Jepara Wooden Carving in the Digital Era

Edi Eskak

1

and Irfa’ina Rohana Salma

1

1

Center for Handicraft and Batik, Ministry of Industry, Jl. Kusumanegara No. 7, Yogyakarta, Indonesia

Keywords: wooden carving, CNC, Jepara, digital era

Abstract: This paper is a study for redefinition of latest arts, in wooden carving. The equipment in work carving in

today's is Computer Numerical Control (CNC). CNC can eliminates manual processes. Also, there was a

diminishing interest in people’s youth of Jepara in pursuing jobs as wood carvers. The presence of CNC is a

solution that can replace human source. However, carving products produced by CNC machines are less

attractive to the consumers. There is a contradiction, wich is this advanced technology can replace most o

f

the production of art to be more effective, efficient, consistent, and precisely, but consumers actually wan

t

the unique and distinctive handiwork. This paper aims to uncover the creativity of entre

p

reneurs and woo

d

carving artists responding to the tastes of markets and to get solutions to the existing problems. The metho

d

used is qualitative by getting data of literature and observation. The solution is to use CNC to speed up the

production in initial engraving and then the carving process is continued with the hand skill manually. The

p

roduct still expresses a distinctive creativity as a carving work done with hand skills, but can be done

faster than using the full manual technique.

1 INTRODUCTION

Jepara is a city of carving, as a tagline shown that

the existence of intelligence carves as an ancestral

heritage is still preserved and developed in

accordance by changing times. The carving brings

blessing to those who pursue it in high persistence.

Art as a living force (Marianto, 2017), has been

practiced significantly by Jepara wood carvers. The

superior products of the Jepara wood industry are on

various beautiful carvings of furniture, reliefs, and

other various interior accessories products. Jepara

known as the center of the carving furniture industry

(Pratiwi, Kenang, & Ruki, 2017). The advantages of

Jepara wood products are mainly in fine carving and

carpentry techniques (Eskak, 2013a).

Jepara is a heaven of wood carving hunters. It is

a city located on the north coast of Central Java

within an area of 949.80 km2. The city which has

been known as the center of wooden furniture is at

the position of 5º 43 '20.67' to 6º 47 '25.83' South

Latitude and 110º 9 '48.02' to 110º 58 '37.40' East

Longitude. Jepara borders the Java Sea in west and

south side, Kudus and Pati Regencies in east side,

and Demak in south side (Cemerlang, 2018). As

Jepara is not crossed by the Pantura transportation

route, which is the largest economic route on the

island of Java. But, it is able to utilize the potential

of its resources, and turn it into a regional economic

power. This makes Jepara is able to align the

economy with other regions, even in some other

sectors Jepara is far more advanced than other

regions (Prastiyan, 2017).

Eventhough it is an area with minimum potential

natural resources and is not located on the main

coastline, it has been able to align itself

economically with other regions, one of them is due

to the presence of wood carving industry. The Jepara

wood carving industry has become one of the

driving forces of the regional economy (Eskak,

2013a). Carving is the art technique of sculpting

material with patterns and decorative structures,

made in a concave or convex style, following the

drawing plot with a chisel (Gustami, 2000). The

material for traditional carving are wood and stone

Eskak, E. and Salma, I.

Jepara Wooden Carving in the Digital Era.

DOI: 10.5220/0008525800310039

In Proceedings of the 1st International Conference on Intermedia Arts and Creative Technology (CREATIVEARTS 2019), pages 31-39

ISBN: 978-989-758-430-5

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

31

(Sunaryo, 2009). Bamboo (Eskak, 2016a) and

coconut shell (Eskak, 2016b) can also be a media for

carving. The traditional Jepara carved motif is a

stylation or a vines formed, the stylation is a

changing form styled and is generally patterned

(Sunaryo, 2018). Its motifs also have the meaning of

beautifying life in beauty with integrity, balance, and

harmony in community. The goodness must be

spread to all directions and places. The ancestors

inherited many noble and meaningness values

contained in artwork (Eskak & Salma, 2018).

