Neural Models for Benchmarking of Truck Driver Fuel Economy

Performance

Alwyn J. Hoffman

School of Electrical, Electronic and Computer Engineering, North-West University, Potchefstroom, South Africa

Keywords: Fuel Economy, Truck Driver, Performance Benchmarking, Generalized Regression Neural Network,

Multilayer Perceptron.

Abstract: The transport industry is a primary contributor towards emissions that impact climate change. Fuel economy

is also of critical importance to the profitability of road freight transport operators. Empirical evidence

identified a variety of factors impacting fuel consumption, including route inclination, payload and truck

driver behaviour. This creates the need for accurate fuel usage models and objective methods to distinguish

the impact of drivers from other factors, in order to enable reliable driver performance assessment. We

compiled a data set for 331 drivers completing 7332 trips over 21 routes to obtain evidence of the impact of

route, payload and driver behaviour on fuel economy. We then extracted various regression and neural models

for fuel economy and used these models to remove the impact of route inclination and payload, allowing the

impact of driver performance to be measured more accurately. All models demonstrated significant out-of-

sample predictive ability. Neural models in general outperformed regression models, while amongst neural

models radial basis models slightly outperformed multi-layer perceptron models. The significance of

compensating for factors not controlled by the driver was verified by demonstrating large differences in driver

performance ranking before and after compensating for route inclination and payload.

1 INTRODUCTION

The contribution of the transport sector towards

greenhouse gas emissions has been widely researched

and is estimated at around 29% of all emissions caused

by human activities (United States Environmental

Protection Agency, 2019). While the contribution of

passenger vehicles towards GHG emissions is

expected to be gradually eliminated over the next few

decades through a transition to electric vehicles and

clean production of electricity, this transition will be

more challenging for long haul freight trucks, due to

the large distances covered by these vehicles. Heavy-

duty vehicle GHG EPA regulations are projected to

reduce CO

2

emissions by about 270 million metric tons

over the life of vehicles built under the EPA program,

saving about 530 million barrels of oil. The proposed

program includes standards that would further reduce

GHG emissions and improve the fuel efficiency of

medium and heavy-duty trucks (United States

Environmental Protection Agency, 2019).

While these efforts towards reducing the

environmental impact of long haul trucks should be

encouraged, road freight transport still remains an

essential element of the global economy. This is

specifically relevant in regions with limited availability

of rail infrastructure (Hoffman, 2010); for example

road transport is responsible for 76% of cargo

movement in South Africa; this figure is even higher in

other African countries (Havenga, 2013). Compared

to the rest of the world the cost of transport in Africa is

much higher as a fraction of the total cost of delivered

goods - 18% compared to a global average of less than

10% (Anon., 2014). Fuel cost is the single biggest

contributor to the cost of road transport operations,

representing approximately 40% of operating costs

(Naidoo, 2013). Fuel economy is therefore a critical

element to be managed by road freight transport

operators to ensure continued profitability in a very

competitive industry.

Historical research in the field of fuel consumption

modeling identified the primary factors that impact on

consumption; this includes driver proficiency, payload

and route inclinations (Weille, 1966) (Biggs, 1988)

(Bennett and Greenwood, 1995). Much of the work in

this field focused on the modeling of fuel consumption

in terms of engine characteristics and driving style

(Rakha and Wang, 2017) (Delgado, et al., 2011). Other

studies applied a Big Data approach to large vehicle

fleets, mostly driving on flat roads and at constant

speeds (Perrottaa, et al., 2019) as well as the use of

Hoffman, A.

Neural Models for Benchmarking of Truck Driver Fuel Economy Performance.

DOI: 10.5220/0008065703790390

In Proceedings of the 11th International Joint Conference on Computational Intelligence (IJCCI 2019), pages 379-390

ISBN: 978-989-758-384-1

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

379

telematics solutions to improve fuel consumption

(Hoffman and Van der Westhuizen, 2014).

The use of neural networks to model the fuel

economy of trucks has been the topic of several

research studies (Zhigang Xu, 2018) (Jian-Da Wu,

2012) (Elnaz Siami-Irdemoosa, 2015) (Hassanean S.H.

Jassim, 2018). In all of these studies one of the

objectives was to identify techniques that will provide

the most accurate modeling of fuel economy in terms

of the input factors mentioned above. While

satisfactory results were achieved through the research

efforts listed above, none of those studies tried to

remove the contributions of factors not controlled by

the driver, like route inclinations and payload, before

assessing the performance of the driver. This is of

critical importance, as the only factors that can be

readily influenced to reduce emissions and fuel costs

without negatively impacting the economic function

fulfilled by transport is the behavior of the driver.

Many road transporters offer schemes of incentives

and penalties for fuel efficient driving behavior. This

creates the need for an accurate and objective method

to distinguish the impact of drivers from other factors,

in order to enable fair and consistent driver

performance evaluations.

In previous work we developed linear and nonlinear

regression fuel economy models for long haul freight

trucks using route inclination and payload as

explanatory variables (Hoffman and Van der

Westhuizen, 2019). We also used these models to

evaluate driver fuel economy performance after

compensating for factors not controlled by the driver

(Hoffman and Van der Westhuizen, 2019). In the

absence of such performance corrections, drivers are

assessed by simply calculating their average fuel

economy over all trips, completed over a variety of

routes and carrying varying payloads. This may lead

to inaccurate outcomes as not all drivers are employed

on identical sets of routes driving trucks carrying

identical payloads. The primary purpose of this paper

is to improve on the modelling abilities of regression

models by employing various neural network

architectures. In this study we included radial basis

networks and multilayer perceptron networks.

Based on available evidence we state the hypothesis

that the presence of factors not under the control of the

truck driver, like route inclinations and payload

differences, will significantly impact the performance

outcomes for truck drivers if not properly compensated

for. In order to prove our hypothesis, we will extract

regression and neural models to quantify the impact on

fuel economy of factors not controlled by drivers.

These models will then be used to remove the impact

of such factors in order to arrive at a residual fuel

economy from which the impact of route and payload

has been removed and that is mainly determined by

driver performance. This is expected to produce a

performance measure that is more reliable than a

simple average of the original fuel economy over all

driver trips and that can be used to assess driver

performance more objectively.

We then compare the performance of drivers prior

to model correction with driver performance after

applying such correction. For this purpose, we defined

two measures of driver performance: the first is

whether the driver performed above or below the

average performance measured over all drivers; the

second is the ranking achieved by each driver when

sorting the performance of all drivers from best to

worst. In addition, we also investigate the extent to

which driver identity and driver behaviour can be used

to model the above residual fuel economy. In each case

the abilities of the different modelling techniques will

be compared in terms of their out-of-sample abilities to

correctly predict fuel economy and residual fuel

economy.

The rest of the paper is structured as follows:

section 2 describes the process to collect a

representative set of fuel consumption data, and

describes the different routes that were covered by the

available data set. In section 3 we extract statistical

measures of fuel economy for the population as well as

per route and driver to provide evidence of the need for

a driver performance model. Section 4 focuses on the

extraction of empirical models that will allow us to

isolate the impact of the driver on fuel consumption. In

section 5 we estimate the impact of model

compensation on driver performance measurement. In

section 6 we conclude and make recommendations for

future research work.

