Compression Earth Block (CEB) with Sawdust Production for the

Wall of Simple Housing Workshop

Vincentius Totok Noerwasito

a

and Fenty Ratna Indarti

b

Departement of Architecture, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia

Keywords: Alternative material, Compression Earth Block, Sawdust, Density, Workshop

Abstract: The need of alternative material for red brick has increased in recent days. It is caused by the high amount of

firewood needed during the production process. Meanwhile, the availability of firewood is significantly

reduced. Compression Earth Block (CEB) is one of the wall material alternative using local soil without

combustion process. The weakness of this block is the weight. The density of CEB is 1600 kg/m3 minimum.

So that the research used sawdust from wood factory waste as a mixture to reduce the density of the block.

The production of CEB and sawdust is not commonly found in the practice. So that it is important to spread

the information about how to make the block on rural area (such as villages). The knowledge transfer was

done by giving workshop for people who were interested and able to develop the workshop further. During

the workshop, the researcher explained the importance of this building material and the relativity for the

environment beneficial. The expected result from this workshop is that the participants are able to understand

the importance of using factory waste as an alternative material to substitute traditional red brick.

1 INTRODUCTION

There are abundance sawdust created by the wood

factory. The factory itself found difficulty to dissolve

that abundance sawdust in Probolinggo. The waste

itself has the potential to be used as material to make

brick for simple houses by giving it a little

modification. The waste is mixed with soil to make it

more resistant towards water and more solid. Unlike

red bricks, the production does not need combustion

process. It needs to be compressed and naturally

dried. The other material addition for this block is

cement.

Compression Earth Block (CEB) is intended to be

used as a wall material. The block is made from soil

and cement. It does not require combustion process

but it needs natural drying. The weakness of this

block is the density, which is 1,800 kg/m

3

. Adding

another material into the mixture is needed to reduce

the weight. Using sawdust as the addition for the CEB

composition is able to reduce the soil volume. So that

the CEB-sawdust block becomes lightweight and

does not need combustion process.

a

https://orcid.org/0000-0002-5660-5995

b

https://orcid.org/0000-0003-2301-7713

The production of CEB is not commonly known in

Indonesia. Many architects and building material

experts do not know about this material. So that it is

important to make a workshop about CEB-sawdust

and its production process. At the same time, it helps

to reduce the waste of wood factory by making it as a

new alternative for building material. The obstacle

found of this workshop is the appropriate composition

of sawdust, soil and cement to make it meets the

minimum standard of red brick compression force.