The Jepara carving industry contributes about

10% of Indonesian furniture, and contributes to the

district's economy by 27%. More than 12,000

furniture artisans operate in Jepara. The main

competitor of Jepara's furniture trade is China,

which it dominates trade by 16% of the world and

prices are 20% cheaper than Indonesian furniture

(Raharjo, Rubijanto, & Solechan, 2015). The price

of Jepara wood carving products is more expensive,

while it loses in competing with China, because of

China's wood carving production process uses

automation machines, so the output can be massive

and have cheaper price. The higher price of Jepara

carving products is due to the longer time production

processes has taken, with high costs, and low output

quantity in the contrary, less futuristic designs, and

manual processes (Raharjo, Rubijanto, & Solechan,

2015). In contrast to the Chinese carving industry

which has collaborated on an advanced technology

and art, so that it can produce massively and has the

lower prices.

In addition, today there is a decline in the

number of professional carvers, further to threatens

the sustainability of the wood carving business in

Jepara. The study and work carving interests of the

younger generation has also wane off. If For this is

left without a solution, the concern about the

extinction of traditional art is close to reality (Eskak,

2013b), which it is truly unfortunate if the existence

of classical archipelago carvings those are beautiful

and comprise with high philosophies (Nizam,

Nugraha, & Gustami, 2018) can not be preserved.

Along with this feeling of concern, the existing

conditions must still be addressed with various

solutions. Jepara entrepreneurs, artisans and carvers

need to take steps forward so that the survival of

their businesses is maintained. The use of more

technology is one of the solution can be taken to

these problems.

The technology can help increase productivity

while resolving the problem of the difficulty of

finding a carving industry workforce. The use of

carving machines is one of the solution. A

sophisticated and reliable carving machine is a CNC

machine. CNC is a computer machine that uses a

numerical control system. CNC itself stands for

Computer Numerical Control. The factory uses CNC

to control their factory machines. At a glance, it is as

if a normal computer controls the machines, but

actually the computer runs using a unique software

and special consoles. With CNC machines, factory

machines are controlled with number controls. The

computer programs are specifically designed to

control machines and objects. The program uses the

CNC machining language (called G-code). This

program organizes features such as feed rate,

coordination, location and speed. With CNC

machining, computer can control the precise position

and velocity of the machine (Mengenal Apa Itu

Mesin CNC, 2019).

There are many benefits to use a CNC machine.

This process is more rigorous than its manual

machining. Besides that, it can also be repeated the

same way many times. CNC machines are a series of

machines with programmable intelligence work

patterns for the execution of drilling system work

(Guiping, Yazhou, & Guangwen, 2010). By seeing

the specificity of CNC machine performance does

not rule out the possibility that CNC machines can

still function with a variety of materials including

wood material. CNC machine components consist of

two basic components, namely hard components in

the form of machine physical devices and soft

components in the form of programable devices or

software executors (Iskra & Hernández, 2010).

Material working patterns using CNC are more

commonly used for soft material types such as

wood, so that the use of CNC machines currently

dominates solid-shaped and wood-based work such

as multiplexes, hardboards, medium-density

fibreboard, and other types of wood particles. CNC

is considered to be more capable of providing a high

level of accuracy compared to other wood manual

machines. CNC is currently being used for

ornamental work on the surface (Iskra & Hernández,

2012). CNC can be used for mass production

patterns. The current CNC development system has

3 axis and 4 axis pattern. The 3 axis pattern can be

found in most furniture industries while the 4 axis

pattern is still rarely found due to the price of CNC

machines those are quite expensive. The CNC

machine reading pattern is based on a code pattern

called G Code contains coordinates of the object to

be pointed by a blade driven by a CNC machine so

that the level of accuracy can be achieved even in

millimeters (Raju, Janardhana, Kumar, & Rao, 2011;

Firstiawan, 2012). CNC is able to provide very

CREATIVEARTS 2019 - 1st International Conference on Intermedia Arts and Creative

32

smooth levels of wood material execution on its

surface (Darmawanto & Minardi, 2017).

The use of CNC can increase a company's

competitiveness, because of the selling price of the

products. However, the reality of the Jepara wood

carving market is different to it. It is said that Jepara

wood carvings do not compete with Chinese wood

carvings, basically it turns out that the sculptures of

Chinese Gods, altars, and Chinese cultural symbols

created by residents of Jepara which are many

buyers are interested in mainland China, Hong

Kong, and Taiwan (Eskak & Sumarno, 2016). This

is shows that Jepara carving lost in terms of mass

production but won in the manual carving

production. The advantages for Jepara wood carving

are better than Chinese’s in quality and durability

(Soedarso, 2006). Some of Jepara carving

companies have also used CNC machines, but their

carving products are less attractive to the foreign

markets, as the main market for wood carving

products from Jepara. There is a contradiction,

which a sophisticated technology can replace most

of the art production processes to be more effective

and efficient, but consumers actually demand a

unique and particular results of handwork carving.

