Application of 3D Printing Technology for Fashion

Products with Kawung Pattern

Nike Jhorda Iftira

1

, Eri Naharani Ustazah

2

1

Institut Teknologi Sepuluh Nopember Surabaya, Indonesia

2

Institut Teknologi Sepuluh Nopember Surabaya, Indonesia

Keywords: 3d printing, fashion, pattern 3d, decorative pattern, Apparel.

Abstract: Current technological developments are growing very rapidly, especially in the development of 3D printing.

3D printing applications in the world of fashion have been carried out by several world-renowned designers.

Indonesia has many ornaments that can be developed using this technology. In a previous author's research,

the author tried to develop the kawung pattern, one of the decorative patterns in Indonesia, using 3d printing

technology. The results are good but need to be further developed. This article reports next experiment that

working to develop the 3D shapes of Kawung's pattern and how to apply on fashion products.

1 INTRODUCTION

The fashion world is increasingly experiencing

rapid development. Both in terms of fashion,

material, application, to production technology. This

rapid application demands that the fashion market

activists continue to innovate. 3D printing is a

technology that is being developed as an alternative

material in fashion design. 3D printing mode is

created with a 3D printing machine in several steps;

create 3d models in software, slice models to 2d, and

imaging layer-by-layer objects to become 3-

dimensional objects

(Perry, 2017). The development of

3d printing in the world starts with the Irish van

Herpen in its collection called Crystallization. In

Indonesia, designers who have developed 3d mode

designs are Tex Saverio. He made an Exoskeleton

Collection containing 5 designs of haute couture

dresses that use a mixture of media between fabric

and 3d printed material.

Currently, designers all over the world are

still developing 3d materials for Clothing Products.

Danit Peleg is the first fashion designer to make

commercial 3d print jackets that can be customized

and purchased on his website. 3D printing is expected

to be an environmentally friendly alternative material

for the development of new fashion designs and has a

process that is easy to work with fashion.

2 PROBLEM STATEMENT

Indonesia has various cultures and arts, one of

which is decoration. Variety of decorative is a

decorative form in the form of repetitive pattern

(Safiera, 2014)

. Ornamental use in Indonesia is

generally used in ornaments for interiors,

architecture, and textiles. For textiles, the variety of

decorative forms is still limited to 2D patterns. In

early 2018, we conducted an experiment to develop

one of the decoration motifs, namely the Kawung

motif, because the form was easily modified by 3D

printer treatment in terms of simple, geometric, and

repetitive motifs

(Faruq, 2017). However, the results

obtained still need to be further developed so that they

can be applied into fashion products. In this study the

authors carried out the application of the results of the

kawung motif experiment with 3D printer techniques

on fashion products, namely in the form of bags and

accessories. The software used in making the product

form is Autodesk Fusion 360.

3 LITERATURE and THEORY

3.1 Rapid Prototyping

Rapid Prototyping (RP) can be defined as the

methods used to construct a prototype model from

starting part of a product or assembly quickly using

three-dimensional Computer Aided Design (CAD)

50

Iftira, N. and Ustazah, E.

Application of 3D Printing Technology for Fashion Products with Kawung Pattern.

DOI: 10.5220/0008526100500055

In Proceedings of the 1st International Conference on Intermedia Arts and Creative Technology (CREATIVEARTS 2019), pages 50-55

ISBN: 978-989-758-430-5

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

data. Rapid Prototyping allows the visualization of a

three-dimensional image into a native three-

dimensional object that has volume. Some of the

current Rapid Prototyping methods are: (Djoko

Kuswanto, 2017)

1. Stereolithography (SLA)

2. Direct Light Processing (DLP)

3. Continuous DLP (CDLP)

4. Selective Laser Sintering (SLS)

5. Both Selective Laser Melting (SLM) and Direct

Metal Laser Sintering (DMLS)

6. Electron Beam Melting (EBM)

7. Multi Jet Fusion (MJF)

8. Fused Depsition Modeling (FDM)

An inexpensive and often used technique is the

so-called fused deposition modelling (FDM) firstly

established by Stratasys (Redwood, 2018), in which a

thermoplastic polymer is molten in an extruder

nozzle, and the fluid material is deposited on the

printing bed line by line, building the first layer of the

planned object. After finishing the first layer, the

printing bed is lowered, and the next layer is printed

on top of it until the highest layer of the object is

finished (C. K. Chua, 2010). The materials used for

printing with the FDM technology are, e.g., ABS

(Acrylonitrile butadiene styrene), PLA (polylactic

acid) and several others with diverse physical and

chemical properties.

