of

parameter turbidity is caused by the presence of

suspended substances in water such as fine sand, clay,

types of compounds such as cellulose, fat, proteins

that float in water or can also be microorganisms such

as bacteria, algae, etc. (Effendi, 2003). In addition,

turbidity also restricts the entry of light into the water

(Kristanto, 2002). This phenomenon results in the

process of photosynthesis not being able to take place

and as a result, microorganisms are disrupted (Kasam

et al., 2009).

There are several methods for treating

contaminated water, such as boiling, pasteurization,

chlorination, disinfectant flocculation, using

ultraviolet (UV), bio-sand filters and so on (Sobsey et

al, 2008). One of the appropriate technology

alternatives that promise to overcome small-scale

household water treatment is by using ceramic

138

Herlina, N., Saragih, M. and Mawarni, H.

Study of Making Clay-based Ceramic Membranes with Additional Rice Husk and Sawdust to Reduce Water Turbidity.

DOI: 10.5220/0008547801380146

In Proceedings of the International Conference on Natural Resources and Technology (ICONART 2019), pages 138-146

ISBN: 978-989-758-404-6

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

membranes (Furqoni et al., 2016). Ceramic

membranes are filters made with a mixture of clay

and combustible organic materials such as tea leaves,

coffee powder, cork seeds, sawdust, corn husks, rice

husks and so on (Widodo, 2015). Ceramic membrane

water filter is very attractive because of their low cost,

ease of fabrication and use, and their ability to filter

water is very effective (Abiriga and Sam, 2014).

Ceramic membrane filter is considered to be highly

effective because of its easy use which is only by

pouring raw water to be filtered into clean water or

potable water (Nugroho, et al., 2015).

The basic ingredients used in the manufacture of

ceramic membranes are clay. Natural clay is a porous

material that has the ability to adsorb (Urabe, 1986).

Clay is a soil that has certain mineral particles that

produce plastic properties in the soil when it is mixed

with water (Grim, 1953).

Meanwhile, the additional materials used in this

study were sawdust and rice husk. The reason for

using these additives is because sawdust and rice husk

are a porous material which means that water is easily

absorbed and fills the pore since the nature of sawdust

and rice husks is hygroscopic or easily absorbs water

(Kasam et al., 2009). Sawdust is a material that

contains the main components of cellulose,

hemicellulose, and lignin so that it can become an

additional material in the manufacture of ceramic

membranes (Slamet, 2013).

Rice husk can be found abundantly and cheap in

many agricultural areas (YayasanTirta Indonesia

Mandiri, 2014). Rice husk as an organic material that

is burned in the combustion process, is able to

increase the pores between ceramic particles. These

pores allow water to flow faster through filters

(Nugroho dkk, 2015) and rice husk ash contains silica

as much as 86% -97% dry weight (Houston, 1972).

Silica is the main raw material in the glass, ceramic

and refractory industries (Krik and Othmer, 1982).

2 RESEARCH OBJECTIVES

The objectives of this study are:

1. Analyzing the effect of variations in the

composition and the size of material in the

production process of ceramic membranes to the

reduction of water turbidity in Deli River;

2. Utilizing clay, rice husk and sawdust as material

for making ceramic membranes as purifiers of

river water into useful and economical potable

water.

3 RESEARCH METHODS

In this study used ceramic membranes made from

clay added with rice husk and sawdust in the form of

pots (pot filters) with each variation of the

composition of clay material and additional materials

namely (80%:20%), (85%:15%) and (90%:10%). In

this study also used variations of sizes of clay and

additional materials by using the material that

escaped in range on 35 mesh and retained on 50

mesh; passed the sieve on 50 mesh and was held in

the sieve on 60 mesh; and passed the sieve on 60

mesh and was held in the sieve on 100 mesh sieve.

Water samples are flowed in batches at each unit at

the same time and the specified discharge between

the three units is as much as 3 liters of water. Then

wait until the water seeps through the media so that it

is accommodated in the container.

3.1 Research Locations

The sample used in this study was water originating

from the Deli river located in Aur Village, Medan

Mainum District, Medan. The clay in this study came

from pot craftsmen located at Jalan Darmo, Ujung

Serdang, Tj. Morawa, Deli Serdang Regency, North

Sumatra. Rice husk in this study was obtained from

the rice husk milling industry located in Gang Turi,

Pasar 7, Tj. Morawa, Deli Serdang Regency, North

Sumatra. Sawdust in this study came from the

property industry located in Dusun Kuini, Pasar 7

Melati II Perbaungan Village, Serdang Bedagai

Regency, North Sumatra.

3.2 Fixed Variables

The fixed variables in this study are as follows:

1. Water samples of Deli River

2. Ceramic membrane media made of clay plus rice

husk and added sawdust in the form of filter

pots;

3. The height of the media is 18 cm with a diameter

of 21 cm and 1 cm thickness;

4. Combustion temperature of 850

o

C - 900

o

Cfor 8

hours.