2 METHOD

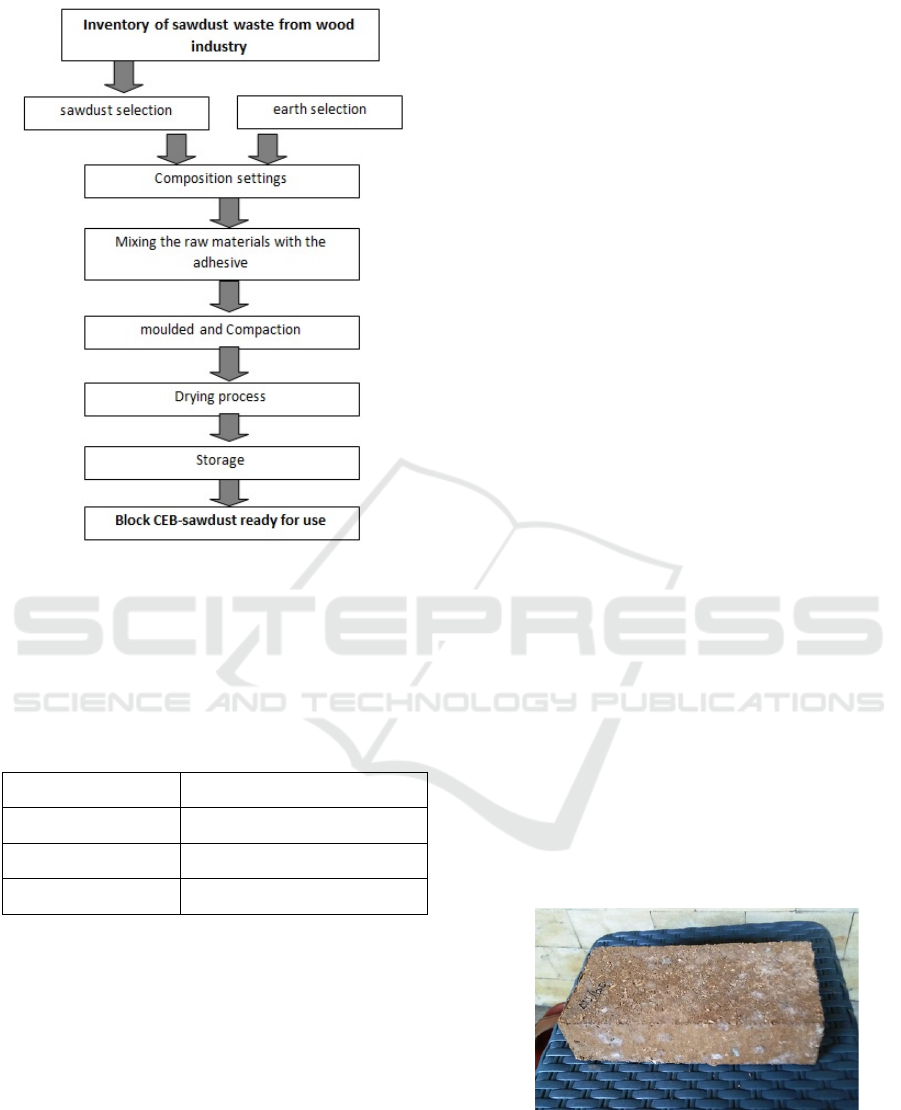

The process of making CEB-sawdust consists of

several stages. The production uses common and

manual technology. Below is the explanation of

the stages (Figure 1).

Noerwasito, V. T. and Indarti, F. R.

Compression Earth Block (CEB) with Sawdust Production for the Wall of Simple Housing Workshop.

DOI: 10.5220/0013056300002836

In Proceedings of the 10th Architecture Research and Design Conference (AR+DC 2019), pages 43-47

ISBN: 978-989-758-767-2; ISSN: 3051-7079

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

43

Figure 1. Activity stages

Molding and compressing the mixture increases the

strength of the block. Table 1 below shows the

composition of soil and sawdust used for the

workshop.

Table 1. Material composition

Soil (%) Sawdust (%)

30 70

50 50

60 40

The aims of the workshop are:

a. Training the wood industry community

to make an alternative for building

material to substitute red brick by using

recycled material, which is sawdust.

b. Reducing the amount of waste produced

by the wood factory by using it as a

mixture to make bricks.

c. Producing standardized and

environmental friendly brick.

The impacts of the workshop are listed below.

a. Stimulating the growth of building

material alternative from waste and local

material.

b. Reducing other building material

production that contributes to the

degradation of the environment

especially forest due to the elimination of

the combustion process.

c. Providing energy conservation and

recycled building material.

3 RESULTS AND DISCUSSION

The workshop consists of 3 stages. The first stage is

the early experiment on making the CEB with

sawdust. Stage 2 and stage 3 are the workshop of

making CEB with sawdust for architects.

3.1 Early Experiment

Before the workshop, an experiment was conducted

to get the prototype of the CEB-sawdust using

commonly found mold with the size of 10 x 20 x 5

cm. The making process of the CEB-sawdust is listed

below.

Preparing materials such as soil, sawdust,

cement and lime (Figure 3)

Adjusting material composition based on

Table 1.

Mixing all the materials evenly so that it

had the same color.

Molding and compressing.

Drying without sunlight but using the

surrounding air.

The finished block is shown in Figure 2.

Figure 2. Forty percent sawdust block

AR+DC 2019 - Architecture Research and Design Conference

44

Figure 3. Fifty percent sawdust block

Figure 4. Seventy percent sawdust block

3.2 Workshop

Young architects in Kabupaten Sidoarjo participated

in the workshop program. It consisted of 2 stages. The

first stage was a brief explanation about recycle brick

which was CEB with sawdust in general. The second

stage was the application of how to make the block as

explained on the previous stage

3.2.1 The Explanation of CEB-sawdust

The explanation was held before the practice on

making CEB-sawdust started. It gave an explanation

about why and how to make CEB-sawdust. The talk

explained what kind of soil that met the requirement

of the block and how the process of making the block

from the beginning was.

3.3 Block Making Practice

The practice of making CEB with sawdust is

explained below:

3.3.1 Preparation

The material for making the block was prepared at the

beginning such as sawdust, soil, cement, compression

and supplementary tools. Figure 6 illustrates the

material used for the experiment while Figure 7

shows the mould.

