The Effect of Natural Preservatives from Jackfruit Wood Percentage

Addition on Palm Oil Sap (Elaeis guuineesis Jacq.) during Storage

Tri Shinta Elvina, Mimi Nurminah and Terip Karo-karo

Department of Food Science and Technology, Faculty of Agriculture, Universitas Sumatera Utara

Keywords: Natural Preservative, Jackfruit Wood, Palm Oil Sap.

Abstract: Oil palm plantations continue to increase in Indonesia. Oil palm which is no longer productive will be

replanted and replace with new seeds. Oil palm replanted still has the potential to produce oil palm sap. Oil

palm sap is perishable so it is necessary to handle palm oil sap before entering a further production process,

one of which is natural preservative from jackfruit wood. This study used a completely factorial randomized

design with 2 factors, namely the concentration of jackfruit wood added (K): (3%, 6%, 9%, 12%) and storage

time (T): (0 days, 1 day, 2 days, 3 days). The result showed that the best oil palm sap was from the treatment

the percentage increase of 12% jackfruit wood and storage for 3 days.

1 INTRODUCTION

African oil palm (Elaeis guineensis Jacq.) is basically

a cultivated plant with good response to

environmental condition. Climates and soil condition

are the main factors beside other factors such as

genetics, plant care and others. Efforts in improving

the production of African oil palm has been seriously

conducted, both through intensification and

extensification. Indonesia is the biggest exporter of

African oil palm. This plant potential is enormous.

Contribution of African oil palm to APBN can reach

9.11 billion dollars. African oil palm export from

Indonesia reached 23 million tons in 2010. An

estimate of 35% from the profit of African oil palm

came from small farmers who lived from certain

sectors. In 2011, around 8 million hectares of African

oil palm expansion in the world came from Indonesia

(Tim Penulis PS, 1997). However, increased

productivity of oil palm plantation is followed by

their waste. Waste produced from oil palm production

(OPP) can be divided into two types, i.e. liquid waste

and solid waste. Solid waste from oil palm include

23% of empty fruit bunches (EFB), boiler ash (around

0.5% of OPP), fibers (around 13.5% of OPP) and

shells (around 5.5% of OPP). Solid wastes produced

from OPP commonly did not cultivated plant with

good response to environmental condition. Climates

and soil condition are the main factors beside other

factors such as genetics, plant care and others. Efforts

in improving the production of African oil palm has

been seriously conducted, both through

intensification and extensification. Indonesia is the

biggest exporter of African oil palm. This plant

potential is enormous. Contribution of African oil

palm to APBN can reach 9.11 billion dollars. African

oil palm export from Indonesia reached 23 million

tons in 2010. An estimate of 35% from the profit of

African oil palm came from small farmers who lived

from certain sectors. In 2011, around 8 million

hectares of African oil palm expansion in the world

came from Indonesia (Authors, 1997).

However, increased productivity of oil palm

plantation is followed by their waste. Waste produced

from oil palm production (OPP) can be divided into

two types, i.e. liquid waste and solid waste. Solid

waste from oil palm include 23% of empty fruit

bunches (EFB), boiler ash (around 0.5% of OPP),

fibers (around 13.5% of OPP) and shells (around

5.5% of OPP). Solid wastes produced from OPP

commonly did not need complicated management.

Solid waste can be reused as fuel, fertilizer, animal

feed, and can be sold to produce extra income. Solid

wastes from oil palm still produces high sale value.

Uprooted oil palm or replanted oil palm are the

biggest waste with minimum management. Uprooted

oil palm can produce sap when tapped on the tip and

can produce other byproducts such as palm sugar. Sap

is a perishable commodity because of fermentation

which changes the taste of sap into acidic. Basically,

fresh sap contains several good microbes in the form

124

Elvina, T., Nurminah, M. and Karo-Karo, T.

The Effect of Natural Preservatives from Jackfruit Wood Percentage Addition on Palm Oil Sap (Elaeis guuineesis Jacq.) During Storage.

