Biomolecular Phage Filter for the Detection of a Small Number of

Pathogens in Large Volumes of Processing Water

Songtao Du

1

, Xu Lu

2

, I-Hsuan Chen

3

, Yuzhe Liu

1

, Shin Horikawa

1

, Tung-shi Huang

4

and Bryan A. Chin

1

1

Material Research and Education Center, Auburn University, Auburn, AL, 36849, U.S.A.

2

Laboratory of Functional Films, Material Science and Engineering, Xi'an University of Technology,

Xi'an, 710048, China

3

Department of Biological Science, Auburn University, Auburn, AL, 36849, U.S.A.

4

Department of Poultry Science, Auburn University, Auburn, AL, 36849, U.S.A.

Keywords: Phage Filter, Me Biosensor, Capture Efficiency.

Abstract: Fresh specialty crop produce such as tomatoes, blueberries, strawberries, sprouts, cantaloupes, lettuce and

leafy greens account for more instances of foodborne illness than any other food category. Recent

announcements to consumers, by the United States (U.S.) Centers for Disease Control (CDCs), to discard all

Romaine lettuce because of bacterial contamination has resulted in hundreds of millions of dollars in losses

to growers and processors. Unfortunately, current microbiological testing of samples of specialty crops

(whole fruits, leaves of spinach, etc.), as specified by FDA’s Bacteriological Analytical Manual (BAM),

requires at least 48 hours to perform the complicated, time-consuming and costly steps of soaking, pre-

enrichment, concentration, enrichment, plate count or PCR to detect pathogens on these samples. Further

complicating the BAM analyses are the realities that: 1) both PCR and ELISA are unable to distinguish

between live and dead cells and 2) only a few samples out of as many as 100,000 fruits, vegetables or leaves

of multi-ton batches of produce can be BAM tested. A Non-clogging Biomolecular Phage Filter has been

developed to simultaneously capture, concentrate and isolate small numbers of pathogens from large

volumes of produce wash water. This phage filter can then be evaluated to screen for live versus dead cells

and ID the specific pathogen in minutes. Capture efficiencies of greater than 94% have been demonstrated.

1 INTRODUCTION

The U.S. Food and Drug Administration (FDA) and

CDCs have, within the last year, taken the

unprecedented step of warning the U.S. public to

discard all Romaine lettuce because of possible

bacterial contamination (CDCs, June 2018; CDCs,

Dec 2018; Staff, 2018). This warning led to all

Romaine lettuce in the food chain being discarded

and a still to be determined loss to producers,

processors and distributors estimated to be in the

hundreds of millions of U.S. dollars. The cost of

foodborne illness in the U.S. is enormous. A report

in 2014 from the U.S. Department of Agriculture

estimated that the direct and indirect costs associated

with illnesses caused by major foodborne pathogens

is more than $15.6 billion per year (Stephen, 2018).

A more recent estimate from Ohio State University

that covered all causes of foodborne illness, not just

illness from the major foodborne pathogens,

concluded the amount was at least $55.5 billion

(Stephen, 2018). Each year in the U.S., about 48

million people get sick from foodborne illness.

These foodborne illnesses result in approximately

128,000 hospitalizations and 3,000 deaths, as

reported by the CDCs (CDCs, Feb 2018). Of the

major foodborne pathogens, Salmonella causes

about 1.2 million illnesses, 23,000 hospitalizations

and 459 deaths in the U.S. each year (CDCs, Nov

2018).

Triple washed, ready-to-eat, salads have found a

ready consumer market in the U.S. The produce that

goes into these ready-to-eat salads typically comes

from numerous farms and are processed in multi-ton

batches. The produce is washed in a series of cleaner

and cleaner water, finally being drip dried on a

vibrating conveyor followed by centrifugal drying.

It is common practice for a few ml samples of the

108

Du, S., Lu, X., Chen, I., Liu, Y., Horikawa, S., Huang, T. and Chin, B.

Biomolecular Phage Filter for the Detection of a Small Number of Pathogens in Large Volumes of Processing Water.