This paper aims to uncover the creativity of wood

carving artists in responding to the tastes of markets

and getting solutions to the existing problems.

2 METHODS

This research categorized as qualitative research, by

obtaining data from the literature and observations.

Literature studies are carried out by reading relevant

references and the observations are carried out in

Jepara. Observation is sighting, but they are carried

out carefully and deeply on an object or problem

(Eskak, 2014). Qualitative research aims to explain

phenomena through deep data collection. If the data

collected is in-depth and can explain the

phenomenon under this study, then there is no need

to look for other sampling. The depth issue is more

emphasized of or quality of the data rather than its

quantity, and researchers actively participate in

determining the type of data desired (Kriyantono,

2010). Data is analyzed qualitatively and

interpretatively through several processes such as:

data verification, data reduction, data presentation,

and conclusion (Moleong, 2012).

3 RESULTS AND DISCUSSION

3.1 Reverse Progress

Technological and community development are

interrelated and influenced to each other in life,

including in the Jepara wood carving industry.

Today there is a significant decrease in the number

of carvers resources, which threatens the

sustainability of the wood carving industry. The

younger generation interests has declined to practice

and become a professional carvers. Learning to

carve requires perseverance and a long enough time

to become skilled. Today's younger generation is

more likely to think and act pragmatically and

instantaneously so they choose to work in cigarette

factories, cables, clothing, and other factories which

are now prevalent in Jepara (Purnomo, 2018). The

regional government has been negligent by giving

many permission to establish factories those are not

in accordance with the regional superiority and

culture of the Jepara community. The large factories

have absorbed a lot of naturally talented human

resources in the field of carving and it is not

immediately taken care off by the government, so it

can turn off the existing efforts of populist carving.

The local governments should have better

understandable according this matter and they are

not solely tempted by the tax revenues from these

factories.

The provision of carvers skilled in Jepara

has 2 lines, those are traditional routes and formal

education routes. The traditional path is taken first

by becoming an assistant (kenek) for professional

carvers while working (Hariyadi, 2010), and

received wages from the learning process. At present

days, it is difficult to find young people who want to

learn to work on carving (Eskak & Sumarno, 2016).

Jepara young generation generally prefer to work in

other fields those are easier and faster to make

income.

Pathways to sculpturing formal education

learning can be passed by taking courses or

conducting studies in vocational schools. The

famous sculpturing course institute in Jepara in

1990s were Nevada and Jenggala Course. Formal

education of carving can be taken at SMK Negeri 2

Jepara which has wood carving as one of its majors.

It is become a favorite major to be chosen in the

school that was formerly called the Jepara State

Craft Industry Middle School (SMIK). Uniformizing

by the national curriculum, the wood carving major

has renamed by the wood craft design and

production major. From its special major in

accordance with the needs of the industry region has

transformed into a national curriculum that no longer

Jepara Wooden Carving in the Digital Era

33

fully learns to carve but to learn wooden crafts in

general. This is has made an decreasing effect on the

graduates ability and competence to carve. The last

stronghold of defense of skilled carvers supply was

already weakening. The Ministry of Education and

Culture should consider wisely about the special

needs those support the progress of regional

industries, and not just do the appliance of

uniformity which would reverse the existing local

industries.

The impact of these policies was truly felt in

difficulty search for carving workers. The wood

carving industry that has raised and made Jepara into

a famous national and international forums is

experiencing production sluggishness, not just even

a few but more than are out of business. The

government should be present to provide for

strengthening policies and refreshment so that the

wood carving industry rises and triumphs again,

instead of deflating and letting it die slowly. The

government must immediately realize and revise the

wrong direction of regional development programs.

It can not be turned upside and down and belated to

be realized, which it is to intend and work to develop

the region, but it turns out to be as a setback.

3.2 Carving Automated CNC Machine

The development of advanced technology can

help solve many human problems, one of which is a

CNC that has the ability to automate the work of

carving. The development of wood carving

production from traditional manuals to CNC

automation machines can be done with various

social and economic considerations. CNC can be

easily obtained in the market, but for small

entrepreneurs the price is still quite expensive. For

medium and large entrepreneurs, investment in CNC

carving machines is very beneficial for the

efficiency and effectiveness of production. Carving

has the potential and opportunity to be developed

into an industrial production business through

coaching to answer the demands era, as well as to

improve the welfare of society (Gustami, 2007).