2 COLLECTION OF FUEL

CONSUMPTION AND INPUT

FACTOR DATA

The purpose of our fuel usage data collection exercise

was to ensure that we cover all the aspects to be

investigated in this study. We collected data from a

fleet of 468 vehicles that cover most of the major routes

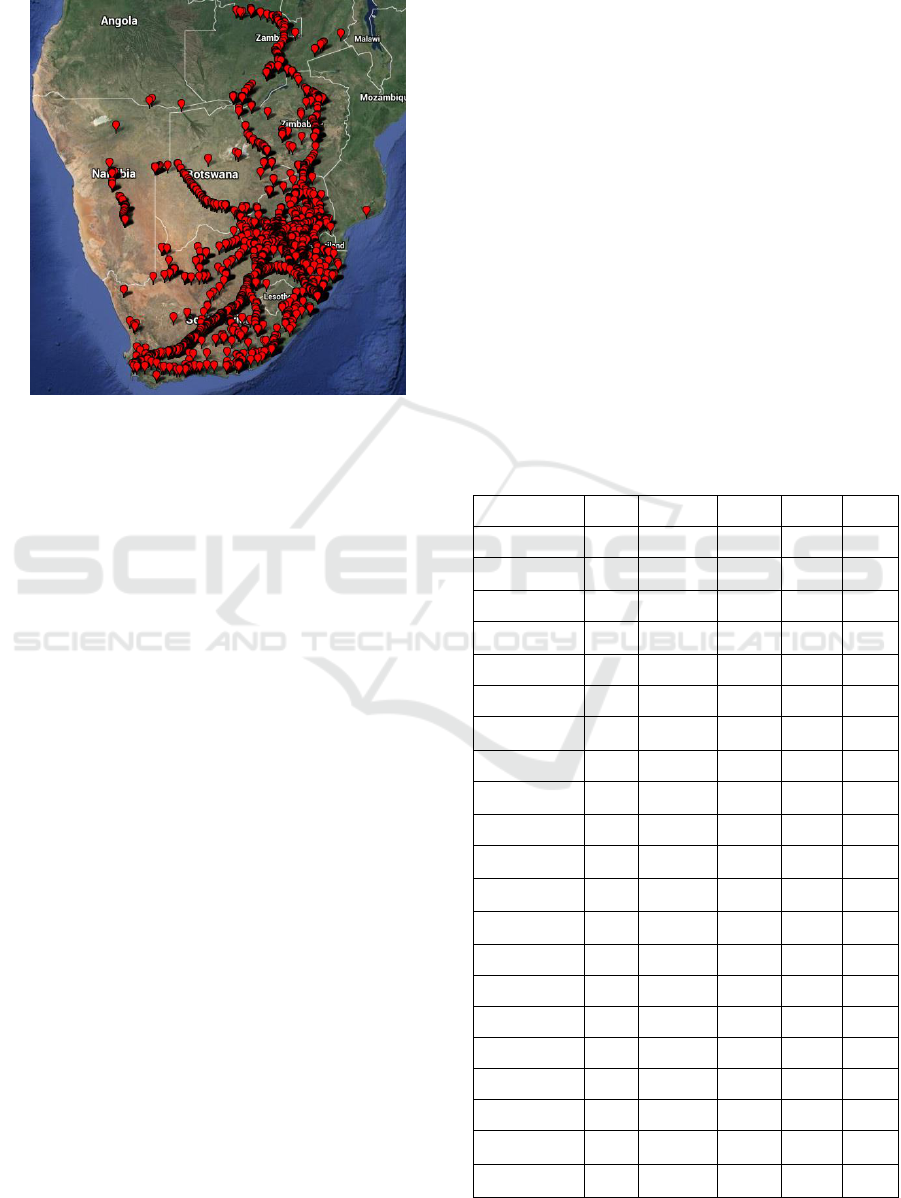

in Southern Africa, as displayed in Figure 1 below.

This allowed us to generate a significant amount of

statistics on routes that include widely ranging

inclinations (e.g. relatively flat from Johannesburg to

Cape Town versus uphill and downhill from Durban to

Johannesburg and back where the Drakensberg

mountain range has to be crossed). Data was collected

NCTA 2019 - 11th International Conference on Neural Computation Theory and Applications

380

over a period of two calendar years, which is important

as the road transport industry tends to be cyclic.

Figure 1: Trip start positions for all trips in the study.

To create a reliable set of fuel consumption

performance benchmarks, we subdivided the data into

subsets per major route that is covered. Different fuel

performance levels can be expected to be achieved on

different routes based on the number of expected stops,

the likelihood of encountering congested traffic and the

average incline. As the fleet of vehicles did not only

cover a defined set of standard routes the major routes

had to be derived from the GPS tracking data itself.

This is discussed in more detail in the sections below.

The GPS tracking systems used by these vehicles

collect fuel usage data via the CAN bus system. While

fuel usage is measured continuously by way of a flow

meter, most of the installed units of this system were

configured to only store and communicate the

aggregate consumption as from when the engine was

switched on until it was switched off again; this is done

mostly to save on communication costs. Due to the

way that trucks are operated many trips last only a very

short duration, e.g. where a vehicle is moved within a

depot. As the fuel efficiency figures expressed as km/l

would not be useful over such short distances and as

the focus of this work is the fuel efficiency when trucks

are driven over much longer distances, we filtered out

all trips with a trip distance of shorter than 100 km.

To obtain confirmation of the impact of route

specific factors, we subdivided the data into subsets per

major route that is covered. In order to quantify the

relationship between inclines and consumption, incline

data was extracted from Google Maps by using the

route descriptions as defined by the set of GPS

coordinates representing each route (Gong, et al.,

2014). The final determinant of fuel usage that was

investigated is payload, as the load carried by a vessel

is expected to have a major impact on its fuel usage

over a specific route, specifically for routes that include

steep inclines. Payload data was collected from trip

records and weighbridge measurements before

departure from origin.

3 EXTRACTING STATISTICS

FOR ROUTE AND DRIVER

FUEL ECONOMY

The statistics for the variables related to fuel economy

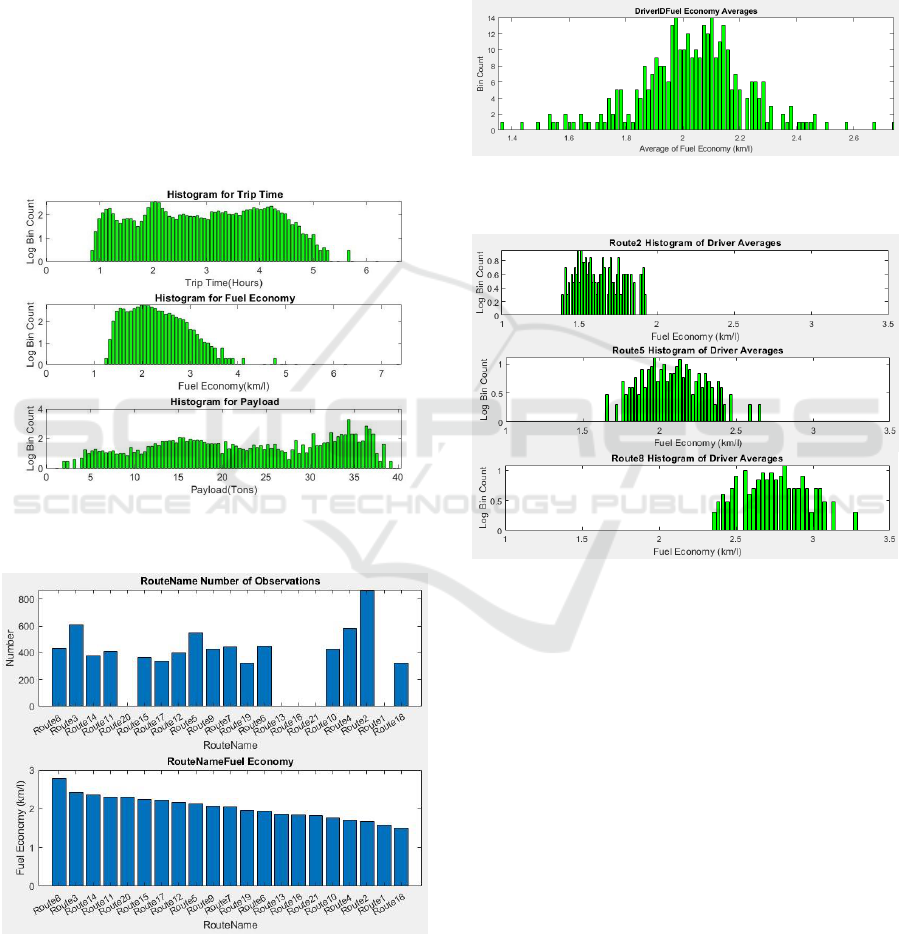

measured across 7,332 observations are summarised in

Figure 2 below, while the histograms for trip time, fuel

economy and payload are displayed in Figure 2 below.