DOI: 10.5220/0007689901080113

In Proceedings of the 12th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2019), pages 108-113

ISBN: 978-989-758-353-7

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

final wash water to be tested for pathogens using

off-site commercial testing laboratories following

FDA accepted BAM procedures using PCR. Despite

this testing, contaminated batches of Romaine

lettuce have reached consumers and resulted in

illness. The U.S.’s recent failures to identify

contaminated ready-to-eat salads, demonstrates the

need for new technologies that are capable of

capturing and concentrating small numbers of

pathogens from large volumes of produce wash

water. To meet these needs, the authors of this paper

are developing a non-clogging, biomolecular phage

filter. This paper presents the concept and design of

the phage filter, and capture efficiencies of two

different designs of the filter system.

2 PHAGE FILTER DESIGN

2.1 Concept

Magnetoelastic (ME) biosensors immobilized with

filamentous E2 phage have been widely studied and

reported in our previous publications (Nambi and

Nyalamadugu, 2003; Guntupalli and Lakshmanan,

2007; Huang and Yang, 2008a; Huang and Yang,

2008b; Shen and Mathison, 2010; Park and Wikle,

2012; Chai and Li , 2012; Li and Horikawa, 2012;

Guntupalli and Sorokulova, 2012; Chai and

Horikawa, 2013a; Park and Park, 2013a; Park and

Li, 2013b; Chai and Horikawa, 2013b; Chai and

Wikle, 2013c; Horikawa and Chai, 2015). These ME

biosensors are typically rectangular strips made of a

magnetoelastic material, 1000 x 200 x 30 microns in

size. As the specific pathogens are captured by the

phage coated on the ME biosensor, the added mass

of the captured pathogens, causes the resonance

frequency of the ME resonator to decrease as a

direct function of number of captured bacteria. E2

phage has been specifically engineered to bind

Salmonella typhimurium. Because of the selective

and specific binding affinity of E2 phage,

Salmonella pathogens can be captured on surfaces of

ME biosensors and are removed from the test liquid,

when the sensors are collected. The biomolecular

phage filter is composed to many individual ME

biosensors, each biosensor serving as an individual

filter element. Each filter element is held in the filter

by a controlled magnetic field.

The phage filter consists of phage immobilized

ME biosensors and supporting frames. Many layers

of frames (arranged at different orientations) can be

combined together to form a single filter. The ME

filter elements are held by a controlled magnetic

field that is applied to align individual ME elements.

Either electromagnets or permanent magnets can be

used to generate the magnetic field. Openings of

supporting frames are close packed with ME filter

elements each immobilized with E2 phage. The

surfaces of ME filter elements are held

perpendicular to the direction of the flowing liquid.