The creation of works of art needs to pay attention to

the development and changes of the times because

each era has different challenges and problems. The

current development demands higher creativity in art

creation with the ability to utilize in multiple

scientific field. Gustami in (Eskak, 2013c) states that

the obligation of today's young generation to

anticipate this change so that later it can be realized

as a new craft according to the soul of the times but

it still reflects the national culture. Jepara’s carving

today, has undergone a shift in definition from the

concept of manual traditional production to digital

automation production. Redefinition of carving

needs to be done so that the current generation is not

confused and being as a technology stuttering. A

simple or sophisticated machine is just a tool to

work, but the core or the essence of art is still

creativity. Today's carving can be interpreted as a

technique of decorating wood by carving using

manual, masinal, or digital programs.

The use of advanced technology is a necessity

in traditional arts, including in carving. In this digital

era, the art and culture space of the community

changes with the development of information

technology and media (Kusrini, 2015). The latest

technology can be used to make carving works in

accordance with the development of the era. In

essence of carving is the technique not in its

decorative design, this has always been the wrong

thing to understand related to finished products

which are often considered lay as carving because of

their motifs (Darmawanto & Minardi, 2017). The

developing technique of carving can be done by

designing a machine that is specially set to be able to

do the work of carving (Raharjo, Rubijanto, &

Solechan, 2015).

It is not something difficult that the production

of wood carving on an industrial scale can be done

with CNC tools because it will increase the

competitiveness of small industries (Making

Indonesia 4.0 - Kementerian Perindustrian, 2016).

Rapid industrial climate change demands market

segmentation related to carving techniques that are

compatible with economical counts so that art

expression changes into commodity calculations. Art

is actually a form of technique that is able to provide

economic results for the actors (Adu-Agyem,

Sabutey, & Mensah, 2013).

a b

Figure 1: a. CNC carving machine, b. Carving process

Carving ornaments still have a high selling

value so that the development of design and design

parameters can be made coding catalysts so as to

CREATIVEARTS 2019 - 1st International Conference on Intermedia Arts and Creative

34

facilitate producers in making the same production.

Traditional decorative motifs can be modernized

according to the tastes of the present, so that

consumer interest increases and producers can feel

the economic impact (Salma & Eskak, 2012). The

use of CNC can maintain production consistency,

carving quantity, and uniformity.

3.3 Speed and Precision

To give a real picture of the effectiveness and

efficiency use of CNC, it take for an example of the

CNC application for carving the krawangan of

calligraphy products. Krawangan is a technique to

carve until it penetrates material (Eskak, 2016a). The

CNC used has the following specifications: 3 axis,

namely X, Y, and Z or can move left and right, back

and forth and up and down. Movement of 400 x 500

x 400 mm. Axle track to adjust the movement of the

wood carving router. The rail uses drawer rail slides,

30 mm in diameter and 600 mm in length. The

carving platform uses an aluminum Profile 150

Series coated with a thickness of 2 mm. 230W /

11000 Spindle Motor as a router carve on the stand.

The drive system uses a Screw ball Pitch 4 mm in

length of 600 mm. Screw ball Pitch bearings use

stainless steel Insert Ball bearings SUC202-10.

Stepper motors - 1/2 ″ dual shafts with X, Y, and Z

axis movements on ball screw. The voltage cable to

the drive component is protected by a chain cable.

Stepper Motor Driver M542 / M752, inventer, and

Omron Automation. The inverter for motor spindle

speed control uses a 2.7 kW 220V VFD inverter.

S8VS-06024 AC-DC Omron Automation; 24V-2.5A

as a power supply for wood carving machines. M542

/ M752 Stepper Motor Driver for drive control

interface, parallel serial cable interface. Core-2

desktop computers equipped with DSP or digital

singal processing systems (Suwignyo & Yanto,

2018). These specifications can be seen in Figure 2.

Figure 2: Protable CNC carving machine

The CNC mentioned above will be used to test the

manufacture of krawangan calligraphy carving

products in Banjaran Village, Jepara Regency. The

production of wood carving calligraphy in the

village averages 20-30 daily sales at a price of Rp.