3.3 Changed Variables

The changing variables in this study are:

a. Material composition :

- (80% : 20%)

- (85% : 15%)

- (90% : 10%)

Study of Making Clay-based Ceramic Membranes with Additional Rice Husk and Sawdust to Reduce Water Turbidity

139

b. Material Size :

- Material that passed on 35 mesh and

retained on 50 mesh.

- Material that passed the sieve on 50 mesh

and retained on the sieve on 60 mesh.

- Material that passed the sieve on 60 mesh

and retained on the sieve on 100 mesh.

3.4 Test Parameters

The parameters examined in this study is the turbidity

of the water.

3.5 Ceramic Membrane Manufacture

The making of ceramic membranes in this study are

as follows:

1. Sliced the soil thinly, then dried in the sun to dry,

then mashed with a ball mill machine and sifted

in the size of (35-50), (50-60) and (60-100) mesh.

2. Additional ingredients, namely rice husk and

sawdust that have been mashed are then sifted

using a range of sizes from 35-50 mesh, 50-60

mesh and 60-100 mesh.

3. Clay and additional material, rice husk and

sawdust, mixed evenly on each batter with a

percent ratio by volume respectively. First

treatment, clay : additional material, (80% :

20%); Second treatment, (85% : 15%) and third

treatment, (90% : 10%). Then, add a little water

into the membrane mixture while stirring evenly

until the mixture of the two is easy to form.

4. Membrane batter is made in the form of a pot-

shaped filter with the membrane diameter of 21

cm, membrane height of 18 cm and membrane

thickness of 1 cm to estimate shrinkage during

the manufacturing process.

5. The batter is removed from the membrane mold,

then dried at room temperature for 7 days.

6. The formed membrane is then dried in the sun to

dry for several days.

7. The next stage, the membrane is burned in a

furnace with a temperature of 850-900 ᵒC for 8

hours.

Based on the ceramic filter guide book (2011), in the

combustion process there are two stages of

combustion temperature, namely:

1. The process of dehydration

2. The process of vitrification (changes in

chemical elements) from the clay will

produce mature ceramic pots.

The temperature of the first stage will produce the

dehydration process at the temperature of 100 ᵒC, the

temperature of the second stage produces the

vitrification process at the temperature of 850 ᵒC.

4 RESULTS AND DISCUSSION

Sampling was carried out twice in this study. In the

first sampling, Turbidity Value Analysis in Deli

River was 13.76 NTU. Then, in the second sampling,

15.6 NTU were obtained. So that the average value

of the two samples is taken with a value of 14.68

NTU in which the value has exceeded the quality

standard in accordance with the Indonesian Ministry

of Health Regulation Number

492/MenKes/Per/IV/2010.

4.1 Test Results of Water Infiltration

Time on Clay and Rice Husk

Ceramic Membrane

A good ceramic filter must have a permeating time

that is not too fast and not too slow (Puspita, 2017).

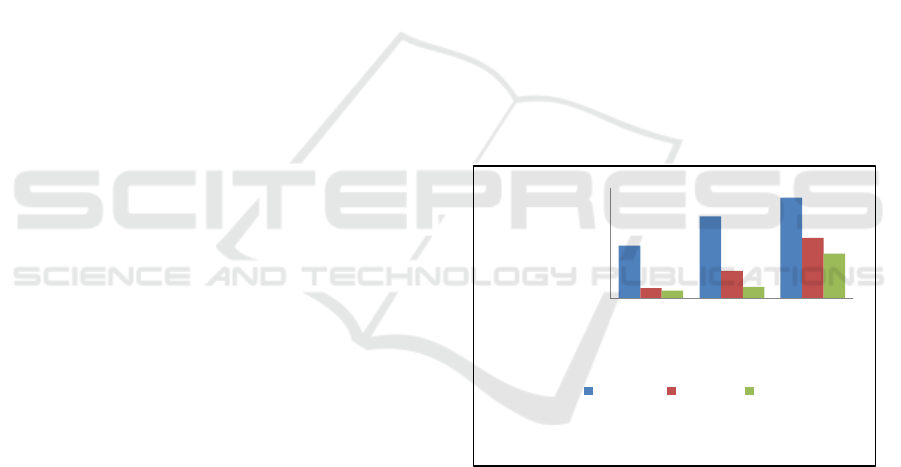

Figure 1: Average Water Infiltration Time (Hours) on

Ceramic Membrane.

In this study, there were two variations carried

out, namely mesh size and material composition, clay

and rice husk. To see the effectiveness of mesh size

and material composition on the time of water

permeation, it is necessary to calculate the average

time of water permeation based on mesh size and

material composition. The fastest time to seize three

liters of water on the membrane is on membrane

number three with a time of 18.38 hours and the

longest time to seize three liters of water on

membrane number seven with a time of 228.22 hours.