Salmonella typhimurium that comes into contact

with a filter element immobilized with E2 phage will

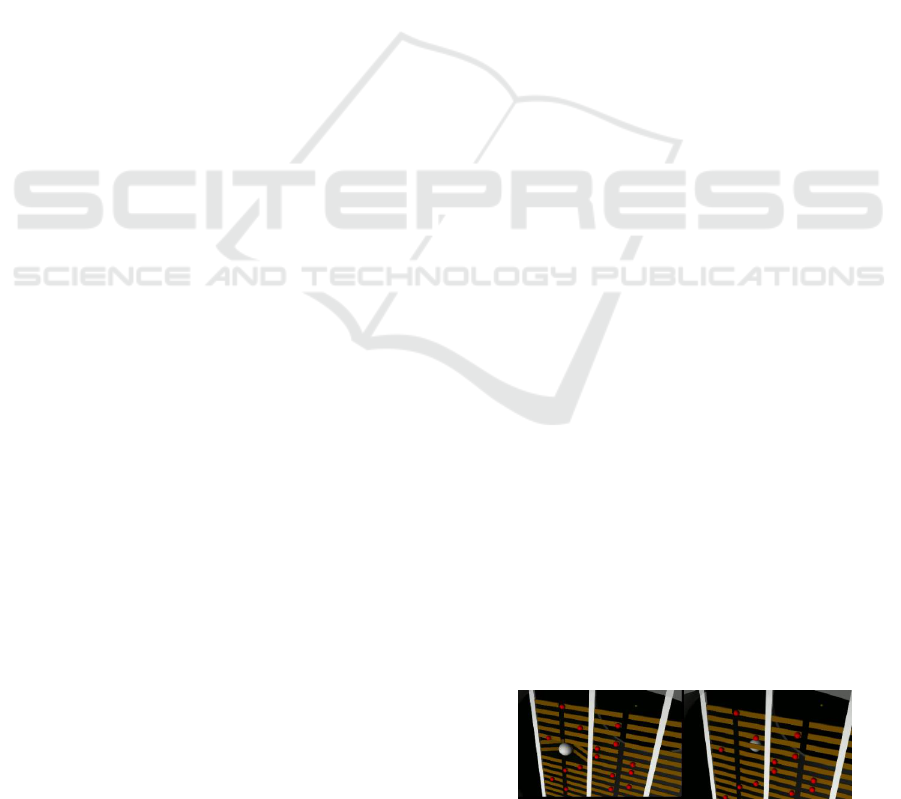

bind to that element. Figure 1 shows how the phage

filter works. Each filter element is held at one end to

the supporting frame by the magnetic field. The field

also holds the ME filter elements in the magnetic

plane. Salmonella typhimurium shown in red, is

captured and bound to the filter element by the E2

phage, once collision occurs. At the same time,

debris, such as fruit pulp and sand, will not be

captured by the phage and pass through the ME filter

elements. Large debris (shown in white) will cause

the ME filter elements to open like a gate, passing

through the phage filter. Once the debris has passed,

the ME filter elements will realign due to the planar

magnetic field. Therefore, this phage filter is

pathogen specific and is non-clogging. Auburn

University has engineering different phages that are

designed to capture different pathogens such as

Salmonella enterica, Salmonella typhimurium,

Campylobacter spp., Listeria spp., and E. coli

O157H7, etc.

Figure 2 compares the differences between the

Biomolecular Phage Filter and conventional packed

magnetic bead filters. As shown in the figure, the

antibody immobilized beads capture the specific

pathogen, but become clogged with larger debris

that cannot pass through the interstitials of the

packed spheres. Debris builds up ahead of the

packed bead column and prevents further flow of

liquid and capture of pathogens by the antibody

immobilized beads.

2.2 Design and Simulation

Magnetic fields were used to attach, align and

release the ME filter elements from the filter and

supporting frames. In the research, two different

methods of filtering were investigated: 1) stationary

filter with gravity-driven, vertical liquid flow and 2)

rotational moving filter driven by electric motor.

Figure 1: White debris passing through phage filter.

Biomolecular Phage Filter for the Detection of a Small Number of Pathogens in Large Volumes of Processing Water

109

Figure 2: Difference between phage filter and

conventional bead filter.

