The Coffee Value Chain Analysis to Support Farmers Livelihood in

Horsik Village, Ajibata Sub-district, Toba Samosir District,

North Sumatra

Henry Sitorus

1

, Ria Manurung

1

, Rizabuana Ismail

1

, Roida Lumbantobing

2

1

Department of Sociology, Universitas Sumatera Utara, Medan, Indonesia

2

Department of Sociology, FISHK, IAKN, Tarutung

Keywords: Coffee Farmers, Low Income, Capacity and Technology Empowerment, Coffee Processing.

Abstract: Coffee is currently very loved by many people. One coffee producer from Horsik village, Toba Samosir is

farming on the hills of Lake Toba. This paper describes how to plant and manage Arabica coffee based on

local community knowledge. The traditionality of technology that is applied causes low production results

so that people's incomes are insufficient for socio-economic life. It is necessary to develop the capacity of

farmers 'resources and technological support to increase farmers' production and livelihood.

1 INTRODUCTION

The history of coffee in North Sumatra started in

1696 during colonialism when Dutch Governor of

Batavia (read: Jakarta) received seeds of arabica

coffee (Coffee Arabica) from India. Indonesia

considered as suitable for coffee plantations because

of its position near the equator with mountainous

regions across the islands, creating micro-climates

for the growth and production of coffee. The first

plantation centralized in Java Island managed by the

Dutch East India Company, known by its Dutch

initials VOC (Vereeningde Osst-Indische Company).

In 1717, VOC shipped 907 kilogram coffee to

Europe. Indonesia became the third place, outside of

Arabia and Ethiopia, where coffee was widely

cultivated (Neilson, 2012). By the mid 0f 1870s,

VOC expanded Arabica coffee growing areas in

Sumatra, Bali, Sulawesi and Timor islands. In North

Sumatra highlands, coffee was first grown in 1888

and followed in Gayo Highland (Aceh) in 1924. In

North Sumatra, coffee was first grown near Lake

Toba. After Gayo, several area which become the

central of Arabica coffee plantation was Lintong,

Mandheling, Sidikalang and Brastagi.

In the late of 1800, Dutch colonialists established

large Arabica coffee plantation in Eastern Java.

Coffee rust disease (Hemileia vastatrix) destroyed

the plantation which grown at lower latitude in 1876

and spread to other islands. To substitute the loss,

new variant of coffee or known as Robusta (C.

canephor var. robusta) was introduced in 1900. The

robusta coffee was planted in Kerinci and spread

quickly in Sumatra during 1920s. Dutch owned

plantation in Java Island was nationalized in 1950s

after national independence. Right now most of

plantation was managed by state-owned company

namely Perusahaan Terbatas Perkebunan Nusantara

(PTPN). PTPN revitalized the plantations by

introducing new varieties of coffee Arabica. These

varieties were adopted by smallholders through the

government and various development programs. The

result, according to International Coffee

Organization (ICO), Indonesia was the fourth largest

producer of coffee in the world in 2014 with an

estimated production reached 540,000 metric tons in

2014.

A value chain is the process of creating value

from the conception of a product through to its final

consumption. It describes the full range of activities

that are required to bring a product or service from

conception, through the intermediary phases of

production and delivery to final consumers, and final

disposal after use (ILO, 2015). Value chain

development for livelihoods and economic

increasing focuses on value chains in which market

demand is substantial and represented as

entrepreneurs or employees. Interventions are then

designed to strengthen the competitiveness of the

value chain while expanding the share of value

438

Sitorus, H., Manurung, R., Ismail, R. and Lumbantobing, R.

The Coffee Value Chain Analysis to Support Farmers Livelihood in Horsik Village, Ajibata Sub-district, Toba Samosir District, North Sumatra.