It is clear that fuel economy displays large variations

between trips, which motivates our efforts to quantify

the contribution of each significant factor towards such

variations.

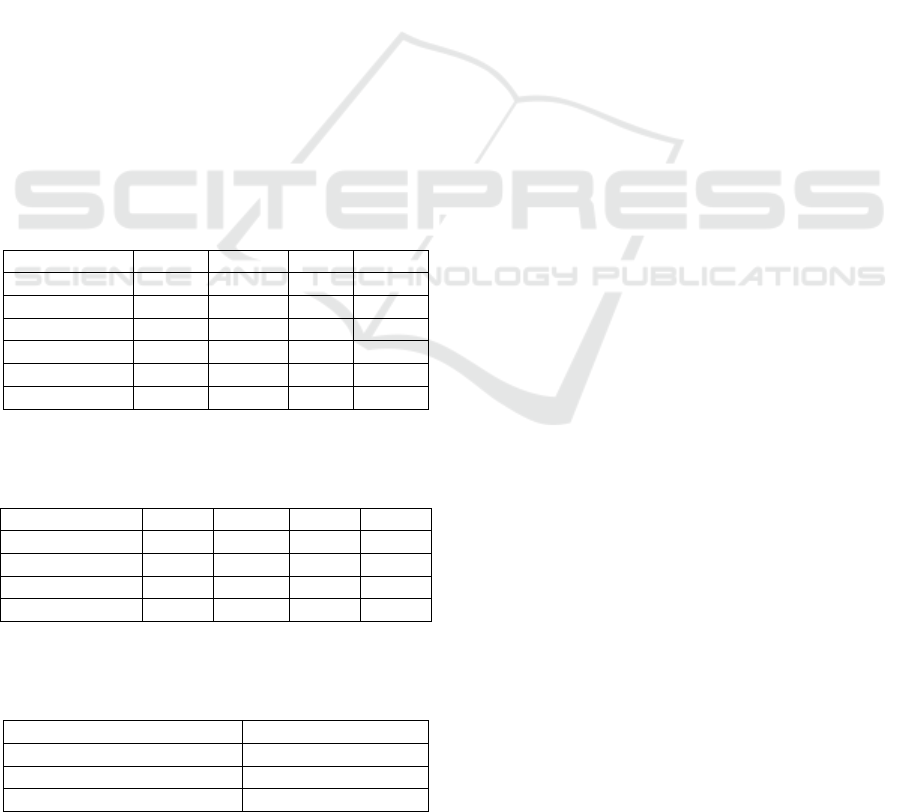

Table 1: Trip statistics over all observations.

Statistic

Ave

Median

Std

Min

Max

TripTime (h)

2,87

2,91

1,08

0,83

6,59

Fuel Econ

(km/l)

2,06

2,03

0,43

1,18

7,34

Payload (tons)

29,01

34,00

8,69

1,00

39,98

MaxSpeed

(km/h)

85,29

85,00

1,74

75,00

98,00

Speeding Time

22,62

0,00

172,39

0,00

5 621

MaxBrake

5,28

5,00

1,59

2,00

27,00

Excessive

BrakeTime

0,00

0,00

0,10

0,00

6,00

MaxAccel

2,74

3,00

0,74

2,00

24,00

Excessive

AccelTime

0,01

0,00

0,36

0,00

25,00

MaxRPM

1930

1900

203

1500

7600

Excessive

RPMTime

0,01

0,00

0,47

0,00

28,00

Excessive

IdleTime

42,71

0,00

124,73

0,00

2 187

Standing Time

(s)

447

311

444

15

1073

ElevGain (m)

1159

967

892

148

2746

ElevLost (m)

-969

-968

586

-1873

-163

MaxSlope asc

0,09

0,07

0,07

0,01

0,28

MaxSlope desc

-0,06

-0,07

0,05

-0,18

-0,01

AveSlope asc

0,01

0,01

0,01

0,00

0,04

AveSlope desc

-0,01

-0,01

0,01

-0,04

0,00

ElevGain

(m/km)

6,63

4,45

4,84

0,79

21,74

ElevLost

(m/km)

-5,68

-5,88

3,47

-22,33

-0,94

Neural Models for Benchmarking of Truck Driver Fuel Economy Performance

381

The available data included observations for 21

different routes, most of which were frequently

driven over the relevant period by a set of 331 drivers.

In order to investigate the impact of route

characteristics and driver behaviour, the available

data set was categorized per route. Figure 3 displays

the number of trips available per route as well as the

average fuel economy per route, sorted from highest

to lowest. It can be seen that the average fuel

economy per route varies by almost a factor of two

from the least to the most fuel efficient. Figure 4

displays the histogram of average fuel economy per

driver across all routes. For drivers the spread of

averages is even wider than for routes; this may

however partly be as a result of route inclination and

payload variations.

Figure 2: Histograms for trip times, fuel economy and

payload.

Figure 3: Number of trips and average fuel economy per

route.

In Figure 5 we display the driver average fuel

economy histograms for a few individual routes; it

can be seen that within a specific route the variation

in performance between drivers is not quite as big as

across all routes. The driver variations within the

same route are however sufficiently large to justify a

more accurate comparison between drivers, aimed at

quantifying the potential for fuel economy

improvement, should all drivers perform at the same

level.

Figure 4: Histogram of average fuel economy per driver for

all routes.

Figure 5: Histograms of average fuel economy per driver

for individual routes.

4 EXTRACTING EMPIRICAL

FUEL ECONOMY MODELS

In a previous article (Hoffman and Van der

Westhuizen, 2019) we described the extraction of

linear fuel economy regression models, as well as

nonlinear regression models based on the following

formula:

i

=

0

+

1

+

3

+

2n-1

(1)

where

i

is the estimated fuel economy value for observation

i

X

ni

are the values of input variables for observation i

NCTA 2019 - 11th International Conference on Neural Computation Theory and Applications

382

0 -

2n

are the estimates of the population regression

slopes and exponents as indicated above.