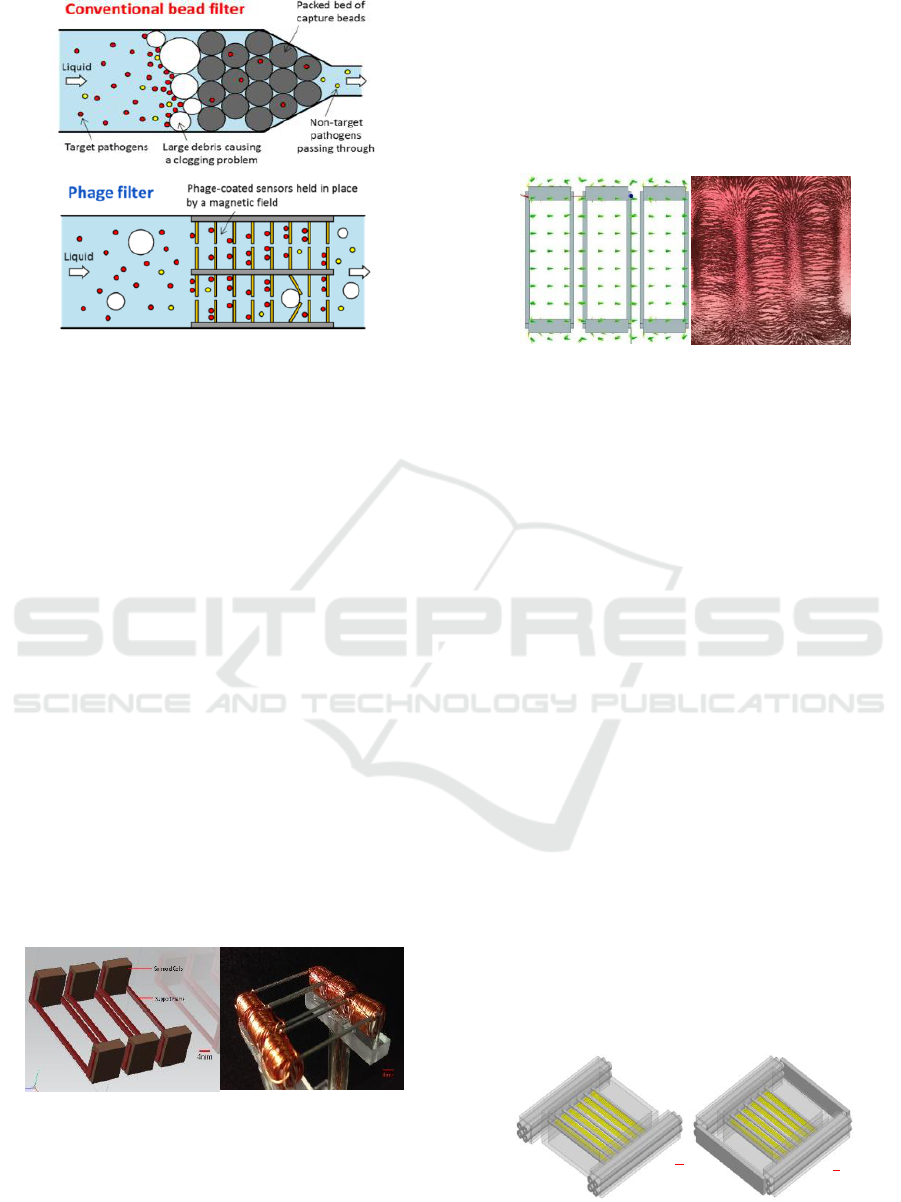

2.2.1 Vertical Flow Model

For the vertical flow model, the magnetic field was

created by electromagnetic coils that were wound

around supporting frames. The solenoid coils were

made of plastic coated electrical wire (28GA). The

ME filter elements were aligned and held to the

frame when current was applied to the coils. The

ME filter elements could therefore be easily released

by turning off the current. The supporting frames

were fabricated from one kind of soft magnetic

material, Permalloy 80, by electric discharge

machining (EDM). A grooved structure of

supporting frame (Figure 3) was selected to

concentrate the magnetic field between the

supporting frames. The distance between frame

members was determined by the length of ME filter

elements and the size of the pipe. Figure 3 shows a

3D model and photo of the phage filter, including

supporting frames and electromagnetic coils. The

ME filter elements were attached by the magnetic

field to the supporting frames perpendicularly to

cover the opening of supporting frame.

Figure 3: 3D model & photo of vertical model phage filter.

The magnetic field was modeled using ANSYS

Maxwell. The 3D model was designed using NX

Unigraphics software. The predicted magnetic field

is shown in Figure 4. ME filter elements align

parallel to the magnetic field vectors. Iron powder

was used to experimentally verify predicted

magnetic flux lines. In addition, the magnetic force

was measured by Gauss meter. A value of 69.72

gauss generated by an electrical current of 1.5A was

enough to hold ME filter elements to supporting

frames.

Figure 4: Simulation and iron powder test of magnetic flux

vectors of vertical model phage filter.

2.2.2 Rotating Filter Model

For the rotating model, permanent magnets (Grade

N52) with diameter of 3/16" were used to generate

the magnetic field instead of electromagnetic coils.

Figure 5 (left) shows the 3D model of the rotating

phage filter with ME filter elements attached.

