Project Planning of Offshore Pipelines Replacement: Study Case at

Offshore North West Java

Jordy Revanda W. Apcar

1

, Silvianita

1

, Daniel M. Rosyid

1

, Mohd. Faris Khamidi

2

and

Januar Adi Murdan

3

1

Department of Ocean Engineering, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia

2

College of Engineering, Qatar University, Qatar

3

PT Pertamina Hulu Energi Offshore North West Java, Indonesia

Keywords: Six Sigma Analysis, Critical Path, Fault Tree Analysis, Event Tree Analysis, Top Event, Project Delay,

Offshore Pipelines Installation.

Abstract: There are many factors that lead to project delay, for example hurricane, one of weather factors that make it

impossible to do work or factors like lack of utilities and construction equipment, delays in purchasing

material orders, lack of experienced and skilled human resources in the field, delay costs down to purchase

activities on the project. In addition, there are delays in critical activities because they have a large impact on

the duration of the project. Therefore, it is necessary to do an analysis by looking for activities that are critical

to the project and factors that can cause delays in the new pipeline project because it can endanger the owners

and contractors. This study will discuss three factors, i.e. (1) the determination of the critical path, (2) the

determination of the root causes that can cause delays, and (3) the risk of over time, of new pipelines

replacement project in North West Java, Indonesia. There are 4 indications of delay in this project, which are

delay that occurred in June 2018, September 2018, and October 2018. The biggest deviation between the

targeted value and the actual value occurred in October 2018, which was 5,05%. This study uses six sigma

methods, critical path, fault tree analysis and event tree analysis. The results of fault tree analysis will get the

probability value for the top event of the project delay. The results of the event tree analysis will get the risk

level of each factor that causes delays. Six sigma results will get to the root of the problem, the value of sigma,

and what corrective action is taken.

1 INTRODUCTION

Project implementation must be supported by good

project management. The absence of project

management will bring about change, unclear goals,

non-challenging planning, high risk, poor project

quality, more expensive project costs, and delays in

improving the project. Project management can be

subdivided such as project time management, project

human resource management, and project risk

management (PMBOK, 2008). The company plans to

carry out the offshore pipeline repair and replacement

project. This project covers the aspects of

engineering, procurement, construction, and

installation, called the EPCI project. Pipeline is

located 80 - 200 km northeast of Jakarta. The core of

this project is to replace pipes that are no longer

suitable for use by installing new pipes for pipes that

are already damaged. There are three pipelines

planned to be replaced, namely:

(i) Pipe A with 12"OD and 1 km length

(ii) Pipe B with10" OD and 7.2 km length

(iii) Pipe C with 8" OD and 7.2 km length

The construction project sector has a high level of

responsibility and complexity. All construction

projects can be categorized as complex projects. This

is caused by a direct relationship between complexity

and involves various interredelayd parts that must be

managed with regard to conditions of differentiation

and interdependence, thus causing construction

projects to have high risks (Baccarini, 1996). Based

on the explanation in the paragraph above, this project

is a complex project because it has three projects with

different pipe sizes and lengths. Therefore, this paper

will discuss project risks in the form of overtime

(project delays) that can have an impact on project

cost overruns. Project risk in the form of overtime and

Apcar, J., Silvianita, ., Rosyid, D., Khamidi, M. and Murdan, J.

Project Planning of Offshore Pipelines Replacement: Study Case at Offshore North West Java.

DOI: 10.5220/0010057701130121

In Proceedings of the 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management (ISOCEEN 2019), pages 113-121

ISBN: 978-989-758-516-6

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All r ights reser ved

113

excess costs must be avoided because it can endanger

all parties such as the owner and contractor, for

example from the owner will suffer losses because the

object of the project cannot operate, so it does not

generate profits. On the other hand, the contractor

must be responsible for delays and the contractor's

good name becomes bad.

Table 1: Indications of Delay in the Development of a New

Pipe Replacement Project on Deteriorated Pipelines.