119,71

185,90

228,22

23,60

62,62

137,76

18,38

26,11

101,55

0,00

50,00

100,00

150,00

200,00

250,00

35-50

Mesh

50-60

Mesh

60-100

Mesh

Time of Water Infiltration

(Hours)

Mesh Size and Composition of Ceramic

Membrane Materials

90:10 % 85:15% 80:20%

ICONART 2019 - International Conference on Natural Resources and Technology

140

Figure 2: Average Time of Water Infiltration (Hours) Based

on Material Size (Mesh).

Figure 3: Sediment on Ceramic Membrane.

Water seeps faster at a larger mesh size, which

ranges from 35-50 mesh with 53.9 hours of water

permeation time. The longest permeation of water

occurs in smaller mesh sizes, namely the range 60-

100 mesh with the time of permeation of water

155.84 hours. With a larger mesh size will produce

large pores also on ceramic membranes so that the

larger the size of the mesh, the faster the permeation

of water.

Figure 4: Average Time of Water Infiltration (Hours) Based

on Material Composition.

Water seeps faster on the composition of clay

compared to rice husk, the ratio is 80%:20% with the

time of permeation of water is 48.68 hours. The water

seeps longer with the composition of the clay

compared to rice husk whose ratio is 90 %:10% with

the time of permeation of water is 177.94 hours. The

water flow rate increases with the increase in the

composition of combustible materials (Zereffa and

Bekalo, 2017).

At the beginning of the study, the water seemed to

seep faster than the time after, due to pressure so that

the water came out faster than the filter. Meanwhile,

when the water has reached half of the membrane

height, the permeation rate decreases and when the

water has reached the bottom of the membrane, the

rate of water permeation is very slow (Puspita, 2017).

This is because solutes that cause turbidity are

retained by ceramic filters so that they will eventually

accumulate on the membrane surface to form a gel or

fouling layer which results in compression or

resistance to the surface of the membrane (Agmalini

et al, 2013).

4.2 Test Results of Water Infiltration

Time on Clay and Sawdust

Ceramic Membrane

The flow rate of ceramic filters is seen from the time

it takes for water to seep up through the ceramic filter

pore, determined by the thickness of the clay, the

composition of the clay used, the proportion and size

of additional material in the clay mixture (Yayasan

Tirta Mandiri, 2011).

Figure 5: Average Time of Water Infiltration on Ceramic

Membrane.

53,9

91,54

155,84

0

20

40

60

80

100

120

140

160

180

35-50 Mesh 50-60 Mesh 60-100 Mesh

Average Water Infiltration

Time (Hours)

Mesh Size

177,94

74,66

48,68

0,00

50,00

100,00

150,00

200,00

90:10 % 85:15 % 80:20 %

Average Water

Infiltration Time (Hours)

Material Compositions

0

50

100

150

200

250

300

90:10% 85:15% 80:20%

35-50 mesh

200,5 60 42,07

50-60 mesh

140 117,23 24

60-100 mesh

265,7 153,15 157,6

Time of Water Infiltration

(Hours)

Material Composition and Size of Ceramic

Membrane Mesh

Study of Making Clay-based Ceramic Membranes with Additional Rice Husk and Sawdust to Reduce Water Turbidity

141

The fastest time to seize three liters of water on a

membrane is membrane number 6 with a time of 24

hours and the longest time to seep three liters of water

on a membrane is membrane number 7 with a time of

265.7 hours.

In this study, there were two variants carried out,

namely mesh size and material composition which is

clay and rice husk. To see the effectiveness of mesh

size and material composition at the time of water

permeation, it is necessary to calculate the average

time of water permeation based on mesh size and

material composition.

Figure 6: Average Water Infiltration Time on Ceramic

Membrane Based on Mesh size.

The graph shows the fastest permeation time based on

the size of the material used, namely the size range of

50-60 mesh with a time of 93.7 hours. Whereas, the

longest average permeation time based on the size of

the material used is in the size range 60-100 mesh

with a time of 192.12 hours.

Figure 7: Average Time of Water Infiltration on Ceramic

Membrane Based on Material Composition.

The graph above shows that the average time of

permeation of water from ceramic membranes based

on the composition of the material used, the

composition of the mixture of clay and sawdust with

a ratio (80%:20%) has the fastest permeation time,

which is 74.5 hours. Whereas the composition of the

mixture of clay and sawdust with a ratio (90%:10%)

has the longest permeation time, which is 202.1

hours. The less composition of additional material,

the more time needed for permeation. According to

Clair (2006) and Dies (2003), when a ceramic filter is

burned, sawdust contained in the mixing filter will

burn out leaving pores or voids through filtered water.

Therefore, ceramic filter with a higher percentage of

sawdust and rice husk composition leave more pores

after combustion, hence greater porosity can be

proved by higher percolation or water flow rates.

There are other factors that have an impact on

permeation times such as pore size distribution, the

formation of cake layers under the ceramic membrane

and the pore volume of ceramic filters (Musa, 2010).

