Determination Method of Asbestos in Electrical and Electronic

Products by using a Scanning Electron Microscope with a X-Ray

Diffraction

Hongwei Wang

1, a

, Jun Liu

2,b

, Ziqiang Tao

1,c

, Yanling Fu

1,d

, Junfang Li

1,e

Haiqing Xiao

1,f

and

Hong Bai

1,g

1

Institute of Industrial and Consumer Product Safety, Chinese Academy of Inspection and Quarantine, China

2

Beijing Petrochemical Engineering Co., Ltd., Beijing 100107, China

f

haiqingx@caiq.gov.cn,

g

hbai@caiq.gov.cn

Keywords: Asbestos, Brake Pads, Scanning electron microscope, X-ray diffraction.

Abstract: Asbestos is a proven carcinogen. It can able to exist in fibrous form, and be suspended in atmosphere and

water for weeks or months, it constantly causing pollution on a large scale. Therefore, the technology of

testing for asbestos in products is particularly important, receiving great attention. In this paper, the method

of using a scanning electron microscope with a X-ray diffraction is used to identify the asbestos, and this

method is simple, reliable and suitable to be widely applied.

1 INTRODUCTION

Asbestos is a proven carcinogen, able to exist in

fibrous form, and be suspended in atmosphere and

water for weeks or months, constantly causing

pollution on a large scale. Long-term intake of

asbestos fiber or fibril at a certain amount can lead

to asbestosis, lung cancer, pleural endotheliomas,

gastrointestinal cancer, etc (Shi H Y, Mao L, 2009;

ISO 22262. 1: 2012). Therefore, testing for asbestos

in products is particularly import for ensuring human

health and living environment.

At present, conventional technologies of testing

for asbestos mainly involve count-concentration, X-

ray diffraction, microscopic, thermogravimetric,

infrared spectrum, and neutron activation methods

(Zhang M, Gao X L, et al, 2010; Zhenglong Chen,

Hongwei Hu, Shizhong Hou, et al, 2013; Hossein

Kakooei, et al, 2009). The components of asbestos

are structurally complicated, and thus are very

difficult to accurately identify by a single

technology, while the methods that can serve arbitral

purpose are over-dependant on expensive

instruments, failing to be widely used (Hossein

Kakooei, Masode Yunesian, Hossein Marioryad ,

Kamal Azam, 2009; Selikoff, I.J. et al, 1966)

Therefore, in this article, multiple methods are used

together to qualitatively identify asbestos. In this

way, not only can instruments are applied in a highly

universal manner, but results also accurate and

reliable, and as a result, this way is suitable to be

widely applied.

2 EXPERIMENT

2.1 Methods Overview

Scanning electron microscopes and X-ray

diffractometers are used for qualitative analyses to

determine whether asbestos is found in analytical

specimens. If failure to find totally 300 asbestos

fiber particles after three parallel measurements by

scanning electron microscopes, it will be determined

that no asbestos is found. If any asbestos is found, an

energy spectrum analysis will be conducted. If the

fibrous particle does not contain such elements as

magnesium, silicon, and oxygen after an energy

spectrum analysis, X-ray diffractometers will be

used for testing. If peaks characteristic of asbestos

diffraction are found after testing by X-ray

diffractometers, it will be determined that asbestos is

found. Otherwise, it will be determined that no

asbestos is found (as shown in Figure1).

Wang, H., Liu, J., Tao, Z., Fu, Y., Li, J., Xiao, H. and Bai, H.

Determination Method of Asbestos in Electrical and Electronic Products by using a Scanning Electron Microscope with a X-Ray Diffraction.

DOI: 10.5220/0008365302650269

In Proceedings of 5th International Conference on Vehicle, Mechanical and Electrical Engineering (ICVMEE 2019), pages 265-269

ISBN: 978-989-758-412-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

265

Figure 1. Determination procedures with scanning

electron microscopes and X-ray diffractometers.

2.2 Pre-treatment of Specimens

Break up the specimen to appropriate size in an

appropriate way. Take about 5 g of the broken

pieces of the specimen, and put them into a crucible

immediately before placing it in a furnace.

Incinerate them for 1 h at 450°C±10°C, and remove

organic substances. Take out the crucible, and put it

into a dryer to cool until it reaches the room

temperature. Grind up the incinerated specimen in

an agate mortar, and sift them through a metallic

sieve, in which the openings are 425 μm - 500 μm in

diameter.

2.3 Preparation of Analytic Specimen

Take three appropriate portions of the specimen

above, and smear them evenly over the specimen

holder, on which electrically conductive glue is

applied, in the scanning electron microscope. Use an

aurilave to blow the particles off the surface of the

specimens.