Supporting frames were made of Permalloy 80 wire

with a diameter of 1mm. Two Permalloy 80 sheets

were fixed on the end of magnets, in order to

improve uniformity of the magnetic field. The

modified 3D model (improved) of the phage filter is

shown in Figure 5 (right). Simulation results are

shown in Figure 6. The magnetic flux vectors were

also perpendicular to the supporting frames of phage

filter, especially for the corners of the supporting

frame. Therefore, the ME filter elements can be

coupled to the supporting frames with the same

direction of magnetic flux vector, passing parallel to

the long axis of ME biosensors.

2.3 Testing of Vertical and Rotating

Filter Systems

Tests of both the Vertical Flow and Rotating Filter

Systems were conducted. The systems were both

constructed of transparent food-grade plastic.

Figure 5: 3D model of phage filter of rotating model

before & after modification.

4mm

4mm

BIODEVICES 2019 - 12th International Conference on Biomedical Electronics and Devices

110

Figure 6: Simulation of magnetic flux vectors of rotating

phage filter.

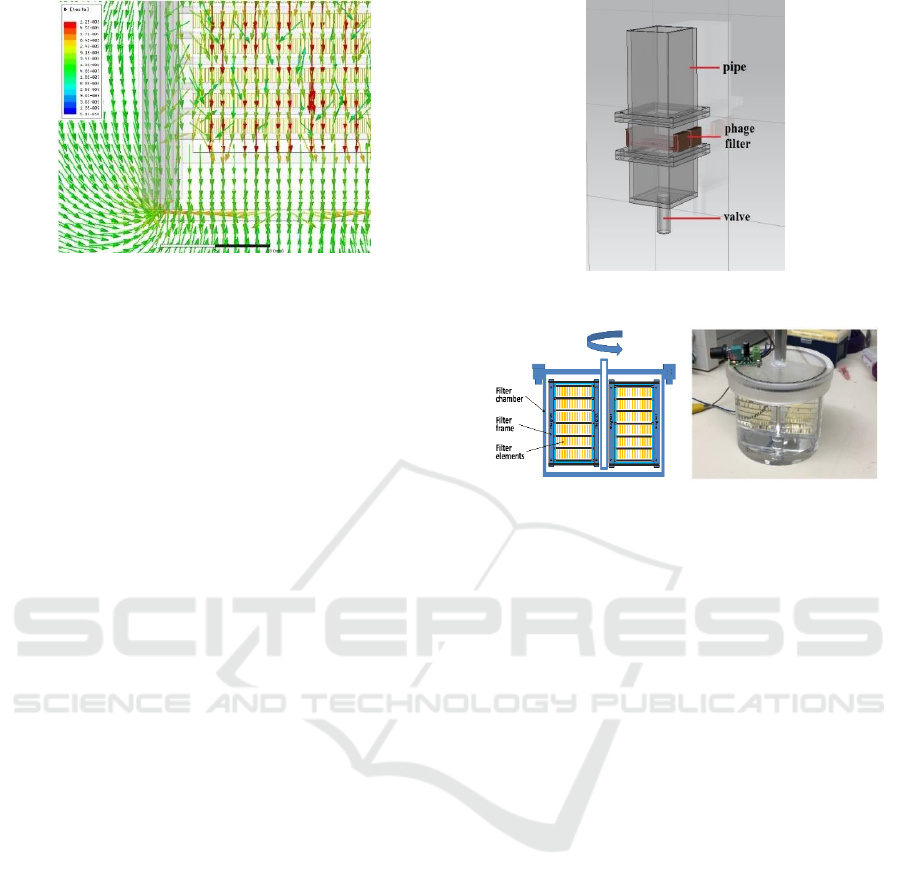

2.3.1 Vertical Flow System

The vertical gravity-fed system consisted of a square

pipe, phage filters and a valve. The valve was used

to control the flow of pathogen solution. For the

phage filter, solenoid coils were placed outside the

pipe to guarantee all the pathogen solution could

pass through the phage filter plane containing the

ME filter elements. ME filter elements with size of

1mm x 0.2mm x 0.03mm were used. Figure 7 shows

the 3D model of vertical system. For multiple layers

of phage filters, each layer was horizontally rotated

90-degree relative to the previous layer. In this way,

a higher packing density of ME filter elements was

obtained, in addition to increasing the probability of

impact and hence capture by phage of the target

pathogen.