Ceramic filter flow rates made of 40% sawdust

decrease from 1.5 L/hour to 0.5 L/hour because the

cake layer is formed at the bottom and particles clog

the pores. The slowing of the permeation time is

caused by the filter being clogged by deposits carried

by water. The longer the use of filters, the higher the

thickness of the sediment that causes the ability of

water to penetrate the filter pore is getting heavier

(Matthies and Obst, 2010). Similarly, in this study,

when water was poured into the ceramic membrane

at the beginning, the water flowed faster when

compared to when it had reached permeation half of

the initial results were entered.

This is proven by the presence of deposits that

are held on the ceramic membrane and the cake layer

on the bottom of the ceramic membrane, so that there

is a blockage when the water flows which results in

long permeation time. However, to prevent a

reduction in the performance of ceramic membranes,

users need to scrub their filters with a brush when the

filter has become slower. Half of the families in one

study, they rubbed their filters no more than once

every week (Nnaji et al., 2016).

4.3 Turbidity Reduction Efficiency on

Clay and Rice Husk Made

Membrane

Water samples originating from the Deli river before

and after filtration turbidity testing were carried out

to determine the effect of ceramic membranes in

reducing turbidity in Deli River water.

0,0

50,0

100,0

150,0

200,0

35-50

mesh

50-60

mesh

60-100

mesh

100,9

93,7

192,12

Average Water Infiltration

Time (Hours)

Mesh Size

0,0

50,0

100,0

150,0

200,0

250,0

90:10% 85:15% 80:20%

202,1

110,13

74,5

Average Water Infiltration Time

(Hours)

Material Composition

ICONART 2019 - International Conference on Natural Resources and Technology

142

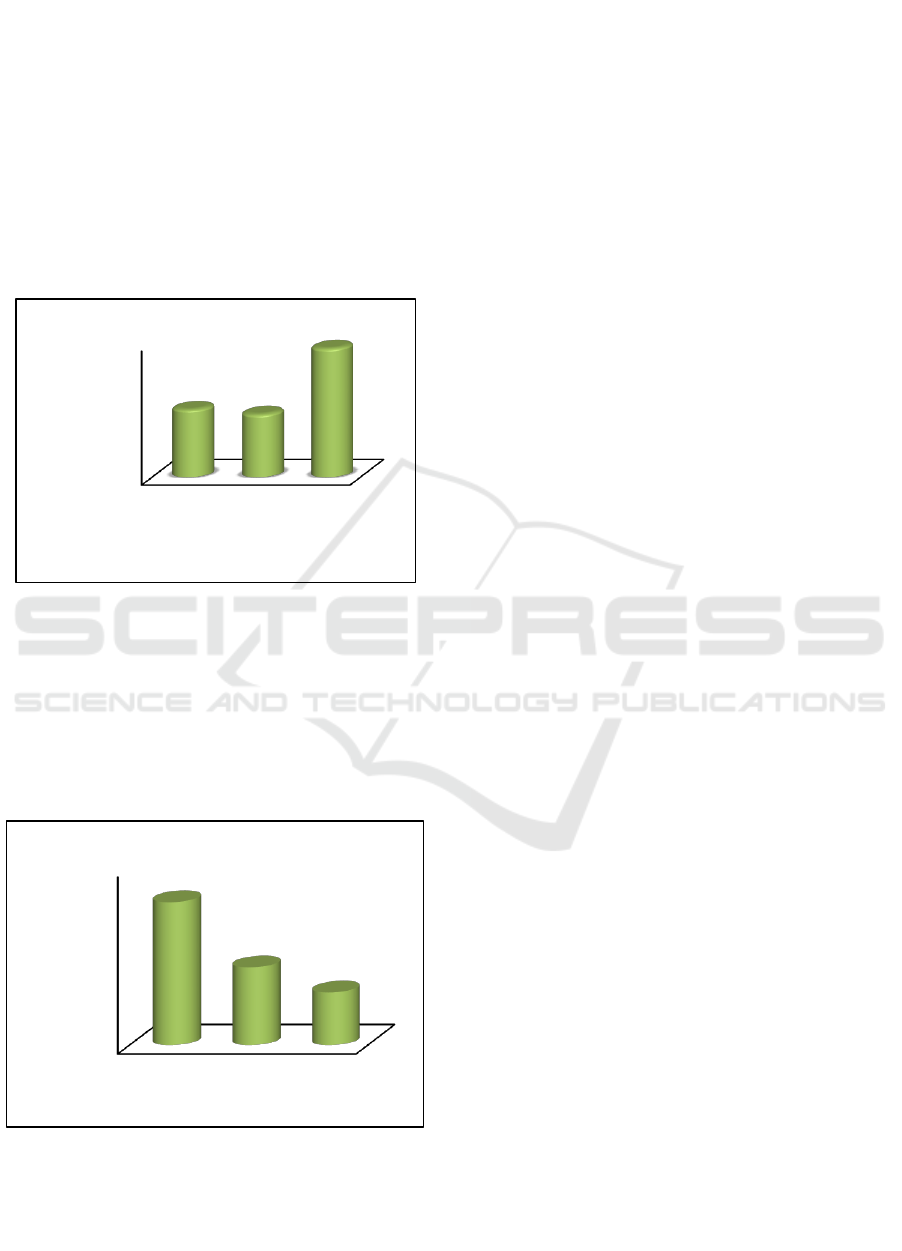

Figure 8: Average Efficiency of Turbidity Reduction in

Ceramic Membrane.