In this paper we expand this work by also

extracting neural network models using identical input

and target variables, and comparing the results

produced by the different models. The first type of

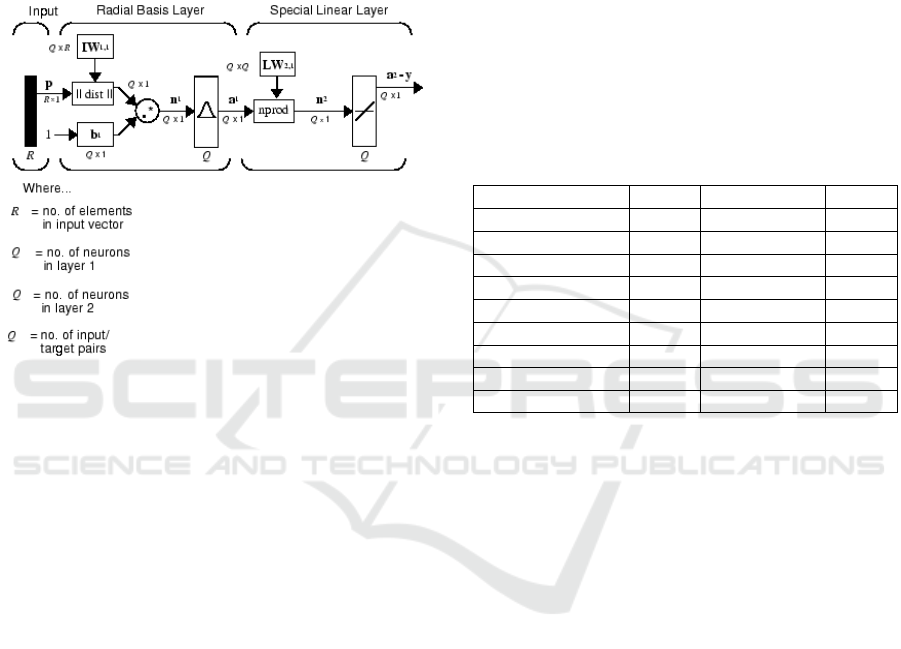

neural model is a generalized regression neural

network (GRNN) that is a variation on radial basis

function networks. The network architecture is

illustrated in Figure 6 below.

Figure 6: Architecture of the GRNN network.

This network uses a spread parameter to regularize

the input-output relationship; the value of spread is the

distance between the centre of a radial basis function

and the points where its magnitude has decreased by a

factor of 2. Larger values of spread therefore result in

smoother input-ouput mappings. We experimented

with GRNN models where the value of spread was

allowed to vary between 1 and 2024 in steps by a factor

of 2. The number of radial basis functions equalled the

number of training observations.

The second type of neural network that was used is

the multilayer perceptron, using a single hidden layer

with sigmoid transfer functions and a linear output

layer. In this case the number of hidden nodes is used

to regularize the input-output mapping: larger numbers

of hidden nodes provide more accurate fitting within

the training set, but may lead to overfitting, resulting in

lack of generalization ability in the test set, while a

smaller number of hidden nodes will result in less good

fits for the training set but more closely matching

goodness of fit for the test set. In our case we allowed

the number of hidden nodes to vary between 2 and 32.

We extracted models using all four modeling

techniques (linear regression, nonlinear regression,

GRNN and MLP NN) from the earliest 70% of all

observations, and predicted fuel economy for the

remaining 30% of observations. In order to compare

our results with results from previous research, we first

extracted models using driver, route and payload

factors as inputs. Input factors were selected by

ranking potential inputs based on absolute value of

linear correlations between inputs and fuel economy.

Table 2 provides the Pearson correlation coefficients

between a list of available input factors and fuel

economy. We only included input factors with a

correlation coefficient of at least 0.1 with the model

target. Once a ranked input factor has been selected,

we only considered additional factors that had a

correlation with already selected factors of less than

0.4, as the use of several higly correlated inputs results

in unstable model parameters.

Table 2: Correlation coefficients between fuel economy and

potential explanatory variables.

Inputs

Corr

Inputs

Corr

Max Speed

-0,133

Payload

-0,174

Speeding Time

-0,044

Elev Gain (m)

-0,627

Max Brake

0,018

Elev Lost (m)

0,465

Excessive Brake Time

-0,010

Max Slope Asc

-0,581

Excessive Accel Time

-0,016

Max Slope Desc

0,333

Max RPM

-0,378

Ave Slope Asc

-0,594

Excessive RPM Time

-0,014

Ave Slope Desc

0,443

Excessive Idle Time

0,026

Elev Gain (m/km)

-0,611

Standing Time

0,061

Elev Lost (m/km)

0,385

The list of model parameters selected on this basis

included Elevtion Gain, Max RPM, Payload and Max

Speed. Elevation Lost and some other factors were not

selected based on their high correlations with Elevation

Gain, that was selected first as it had the highest

absolute correlation with fuel economy.

The regression coefficients for the linear and

nonlinear regression models are displayed in Table 2 to

Table 4 below. For the nonlinear regression models

both the input factor coefficients and exponents are

given; for the linear models the exponents are always

1 as indicated. It can be seen that the relationships

between some inputs factors and fuel economy is

significantly nonlinear, as some exponents deviate

substantially from a value of 1.

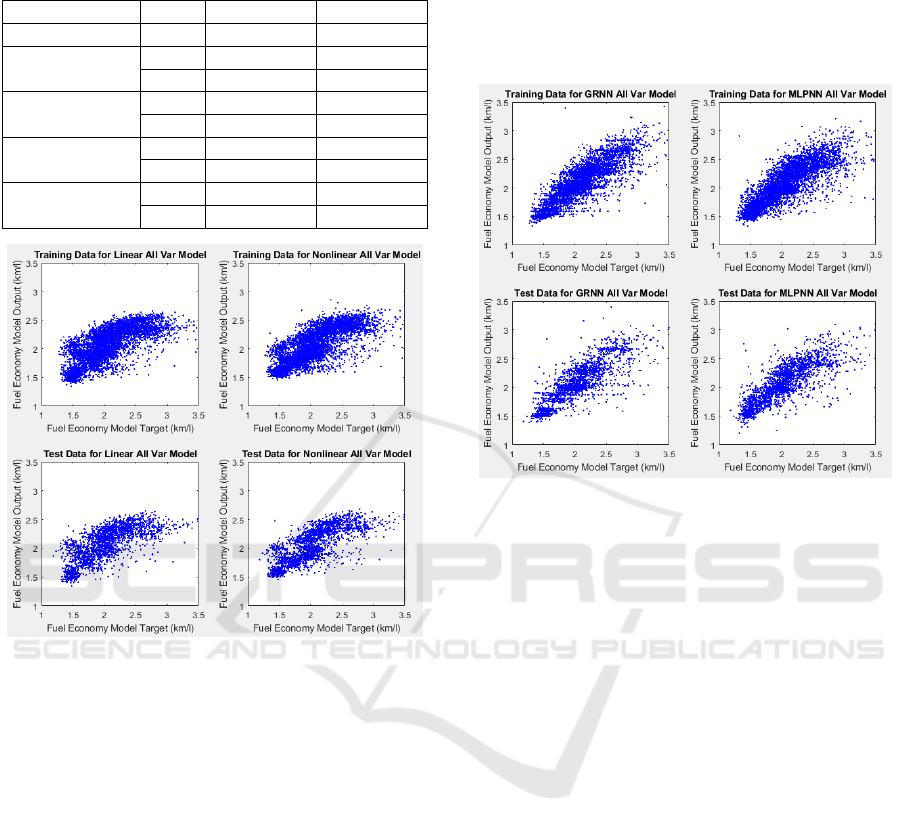

Figure 7 and Figure 8 displays scatterplots of

Target vs Output for the regression and neural models

respectively. Based on the scatterplots the model fits

for the test sets appear to be very similar to that for

the training sets, which indicates that the models have

good generalization capability. It can also be seen

that the neural models provide a superior fit of output

to target compared with the regression models, while

the GR neural network seem to be slightly superior to

the MLP network. These observations will be

confirmed using correlation analysis.

Neural Models for Benchmarking of Truck Driver Fuel Economy Performance

383

Table 3: Regression coefficients for general fuel economy

models.