400,000 - Rp. 6,000,000 each, while for exports per

month 1 container contains 4000-5000 pieces.

Banjaran Village has 2 groups of artisans, that is:

The Harjo Kaligrafi Cahaya Seni group. The

problem faced is that the small production capacity

and product precision are not maintained. The use of

CNC succeeded in accelerating the process of

carving and increasing the precision of significant

carving products (Suwignyo & Yanto, 2018).

3.3.1 Speed of the Carving Process

Carved calligraphy with CNC has gained a

significant working speed. Calligraphy design was

carried out on the help of Computer Aided Design

(CAD) with CorelDRAW. The size of the carving

calligraphy is 25cm long and 45cm wide using a

3mm chisel. Software for running programs using

Max3. The time of the process of carving

calligraphy with variables into the feed rate of 50, 60

and 70 mm / rev. Cutting speed 30 m / min, 1 mm

depth of cut, and 200 rpm spindle speed. The type of

wood used is mahogany with a water content of 26%

and density of 512 kgs / m3. The speed of the

process of carving calligraphy with the feed rate

variable is shown in Table 1, and the product results

in Figure 3.

Jepara Wooden Carving in the Digital Era

35

Figure 3: Carved products with variabel feed rate

(Source: Suwignyo & Yanto, 2018)

The lowest feed rate is 50 mm / rev for the longest

carving process time is 2:33 hours better than the

manual carving process of 80%. Increasing the feed

rate speeds up the process of carving at a 60 mm /

rev feed rate which takes 2:12 hours. This can cut

time by 2; 23 hours or 108% of the process of

carving manual calligraphy. The fastest CNC

carving process at the 80 mm / rev feed rate is

shown in Table 1. The carving process time is 1:33

hours and is able to save time compared to the

manual by 2:56 hours or 177%. The increase in the

feed rate accelerates the process of carving

calligraphy because the feeding process is higher

and the completion time is faster. Savings in the

process of carving calligraphy can increase

productivity. Within 1 working day of 8-hour work,

CNC engraving can produce 4-5 calligraphy

carvings (Suwignyo & Yanto, 2018).

Table 1: Manual and CNC carving times

Carving

Calligraphy

Process

Time Process of Carving Calligraphy

(hours)

50 mm/rev 60 mm/rev 70 mm/rev

Manual 4:35 4:35 4:35

Carving 1 2:35 2:09 1:33

Carving 2 2:28 2:14 1:30

Carving 3 2:37 2:14 1:36

Average 2:33 2:12 1:33

(Sumber: Suwignyo & Yanto, 2018)

3.3.2 Precision of Carving Results

CNC carving precision results show better results

compared to its manual. Feed rate speed has a

significant effect on product precision. Repetition of

the process is done to accuracy test of the design.

Table 2 shows a 73% manual carving precision,

while a CNC carving with a 50 mm / rev feed rate

reaches 93%, it has a difference of 20%. By

increasing the feed rate to 60 mm / rev, precision has

decreased to 90%. As the feed rate increases to 70

mm / rev, the precision decreases again to 85%

(Suwignyo & Yanto, 2018).

Table 2: Level of precision of manual and CNC

carving

Carving

Calligraphy

Process

Level of precision carving (%)

50 mm/rev 60 mm/rev 70 mm/rev

Manual 73 73 73

Carving 1 93 89 85

Carving 2 92 90 84

Carving 3 94 91 86

Average 93 90 85

(Sumber: Suwignyo & Yanto, 2018)

Increased feed rate speed carving wood

calligraphy decreases to the precision of the product.

High precision level is influenced by wood hardness

and chisel feeding speed. A high feed rate makes the

surface of the carving product rough and fibrous and

decreases its precision (Rahman & Kadirgama,

2015). The difference in the products precision of

the carved calligraphy with CNC machine feed rate

variables is very small, but it affects the tidiness,

surface cleanliness, and beauty of the products

produced. Suwignyo & Yanto, 2018).

3.4 Quick Tips and Taste Tricks

The existence of a CNC carving machine is a

solution that can replace human resources for the

process of making wood carving products, but the

carved products produced are less attractive to

consumers. Overseas consumers as the main market

for wood carving products from Jepara do not like

products those are automatically processed with

these CNC. The contradictory thing is that CNC

technology can replace most of the production or

work processes of art in a more effective, efficient,

consistent and precise way, but consumers actually

want a unique and distinctive handwork. Therefore

wood carving artists need to be creative in

addressing the market's tastes. Carving artists can

use CNC to speed up the process of producing wood

carvings.