2.4 The Method with A Scanning

Electron Microscope

Observe the analytic specimens under the scanning

electron microscope, move the field of view

magnified 500 to 50000 times, and do a count.

Observe 100 particles in the same area, and record

the number of fibrous particles in it. Repeat the

determination procedure three times, and do an

energy spectrum analysis if there is any asbestos

fiber among the total 300 particles observed in the

three parallel determinations, and continue to do the

energy spectrum analysis if the asbestos fiber

particles contain such elements as magnesium,

silicon, and oxygen. It will be determined that no

asbestos is observed, if no asbestos fiber particle is

found.

2.5 Energy Spectrum Analysis

If the results of the energy spectrum analysis

indicate that the analytic specimens of fibrous

particles contain such elements as magnesium,

silicon, and oxygen, the elements composing the

powdery substrate will need to be analyzed. If the

elements contained in the powdery substrate are

obviously inconsistent with fibers, it will be

determined that asbestos is observed. If the powdery

substrate contains such elements as silicon,

magnesium, and oxygen to a higher degree, the

determination procedure with the method of X-ray

diffraction will be gone through.

2.6 Determination with the Method of

X-Ray Diffraction

Put the analytic specimens on the specimen holder,

and press them until they become flat. Determine

whether the analytic specimen shows any diffraction

peak that is characteristic of asbestos, under the

analytic conditions for X-ray diffraction in

Appendix B. Repeat the test three times. If any

diffraction peak characteristic of asbestos is found

during any of the three tests, it will be determined

that asbestos is observed. If no diffraction peak

characteristic of asbestos is found, it will be

determined that no asbestos is observed.

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

266

3 RESULTS AND DISCUSSION

3.1 Results of Testing for the Standard

Substances in 6 Types of Asbestos

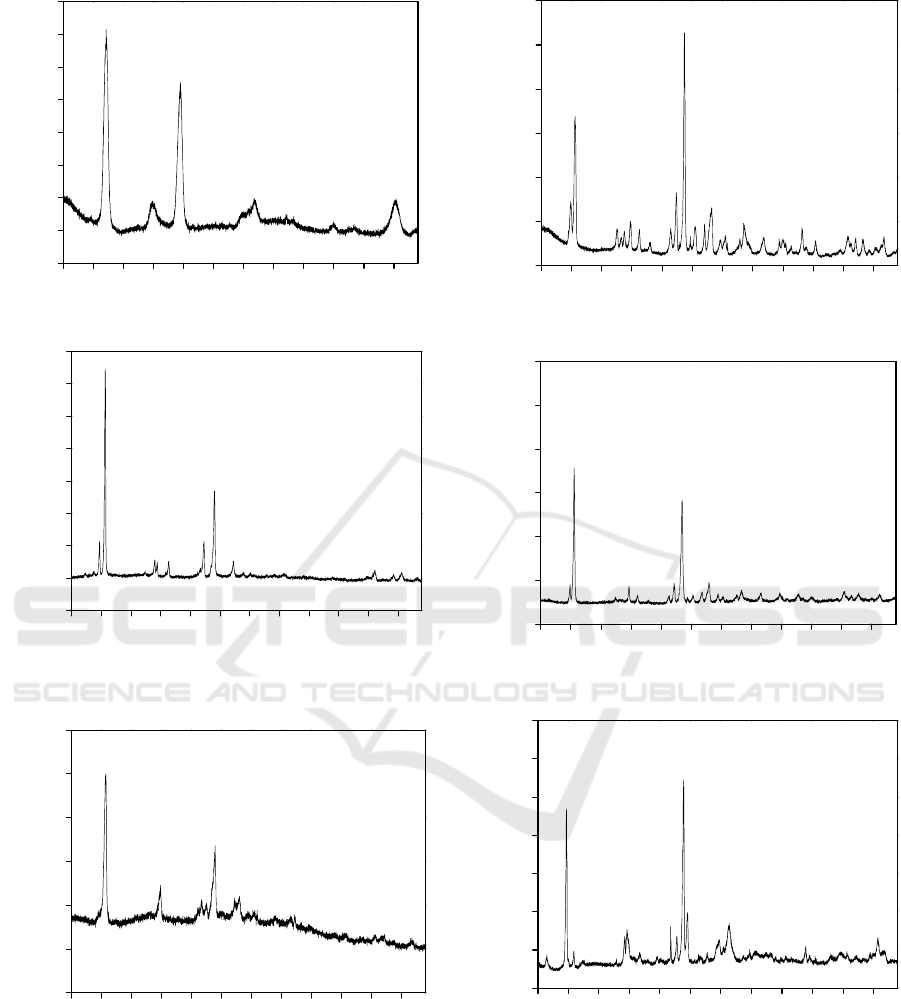

Figure2 is the picture showing the characteristic

features observed under a scanning electron

microscope of the standard substances in 6 types of

asbestos.