The efficiency of turbidity values that have been

averaged after passing through ceramic membranes

on each membrane has decreased significantly to

below the quality standard that is below 5 NTU. The

highest efficiency is 88.91% on membrane number

seven with the ratio of composition of clay and rice

husk is 90% and 10% with the material size of 60-100

mesh. Meanwhile, the lowest efficiency is 70.71% on

membrane number eight with the ratio of composition

of clay and rice husk is 85% and 15% with the

material size of 60-100 mesh.

Figure 9: Average Efficiency of Turbidity Reduction on

Ceramic Membrane Based on Mesh Size.

The average efficiency of turbidity value based on

mesh size has the highest value on 35-50 mesh size

with an efficiency value of 82.01% and the lowest

efficiency with the size of 50-60 mesh with an

efficiency value of 80.89%.

Figure 10: Average Efficiency of Turbidity Reduction on

Ceramic Membrane Based on Material Composition.

The average efficiency of turbidity value based

on the composition of clay material and rice husk has

the highest value at the composition ratio of

90%:10% with an efficiency value of 84.95% and the

lowest efficiency with a composition ratio of

85%:15% with an efficiency value of 77.63%.

In this study, the results obtained were not

inversely proportional to the time of permeation of

water, because the process of forming and mixing

ceramic membranes was done by hand or manually,

not using a mixing machine in the process of mixing

ceramic membrane making materials and not using a

friction machine or press machine on the process of

forming ceramic membranes. The process of mixing

the material is important so that the mixture of

ceramic raw material with the arrangement of the

composition and size of the grain becomes

homogeneous. In addition, this process also reduces

the porosity found in the membrane (Puspitasari,

2013). Mixing less homogeneous materials produces

membranes that tend to have porosity, the limited

number of pores and surface area. The inhomogeneity

in ceramic membranes shows that some particles are

released from the membrane body so that it covers the

pore area on the membrane surface (Susanto dan

Nurhayati, 2017).

In the process of forming a membrane, the

density and the size of the filter pores are two factors

that affect membrane performance (Hagan et al,

2009). The press machine is needed to condense the

mixture of clay and rice husk (Jerefasio, 2015).

Consistency between elements is easier to maintain

with the use of a press machine compared to forming

membranes with hands assisted with turning wheels

(Dies, 2001). So that the density of clay and rice husk

in the membrane formation process cannot be the

84,75

82,68

78,60

81,19

79,51

81,97

88,91

70,71

85,92

0,00

10,00

20,00

30,00

40,00

50,00

60,00

70,00

80,00

90,00

100,00

90:10 % 85:15 % 80:20 %

Turbidity Reduction Efficiency (%)

Material Composition and Size of Ceramic Membrane Mesh

35-50 Mesh 50-60 Mesh 60-100 Mesh

82,01

80,89

81,85

80,2

80,4

80,6

80,8

81

81,2

81,4

81,6

81,8

82

82,2

35-50 Mesh50-60 Mesh 60-100

Mesh

Average Turbidity Reduction

Efficiency (%)

Mesh Size

84,95

77,63

82,16

72,00

74,00

76,00

78,00

80,00

82,00

84,00

86,00

90:10 % 85:15 % 80:20 %

Average Turbidity Reduction

Efficiency (%)

Material Composition

Study of Making Clay-based Ceramic Membranes with Additional Rice Husk and Sawdust to Reduce Water Turbidity

143

same because of the limited emphasis during the

process of forming ceramic membranes.

Based on the research of Widodo et al (2015)

clay filters made by press molding are more effective

than clay filters made without a press molding

(manually).

4.4 Turbidity Reduction Efficiency on

Clay and Sawdust Ceramic

Membrane

Turbidity testing results from the nine ceramic

membranes with variations in material composition

and material size have different turbidity values,

where the overall turbidity value on ceramic

membranes has been below the quality standards set

by Regulation of Ministry of Health Number

492/Menkes/Per/ IV/2010 that concerning the

maximum level allowed in drinking water which is 5

NTU.