CREATIVEARTS 2019 - 1st International Conference on Intermedia Arts and Creative

36

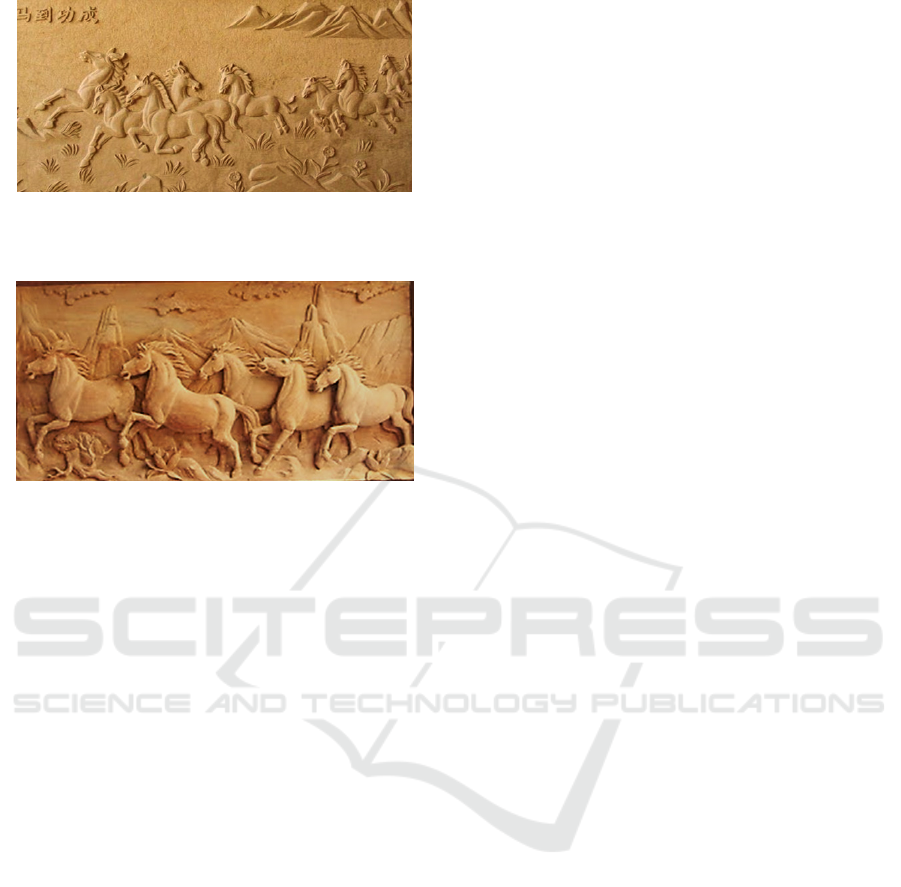

Figure 4: Carved product of CNC carving machine from

China (Wood Cnc Router, 2018)

Figure 5: Combined product of CNC and manual carving

(Jepara)

The tread carved by a CNC is different from

hand carving. The process of CNC carving uses a

router system, not a chisel knife. The router system

only works in the form of a straight one-way rotation

from above. The machine is only able to work

according to the program's instructions, not as

creative as humans. CNC carving results can be seen

in Figure 4. The carving works still feel stiff and

empty of meaning. Carving artists can use CNC to

speed up the production process, especially in the

initial carving process, then continued with hand

skills manuals. The artwork produced still expresses

a distinctive creative expression as a pieces of work,

but can be done faster than when it using manual

techniques completely. CNC carving results that are

enhanced by manual carving can be seen in Figure 5.

4 CLOSING

4.1 Conclusion

The creative industry needs to pay attention to the

development and changes of the times because every

era has different challenges and problems. The

development era demands an increasingly high

artistic creativity with the ability to utilize multiple

scientific fields. The carving today, has undergone a

shift in definition from the concept of manual

traditional production to digital automation

production. A simple or sophisticated machine is

just a tool to work, the essence of art is creativity.

Today's carving can be interpreted as a technique of

decorating wood by carving using manual, masinal,

or digital programs. Entrepreneurs and carving

artists can use CNC to accelerate the process of

wood carving, while respond to the increase

difficulty of workforce seeking. CNC carvings that

still feel stiff and empty of meaning, can be given a

touch of hand carved so that the results are more

flexible, lively and soulful.