Input Factor

Linear

Nonlinear

Constant

3,279

4,292

Max Speed

Coeff

0,006

0,007

Exp

1,000

0,945

Max RPM

Coeff

-0,001

-0,001

Exp

1,000

0,933

Payload

Coeff

-0,008

-0,101

Exp

1,000

0,514

Elevation Gain

Coeff

0,000

-0,136

Exp

1,000

0,348

Figure 7: Scatterplots for linear and nonlinear regression

Targets and Outputs.

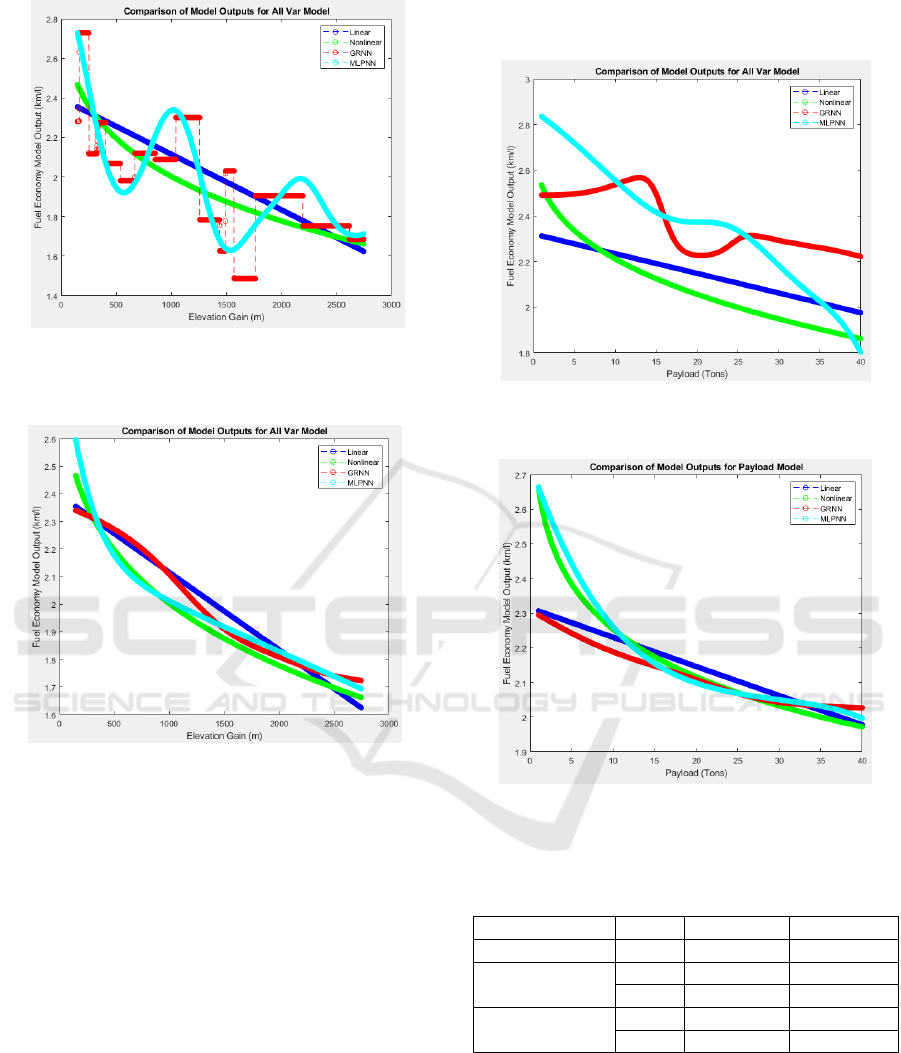

More insight into nature of the various modelling

techniques is obtained by constructing input-output

graphs where one input is varied across its entire

range of values, while the remaining variables are

kept constant at their average values. As we created

the outputs using artificial inputs values, it is not

possible to display corresponding target values. We

constructed such graphs for the four model types, and

repeated this for different levels of regularization

applied to the neural models to observe the impact of

changing the spread parameter and the number of

hidden nodes. In the Figure 9 and Figure 10 below

we display the relationship between Elevation Gain

as input and the modelled Fuel Economy as output for

different levels of regularization applied to the neural

models.

It can be seen that all models display a similar

trend in the modelled relationship. When low levels

of regularization are applied to the neural models,

they tend to display extreme variations in the output,

which is indicative of overfitting. When the level of

regularization is increased, most of this behaviour

disappears, and the relationships are much closer to

those for the regression models. Similar results are

obtained when using Payload as input variable, as

displayed in Figure 11 and Figure 12.

Figure 8: Scatterplots for GRNN and MLP neural network

Targets and Outputs.

We subsequently extracted models that only used

inputs not impacted by driver behaviour; regression

coefficients for these models are displayed in Table 4

below. To assess driver impact on performance, we

extracted both a driver behavioural model, that

utilizes behavioural variables like Maximum RPM,

Speeding Time and Maximum Speed as inputs

(regression coefficients displayed in Table 5), as well

as a driverID model, that uses driver identity as input.

To model the impact of driver identity we defined

driver dummy variable inputs (one variable per driver

that assumes the value of one when the respective

driver is present and zero otherwise). A positive

driver ID regression model coefficient indicates

above average performance while a negative model

coefficient indicates below average performance. We

then proceeded to extract both driver models using

the residuals of the route inclication and payload

models as targets. For the driverID model we thus

obtain regression model coefficients that provide a

direct indication of driver performance, compensated

for the impact of route and payload. Comparison

between the two sets of driver ID model coefficients

before and after correcting for non-driver factors will

provide a clear indication of the impact of model

correction.

NCTA 2019 - 11th International Conference on Neural Computation Theory and Applications

384

Figure 9: Elevation Gain vs Fuel Economy for all four

model types, using low levels of regularization for neural

models.

Figure 10: Elevation Gain vs Fuel Economy for all four

model types, using high levels of regularization for neural

models.

In order to evaluate model accuracy, we

calculated the correlations between model outputs

and target variables both for the training and test sets,

as displayed in Table 6 to Table 9 below. It can be

seen that the models that include driver, route and

payload inputs have the biggest correlations between

output and target, as would be expected. Most of the

correlation obtained in the training set is retained in

the test set, indicating that the observed relationships

between fuel economy and the respective explanatory

variables are strong and consistent. It can also be seen

that the nonlinear regression models perform slightly

superior to the linear regression models, while the

neural models outperform the regression models, both

for the general, the route & payload and the driver

models. The driver behavioural model, that uses Max

RPM, Max Brake and Max Speed as inputs, perform

slightly better than the driver ID model, that uses

driver identity as input.

Figure 11: Payload vs Fuel Economy for all four model

types, using low levels of regularization for neural models.

Figure 12: Payload vs Fuel Economy for all four model

types, using high levels of regularization for neural models.

Table 4: Regression coefficients for route and payload

models.

Input Factor

Linear

Nonlinear

Constant

2,707

4,540

Payload

Coeff

-0,012

-0,104

Exp

1,000

0,568

Elevation Gain

Coeff

0,000

-0,407

Exp

1,000

0,243

We investigated the consistency in driver

performance over time by correlating both the

uncompensated and compensated driver fuel

economies between the training and test sets. In

Table 10 below it can be seen that the consistency in

driver performance is increased by compensating for

the impact of route inclination and payload, as the

correlation between training and test set performance

Neural Models for Benchmarking of Truck Driver Fuel Economy Performance

385

is higher for compensated compared to

uncompensated performance. This confirms that

factors like route inclination and payload add

variability to driver performance measures that is

unrelated to actual driver performance. It is

furthermore observed that, after also compensating

for driver identify, the correlation of residual driver

performance between the training and test sets is

almost zero. This is to be expected as most of the

driver impact is now present in the driver model

output, with the remaining model residual fuel

economy being mostly noise.