DOI: 10.5220/0010122704380443

In Proceedings of the 3rd International Conference on Social and Political Development (ICOSOP 3 2019) - Social Engineering Governance for the People, Technology and Infrastructure in

Revolution Industry 4.0, pages 438-443

ISBN: 978-989-758-472-5

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

added that reaches target groups. Such interventions

connect micro and small enterprises to larger

companies with access to wider markets, creating

forward and backward linkages where farmers can

participate.

Therefore, however the assessment is designed, it

will need to incorporate micro-macro linkages, these

being. the linkages between issues that influence

livelihoods and economic recovery at the individual,

household, and community level (the micro level)

and those issues that relate to the economy, policy

framework, and systems of governance at provincial,

national and, where relevant, regional levels (the

macro level) (UNDP, 2013). In detail, the mapping

and analysis will cover the market size, volume,

distance, demand for and supply chain/competition,

type of producers (large, medium, and small),

existence of middle man, men and women led

business/trades, available mode of transportation and

market associations/trade organizations. It will also

capture information about credit institutions, training

providers, market associations, and enabling actors

in the value chains of selected commodities.

The intervention developed, as follow up of the

assessment; consist of vertical and horizontal

aspects. Vertical value-chain interventions focus on

strengthening dialogue between large enterprises

that dominate the value chain and smaller enterprises

in order to identify opportunities for increased

participation in the value chain by small, local firms.

Horizontal value-chain interventions focus on the

access that smaller, less powerful businesses have to

the business and financial services they require to

participate more effectively in national and global

value chains, as well as to the collective actions they

can engage in through business associations and

cooperatives.

2 METHOD

Method to meet the research objectives, this study

used a mix of quantitative and qualitative methods.

It employed strategies of inquiry that involve

collecting data either simultaneously or sequentially

to best understand research problems. The data

collection involved gathering both numeric

information as well as text information so that the

final database represents both quantitative and

qualitative informations (Creswell, 2003).

Purposive sampling methodology is selected for

quantitative approach to focus on particular

characteristics of a population that are of interest,

which will best enable us to answer the research

questions. Considering that the projects has varied

approach to achieve the same outcomes, maximum

variation sampling techniques will be exercised to

capture and to describe the central theme that cut

across a great deal of participants or program

variation. Any common patterns that emerge from

great variation are of particular interest and value in

capturing the core experience and central, shared

aspects or impacts of a program (Patton, 1990).

The criteria being used to determine the

respondents is designed together with the program

owner and considered purposed theoretical approach

that being used as the basis of this study. The criteria

are: (i) covered 50 farmers interviewed in the sample

area; (ii) 20% of the producer groups operational in

current project; (iii) the respondent is listed as

beneficiaries of the program; and (iv) the sampling

will cover 30% of female respondents to get gender

perspective of the program.

Qualitative approach emphasized on culturally

specific information about the values, opinions,

behaviors, and social contexts of particular

populations and to identify intangible factors, such

as social norms, socioeconomic status, gender roles,

ethnicity, and religion, whose role in the research

issue may not be readily apparent. The strength of

qualitative research is its ability to provide complex

textual descriptions of how people experience a

given research issue. It provides information about

the “human” side of an issue – that is, the often

contradictory behaviors, beliefs, opinions, emotions,

and relationships of individuals. Qualitative methods

are also effective (Denzen et al., 2000).

The methodology being used to obtain

qualitative data consist of:

a. Document study consist of production and trades

volume before and during the period of eruption;

underlying policies, institutional and

infrastructural issues that affect the

competitiveness of the selected value chains; and

the current planned investment and priorities of

governments and development agencies in the

sectors;

b. Key informant interview participated by District

Agriculture Office; District Cooperative,

Industry and Trade Office; District Statistics

Bureau; District Planning Agency; Key

Distributors at village until district level;

Pesticides Suppliers at district level, Farmers

Group Leaders, and Community Leaders.

c. Focus Group Discussion (FGD) involved

farmers, local trader, and consumers.