June

2018

June

2018

Sept

2018

Oct

2018

Planned

Value

0,06% 6,35% 40,11% 53,20%

Earned

Value

0,00% 5,63% 39,71% 48,15%

Table 1 explains that there are indications of

delays in the construction of new replacement pipe

projects for damaged pipelines. Indications occurred

in June 2018, September 2018, and October 2018.

The largest deviation between the planned value and

the value obtained occurred in October 2018 at

5.05%. Many factors can make a project experienced

delay, for example weather factors that make it

impossible to do work or factors of lack of utilities

and construction equipment, delays in purchasing

material orders, lack of experienced and skilled

human resources in the field, delay costs down to

purchase activities on the project, in addition, there

are delays in critical activities because critical

activities have a large impact on the duration of the

project.

Therefore it is necessary to analyze the delay by

looking for any activities that are critical to the project

and factors that can cause overtime. To avoid

overtime in this new pipeline project because it could

endanger the owner and contractor as explained in the

previous paragraph. In this study, we will discuss

determining the critical trajectory, determining the

root cause or factors that can cause delays, a large risk

of delay, and what improvements can be made.

2 BASIC THEORY

2.1 Project Management

Project management is planning, organizing, leading,

and controlling company resources to achieve short-

term goals that have been determined. Project

management has a basic function consisting of

managing the scope of work, time, cost, and quality.

The key to successful implementation of a project if

you can manage these aspects correctly (Samad,

2019).

2.2 Risk

Risk is a combination of the probability of an event

and the impact of the event, the impact can be more

than one for one event. However, risks are generally

seen as negative things such as danger, loss, and other

impacts. These impacts and losses is actually a form

of uncertainty that should be understood and managed

effectively by the project implementer (Szymanski,

2017).

2.3 Critical Path

Critical path is a project management technique that

uses only one-time factor per activity. Critical path or

critical path is the fastest path in project work, every

project included in this path is not given a break /

break for the process. Critical path is a path that

consists of activities which if delay will result in delay

completion of the project Heizer, 2014).

2.4 Six Sigma Analysis

The statistical concept that measures a process that is

redelayd to the sigma number, where the closer to 6

the results will be as expected. Six Sigma is a

management philosophy that focuses on removing

defects by emphasizing understanding, measuring

and improving processes (Brue, 2002). Six Sigma has

5 stages, as follows (Larasatie, 2019):

(i) Define

Define aims to identify the process to be improved

and determine what resources are needed in project

implementation.

(ii) Measure

Measure is an advanced stage of define where at this

stage validation of a problem is done by calculating

and obtaining numbers that can provide clues about

the problem.

(iii) Analyze

At this stage, the cause of the deviation in a project

will be investigated with a hypothesis which will then

be tested.

(iv) Improve

At this stage, the main factors are ascertained and

give new influences so that they get the desired

results. The purpose of this stage is to implement a

new system so that the project can run more

optimally.

(v) Control

Maintain changes that have been made through

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

114

certain measuring devices so that it can be assessed

whether the new system is optimally implemented in

the project.

2.5 Fault Tree Analysis

Fault tree analysis is a method to identify and analyze

all the factors that might cause a system failure and

provide a basis for calculating the probability of a

failure event. Unwanted events that are on top (top

event) for all root causes that might occur at the

bottom. The causative factors are deductively

identified, logically arranged and represented using

pictures in a tree diagram illustrating the causal

factors and their logical relationship to the peak event

(ISO, 2009).

2.6 Event Tree Analysis

Event tree analysis is a method used to evaluate

processes and events that lead to the possibility of

failure. This method is useful in analyzing the

consequences arising from failures or unwanted

events. The consequences of events are followed

through a series of possibilities. By analyzing all

possible outcomes, it is possible to determine the

percentage of results that lead to both desired and

undesirable results (Silvianita et al, 2017).