DOI: 10.5220/0008546901240127

In Proceedings of the International Conference on Natural Resources and Technology (ICONART 2019), pages 124-127

ISBN: 978-989-758-404-6

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

of yeast and bacteria. Fermentation process occurs

when tapping process was started. Sap has quite high

nutritional content, i.e. 87.66% water, 12.04% sugar,

0.36% protein, 0.36% fat, and 0.21% ash; therefore,

sap is suitable as a media or a place for microbes to

grow, such as fungi or bacteria during fermentation

process (Gafar and Heryani, 2012). There are several

natural preservatives commonly added by the tappers

to inhibit fermentation in sap, including the wood or

sap of jackfruit (Artocarpus heterophylla Lamk.),

which is a local plant often found in various regions

in Indonesia. Jackfruit is usually used as traditional

medicine. The chemical contents of jackfruit wood

include morin, cyanomaclurine (tanned substance),

flavone, and tannin, Other than that, there are new

flavonoid substances in the skin of jackfruit wood, i.e.

morusin, artocarpin, artonin E, cycloartobilosanton,

and artonol B. The bioactivity of those flavonoid

substances is known empirically as anticancer,

antivirus, antiinflammation, diuretic, and

antihypertension (Robinson, 1995).

2 MATERIAL AND METHOD

This research was conducted at Food Technology

Laboratory, University Sumatera Utara. The

materials used were white sugar, jackfruit wood and

oil palm sap which were obtained from Bingkat

Village, Pegajahan, Serdang Berdagai Regency,

North Sumatera. The preservatives were taken from a

part of jackfruit wood, then cut into small size, then

scaled for 100 g. Five liters of water was heated to

boil for 30 minutes, then 100 g of jackfruit wood was

put into boiling water and stirred evenly. Afterwards,

the natural preservatives were left to cool. Natural

preservative was added into container of tapped sap.

Preservative was given incrementally to prevent

damage to sap during collection. Previously prepared

preservative then added into container with

concentrations of 3% (K1), 6% (K2), 9% (K3), and

12% (K4) in 1 liter of sap. Afterwards, oil palm sap

was left at room temperature for 0, 1, 2, and 3 days of

shelf-life. This study was conducted using Complete

Random Design which consisted of two factors, i.e.

Factor I: Percentage of natural preservatives (K)

which consisted of 4 phases, which are K1 (3%), K2

(6%), K3 (9%), K4 (12%), and Factor II: Storage

duration (T) which consisted of 4 phases, which are

T1 (0 day), T2 (1 day), T3 (2 days), T4 (3 days). The

number of treatment combination (Tc) was 4 x 4 = 16.

Two repetitions were performed for precision. The

analytical parameters for sap and palm sugar include:

reduction sugar (AOAC, 1995), sucrose, total sugar

(Sudarmadji, et al., 1997).

3 RESULTS AND DISCUSSIONS

3.1 Reducing Sugar

Preservative addition (Table 1) and storage duration

(Table 2) affected reducing sugar of oil palm sap

significantly (p < 0.01), and the interaction of the two

gave significantly different effect (p < 0.01). The

decrease of reducing sugar level during the addition

of jackfruit wood solution from the lowest to highest

concentration, i.e. 3% of addition of jackfruit wood

solution in 100% of oil palm sap, which was 0.778%

(Table 1). The decrease of reducing sugar level of oil

palm sap was caused by the wood percentage which

cause reduced sap percentage needed, where the use

of jackfruit wood solution of 3% needed 97% of sap,

while the use of 12% jackfruit wood solution needed

88% sap, therefore the highest reducing sugar level

was found in the lowest concentration of jackfruit

wood. This was in accordance with Gusti et al, (2016)

which stated that when a solution was added to sap,

it will affect the concentration of sugar level, because

added sap has high sugar level, which is 12.04%.

Storage duration for 3 days resulted in highest

reducing sugar level concentration, i.e. 0.846%

(Table 2). Increased reducing sugar level in oil palm

sap was caused by changes in components or sugar

degradation such as sucrose by the changes of acidic

environment or enzyme during storage, thus

increasing the number of simple sugar or reducing

sugar in oil palm sap. Sucrose will undergo

degradation due to acidic, hot environment, and

certain minerals through hydrolytic reaction.

Hydrolysis or inversion of sucrose can occur

spontaneously in acidic condition. Hydrolysis

reaction or inversion reaction to sucrose molecules,

both full and partial, will create D-glucose and D-

fructose monosaccharides which are more stable than

sucrose.