The following data specific to 3 commodities

were collected: a) Data on costs, production, sales

The Coffee Value Chain Analysis to Support Farmers Livelihood in Horsik Village, Ajibata Sub-district, Toba Samosir District, North

Sumatra

439

volumes, values and margins. b) Data on service

providers, type of facilities and services they offer,

terms and conditions of accessing such services,

processing, marketing, constraints faced and

opportunities available to the providers. c) Other

value chain institutions like market information

providers, input suppliers, and technology providers

also provided data on nature of services, their target

recipients, constraints and opportunities.

3 RESULT AND DISCUSSION

The History of Coffee Commodity in North

Sumatra: Production of Coffee Commodities in Desa

Horsik

The analysis of value chain mapping of coffee

commodity in Desa Horsik is divided into four steps:

mapping the main process of Value Chain;

identifying the actors and the supporting institution

in the Value Chain (VC); mapping the Value Chain

distribution, and identify potentials problems and the

solutions.

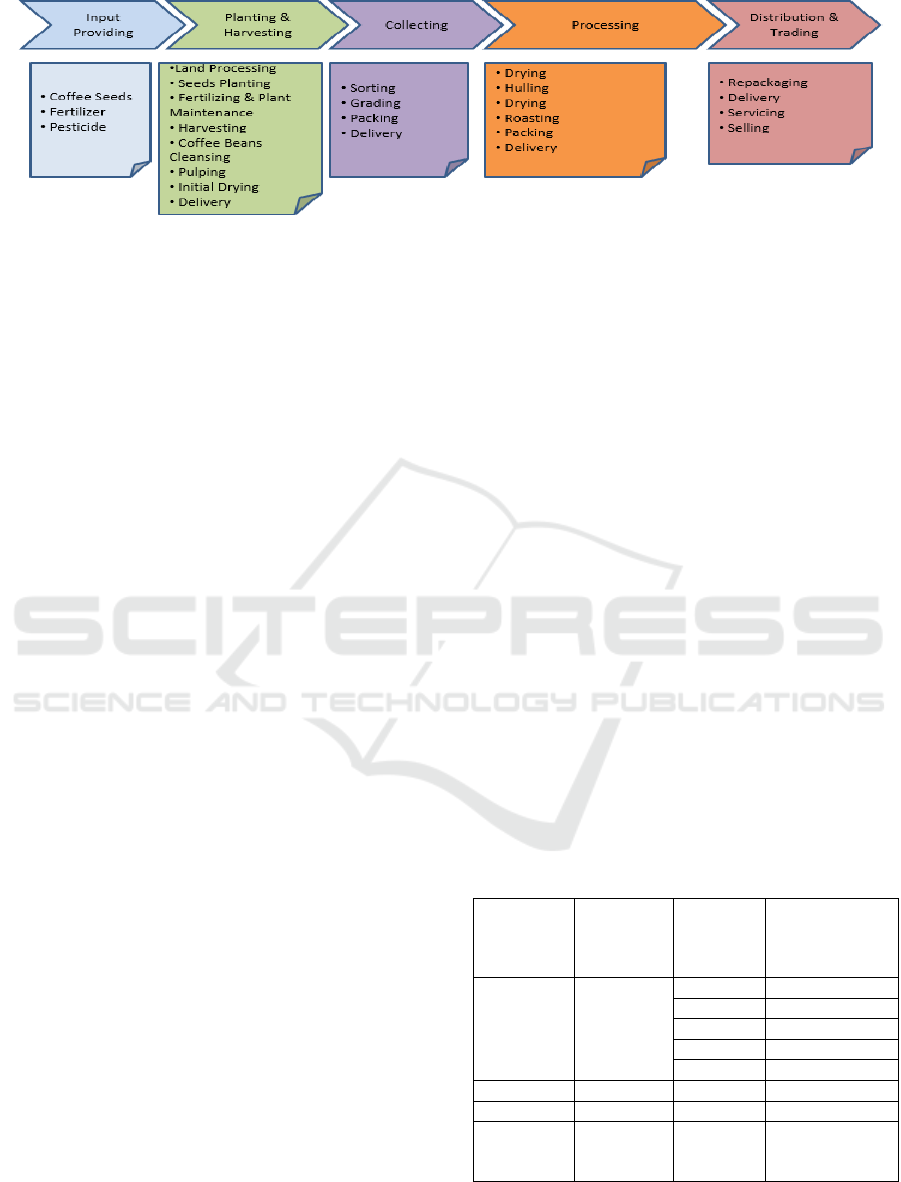

Based on the mapping process, there are 5 stages

applied in VC for coffee commodity in Desa Horsik

those are input providing; planting and harvesting;

collecting; processing; distribution and trading.

Mapping of value change of coffee commodity in

desa horsik.

3.1 Input and Supply of Coffee

Commodity in Horsik Village

Seventy households (HH) live in Horsik village.

Most of the villagers work as farmers. Compared

with other commodity such as cocoa, coffee is the

major product in these villages. In 2018, Horsik

Village produced 23.00 ton of coffee parchment.

Coffee commodity supports the income generation

of the villagers in this village. The cost for

production cost is affordable since they just need to

put expense in subsidized fertilizer. For production,

the farmers is using their own capital because

limited access to micro finance institutions such as

bank and cooperation. There is a financial institution

in Horsik Village which can give financial support

for the farmers. Input and supply stage for coffee

commodity consists of supplying seeds, fertilizer

and pesticide. Farmers do not need to buy the seeds

because it is already provided by nature. Hence, they

never use certified seeds. In term of fertilizer, the