2.3.2 Rotating Filter System

The rotating system was constructed using a

transparent food grade plastic chamber, phage filter

on a spindle and a motor with speed control unit.

Figure 8 shows the 2D model and photo of rotating

filter system. ME filter elements of size 4mm x

0.8mm x 0.03mm were used. All the phage filter

layers can be rotated along the spindle, which was

driven by a speed-controlled electric motor. The

pathogen containing solution was filtered by the

phage filter when rotated.

3 MATERIAL AND METHODS

3.1 ME Filter Elements

ME filter elements were fabricated from Metglas

2826MB as cast ribbon. The raw material was diced

to form individual ME filter elements that were

rectangular in shape. An Ultraviolet (UV) sensitive

Figure 7: 3D model of vertical flow system.

Figure 8: 2D model and photo of rotating flow system.

film was used to hold the Metglas material during

dicing with an automated saw (Disco 3220).

Acetone was used to wash the UV sensitive film

with the ME filter elements prior to exposure to UV

radiation to release the ME filter elements from the

film. After release, ME filter elements were

ultrasonically cleaned in acetone followed by

methanol. The ME filter elements were then vacuum

annealed at 220℃ for 3 hours to remove residual

stresses caused by the dicing process. Chromium

(30µm) and then gold (150µm) were sputtered onto

all surfaces of the ME filter elements. The Cr layer

was used to improve the adhesion of Au on surfaces

of ME filter elements. The Au layer provided a

bioactive surface for phage immobilization and

corrosion resistance.

3.2 E2 Phage and Surface Blocking

The filamentous E2 phage was prepared and

provided by the Department of Biological Sciences.

E2 phage is a genetically engineered landscape

phage with bio-receptors designed to capture

Salmonella typhimurium bacteria. The E2 phage

solution was diluted to 5x10

11

vir/ml with Tris-

Buffered-Saline (TBS) solution. ME filter elements

were incubated in a 1.5ml centrifuge tube for 1 hour

using a 3D rotating incubator at a speed of 8 rpm.

After attaching the phage to the ME filter elements,

the ME filter elements were washed in TBS solution.

The ME filter elements were then incubated in super

Biomolecular Phage Filter for the Detection of a Small Number of Pathogens in Large Volumes of Processing Water

111

blocking buffer (1x, Thermo Fisher Scientific) for

40mins, in order to reduce non-specific binding.

After blocking, the ME filter elements were

washed with TBS solution and filtered deionized

water one time. After final washing, the ME filter

elements were ready for placement into the filters to

capture Salmonella pathogen.

3.3 Phage Filter Performance

The Salmonella pathogen with an original

concentration of 5 x 10

8

cfu/ml was prepared and

provided by the Department of Biological Sciences.

The concentration of Salmonella solution was

diluted to 5 x 10

4

cfu/ml and 5 x 10

3

cfu/ml with

filtered deionized water. The total theoretical

number of Salmonella pathogen input were 1650cfu

in the vertical gravity-fed system and 5 x 10

4

cfu in

the rotating flow system, respectively. The phage-

immobilized ME filter elements were aligned

compactly on phage filters and placed into the test

system. For the vertical gravity-fed system, a liquid

velocity of 3mm/s was controlled by the valve. The

tested Salmonella solution was passed through

phage filter one-time in. For the rotating flow

system, single and double layers were tested,

separately. A rotational speed of 12 rpm was

maintained for 30mins.