The Effect of Natural Preservatives from Jackfruit Wood Percentage Addition on Palm Oil Sap (Elaeis guuineesis Jacq.) During Storage

125

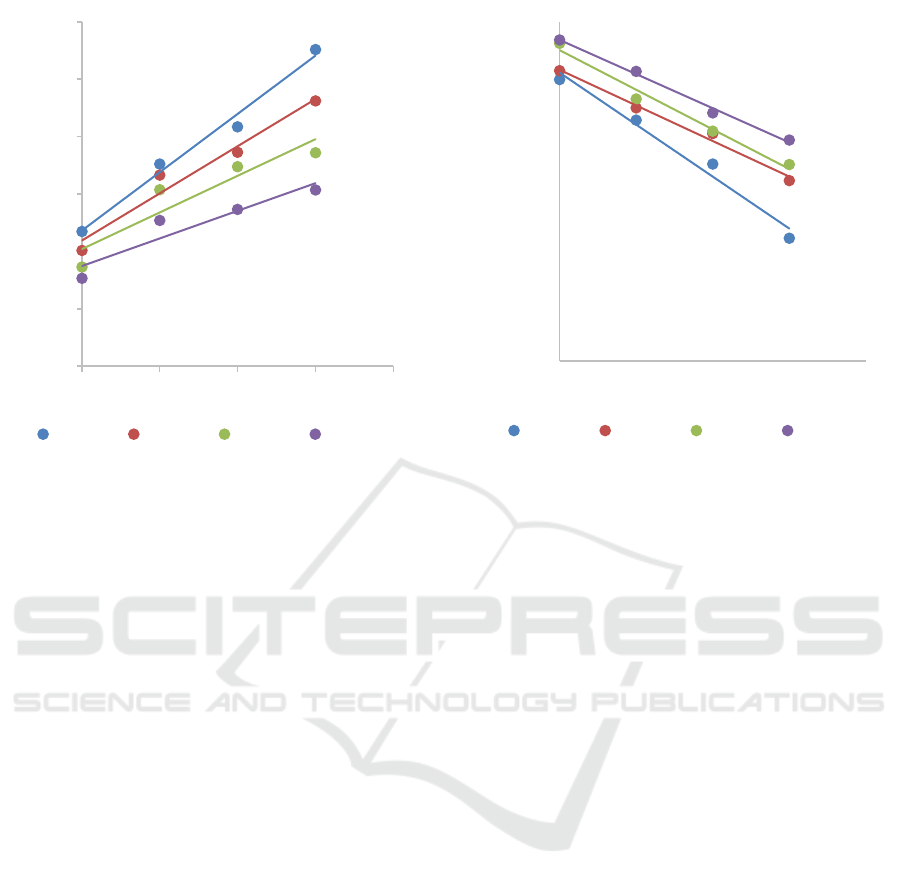

Figure 1: The interaction of addition of preservatives and

storage time with reducing sugar palm oil sap.

3.2 Sucrose

Preservative addition (Table 1) and storage duration

(Table 2) give significant difference (p < 0.01) to

sucrose in oil palm sap, the interaction gives

significant differences (p < 0.01). There was an

increase of sucrose level during the addition of

jackfruit wood solution of 12% to 15.570% (Table 1).

Preservative addition caused inhibition of acidic

condition in sap and inactivate enzyme activity which

can degrade sucrose in sap. Therefore, highest

addition of jackfruit wood solution had higher sucrose

level. This result was in accordance with Ersam

(2001) which stated that the chemical substances of

jackfruit wood include morin, cyanomaclurine

(tanned substance), flavone, and tannin which had

bacteriostatic effect. These substances were strongly

thought to play a role in inhibiting fermentation

process of sap which produced acid, thus sucrose

level in sap can be maintained. Decreased sucrose

level in oil palm sap during storage duration (Table 2)

was caused by spontaneous fermentation process that

occurred during storage process, which cause changes

in sucrose and increased acidity of sap. This was in

accordance with Budiyanto (2014) which stated that

the longer the storage duration, then the lower the pH

of sap because sap is a fertile growth media for

microorganism.

Figure 2: The interaction of addition of preservatives and

storage time with sucrose palm oil sap.

3.3 Total Sugar

Preservative addition (Table 1) and storage duration

(Table 2) showed significant differences (p < 0.01) in

sucrose of oil palm sap, including the interaction of

both (p < 0.01).

The addition of jackfruit wood solution showed

increase by adding the concentration of jackfruit

wood solution to 12%. This was caused by

antimicrobial substances in jackfruit wood which can

inhibit the activity of microbes and inhibit

fermentation which can reduce sugar level in sap.

This was in accordance with Fauzi, et al, (2013),

which stated that the addition of natural preservatives

from jackfruit wood showed that higher concentration

resulted in higher total sugar level in sap. Jackfruit

wood contains yellow substances called morine,

alcohol, saponins, glucosides and calcium oxalate.