association of farmer groups (Gapoktan) receives

subsidized fertilizer from government regularly. The

subzidised fertilizers are urea, KCL and SP. Only

few farmers use pesticide. They buy the pesticide

from pesticides store in Parapat.

The farmers have limited knowledge on how to

conduct Good Agricultural Practices (GAP) even

though the government already regulated the

standards since 2006. The reasons for the late

implementation are the lack of number of

agricultural field facilitator who could assist the

farmers in day to day activity and the farmers have

limited access to information about GAP. Gapoktan

members who were involved in the trainings did not

consistently apply and share the knowledge to other

farmers. Meanwhile, Local District Agriculture

Service has limited resources to monitor the impact

of the training.

3.2 Planting and Harvesting

Farmers in target area plant the coffee seeds within

space of 2 x 2 meters. If they have 1000 m2 means

that they can plant for about 150 seeds. The

fertilizing method is applied differently amongst

farmers. Due to the high cost of fertilizer and the

lack of knowledge in using organic fertilizer,

farmers conduct fertilizing based on their financial

condition. Most of them rely on government’s

subsidy through Gapoktan. Farmers start to harvest

the coffee after 3-4 years planting period with major

production of 4-5 months in a year. It takes 7-14

harvesting days for each month. Farmers can harvest

their crops themselves in picking the right coffee

cherry since they never been trained before; only

based on field experience. However, since the

farmers only focus on having quick process during

harvesting, this concern has been abandoned.

When the coffee bean has been harvested, it

should be cleaned using water and being fermented.

It would be better done in the flowing water.

However, farmers in Horsik Village using the

method by soak the coffee in pails. After being

cleaned, the coffee is processed for pulping. Pulping

is a process to peel and take the coffee pit. It can be

done manually or using a machine that bought in

Parapat for IDR 500.000. After being peeled, the pits

are dried and sorted. In sunny days, it takes 2 hours

to dry the pits before sell them to the collectors in

Parapat market.

ICOSOP 3 2019 - International Conference on Social Political Development (ICOSOP) 3

440

Figure 1. Map of Value Change Process for coffee commodity.