(a) The standard substances in chrysotile

(b) The standard substances in amosite

(c) The standard substances in crocidolite

(d) The standard substances in tremolite

(e) The standard substances in actinolite

(f) The standard substances in anthophylite

Figure 2. The scanning electron microscope images

for all types of asbestos.

From Figure 3 we could get that the scanning

images of the X-ray diffraction peaks for all types of

asbestos.

Determination Method of Asbestos in Electrical and Electronic Products by using a Scanning Electron Microscope with a X-Ray Diffraction

267

5 1015202530354045505560

0

500

1000

1500

2000

2500

3000

3500

4000

Diffraction intensity( cps)

Angle(2theta. Cu Ka)

(a) Chrysotile

5 1015202530354045505560

0

2000

4000

6000

8000

10000

12000

14000

16000

Diffraction intensity( cps)

Angle( 2theta. Cu Ka)

(b) Amosite

5 1015202530354045505560

0

1000

2000

3000

4000

5000

6000

衍射强度( cps)

Angle( 2theta. Cu Ka)

(c) Crocidolite

5 1015202530354045505560

0

1000

2000

3000

4000

5000

6000

Diffraction intensity( cps)

Angle( 2theta. Cu Ka)

(d)Tremolite

5 1015202530354045505560

0

2000

4000

6000

8000

10000

12000

Diffraction intensity( cps)

Angle( 2theta. Cu Ka)

(e) Actinolite

5 1015202530354045505560

0

1000

2000

3000

4000

5000

6000

7000

Diffraction intensity( cps)

An

g

le( 2theta. Cu Ka)

(f) Anthophylite

Figure 3. The scanning images of X-ray diffraction

peaks for all types of asbestos.

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

268

Table 1. The data on the X-ray diffraction characteristics

of all types of asbestos

Chrysotile Crocidolite Amosite

2θ°

I

CPS

2θ°

I

CPS

2θ°

I

CPS

12.06 100 10.68 100 10.68 100

24.50 78 28.9 67 29.17 49

60.38 28 19.84 49 27.29 29

36.85 27 33.04 44 9.65 28

19.83 27 26.62 43 18.89 22

Anthophylite Tremolite Actinolite

2θ°

I

CPS

2θ°

I

CPS

2θ°

I

CPS

28.97 100 28.6 100 10.48 100

9.73 87 10.58 60 28.42 79

36.34 31 33.12 29 33.04 27

26.82 29 9.83 25 27.09 26

19.64 28 33.14 23 9.73 25

From Table 1 we could get that the data on the

X-ray diffraction characteristics of all types of

asbestos.

4 CONCLUSIONS

Based on the combination of SEM and XRD

methods, the method of testing for asbestos in

electronic and electric products has been worked

out. In this method, SEM is used to initially screen

the specimens. XRD is used to identify for the

second time the specimens with particles similar to

those of asbestos fibers, largely improving the

accuracy and reliability of the test.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the financial

support provided for this research work by Fund:

National key R & D program of China

(2017YFF0210703) and (2017YFF0210002).

REFERENCES

Hossein Kakooei, Masode Yunesian, Hossein Marioryad ,

Kamal Azam, Assessment of airborne asbestos fiber

concentrations in urban area of Tehran, Iran, Air Qual

Atmos Health, 2009, 2:39.

ISO 22262. 1: 2012, Sampling and qualitative de-

termination of asbestos in commercial bulk materials.

Selikoff, I.J. et al., The occurrence of asbestosis among

insulation workers in the United States. Annals of the

New York Academy of Sciences., 132, pp139-155,

1966.

Shi H Y, Mao L. Research development of health hazards

and safe handling of asbestos. Shanghai Journal of

Preventive Medicine, 2009, 219(3): 125-128.

Zhang M, Gao X L, et al. Quantitative detection of trace

asbestos by X-ray diffraction system. Rock and

Mneral Analysis, 2010, 29 (3): 319-322.

Zhenglong Chen, Hongwei Hu, Shizhong Hou, et al.

Investigation of Several Common Methods for

Asbestos Detection. 2013.10: 89-94.

Determination Method of Asbestos in Electrical and Electronic Products by using a Scanning Electron Microscope with a X-Ray Diffraction

269