3.2 Indonesian Decorative Pattern

(Kawung Pattern)

Decorative variety is one form of art that is

very attached to the identity of the Indonesian nation.

Various kinds of decorations can be found in

Indonesia, whether in batik cloth, woven fabric,

songket, temple, and praying place. Types of

decoration are generally classified into 4 parts,

namely geometric, flora, fauna, and figurative.

Kawung motif is included in Indonesian geometric

Pattern. The following are the types of kawung

motives and their pattern elements:

(Sarwono, 2005)

1. Kawung Sari

The main ornaments are oval-shaped

spheres, and on each part of the kawung pattern

are given a line that divides into two parts as if

they resemble the shape of a broken coffee fruit.

This kawung pattern is often also referred to as

Kawung Kopi.

2. Kawung Sekar Ageng

The main ornament is in the form of four

oval spheres that have changed into a square or

square shape. In each main ornament there are

three lines (sawut) and three points (cecek).

3. Kawung Sen

The main ornament in the form of four oval

spheres composed by the main is arranged in the

direction of a diagonal oblique angle as if the

kawung pattern is limited by curved lines.

4. Kawung Pecis

The main ornaments are oval spheres, and

are smaller in size compared to the main

ornaments in Kawung Sen and the batik pattern

in Kawung Pecis are rather oval square. The

pattern of Kawung Pecis consists of two dots

(cecek) contained in the main ornament.

5. Kawung Beton

The shape of the ornament on this motif is

very large, and somewhat rounded, but still in an

oval shape. Isen motif found in the main

ornament in the form of cecek (dots) with a large

size and in the middle there is a small circle

shape. The shape of this circle

divides into four parts as if the main

ornament is crossed.

6. Kawung Semar

The main ornament is in the form of four

oval spheres with a large size as in concrete

Kawung, but inside the main ornament is a

smaller oval shape. Isen pattern on Kawung

Semar consists of the form of cecek (dots) found

in the circle inside the Kawungan sphere. In the

middle of the main ornament is a rhombus-

shaped motif that is filled with cecek (dots) and

several circular shaped dots.

7. Kawung Buntal

The main ornaments in the form of a

mixture from Kawung Pecis are combined with

floral pattern. The flower pattern found in the

Kawung Puffer are in the form of kenikir

flowers, so the shape of the mixture of motifs is

characteristic of the pattern of Kawung Buntal.

Isen batik motif in Kawung Buntal consists of a

small oval round shape which is divided into

two parts placed in its main ornament, and a

small, medium and rather large rhombus shape

placed in the middle of the main ornament.

8. Kawung Kembang

The main ornament in the form of four oval

spheres is made to resemble the shape of a

flower (flower), so this motif is called Kawung

Kembang.

Application of 3D Printing Technology for Fashion Products with Kawung Pattern

51

9. Kawung Seling

The main ornament in the shape is almost

the same as the Flower Kawung, which is an oval

shape interspersed with flower shapes. But the size

and variation of the flowers are not the same and

made with striking color differences.

3.3 Fashion Product

Fashion is a vast and diverse industry

that offers products consumed by everyone. Products

used as a purpose to beautify themselves. Fashion

products themselves are included in tertiary needs

where objects do not have to be bought in a short time.

Some common types of fashion products are bags and

accessories.

4 METHOD

4.1

Observation

Observation methods are used to find out,

obtain, and collect data by visiting sources directly.

The results obtained are in the form of photos, video

recordings, notes, etc. To find out the types of

existing filament material characters, observations

were made by visiting and observing intensely the

research in the laboratory, ITS design, Kota

Surabaya, East Java.

4.2 Study of the Similar Product’s

Collecting data about similar products that

are already on the market (already available), is an

analysis process in designing. From this analysis

arises a variety of needs and problems, and then

developed again so that it can find solutions and needs

of existing problems. We find solutions and needs of

existing problems.