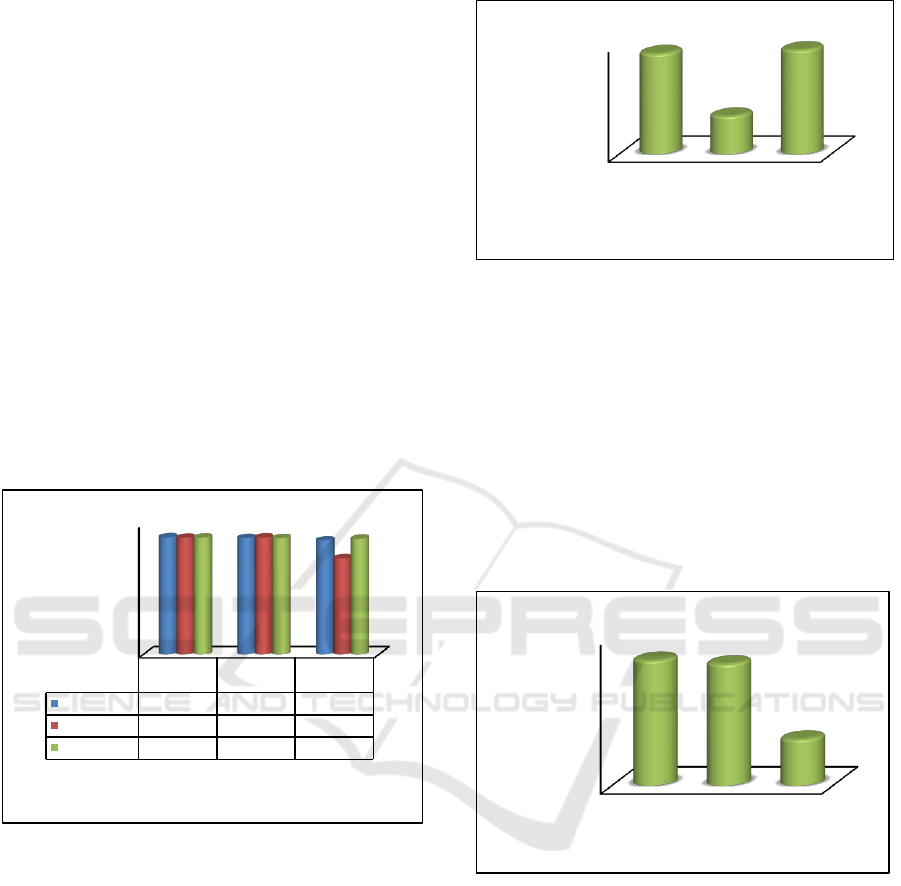

Figure 11: Average Efficiency of Turbidity Reduction on

Ceramic Membrane.

The efficiency of turbidity values that have been

averaged after passing through ceramic membranes

on each membrane has decreased significantly to

below the quality standard that is below 5 NTU. The

graph of turbidity testing results above shows that the

highest turbidity reduction efficiency is indicated by

ceramic membrane number 1 with the composition

ratio of the mixture of clay and sawdust is 90% and

10% with an efficiency value of 90.36%. While the

lowest efficiency was indicated by ceramic

membrane number 6 with the composition ratio of the

mixture of clay and sawdust is 90% and 10% with an

efficiency value of 74.19%.

Figure 12: Average Efficiency of Turbidity Reduction on

Ceramic Membrane Based on Mesh Size.

The average efficiency of turbidity values based

on mesh size has the highest efficiency indicated in

the range of 60-100 mesh with an efficiency value of

89.59%. This shows that filters that have smaller

(finer) material sizes have advantages in terms of

quality in reducing water turbidity, but the filtered

volume becomes less and takes a long time (Widodo

et al, 2015). Meanwhile the lowest efficiency is

shown in the size range 50-60 mesh with an efficiency

value of 84.78%.

Figure 13: Average Efficiency of Turbidity Reduction on

Ceramic Membrane Based on Material Composition.

The average efficiency of turbidity value based

on the composition of the materials used for the

highest efficiency is shown in the composition of the

mixture of clay and sawdust (90%: 10%) with an

efficiency value of 90.11%. This shows that the less

additional material used in the process of making

ceramic membranes, the less pore formed after the

combustion process so that it can provide good

quality turbidity values. Meanwhile, the lowest

efficiency is shown in the composition of the mixture

of clay and sawdust (80%: 20%) with an efficiency

value of 83.75%. Conversely, the more additional

material used, the greater the pore formed after the

0,00

10,00

20,00

30,00

40,00

50,00

60,00

70,00

80,00

90,00

100,00

90%:1

0%

85%:1

5%

80%:2

0%

35-50 mesh

90,36 89,69 87,93

50-60 mesh

89,93 90,21 74,19

60-100 mesh

90,05 89,59 89,12

Turbidity Reduction

Efficiency (%)

Material Composition and Size of Ceramic

Membrane Mesh

82,00

84,00

86,00

88,00

90,00

35-50

mesh

50-60

mesh

60-100

mesh

89,33

84,78

89,59

Turbidity Reduction

Efficiency (%)

Mesh Size

80,00

82,00

84,00

86,00

88,00

90,00

92,00

90:10% 85:15% 80:20%

90,11

89,83

83,75

Turbidity Reduction

Efficiency (%)

Material Composition

ICONART 2019 - International Conference on Natural Resources and Technology

144

combustion process so that organic materials with

smaller sizes than membrane pores can escape which

cause high turbidity values and low turbidity

reduction efficiency. This shows that larger pores

because of the high content of sawdust cause less

effectiveness of ceramic filters in reducing the

turbidity of water and other pathogens.