4 RESULTS AND DISCUSSION

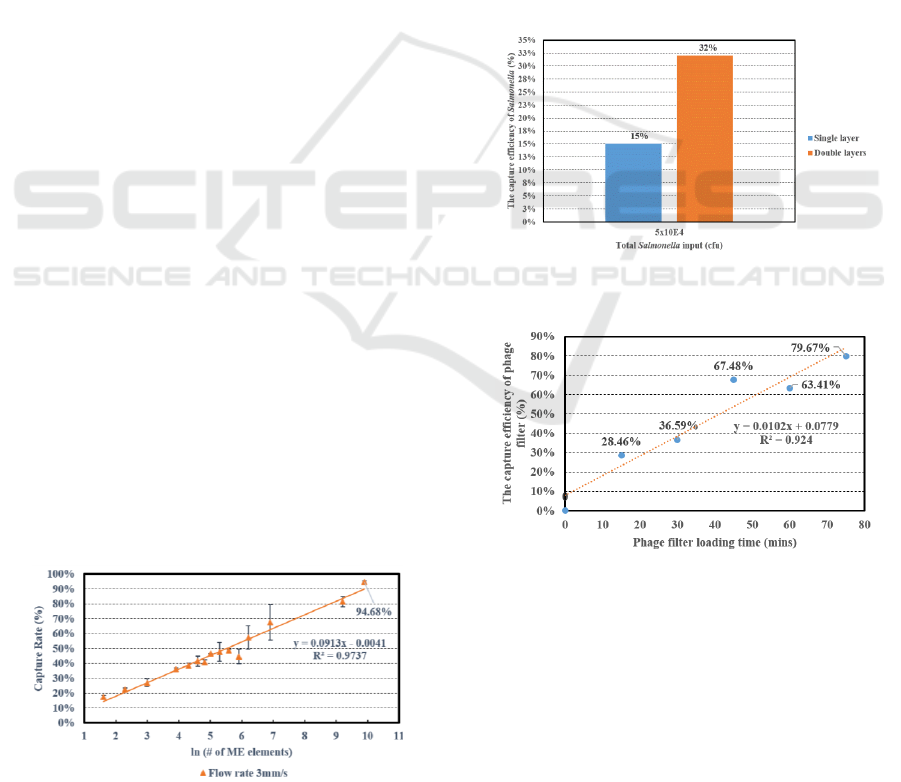

4.1 Vertical Flow System

The stability of the vertical flow system was tested

using filtered deionized water. Experiments showed

that the ME filter elements could be suspended

perpendicular up to the maximum obtained

volumetric flow rate of 20 l/min (bottom exit valve

wide open). In all tests, no ME filter elements

detached from the filter frame elements, except

when the current was removed.

Figure 9: Capture efficiency of the vertical flow system.

Plate counts were conducted on input and exit

solutions to determine the capture efficiencies. For

fluid velocities of 3mm/s, capture efficiencies of

94%+ were obtained, which was shown in figure 9.

Figure 9 demonstrates that the capture rate of

Salmonella increases with an increase in number of

ME filter elements.

4.2 Rotating Flow System

Figure 10 shows the capture efficiency of single

layer and double layers for the rotating flow filter

system in 30mins. The capture efficiency increases

with increasing the number of filter layers.

In addition, the capture efficiency was measured

as a function of time for double filter layers. Figure

11 shows the capture efficiency of the rotating filter

also increased with time. A capture efficiency of

nearly 80% was obtained for a two-layer system

after 75 minutes.

Figure 10: Capture efficiencies of single and double layers

rotating systems.

Figure 11: Capture efficiency increases with time, rotating

filter.

5 CONCLUSIONS

The concept, design and testing of a Non-clogging

Biomolecular Phage Filter has been presented in this

paper. This phage filter when deployed will be able

to simultaneously capture, concentrate and isolate

small numbers of pathogens from large volumes of

BIODEVICES 2019 - 12th International Conference on Biomedical Electronics and Devices

112

produce wash water. Two different filter designs

(vertical, gravity driven and rotating system) are

presented and tested. Adding multiple layers of ME

filter elements increases capture efficiencies.

Capture efficiencies of greater than 94% have been

demonstrated for flow velocity of 3mm/s.

Future research will address the effects of

temperature, flow rate, and water organic content on

capture efficiencies.

ACKNOWLEDGEMENTS

This material is based upon work, which is

supported by the National Institute of Food and

Agriculture (NIFA), U.S. Department of Agriculture

(USDA) and the Auburn University Detection Food

Safety Center (AUDFS).