Jackfruit bark contains resins, cycloheterophyllin and

tannins. Tannin has bacteriostatic properties that can

inhibit bacterial growth (Filiyanti et al, 2006;

Dalimarta, 2008). Sap is a sweet liquid that has 12.30-

17.40 gr of sucrose. Fresh sap has a number of

microbes in the form of yeast or bacteria from

bunches or air when the tapping process takes place

(Mussa, 2014). There was a decrease in sap up to 3

days of storage in the amount of 14.634%. The

decrease of total sugar was caused by spontaneous

fermentation during storage process, which caused

changes in acidic environment and degradation of

carbohydrates, thus resulted in decreased total sugar.

T1 = ŷ = 0,2032T + 0,4728

r = 0,9921

T2 = ŷ = 0,1643T + 0,4379

r = 0,9793

T3 = ŷ = 0,127T + 0,408

r= 0,9264

T4 = ŷ = 0,0963T + 0,3489

r = 0,9385

0,00

0,20

0,40

0,60

0,80

1,00

1,20

0 1 2 3 4

Reducing sugar (%)

Storage time

K1 = 3% K2 = 6% K3 = 9% K4 = 12%

T4 = ŷ = -1,0729x + 15,951

r = 0,9882

T3 = ŷ = -0,7347x + 16,01

r = 0,9938

T2 = ŷ = -0,8177x + 16,416

r = 0,9901

T1 = ŷ = -0,7053x + 16,628

r = 0,9970

10,00

11,00

12,00

13,00

14,00

15,00

16,00

17,00

0 1 2 3 4

Sucrose (%)

Storage time

K1 = 3% K2 = 6% K3 = 9% K4 =12%

ICONART 2019 - International Conference on Natural Resources and Technology

126

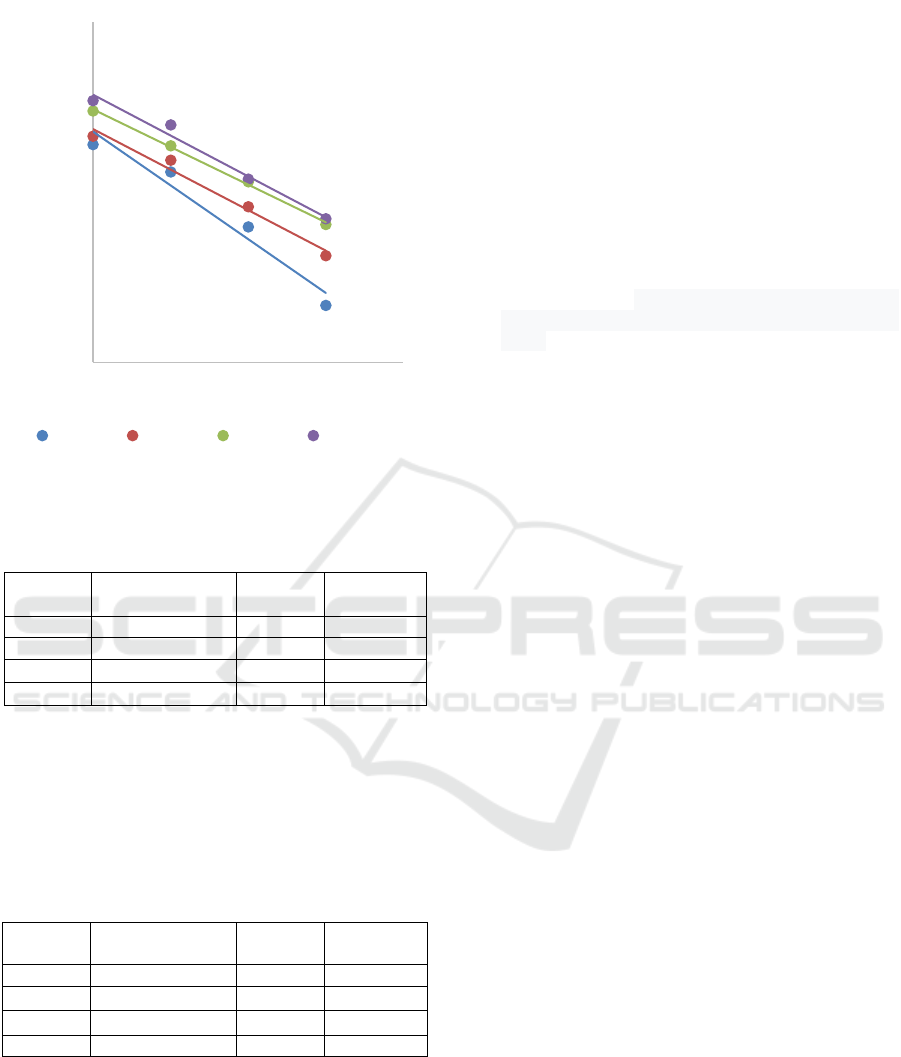

Figure 3: The interaction of addition of preservatives and

storage time total sugar palm oil sap.