The average turbidity value of all ceramic

membranes obtained from the results of water

samples that have been passed through ceramic

membranes shows results that are below the quality

standard. However, the chart also shows results that

tend to fluctuate between the size of the material and

the composition of the material forming the ceramic

membrane. This happens because in the process of

forming ceramic membranes using manual

techniques by hand so that the pressing process is less

effective than using a press machine. Certainly, this

also results in more pore space due to uneven

compression and non-homogeneous mixing when

using hands. Manually pressing clay into the mold is

very time-consuming. Pressing the shape by hand

requires a mixture of clay that contains relatively

more water so that the material retains its shape and

blends together. Consistency between elements is

more easily maintained by the use of a press machine

compared to forming a membrane with a hand

assisted with a turning wheel (Dies, 2003).

According to a study conducted by Ervin et al.

(2000), the greater the printing pressure, the greater

the force applied to suppress the material so that the

distance between the clay particles becomes more

tight and uniform. According to the research

conducted, the technique of using a press machine on

the manufacture of ceramic membranes can affect the

results of the membrane. The use of press machines

makes membranes have denser pores and have the

same pressure so that the resulting pores are more

uniform (Dies, 2003) Membranes made by the slip

casting method show lower densities than those

formed by pressing techniques. The sample produced

by slip-casting has a higher turbidity level than the

pressing process which shows that large diameter

pores make it easy to cross particles through filter

samples. But the pressing technique gives less

turbidity value because of the compaction strength

which causes the convergence item (Isikwue and

Emmanuel, 2011). This condition shows that with a

large printing pressure, the distance between clay

particles is getting tight so that the formed pore is

smaller so that it has the best quality in the turbidity

level efficiency (Ervin et al, 2000).

5 CONCLUSIONS

The conclusions in this study are as follows:

1. The most effective ceramic membrane in reducing

turbidity is ceramic membranes made from clay

with additional sawdust with a turbidity reduction

efficiency of 90.36% with the compositions ratio

of clay and sawdust is 90% and 10%, and range

35-50 mesh material size.

2. Ceramic membranes made from clay and

additional rice husks are able to reduce turbidity

by reducing turbidity efficiency by 88.76% with

the composition ratio of clay and rice husk is 90%

and 10%, and the size of the material range from

60-100 mesh.

3. The membrane that most quickly seals 3 liters of

water on the ceramic membrane is a ceramic

membrane made from clay and sawdust with a

permeation time of 24 hours, which is membrane

number 6 with the composition ratio of clay and

sawdust is 80% and 20%, and in the range 50- 60

mesh.

4. Ceramic membranes with clay material and

additional rice husk seep 3 liters of water within

18.38 hours with the composition ratio of clay and

rice husk is 80% and 20%, and range 35-50 mesh.

REFERENCES

Abiriga, F., Sam, O.K. 2014. Effect of Grogs on in the

Performance of Ceramic Water Filters. Science Journal

of Physics ISSN: 2276-6367. Kyamboga University.

Kampala Uganda. (In Indonesia)

Agmalini, S., Lingga, N. N., and Nasir, S. 2013. Improving

the Quality of Swamp Water Using Ceramic Membrans

Made from Natural Clay and Coal Ash. Departement:

Chemical Engineering, Faculty of Engineering,

Universitas Sriwijaya. (In Indonesia)

Badan Pengendali Dampak Lingkungan Daerah Provinsi

Sumatera Utara (BAPEDALDASU). 2007. Report on

the Enviromental Status of the Northern Sumatra

Province. North Sumatra Province in 2007. Medan. (In

Indonesia)

Clair, M. 2006. House hold ceramic filter evaluation using

three simple low cost methods: membrane filtration, 3m

Petri film and Hydrogen sulphide bacteria in Northern

region Ghana.Mscthesis. Massachusetts Institute of

technology (USA).

Dies, R. 2001. Development of a Ceramic Water Filter for

Nepal. Departement of Civil and Enviromental

Engineering. Canada: University of British Columbia.

Dies R. 2003. Development of a ceramic water filter for

Nepal. Master Thesis, MIT, Massachusetts, USA.

Study of Making Clay-based Ceramic Membranes with Additional Rice Husk and Sawdust to Reduce Water Turbidity

145

Effendi, H. 2003. Reriew Water Quality for the

Management of Water Resouces and Environment.

Kanisisus. Yogyakarta. (In Indonesia)

Ervin, Y, et.al. 2000. The Effect of Combustion

Temperature on the Properties of Alumina-Zirconia

Ceramic Compositis. Proceedings of the Natural

Physics Symposium XVII. (In Indonesia)

Furqoni, R.A., Mahardika, P., Sulhadi. 2016. Development

of Water Filters with Ceramic Materials to Inprove

River Water Quality. Proceedings of the Natural

Physics (E-Journal) SNF. Vol. V. Semarang. (In

Indonesia)

Grim, R.E. 1953. Clay Mineralogi. New York: McGraw

Hill.