Table 5: Linear regression coefficients for driver fuel

economy models (both uncompensated and compensated

for route and payload factors).

Input Factor

Uncompensated

Compensated

Const

4,702

-0,205

Max Speed

-0,001

0,001

Max RPM

-0,012

-0,009

Max Brake

0,019

-0,014

Table 6: Correlation coefficients between fuel economy

model outputs and targets for the training set.

Inputs

LinRegr

NonLinR

GRNN

MLPNN

All Var

0,695

0,721

0,856

0,800

Route

0,627

0,660

0,740

0,735

Payload

0,174

0,184

0,221

0,257

Route&Payload

0,671

0,705

0,814

0,783

DriverBeh

0,381

0,381

0,392

0,400

DriverID

0,357

-

0,300

0,327

Table 7: Correlation coefficients between fuel economy

model outputs and targets for the test set.

Inputs

LinRegr

NonLinRe

GRNN

MLPNN

All Var

0,592

0,655

0,763

0,741

Route

0,607

0,636

0,710

0,706

Payload

0,180

0,202

0,240

0,282

Route&Payload

0,640

0,678

0,768

0,744

DriverBeh

0,139

0,159

0,315

0,341

DriverID

0,121

-

0,127

0,148

Table 8: Training set correlation coefficients between

outputs and targets for models trained on the route and

payload residual fuel economy.

Inputs

LinRegr

NonLinR

GRNN

MLPNN

DriverBeh

0,263

0,262

0,271

0,277

DriverID

0,435

0,067

0,368

0,414

Table 9: Test set correlation coefficients between outputs

and targets for models trained on the route & payload

residual fuel economy.

Inputs

LinRegr

NonLinR

GRNN

MLPNN

DriverBeh

0,024

0,044

0,173

0,200

DriverID

0,134

0,033

0,112

0,131

Table 10: Correlations between driver fuel economy

performance measured over the training and test sets.

Fuel Economy Measure

Train vs Test Corr

Uncompensated

0,292

Route&Cargo Compensated

0,326

Driver,Route&Cargo Compensated

0,012

5 ESTIMATING MODEL

COMPENSATION IMPACT ON

DRIVER PERFORMANCE

MEASUREMENTS

One of our stated objectives is to measure driver

performance more consistently by compensating for

those factors over which the driver has no control. We

therefore calculated a compensated fuel economy

figure for each trip by subtracting the route & cargo

fuel economy model output from the original fuel

economy, and then adding the population average

fuel economy to this residual to obtain a fuel economy

figure that is mostly attributed to driver behaviour:

(2)

We expect variations in driving performance to be

reduced after compensating for the impact of route

and payload. To verify if this is the case we

calculated the standard deviation of uncompensated

driver fuel economy averages over all drivers, and

obtained a figure of 0.192 km/l. The compensated

driver fuel economy in equation 2 above was used to

calculate compensated driver averages. The standard

deviation of compensated driver averages was then

calculated as 0.158 km/l, which is indeed somewhat

lower than the figure before compensation.

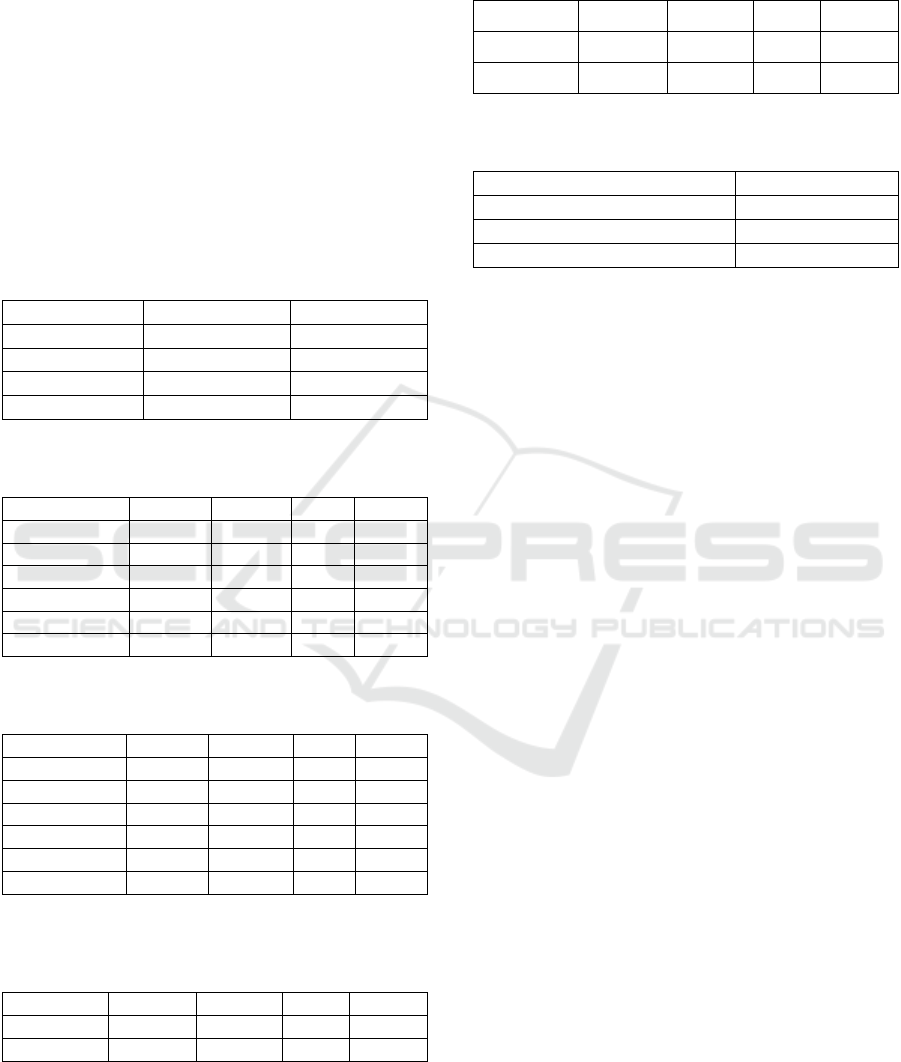

Figure 13 displays histograms of the compensated

fuel economy using both the linear and nonlinear

route and payload models. When compared against

the uncompensated histogram the distributions have

clearly changed. In Figure 14 we compare

uncompensated versus route and cargo compensated

fuel economy histograms for a sample of drivers. The

change in distribution is clearly visible; in cases

NCTA 2019 - 11th International Conference on Neural Computation Theory and Applications

386

where the average did not change much, as for driver

923, the spread became narrower as expected, due to

removal of the impact of varying route inclinations

and payloads.

Figure 13: Histograms for route and cargo compensated

fuel economy.

To investigate the relationships between

uncompensated and compensated driver performance

measures, we calculated correlations between driver

fuel economy averages and the linear regression

model coefficients of the Driver ID based models.

Table 11 below displays the correlations between the

coefficients of both the uncompensated and route &

payload compensated Driver ID models, versus the

uncompensated and compensated fuel economies, as

observed over both the training and test sets. The

correlation between the uncompensated fuel

economy and uncompensated driver ID model

coefficients is almost 1 for the training set as

expected, as the model coefficients were extracted

from this data. For the test set it is still significantly

positive, confirming that driver ID explains a

significant fraction of observed fuel economy. We

also observe a large positive correlation between the

compensated driver ID model coefficients and

compensated fuel economy over the training set.