Event tree analysis is an analysis technique to

identify and evaluate the sequence of events in a

potential accident scenario after the initial event or

initiating event. Event tree analysis uses a visual logic

tree structure known as an event tree. The purpose of

the event tree analysis is to determine whether the

initiating event will develop into a serious accident or

whether the event is sufficiently controlled by the

safety system and procedures applied in the system

design. Event tree analysis can produce many

different results from one initial event, and this

provides the ability to obtain probabilities for each

outcome (Ericson, 2005). Project delay using ETA

and Bow Tie Analysis for mooring change

replacement can be seen in (Silvianita et al, 2018).

and project delay for HRSG has been discussed

(Silvianita et al, 2017b).

3 METHODOLOGY

The procedures of the research are as follow:

1. Formulations of Problems

The formulations of the problems are decided as the

purpose or the goal of the research.

2. Literature Studies

To support the research itself, literature studies are

needed to develop insight and analysis. In this case,

the literature needed is as follows:

a. A study about offshore pipeline projects.

b. A study about project management and project

delays.

c. A study about critical path methods.

d. A study about six sigma analysis.

e. A study about fault tree analysis

f. A study about event tree analysis.

g. A study about risk matrix

3. Data Collection

Data collection is needed as material to support the

research hypothesis. The data corredelay with the

evaluation and the current conditions. The data

needed are as follows:

a. Pipeline repair and replacement project report

data

b. Pipeline repair and replacement project master

schedule data

c. General data about the pipeline installation project

d. Make a questionnaire to look for the probability

of basic FTA events, pivotal ETA events, and

determination of risk matrices.

4. Data Analysis and Discussion

The data that has been collected will be analyzed and

discussed:

a. Make network diagrams and find project critical

activities using the critical path method.

b. Identification uses 4 stages of six sigma analysis

(define, measure, analyze, and improve).

c. Determine the root causes that can cause the

project to be delayed by using fault tree analysis.

d. Determine risk by using event tree analysis.

e. Determine the probability of project delay.