3.2.1 Collecting

The collecting stage happens when the collectors

come to collect the coffee directly from the farmers

in Toba Samosir Dictrict. There are only few

collectors in Parapat Market. The well-known ones

is Joko. These collectors sort the coffee pits based

on the physical performance. If the coffee is

physically good, collector will pay IDR 20,000

rupiahs per kilogram. In the other hand if it is not

good, they will pay around IDR 18,000 per

kilogram.

3.2.2 Processing

The processing stage is being done in Siborong-

borong. This process is done by whole sellers,

manufactures or cafes. The most well-known actors

is Joko. The first step in processing stage is Huller

process. This is a process when the green bean

separated from its horn cover. Huller process

produces green beans. They will be sorted manually

by hand picking before they were sold to local

market or being exported. The farmers usually ride

motor cycle to transport the coffee to the collectors

in Parapat. The commodity sells to local and

international market. Every 2 weeks, the farmers

take their coffee to the collectors. The coffee from

this villages considered low and based on

observation and discussion with local farmers, the

reason for low quality is the hesitance of farmers to

give fertilizer periodically. They only gives fertilizer

once they have money to buy it.

Value chain stages role input and supply for

production this stage involves the pesticides store

that that provide the farmers with information about

pesticide products and spraying service; Agriculture

Store in Parapat which provides fertilizer; and

Gapoktan who managed subsidized fertilizer.

Planting and Harvesting the VC actors in this stage

are the farmers and the farmers focus on preparation

of the field, maintenance and disease treatment and

harvesting. Collecting the VC actors of this stage are

pooled/intermediate trader open a small shop in

Parapat. Marketing and distribution the VC actors in

this stage are supplier/grocery, exporter, distributor,

retailer and coffee shop. Coffee bean suppliers are

located in Medan, Sidikalang and Siborong-Borong.

They are Joko, Sari Makmur, Ecom etc Supported

institutions Agriculture District Office, Agriculture

Extention Agency, Food Security Agency, micro

finance institutions and Community Development

Board.

3.2.3 Financial Analysis of Coffee

Commodity

Value Chain mapping of coffee commodity assumes

that the final product is roasted coffee. The actors

are located in Siborong-borong. The roasted coffee

price is IDR 59,000 per kilogram which the roasting

process itself costed IDR 15,000. The price of

roasting process is higher than the green bean in

farmers/collectors levels. Roasting process is

expensive since it determines the taste of the coffee

that is why coffee from the same area can be

different in taste.

Table 1: Economic Analysis of Green Bean (Primary

Data, 2019)

Description

Parchment

with

moisture

40 %

Process/

kg

Green Bean

with Moisture

13%

Price/kg 25.000

53.000

Hulling 250

Transport 1.000

Worker 1.500

Yield 50 % 50.000

Margin/kg 750

Market Collectors

in Parapat

Market

Sub importer

The Coffee Value Chain Analysis to Support Farmers Livelihood in Horsik Village, Ajibata Sub-district, Toba Samosir District, North

Sumatra

441

Table 2: Economic Analysis of Roasted Bean (Primary Data, 2019)

Process/kg

Coffee Premium

Quality

Process/

kg

Roasted and

ground coffee

Process/Kg

Coffee with 70 gram/

pack

77.000 150.000 Rp 15.000/pack

worker 3.000 Roasted fee 35.000

Packs and

label

26.000

Tools

depreciation

500 Transport 2.000 Worker 5.000

worker 2.000

Tools

depreciation

2.000

Packaging 5.000 Electricity 1.000

75 % 70.670 80 % 93.750

2.830 9.750 11.000

roaster Café End consumer in

Parapat, Samosir,

Balige and others as

tourism area

Cost production for farmers in input process is

varied amongst farmers. They explain that the use of

fertilizer and pesticide depends on their financial

condition. For one kilogram of coffee, the farmers

need to spend IDR 2.500 for the fertilizer. Based on

this fact, farmers have limitation in coffee

cultivation especially in the domain of product

management and cultivating knowledge.

In average, the farmers get the margin about

34.73% - 37.27% with the price assumption of IDR

23,000 – IDR 24,500 per kilogram coffee. This

margin is the second highest margin after the roaster

one.