In contrast the correlations between the route

compensated Driver ID model coefficients and

uncompensated fuel economy are negative for both

the training and test sets; this indicates significant

differences between driver performance before and

after eliminating the impact of route inclination and

payload. It is confirmed by the fact that the route &

payload compensated fuel economy is also negatively

correlated with the uncompensated Driver ID model

coefficients for both the training and test sets. The

correlation of -0.729 between driver ID regression

coefficients before and after compensation confirms

how drastically driver performance assessment is

changed by the model correction. This is a very

important result, as it provides evidence for the

acceptance of our hypothesis that driver performance

measures are drastically impacted by the presence of

factors that are not identical for all drivers and not

within the driver’s control.

Figure 14: Comparison of uncompensated and route and

cargo compensated fuel economy histograms for different

drivers.

Table 11: Correlations between driver average fuel

economy and Driver ID based model coefficients.

Driver Fuel Economy

Coeff

Uncomp

Coeff Route

Comp

Uncompensated Train

0,976

-0,594

Uncompensated Test

0,243

-0,066

Route & Payload Comp Train

-0,581

0,525

Route & Payload Comp Test

-0,124

0,082

Driver & Route Comp Train

0,014

0,000

Driver & Route Comp Test

-0,383

0,536

DriverID Coeff Route Comp

-0,729

1

As a further confirmation of these results we

calculate correlations between average driver fuel

economy performance before and after

compensation. Table 12 indicates that driver

performance before and after route and payload

compensation is negatively correlated. The fact that

this is almost equally strong for the training and test

sets provides evidence that it is not as a result of

model overfitting. We furthermore observe that when

also removing the impact of driver ID the remaining

Neural Models for Benchmarking of Truck Driver Fuel Economy Performance

387

correlation for the training set is almost zero, as the

remaining model error will now have little

resemblance to the original fuel economy. A small

positive correlation remains for the test set as the

models could not capture all variations present in the

data; this is also to be expected as not all factors

impacting fuel economy are present in the model (e.g.

wind speed and traffic conditions).

Table 12: Correlations between compensated and

uncompensated driver fuel economy performance.

Variable

Train

Test

Route&Cargo Compensated

-0,598

-0,554

Driver,Route&Cargo Compensated

0,007

0,240

To quantify the degree to which driver

performance measures are impacted by model

compensation we calculated each driver’s ranking

compared to other drivers, firstly based on

uncompensated and secondly based on compensated

performance averages. For each driver the difference

in ranking position was determined before and after

model compensation; this change in ranking was

normalized by division through the total number of

drivers. The average absolute change in ranking

differences was then calculated over all drivers to

obtain an overall figure of the degree to which

ranking was impacted by performance compensation,

as indicated in equation 3 below:

(3)

where N is the total number of drivers.

For random changes to all driver rankings this

figure will be 0.5; for no ranking changes it will be

zero. To verify the consistency in driver performance

over time, we first calculated the relative change in

ranking between the training and test sets for both the

uncompensated and compensated fuel economies.

We obtained a relative ranking change of 0.27; this

indicates that performance does change over time, but

that it is not entirely random, with some level of

consistency. We then proceeded to compare the

ranking of driver performances between the case with

no compensation and the case after model

compensation. Table 13 and Table 14 displays the

relative ranking changes for different compensation

models for the training and test sets. It can be seen

that the change in driver ranking before and after

compensation is bigger than the difference of 0.27

observed between the training and test sets; this

indicates that, over and above changes in

performance over time, the model based

compensation results in a significant difference in

driver ranking.

Table 13: Average relative change in driver performance

ranking before and after compensation for the training set.

Inputs

LinRegr

NonLinR

GRNN

MLPNN

All Var

0,468

0,468

0,447

0,456

Route

0,477

0,469

0,465

0,466

Payload

0,493

0,489

0,495

0,494

Route&Payload

0,479

0,471

0,472

0,473

DriverBeh

0,460

0,459

0,482

0,458

DriverID

0,343

0,494

0,500

0,411

Table 14: Average relative change in driver performance

ranking before and after compensation for the test set.

Inputs

LinRegr

NonLinR

GRNN

MLPNN

All Var

0,471

0,468

0,462

0,462

Route

0,483

0,472

0,471

0,467

Payload

0,493

0,486

0,493

0,493

Route&Payload

0,482

0,464

0,473

0,475

DriverBeh

0,470

0,467

0,477

0,472

DriverID

0,414

0,495

0,499

0,445

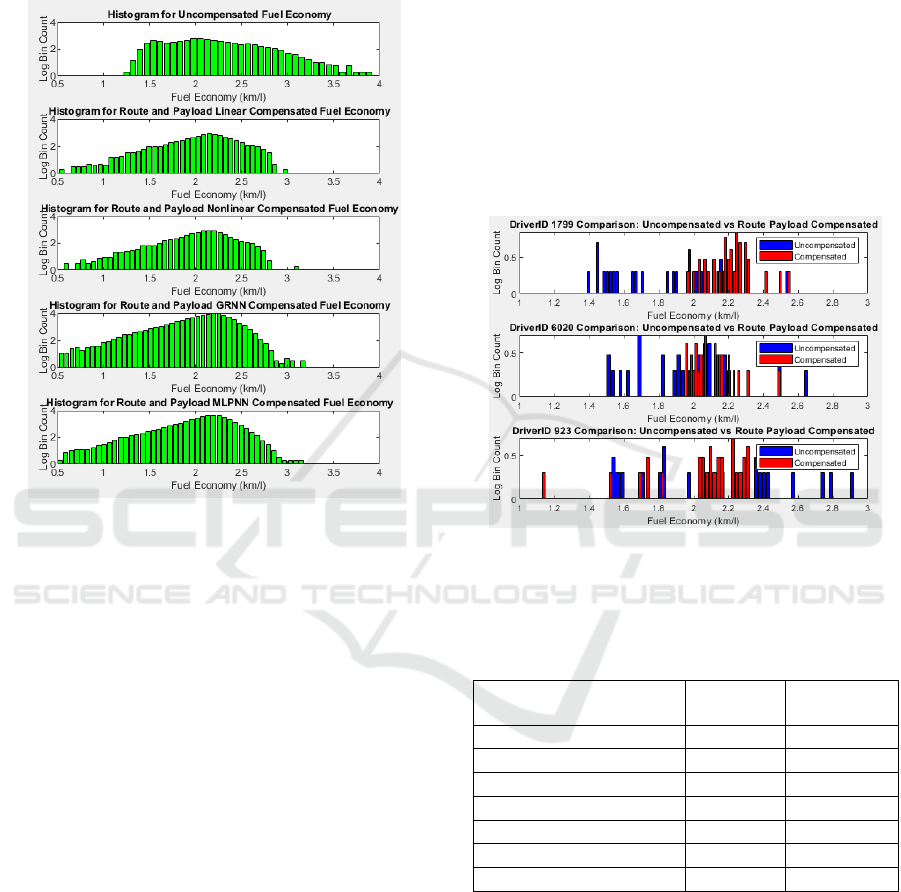

Figure 15: Comparison between driver ranking before and

after compensating for route and cargo.

These results are confirmed by the scatterplot of

driver rankings before and after compensation as

displayed in Figure 15. The series of drivers that

seem to have retained the same ranking before and

after (straight line in the middle of the graph) are

drivers with no trips in the test set and to whom we

allocated average performance; they therefore

assumed sequential positions in the ranking list.

As a last measure of the impact of model

compensation we calculated the fraction of drivers for

whom performance relative to the population average

changed from positive to negative or vice versa after

NCTA 2019 - 11th International Conference on Neural Computation Theory and Applications

388

compensation. If performance before and after model

compensation is unrelated (e.g. random performance

changes) the total fraction of changes should be 0.5.