5. Results and Conclusions

The results of this study are used as a reference for

decision making in planning subsea pipeline projects

in the future, so as to advance the performance and

smoothness of all underwater pipeline project

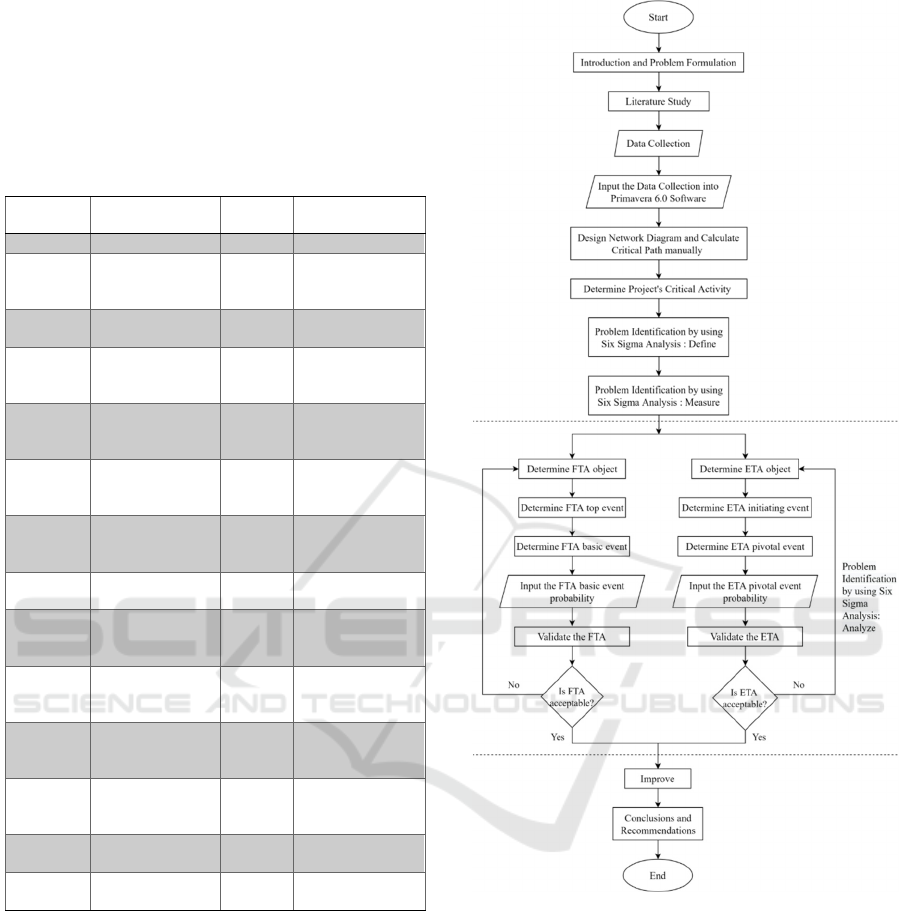

activities. The flowchart of this paper are shown in

Figure 1.

4 ANALYSIS RESULTS AND

DISCUSSIONS

4.1 Data Collection

Data collection is the most important thing in project

planning because without the complete data planning

Project Planning of Offshore Pipelines Replacement: Study Case at Offshore North West Java

115

the project cannot be planned properly. In this study,

the following data were obtained from one of the oil

and gas company. Data that are needed in this study

include work data on project activities, duration of

project activities and relationships between the

project activities (predecessors).

Table 2: Project Activity, Duration, and Predecessor.

Activity

ID No.

Activities Duration

(day)

Predecessor

1 Project Star

t

0 -

2 Project

Management &

Service

78 1FS+5

3 Pipeline Report

(Engineering)

66 1FS+2

4 Pipeline

Drawing

(Engineering)

65 1FS+2; 3SS

5 Material Take

off

(Engineering)

45 1FS+2; 3SS

6 Request for

Quotation

(Engineering)

37 1FS+3; 3SS+1

--------------------

--------------------

--------------------

32 Post-Lay Survey

(Installation)

5 26FS

33 Pre-

Commissioning

Pipeline A

6 0FS; 31FS;

32FS

34 Pre-

Commissioning

Pipeline

C

9 33FS

35 Pre-

Commissioning

Pipeline B

9 34SS

36 Provisional

Acceptance

(PAC)

0 35SS

37 Punch List PAC

Completion

18 33FS

38 Final

A

cceptance

12 36FS; 37FS+20

4.2 Creating a Gantt Chart using

Primavera P6 to Obtain a Network

Diagram

Primavera P6 outputs are in the form of Gantt charts

and network diagrams. The network diagram formed

in Primavera P6 is a diagram of type AON (Activity

on Node) where project activities are represented in

nodes. However, Primavera P6 is not able to show the

number of ES (Initial Start), EF (Initial Finish), LS

(Delayst Start), and LF (Delayst Finish) manually.

Figure 1: Flowchart.

4.3 Make Network Diagrams and

Perform Critical Path Method

Calculations Manually

This critical activity forms a critical path where if one

or more project activities are delayed, it will cause the

entire project to be delayed. Therefore, activities in

the critical path need more supervision in the

timeliness of completion. The activity nodes coloured

in red indicate the critical activities and the direction

of the red arrows indicate the critical paths.

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

116

4.4 Problem Identification using Six

Sigma Analysis (Define)

At this stage a project charter will be made to revew

information and problems that will occur in the

offshore pipeline replacement project of the company

under study. Project charter can provide information

about general information, project scope, resource

requirements, critical time schedules, roles and

responsibilities of the project team.

Table 3: Project Charter - Project Scope.

Project Scope

Situation / Problem / Opportunit

y

In this project there are indications of delays due

to a lar

g

e deviation in the pro

j

ect plannin

g

data.