Table 1: Effect of additon jackfruit on reduction sugar,

sucrose, and total sugar of palm oil sap.

Treatment

Reduction Sugar

(%)

Sucrose

(%)

Total Sugar

(%)

K1 (3%)

0,777

cD

14,341

cD

15,204

cC

K2 (6%)

0,684

bC

14,907

bC

15,534

bcBC

K3 9%)

0,599

bB

15,189

bB

15,886

abAB

K4 (12%)

0,493

aA

15,570

aA

16,031

aA

The numbers followed by different letters on the

same line show significantly different effects at the

level of 5% (lowercase letters) and are very

significantly different at the level of 1% (uppercase

letters) with the LSR test.

Table 2: Effect of additon jackfruit on reduction sugar,

sucrose, and total sugar of palm oil sap.

Treatment

Reduction Sugar

(%)

Sucrose

(%)

Total Sugar

(%)

K1 (3%)

T1 (0 day)

0,381

dD

16,245

aA

K2 (6%)

T2 (2 days)

0,623

cC

15,394

bB

K3 9%)

T3 (3 days)

0,705

bB

14,654

cC

K4 (12%)

T4 (4 days)

0,846

aA

13,716

dD

The numbers followed by different letters on the

same line show significantly different effects at the

level of 5% (lowercase letters) and are very

significantly different at the level of 1% (uppercase

letters) with the LSR test.

4 CONCLUSIONS

From this study, the best oil palm sap was shown by

K4T4 treatment, which was 12% addition of jackfruit

wood and 3 days storage duration. This was obtained

based on reducing sugar value.

REFERENCES

AOAC. 1995. Official methods of analysis of the

association of analytical chemists. Washington D.C.

Dalimartha, S., 2008. Atlas of Plants Indonesian Medicine

Volume 5 Reveals the Wealth of Indonesian Medicinal

Plants. Pustaka Bunda, Indonesia.

Ersam, T. 2001. Macromolecular chemical compounds of

several artocarpus plants in tropical forests of West

Sumatra. Dissertation. Chemistry Department. Institut

Teknologi Bandung.

Fauzi, R. L., Nainggolan R. J., Nurminah M.. 2013. The

effect of increasing the concentration of natural

preservatives on palm sap during storage on the quality

of liquid palm sugar. Jurnal Rekayasa Pangan dan

Pertanian 1(4): 76-82.

Filianty, F., Sapta, Raharja, Suryadarma, P. 2006. Changes

in the quality of sugar cane juice (Saccharum

officarum) during storage with the addition of kawao

root (Millettia Sp.) And mangosteen bark (Garnicia

mangostana L.) as preservatives. Jurnal Teknologi

Industri Pertanian. 20:63

Gafar, P. A., Heryani, S.. 2012. Development of processing

of palm juice drinks using ultrafiltration and

deodorization techniques. Balai Besar Industri Agro.

Vol 25(1): 1-10.

Mussa, R. 2014. Study of the fermentation duration of palm

sap (Arenga pinnata) against microbial abundance and

organoleptic quality of palm wine. Biopendix. Vol 1(1):

54-58.

Robinson, T., 1995. Organic content of higher plant. ITB,

Bandung.

Sudarmadji, S., B. Haryono, dan Suhardi. 1997. Procedure

analysis forr food ingredient and agriculture product.

4

th

Edition. Liberty, Yogyakarta.

Tim Penulis Penebar Swadaya, 1997. Palm oil. Penebar

Swadaya. Jakarta. Indonesia.

T4 = ŷ = -0,7891x + 16,388

r = 0,9783

T3 = ŷ = -0,5948x + 16,426

r = 0,9894

T2 = ŷ = -0,5528x + 16,715

r = 0,9988

T1 = ŷ = -0,5997x + 16,931

r = 0,9906

13,00

14,00

15,00

16,00

17,00

18,00

0 1 2 3 4

Total sugar (%)

Storage time

K1 = 3% K2 = 6% K3 = 9% K4 = 12%

The Effect of Natural Preservatives from Jackfruit Wood Percentage Addition on Palm Oil Sap (Elaeis guuineesis Jacq.) During Storage

127