4.2 Suggestions

The policies issued by the government should really

be through in-depth studies of the specificities and

needs of the region, not to aim at advancing but

instead of to reverse the existing conditions. This has

happened to the Jepara wood carving industry

sector. The government should be present to provide

policies for strengthening and invigorating it so that

the wood carving industry rises and triumphs again.

REFERENCES

Adu-Agyem, J., Sabutey, G. T., & Mensah, E. ,

2013. New trends in the Ahwiaa wood carving

industry in Ghana: Implications for art

education and socio-economicgrowth.

International Journal of Business and

Management Review, 1(3), 166–187.

Darmawanto, E., & Minardi, J., 2017.

Pengembangan Produk Ukir Berbasis Desain 3

Dimensi Menggunakan Mesin Cnc Untuk

Industri Mebel. DISPROTEK, 8(2), 82–101.

Eskak, E., & Salma, I. R., 2018. Menggali Nilai-

nilai Solidaritas Dalam Motif Batik Indonesia.

Jantra, 13(2), 240–255.

Eskak, E., 2013a. Krisis Bahan Baku Seni Kerajinan

Kayu Di Jepara Dan Solusi Pemecahannya.

Dinamika Kerajinan Dan Batik, 30(2), 73–84.

http://dx.doi.org/10.22322/dkb.v30i2.1112

Eskak, E., 2013b. Mendorong Kreativitas Dan Cinta

Batik Pada Generasi Muda Kritik Seni Karya

Pemenang Lomba Desain Batik Bbkb 2012.

Dinamika Kerajinan Dan Batik, 30(1), 1–10.

http://dx.doi.org/10.22322/dkb.v30i1

Eskak, E., 2013c. Rupa Karsa: Eksplrorasi Limbah

Dalam Seni. Tesis Pascasarjana. Institut Seni

Indonesia Yogyakarta.

Eskak, E., 2014. Metode Pembangkitan Ide Kreatif

Jepara Wooden Carving in the Digital Era

37

Dalam Penciptaan Seni. Corak, 2(2), 167–174.

https://doi.org/DOI: 10.24821/corak.v2i2.2338

Eskak, E., 2016a. Bambu Ater (Gigantochloa Atter)

Sebagai Bahan Substitusi Kayu Pada Ukiran

Asmat. Dinamika Kerajinan dan Batik, 33(1),

55–66.

http://dx.doi.org/10.22322/dkb.v33i1.1039.g11

75

Eskak, E., 2016b. Identifikasi Pola Laminasi

Tempurung Kelapa. Dinamika Kerajinan Dan

Batik, 32(2), 107–116.

http://dx.doi.org/10.22322/dkb.v32i2.1366

Eskak, E. dan Sumarno., 2016. Peningkatan Nilai

Tambah Pada Cacat Batang Kayu Dengan

Kreasi Seni. Dinamika Kerajinan Dan Batik,

33(2), 133–143.

http://dx.doi.org/10.22322/dkb.v33i2.1649.g16

56

Firstiawan, N., 2012. Optimasi Parameter Proses

Pemesinan CNC Milling Terhadap Kekasaran

Permukaan Kayu Jati Dengan Metode

Taguchi. Jurnal Nosel, 1(2).

Guiping, W., Yazhou, J., & Guangwen, Z., 2010.

Evaluation method and application of CNC

machine tool’s green degree based on Fuzzy-

EAHP. Journal of Mechanical Engineering,

46(3), 141–147.

Gustami, SP., 2000. Seni Kerajinan Furniture Ukir

Jepara, Kajian Estetik Melalui Pendekatan

Multidisiplin. Yogyakarta: Penerbit Kanisius.

Gustami, S., 2007. Butir-Butir Mutiara Estetika

Timur: Ide Dasar Penciptaan Seni Kriya

Indonesia. Yogyakarta: Pratista.

Hariyadi, K., 2010. Macan Kurung Belakang

Gunung. Jepara: Pemerintah Kabupaten

Jepara.

Iskra, P., & Hernández, R. E., 2010. Toward a

process monitoring and control of a CNC

wood router: Development of an adaptive

control system for routing white birch. Wood

and Fiber Science, 42(4), 523–535.