4.3 Analysis of Artifact

Identify users in assessing a fashion product

based on 3 elements, namely behavioral, visceral and

reflective to identify user decisions in buying an item,

habits of users in using goods, knowing the

impression of users of a product, knowing the tastes

of users in terms of appearance of a product

4.4 Design Development

Used to find ideas, solutions in the form of

images of bag and accessories products in two or

three dimensions along with their shape, operation

and size.

5 EXPERIMENTS

We conducted our experiments into three

categories: motive stylation experiments, motive

composition experiments, and experiments with rigid

3D printer techniques. In making 3D objects,

Autodesk Fusion 360 author use software. Then the

3D object file that has been exported into the STL file

format and imported software to make the printing

process settings. 3d printer machine used manifold

FDM with brand Anycubic I3 Mega 3D Printing. In

this experiment use PLA filaments due to engine

limitations. This printer's settings of 3D machine is a

temperature of 195 ° C and the printing bed

temperature to 50 ° C. The layer height was 0.2 mm.

Table 1: Stylation of Kawung Pattern.

KawungPattern Stylation

1. Kawung Sari

or Kawung

Kopi

2. Kawung Pecis

CREATIVEARTS 2019 - 1st International Conference on Intermedia Arts and Creative

52

For the second experimental process, which is

the experiment of composition of patterns, it is done

by combining the modules that have been distilled

beforehand.

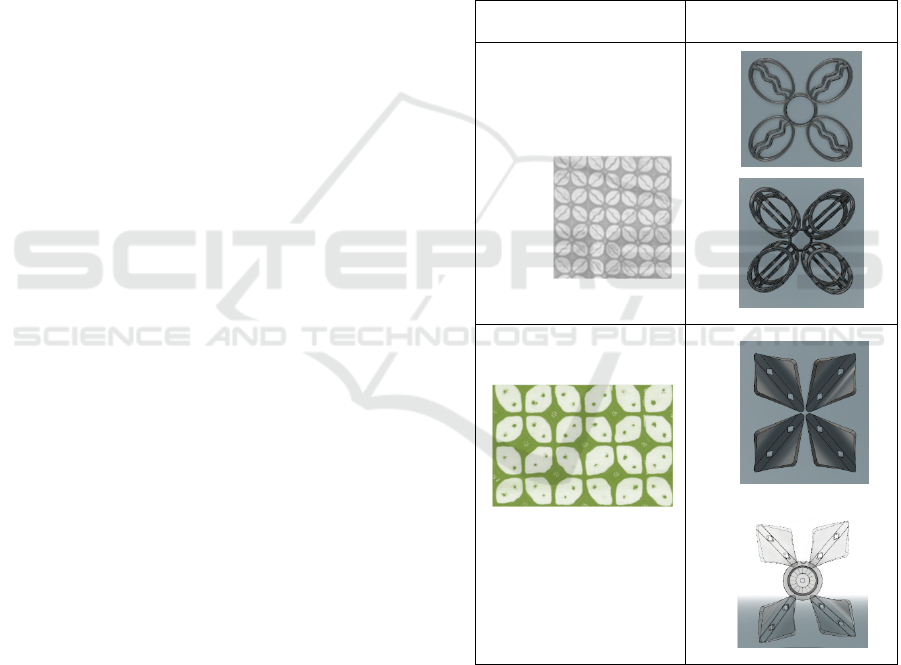

Figure 1: Experiments pattern composition.

The third experimental process is a rigid 3D

printing technique. This experiment aims to

determine the extent to which the kawung pattern can

be explored in a rigid form so that it can be applied as

a structure to accessories and bags products

Figure 2: First trial of rigid 3D printing experiment.

In this first experiment of rigid form there

were several forms which almost broke because the

thickness of the motif was still very thin, but in terms

of the overall results of the Kawung motif it was quite

good and neat. So that to apply this motif to the

product, the motif must have sufficient thickness.

Figure 3: Second trial of rigid 3D printing experiment.

In the second experiment of rigid form, the

overall results of the 3D kawung motif are quite good

and neat and can be used as recommendations to be

applied to the product.

Figure 4: Third trial of rigid 3D printing experiment.

In the third experiment of rigid form, the

overall results of the 3D kawung motif are quite good

and neat and can be used as recommendations to be

applied to the product.

Figure 5: Fourth trial of rigid 3D printing experiment.

KawungPattern Stylation

3. Kawung

Kembang

Application of 3D Printing Technology for Fashion Products with Kawung Pattern

53

In the last experiment the overall results of the

3D kawung motif are quite good and neat.