REFERENCES

CDC, June 2018, https://www.cdc.gov/ecoli/

2018/o157h7-04-18/index.html.

CDC, December 2018, https://www.cdc.gov/ecoli/

2018/o157h7-11-18/index.html.

CDC, February 2018, https://www.cdc.gov/

foodsafety/foodborne-germs.html.

CDC, November 2018, https://www.cdc.gov/ salmonella/

index.html.

Chai Y, Li S, (2012) Rapid and sensitive detection of

Salmonella typhimurium on eggshells by using

wireless biosensors. Journal of Food Protection, 75

(4), 631-636.

Chai Y, Horikawa S, (2013a) A surface-scanning coil

detector for real-time, in-situ detection of bacteria on

fresh food surfaces, Biosens. Bioelectron, 50, 311.

Chai Y, Horikawa S, (2013b) Surface-scanning coil

detectors for magnetoelastic biosensors: A comparison

of planar-spiral and solenoid coils, Appl. Phys. Lett,

103, 173510.

Chai Y, Wikle H. C, (2013c) Design of a surface-scanning

coil detector for direct bacteria detection on food

surfaces using a magnetoelastic biosensor, J. Appl.

Phys, 114, 104504.

Guntupalli R, Lakshmanan R, (2007) Magnetoelastic

biosensor for the detection of Salmonella typhimurium

in food products, Sensing and Instrumentation for

Food Quality and Safety, Volume 1, Issue 1, Pages 3-

10. doi:10.1007/s11694-006-9003-8.

Guntupalli R, Sorokulova I, (2012) Detection and

identification of methicillin resistant and sensitive

strains of Staphylococcus aureus using tandem

measurements, J. Microbiol. Methods, 90(3), 182-91.

Huang S, Yang H, (2008a) The Effect of Salt and Phage

Concentrations on the Binding Sensitivity of

Magnetoelastic Biosensors for Bacillus anthracis

Detection, Biotechnol. Bioeng, 101, 1014-1021.

Huang S, Yang H, (2008b) Optimization of Phage-Based

Magnetoelastic Biosensor Performance, NSTI

nanotech 2008 conference, symposium on Phage

Nano-biotechnology, pp. 642-645.

Horikawa S, Chai Y, (2015) Direct detection of

Salmonella on fresh produce. ECS Transactions 69

(38), 25-31.

Li S, Horikawa S, (2012) Amorphous metallic glass

biosensors, Intermetallics 30, 80-85.

M. K. Park, J. W. Park, (2013a) Evaluation of phage-

based magnetoelastic biosensors by comparison with

TaqMan-based quantitative PCR, Sens. Actuators, B:

Chem, 176, 1134-1140.

Nambi S, Nyalamadugu S, (2003) Radio Frequency

Identification Sensors for Food Safety, Wireless

Communications Systems and Circuits Design in the

7

th

World Multi-Conference on Systemics, Cybernetics,

and Informatics, pp. 386-390.

Park M.K, Wikle H. C, (2012) The effect of incubation

time for Salmonella typhimurium binding to phage-

based magnetoelastic biosensors, Food Control,

Vol.26 (2), pp 539-545.

Park M. K, Li S, (2013b) Detection of Salmonella

typhimurium grown directly on tomato surface using

phage-based magnetoelastic biosensors, Food

Bioprocess Tech, 6(3), 682-689.

Staff, November 2018, FDA Update on Romaine Lettuce

Outbreak as Yuma, AZ, Growing Season Begins,

Food Safety Magazine.

Stephen Ostroff, M.D. June/July 2018. The Costs of

Foodborne illness, Product Recalls Make the Case for

Food Safety Investments. Food Safety Magazine.

Shen W, Mathison L.C, (2010) Design and

characterization of a magnetoelastic sensor for the

detection of biological agents, Journal of Physics D:

Applied Physics, 43 (2010) 015004. DOI:

10.1088/0022-3727/43/1/015004.

Biomolecular Phage Filter for the Detection of a Small Number of Pathogens in Large Volumes of Processing Water

113