Iskra, P., & Hernández, R. E., 2012. Toward a

Process Monitoring of CNC Wood Router:

Sensor Selection and Surface Roughness

Prediction. Wood Science and Technology,

46(1–3), 115–128.

Kriyantono, R., 2010. Teknik Praktis Riset

Komunikasi. Jakarta: Kencana Prenada Media

Group.

Kusrini, 2015. Potret Diri Digital dalam Seni dan

Budaya Visual. Journal of Urban Society’s

Arts, 2(2), 2(2111–122.

https://doi.org/https://doi.org/10.24821.

Making Indonesia 4.0 - Kementerian Perindustrian.

(2016). Retrieved February 20, 2019, from

www.kemenperin.go.id/download/18384

Marianto, M. D., 2017. Art and Life Force in a

Quantum Perspektive. Yogyakarta: Scritto

Book Publisher.

Mengenal Apa Itu Mesin CNC?, 2019. Retrieved

January 26, 2019, from

http://technopark.surakarta.go.id/id/media-

publik/sains-dan-edukasi/539-mengenal-apa-

itu-mesin-cnc

Moleong, L. J., 2012. Metodologi Penelitian

Kualitatif. Bandung: Remaja Rosdakarya.

Nizam, A., Nugraha, W., Ch. R., & Gustami, SP.,

2018. Eksistensi Ragam Hias Sulur Gelung

Teratai. Journal of Urban Society’s Arts, 5(1),

37–48.

Prastiyan, D., 2017. Dinamika Industri Kerajinan

Seni Ukir Jepara 1989-2008. Universitas

Negeri Yogyakarta.

Pratiwi, A. P., Kenang, K. K., & Ruki, U. A., 2017.

Analisa Perkembangan Motif Ukiran Di Jepara

Pada Abad Ke-16 Hingga Abad Ke-17. 2.

Kreasi, 2(2), 5–25.

Purnomo, A., 2018. Nilai Investasi Tembus Rp 74

Triliun. Suara Merdeka News. Semarang.

Raharjo, S.S., Rubijanto, J.P., & S., 2015. Rancang

Bangun Mesin Ukir Otomatis Ibm Mebel Ukir

Kayu Di Desa Banjar Agung Bangsri

Kabupaten Jepara. In Prosiding SNST ke-6

Tahun (pp. 79–83). Semarang: Fakultas

Teknik Universitas Wahid Hasyim.

Raju, K. V. M. K., Janardhana, G. R., Kumar, P. N.,

& Rao, V. D. P., 2011. Optimization of cutting

conditions for surface roughness in CNC end

milling. International Journal of Precision

Engineering and Manufacturing, 12(3), 383.

Salma, I. R., dan Eskak, E., 2012. Redesain Motif

Batik Tradisional Berorientasi Pasar. In

Semnas Teknoin: Pengembangan Teknologi

Manufaktur untuk Menunjang Penguatan

Daya Saing Bangsa. Yogyakarta: Fakultas

Teknik Industri UII Yogyakarta.

Soedarso., S., 2006. Tinjauan Seni: Sebuah

Pengantar untuk Apresiasi Seni. Yogyakarta:

BP ISI Yogyakarta.

Sunaryo, A., 2009. Ornamen Nusantara: Kajian

Khusus Tentang Ornamen Indonesia.

Semarang: Dahara Prize.

Sunaryo, A., 2018. Seni Rupa Nusantara: Pengantar

Kajian dan Apresiasi Seni. Semarang: Dahara

Prize.

Suwignyo, J., & Yanto, T., 2018. Studi Penerapan

Mesin Ukir Kaligrafi Kayu Untuk

Meningkatkan Produksi Dan Kepresisian

CREATIVEARTS 2019 - 1st International Conference on Intermedia Arts and Creative

38

Produk Di Desa Banjaran Kecamatan Bangsri

Kabupaten Jepara. In Prosiding Seminar

Pengabdian Kepada Masyarakat 4.0:

Peningkatan Kualitas Pemberdayaan

Masyarakat Memasuki Era Revolusi Industri.

Palembang: UNISRI. Retrieved from

http://ejurnal.unisri.ac.id/index.php/sndms/arti

cle/view/2443%0A2018

Wood Cnc Router, 2018. Retrieved from

http://id.qilicncrouter.com/wood-cnc-

router/1530-cnc-router-woodworking-series-

cnc-wood.html

Jepara Wooden Carving in the Digital Era

39