After doing a few experiments, then I made a

comparison of the experiment like the table above. Of

the four rigid 3D printer techniques, the most

competent to be applied to bags and accessories are

the second, third, and fourth experiments.

The next stage after the experiment process,

applying the motif to the bag product with the type of

bag in the form of clutch and sling bag, then applying

the motif to the accessories product with the type of

accessories in the form of earrings and necklaces.

In the process of slicing a 3D printer on a bag

product using a 0.12 mm layer height, using tree

support because it can produce a neat design, using

Infill 75% because it produces a design that is not

easily broken, uses a melt filament temperature of

195 degrees Celsius, and uses a 100 mm speed

setting / s serves to adjust the speed of the 3D printer

while operating

In the process of slicing a 3D printer on

accessories products using a 0.1 mm layer height, not

using support because it can produce a neat design,

using infill 75% because it produces a design that is

not heavy, uses a 195 degree celsius melt

temperature and uses a speed setting of 30 mm/s

function to adjust the speed of the 3D printer when

operating.

Figure 6: Final Product series 1.

Figure 7: Final Product series 2.

Figure 8: Final Product series 3.

Here are the final results of bags and accessories

making based on 3D Printing Technology.

Table 1: Experiments of 3D Printer Techniques with Rigid

Forms Comparative.

Trial1

Trial2

Trial3

Trial4

Pattern

Photo o

f

experime

ntal

results

Result There are

several

broken

shapes

The overall

results from

the 3D

kawung

motif are

quite good

and neat

The overall

results from

the 3D

kawung

motif are

quite good

and neat

The overall

results from

the 3D

kawung

motif are

quite good

and neat

CREATIVEARTS 2019 - 1st International Conference on Intermedia Arts and Creative

54

6 CONCLUSION

The use of PLA filament material with 3D

printer techniques can be applied to accessories and

bag products with the aim of introducing techniques

and providing alternative materials to the community.

In previous experiments it was found that Indonesian

decorative pattern that can be applied to 3D printer

techniques are Kawung's patterns because the form is

easily modified by 3D printing treatment in terms of

simple, geometric, and repetitive patterns. Kawung's

pattern experiment is quite interesting. But it requires

a detailed process because of the unusual use of

techniques and materials in the production process of

making bags and accessories. Then some treatment is

needed for the process of 3D printer slicing, and some

standardization so that the product has a selling value

that is equivalent to the materials and techniques that

are often used in the production of bags and

accessories.

ACKNOWLEDGEMENT

This work was supported by iDIG Laboratory

Research of Product Design Department Institut

Teknologi Sepuluh Nopember Surabaya, Indonesia.

REFERENCES

C. K. Chua, K. F. (2010). Rapid Prototyping: Principles and

Applications. World Scientific.

Djoko Kuswanto, O. M. (2017). Indonesian Pattern for 3D

Printing Fashion Development. The 4th

Internation Conference on Creative Industry.

Surabaya: Department of Industrial Design ITS.

Faruq, H. A. (2017). Pengertian Motif dan Pola Ragam

Hias (Lengkap). Retrieved from Habibullah Al

Faruq:

http://www.habibullahurl.com/2017/08/pengerti

an-motif-dan-pola-ragam-hias.html

Perry. (2017). 3D Printed apparel and 3D printer: exploring

advanteges, concern, and purchases.

International Journal of Fashion.

Redwood. (2018, April 16). Additive Manufacturing

Technologies: An Overview. Retrieved from 3D

HUBS: https://www.3dhubs.com/knowledge-

base/additive-manufacturing-technologies-

overview

Safiera. (2014, December 15). Perkembangan Busana

Futuristik dari Teknologi Printer 3D di Industri

Mode. Retrieved from wolipop.detik.com:

https://wolipop.detik.com/read/2014/12/15/1553

52/2777769/233/2/perkembangan-busana-

futuristik-dari-teknologi-ltigtprinterltigt-3d-di-

industri-mode#picmp

Sarwono. (2005). Motif Kawung sebagai Simbolisme

Busana Para Abdi dalam Wayang Kulit Purwa

Gaya Surakarta. Harmonia: Jurnal pengetahuan

dan pemikiran seni.

Application of 3D Printing Technology for Fashion Products with Kawung Pattern

55