Figure 6. Experiment material

Figure 7. Mouldings

3.3.2 Measurement of primary material

composition

The composition for the mixture are surrounding soil,

cement in 10% heavier than the soil, lime in 10%

heavier than the soil and sawdust. The percentage was

calculated on the previous research which was the

making of paper brick by the writer.

3.3.3 Mixing compositions

The prepared material was mixed in dry and damp

condition. The stirring process without cement and

lime took place in dry condition. On the other hand

the damp condition was created by adding water

during the stirring process. (Figure 8)

Figure 8. Mixing soil and sawdust

Compression Earth Block (CEB) with Sawdust Production for the Wall of Simple Housing Workshop

45

After the damp mixture became homogen, it went to

molding process using commonly found mold. The

homogen mixture was molded and compressed in

damp condition (Figure 9, 10 and 11).

Figure 9. The mixture inside moulding

Figure 10. The mixture was ready to be pressed

Figure 11. The pressing

The damp brick then were taken of from the mold by

pushing the mold in the down part (Figure 12). After

that the block was stored in a specific space to get

dried and avoid direct sun (Figure 13).

Figure 12. Taking the mould process

Figure 13. Wet soil and sawdust block

3.3.4 Obstacles and Solution

Sawdust brick is not commonly known among

people. Many people had doubt regarding the

excellency of the making process due to the

assumption that the brick used a high technology. So

that it is really important to run a workshop on how

to make the block as well as providing a prototype.

The duration to get the brick dry becomes another

consideration since it took time to get the result.

4 CONCLUSIONS

Sawdust brick helped the wood industry to reduce the

waste produced during the sawing process. Sawdust

brick mixed with soil is an alternative to substitute red

brick and never been commercialized before. The

sawdust should be 50% of the soil weight to achieve

the best composition while the cement should be 10%

of the soil weight. The sawdust block is lighter than

red brick. The density of sawdust block is 1000 kg/m

3

AR+DC 2019 - Architecture Research and Design Conference

46

while the density of red brick is 1700 kg/m

3

so that

sawdust brick is a convenient wall material in seismic

area. The soil in the block functioned as a

compressive strength enhancer. Without the soil the

block is lightweight but easy to break.

REFERENCES

GEIGER, 14.7.4.23 COMPRESSED EARTH BLOCK

CONSTRUCTION (CEB), Compressed Earth Block

Building Code, RESEARCH INSTITUTE of

SUSTAINABLE BUILDING, Crestone, Colorado

81131.

Halima Chemani et al, (2013), Valorization of wood

sawdust in making porous clay brick, Academic

Journals , Vol. 8(15), pp. 609-614, 18 April, 2013.

John Amatruda, (2004), Green product, National Institute

of Building Sciences, http://www.wbdg.org/design/

hour 5 am 3 August 2004.

Nelson wayne, (-). Compressed Earth Blocks, Construction

and Environment Resources Habitat for Humanity

International,

http://www.networkearth.org/naturalbuilding/ceb.html

, September 03, 2011

Obonyo Esther, Joseph Exelbirt and Malarvizhi Baskaran,

(2010), Durability of Compressed Earth Bricks:

Assessing Erosion Resistance Using the Modified

Spray Testing, sustainability journalISSN 2071-1050,

volume 2.

Rigassi Vincent, (1995), Blocs de terre comprime Vol 1

Manuel de Production, CRA-Terre EAG, Grenoble,

France.

satprem_cpcb (2010), EARTHEN ARCHITECTURE FOR

SUSTAINABLE HABITAT. Auroville's Case study,

Auroville building center/earth unit. India,

www.scribd.com/doc/38591789/satprem-cpcb

Stulz Roland and Kiran Mukerji, (1993), Appropriate

Building Materials, Third Revised Edition. SKAT

Publication. Switzerland.

Subroto Roy, (-), Stabilized Compressed Earth Block

Technology,

http://www.daenvis.org/daesat/compressed.htm, 18

Agustus 2011, New Delhi.

Zziwa1 A, (2006), Production of composite bricks from

sawdust using Portland cement as a binder, Journal of

Agricultural Sciences, vol 12(1), pp. 38-44.

Compression Earth Block (CEB) with Sawdust Production for the Wall of Simple Housing Workshop

47