This margin is fair since they take a lot of

process in the coffee production even though

farmers in both villages have lack of knowledge in

coffee production. Soil fertile gives advantage and

simplifies the farming process as the plants can still

grow with limited maintenance. Coffee collectors in

Parapat got cost margin about 0.84% - 1.69 % or

equal to IDR 500 – 1000 per kilogram coffee pits. In

the peak season of harvest time (October-

November), collectors get 40-50 ton per day of

coffee pits. It means they get profit about IDR

40,000,000 –IDR 50,000,000 per day.

4 CONCLUSIONS

1. Seedlings, no special seeds utilization by farmer

mostly they put free on their own land.

2. Fertilizing, no pattern on fertilizer and pesticide

utilization. Plant maintenance, lack of knowledge

to maintain the crop has influence the harvesting.

Post harvest, there is no peeling machine in the

village that can be used by all farmers. The

farmers also had limited knowledge to maintain

the machine. Coffee branding and packaging is

not being done at farmers’ level. The farmers

only sell dried coffee in which its price being

determined by collectors in Parapat market after

passed sorting steps. Cash flow management,

most of the farmers do not know about cash flow

management in coffee production.

3. Gapoktan capacity building. Gapoktan members

not yet well organized in conducting their

program. The group still focus on managing

government support only.

4. Financial Institution, no financial institution at

village level.

5. Pulping tool, the cost to provide this machine is

high and none of the farmers has capacity to

maintain it.

6. Household management, the ability manages

income and expense still need to be increased so

that farmers can set up better planning during

cropping season.

REFERENCES

Asbjorn Eide (et.all), 1995, Economic, Social and Cultural

Rights, A Textbook.

Chambers, R., 1994, Participatory Rural Appraisal:

Challenges, Potentials and Paradigm, IDS, Brighton,

UK.

Chambers, R & Conway, GR, 1991, Sustainable rural

livelihoods: practical concepts for the 21st century,

IDS Discussion Paper 296.

Cook, KE, 2008, “In-depth Interview” in LM Given, the

Sage Encyclopedia of Qualitative Research Methods,

Safe, London.

ICOSOP 3 2019 - International Conference on Social Political Development (ICOSOP) 3

442

Cornwal, et. al., 1995. What is Participatory Research;

Elsevier Science Ltd.

Creswell, 2003, Research Design: Qualitative,

Quantitative, and Mixed Methods Approachs, Second

Edition, University of Nebraska.

Hennink, M.M. ,2007, International focus group research:

A handbook for the health and social sciences.

Cambridge University Press: Cambridge.

Neilson, J. (2008). Regulasi swasta global dan

restrukturisasi rantai nilai dalam sistem kopi petani

kecil Indonesia, Pembangunan Dunia.

Neilson, J. (2012). Kopi (Indonesia): 1900 hingga

sekarang: Asia Timur dan Tenggara.

Nutz and Sievers, 2015, A Rough Guide to Value Chain

Development, ILO.

Maskrey, A., Module on Community-based Disaster Risk

Management, CBDRM-2 Handout, Bangkok, (1998);

Mukherjee, A, 1995. Participatory Rural Appraisal;

Methods and Application in Rural Planning, Vikas

Publishing House PVT LTD.

Patton, 1990, Qualitative Evaluation and Research

Methods, Beverly Hills, CA: Sage.

United Nation, United Nation Partnership for evelopment

Framework 2011 – 2015 Indonesia

UNDP, 2013, Livelihoods and Economic Recovery in

Crisis Situations, New York.

UNDP, 2012, Development of Inclusive Markets in

Agriculture and Trade (DIMAT); An Assessment of

the Beans Value Chain in Uganda.

The Coffee Value Chain Analysis to Support Farmers Livelihood in Horsik Village, Ajibata Sub-district, Toba Samosir District, North

Sumatra

443