Hagan, J., Nick, H., Robert, H., Ajay, C., David, P.,

Mickey, S., Vanna , SAOM., and Kathryn, S. 2009.

Resource Development International - Cambodia

Ceramic Water Filter Handbook , Version 1.1, Phnom

Penh.

Henry, M., 2013. Designing a Low-Cost Ceramic Water

Filter Press.International Journal for Service Learning

in Engineering, 8(1), pp.62–77.

Houston, D.F. 1972. Rice Chemistry and Technology,

American Association Of Cereal “ Chemist Inc. St.

Paul, Minnesota.

Isikwue, M.O., and Emmanuel N.A. 2011. “Evaluation of

a ceramic pot made from local materials as water

purification systems”, International Journal of Science

and Advanced Technology (ISSN 2221-8386), Vol. 1

No 6.

Jerefasio, N. 2015. Nanoporous Ceramics Filter for Water

Purification. Departement of Physics. Thesis,

Submitted for Examination in Partial Fulfillment of the

Requirements for Award. Nairobi: University of

Nairobi.

Kasam, Eko, and Rina. 2009. Use of Ceramic Membranes

to Reduce E.coli Bcteria and Total Suspended Solid

(TSS) in Surface Water.Chemical Engineering Journal.

No.1, Vol. 1. (In Indonesia)

Kirk and Othmer. 1982. Kirk-Othmer Encyclopedia of

Chemical Technology. Vol. 17, John Wiley and Sons,

Inc., Canada.

Kristanto. 2002. Liqued Waste Pollution. Jakarta:

Yudistira. (In Indonesia)

Matthies, K.,Obst U. 2010. Concept of appropriate water

and waste water treatment in the karst region Gunung

Kidul, Southern Java, Indonesia. Proceedings.

Integrated Water Resources Management International

Conference Karlsruhe.

Musa K. 2010.“Performance of ceramic water filters made

from selected Uganda clays for point-of-use”. Thesis of

masters of science (physics) degree of makerere

university.

Nugroho, A., Adi, H.S., Susi, I., Sarto, Yulia, R. W. 2015.

Study of Method of Adding Silver Nitrate to Ceramic

Filters Against Eschericia coli of Dringking Water.

Public Health Study Program, Universitas Sumatera

Utara. Vol. 10. (In Indonesia)

Regulation of the Minister of Health RI No.

492/MenKes/Per/IV/2010 Redarding Drinking Water

Quality Requirements. (In Indonesia)

Puspitasari, D. 2013. Mechanical Properties Analisis and

Microscopic Photos of Ceramics Made from Scaly Clay

Based on Larang Continued Kebumen Formations

Sekription, Faculty of Math and Science. Semarang:

Universitas Negeri Semarang. (In Indonesia)

Puspita, I.R. 2017. Preparation and Characterization of

Porous Ceramic Filters for Recycling Ablution Water.

Bandung: Universitas Islam Negeri Sunan Gunung

Djati. (In Indonesia)

Slamet, J.S. 2000. Enveromental Health. Gajah Mada

University Press: Yogyakarta. (In Indonesia)

Slamet, S. 2013. Composit Characterization of Wood

Sawdust (Sawdust) by Process Hotpress as a Particle

Board Raw Material. Proceedings SNST ke-4, ISBN

978-602-99334-2-0.UniversitasMuria Kudus.

Semarang. (In Indonesia)

Sobsey MD, Stauber CE, Casanova LM, Brown JM, and

Elliott MA. 2008.“Point of use household drinking

water filtration:A practical, effective solution for

providing sustained access to safedrinking water in the

developing world.”Environ. Sci. Technol., 42(12):

4261–4267.

Susanto, T., and Nurhayati, C. 2017. Surface Water

Treatment in Banyuasin Uses Coal-Based Ceramic

Membranes and Nano Clay. Research Journal.

Industrial Pollutan Prevention Technology. (In

Indonesia)

Urabe, M. 1986. Interaction of Metal Ion with Clays: I. A

case study with Cu (II). Applied Clay Science. 30: 199-

208.

Widodo., dkk. 2015. Study of Total Coliform Springs

Purification Using Clay Filters. Semarang: Universitas

Diponegoro. (In Indonesia)

Willshaw, G.A., Cheasty, T., and Smith, H.R. 2000.

Escherichia coli The Microbiological Safety and

Quality of Food. Aspen Publishers, Inc. Gaithersburg,

Maryland USA. Volume 2.

Yayasan Tirta Indonesia Mandiri. 2011. Manual for

Making Trial Edition Ceramic Filters.Jakarata. (In

Indonesia)

Yuniarti, B. 2007. Measurment of Turbidity Levels Using

Turbidimeters Based on the Principle of Light

Scattering. Skription. Universitas Sanata Dharma.

Yogyakarta. (In Indonesia)

ICONART 2019 - International Conference on Natural Resources and Technology

146