Table 15 displays the fraction of drivers with reversed

relative performance. We observe that for the route

& cargo model compensations the relative changes

are the biggest. For the driver models the fraction of

changes approach 0.5, because the residues from

these models are largely unrelated to driver identity

and would therefore appear to be random.

To compare the impact of the different models on

driver performance after correction, we calculated the

differences in average relative change in ranking

between the models. The comparison matrix in Table

16 provides evidence that all the models largely agree

in terms of the required changes in driver ranking, as

these differences are fairly close to zero (in those

cases where a model was compared against itself a

result of exactly zero was obtained). Lastly we

performed a similar comparison between route

models and payload models that used the same

modelling technique; these results appear in Table 17.

The differences are slightly larger than in the previous

case, as payload represents a smaller fraction of fuel

economy changes compared to route inclination and

is therefore less effective when used on its own.

Table 15: Fraction of drivers with reverse in relative

performance before and after compensation.

Inputs

LinRegr

NonLinR

GRNN

MLPNN

All Var

0,565

0,565

0,529

0,511

Route

0,577

0,565

0,544

0,532

Payload

0,601

0,592

0,592

0,583

Route&Payload

0,577

0,583

0,544

0,571

DriverBeh

0,565

0,553

0,577

0,562

DriverID

0,363

0,607

0,598

0,447

Table 16: Difference in average relative change in driver

performance ranking after compensation between on

different route and payload models.

Model Type

LinRegr

NonLinR

GRNN

MLPNN

LinRegress

0,000

0,070

0,091

0,078

NonLinRegr

0,070

0,000

0,109

0,095

GRNN

0,091

0,109

0,000

0,059

MLPNN

0,078

0,095

0,059

0,000

Table 17: Difference in average relative change in driver

performance ranking after compensation based on different

route vs payload models.

LinRegress

0,082

NonLinRegress

0,123

GRNN

0,100

MLPNN

0,121

6 CONCLUSIONS AND FUTURE

WORK

In this paper we derived models for truck fuel

economy using four different modelling techniques.

We proved that neural models outperform linear and

nonlinear regression models, regardless of the set of

input factors that are used, and that both radial basis

and MLP networks produced satisfactory results. We

also demonstrated that selecting the width of the

radial basis functions or the number of hidden layer

nodes can be used to obtain the required level of

accuracy and generalization ability.

The point of departure of our research was a

hypothesis that factors beyond the control of a truck

driver has a significant impact on fuel economy

performance measures. The results reported in this

paper provides conclusive evidence that the

hypothesis can be accepted. Firstly, we found that

factors like route inclination and payload explain a

significant fraction of total observed fuel economy

deviations. Secondly we observed that variations

between averages of driver performance are reduced

after compensating for route and payload. Thirdly we

found that there is more consistency between driver

performance in the training and test sets after

compensating for route and payload than before. In

the fourth place we proved that average driver

performance measured before and after compensating

for route and payload are negatively correlated. In the

fifth place we observed large changes in driver

performance ranking after compensation, and lastly

we found that the fuel economy performance of the

majority of drivers, relative to the population average,

changes in sign after compensating for route and

payload.

The default measure currently used for driver fuel

performance is the observed average over all

completed trips. The new performance measure that

we propose, to replace the default measure of average

over all completed trips, is to use the residual of the

model that predicts fuel economy in terms of route

inclinations and payload. The population average for

fuel economy is then added to this residual to obtain

a realistic fuel economy figure for each driver.

Future work will involve the inclusion of additional

input factors not related to driver behaviour, like wind

speed and traffic conditions, as factors to be

compensated for, as well as the use of more

sophisticated neural network techniques, e.g. using

clustering techniques to determine the optimal

number of radial basis functions.

Neural Models for Benchmarking of Truck Driver Fuel Economy Performance

389

REFERENCES

Anon., 2014. Stopping the flow of illegal black gold.

Transport World Africa, June, p. Vol. 12 No. 3.

Bennett, I. Greenwood, C., 1995. HDM-4 Fuel

Consumption Modelling, Preliminary Draft Report to

the International Study of Highway Development and

Management Tools, Birmingham: University of

Birmingham.

Biggs, D., 1988. ARFCOM - Models For Estimating Light

to Heavy Vehicle Fuel Consumption, Research Report

ARR 152, Nunawading: Australian Road Research

Board.

Delgado, O., Clark, N. Thompson, G., 2011. Modeling

Transit Bus Fuel Consumption on the Basis of Cycle

Properties. Journal of the Air & Waste Management

Association, pp. 443 - 452.

Elnaz Siami-Irdemoosa, S. R. D., 2015. Prediction of fuel

consumption of mining dump trucks: A neural networks

approach. Applied Energy 151, p. 77–84.

Gong, L., Morikawa, T., Yamamoto, T. Sato, H., 2014.

Deriving Personal Trip Data from GPS Data: A

Literature Review on the Existing Methodologies.

Beijing, China, s.n.

Hassanean S.H. Jassim, W. L. T. O., 2018. Assessing

energy consumption and carbon dioxide emissions of

off-highway trucks in earthwork operations: An

artificial neural network model. Journal of Cleaner

Production 198, pp. 364-380.

Havenga, J., 2013. 10th Annual State of Logistics Survey

for South Africa, ISBN number: 978-0-7988-5616-4, p.

9., Stellenbosch, South Africa: s.n.

Hoffman, A. J., 2010. The use of technology for trade

corridor management in Africa. Sandton,

Johannesburg, South Africa, s.n.

Hoffman, A. J., Van der Westhuizen, M., 2014. An

Investigation into the Economics of Fuel Management

in the Freight Logistics Industry. Qingdao, PRC, s.n.

Hoffman, A. J. , Van der Westhuizen, M., 2019. An

empirical model for the assessment of truck driver fuel

economy. Auckland, New Zeeland, IEEE, p. to be

published.

Hoffman, A. , Van der Westhuizen, M., 2019. Empirical

model for truck route fuel economy. IEEE Intelligent

Transportation Systems Conference, p. Submitted for

publication.

Jian-Da Wu, J.-C. L., 2012. A forecasting system for car

fuel consumption using a radial basis function neural

network. Expert Systems with Applications Vol 39, p.

1883–1888.

Naidoo, J., 2013. Transport White Paper: The South

African Cross-Border Industry, THRIP Research

Report, Potchefstroom, South Africa: North-West

University.

Perrottaa, F. et al., 2019. Verification of the HDM-4 fuel

consumption model using a Big data approach: A UK

case study. Transportation Research Part D, pp. 109 -

118.

Rakha, J. , Wang, H., 2017. Fuel consumption model for

heavy duty diesel trucks: Model development and

testing. Transportation Research Part D, pp. 127 - 141.

United States Environmental Protection Agency, 2019.

Sources of Greenhouse Gas Emissions. [Online]

Available at: https://www.epa.gov/ghgemissions/

sources-greenhouse-gas-emissions

United States Environmental Protection Agency, 2019.

Transportation and Climate Change. [Online]

Available at: https://www.epa.gov/transportation-air-

pollution-and-climate-change/carbon-pollution-

transportation

Weille, J. d., 1966. Quantification of Road User Savings.

World Bank Occasional Papers No. 2, World Bank,

Washington D.C..

Zhigang Xu, T. W. S. E. X. Z., 2018. Modeling

Relationship between Truck Fuel Consumption and

Driving Behavior Using Data from Internet of Vehicles.

Computer-Aided Civil and Infrastructure Engineering

Vol 33, p. 209–219.

NCTA 2019 - 11th International Conference on Neural Computation Theory and Applications

390