Pro

j

ect Goals

Maintaining the company's oil and gas production

as well as to obtain additional production by

installing a new pipeline to replace the existing

dama

g

ed pipe.

Table 4: Project Charter - Project Scope.

In Scope / Out of Scope

In Scope:

● Installation of new pipes with a 12 "OD size

and 1 km pipe length.

● Pre construction survey.

● Removal of the subsea obstacle that can

hinder the installation of new pipes.

● Survey of laying subsea pipelines with ROV.

● Installing risers, bends, and spools.

● Post lay survey.

● Installation supports on pipelines identified

as free spans.

● Flooding, pigging, hydrotest, drying, purging

and pre-commissioning of new pipes.

● Installation of break out spool between riser

and topside piping.

● Disassemble existing OD 8 "riser sizes,

including riser clamps and end caps

installation.

● Carry out work activities using a pressurized

environment for installing riser clamps.

● Perform bevel end repairs at the end of the

pipe.

● Welding procedure specifications using

ASME IX code, API 1104 (PSL 2), AWS

D1.1 and compan

y

specifications.

Out of Scope:

● There are no monetary problems at home or

abroad during the project work.

● Project detail procedure has not changed and

is in accordance with the contract during the

p

ro

j

ect work.

Table 5: Project Charter - Project Scope.

Ob

j

ectives

● Project on schedule.

● Without problems or work accidents.

● The project does not over cost.

● Stages of work are carried out according to

qualit

y

standards.

Pro

j

ect Assumptions

● The document engineering process ran

smoothly.

● The procurement process went smoothly.

● The construction process is running

smoothly.

● The installation and checking process runs

smoothl

y

.

Risk and Dependencies

● Lack of resources.

● The risk of a project being delayed due to

concurrent workers.

Risk and Dependencies

● Increased project costs due to accuracy of

cost estimates and poor scope.

● Risk that the project will fail to produce

results according to project specifications.

● Mistakes in strategies such as choosing

technology that cannot function properly.

● Operational risks include risks from poor

implementation and process problems such

as procurement, production and distribution.

● Risks associated with external hazards,

includin

g

storms, floods and earthquakes.

4.5 Problem Identification using Six

Sigma Analysis (Measure)

In calculating and identifying the problem, timeliness

is defined as an element which directly redelayd to

the expected time calculation. Project planning time

must be according to actual progress time. Therefore,

at this stage an analysis is carried out to determine the

sigma value with a percentage deviation between the

time of planning and the time of progress with the

maximum value of 6. The sigma value is obtained

from the conversion of DPMO (defects per million

opportunities) value. The DMPO value is derived

Project Planning of Offshore Pipelines Replacement: Study Case at Offshore North West Java

117

from the difference of project time (in percentage),

i.e. the deviation that occurs between the time of

project planning and the time of actual progress.

For detailed calculation, the biggest deviation

between monthly planning time and the actual time is

taken. The result found that in October there was a

time lapse of 5.05%. Defective Value per Million

Opportunities (DPMO) is obtained from the formula:

In this calculation, the DPMO value is:

DPMO = 5.05% × 1000000 = 50500

DPMO calculation results show any deviations

from the target that was decided. This DPMO number

will then be used to get the sigma level by converting

the DPMO number to the sigma number.

In the calculation of more specific sigma numbers,

calculations can be performed using Microsoft Excel.

The formula for calculating sigma number is:

By using pre-existing data, the sigma number is as

follows:

Sigma Number = NORMSINV (1 - 5.05%) +1.5 =

3.140025

The sigma calculation results show a more

specific result of 3.14 out of 6 (maximum) which can

be increased again with improvements made. This

result occurred in October where there were 3

procurement, construction and installation.

Table 6: The Basic Event and Intermediate Event of the

FTA Procurement Phase Experienced Interference.

Intermediate

Event Level 1

Intermediate

Event Level 2

Basic Event

Procurement

Stage

Experiencing

Interference

Problem in

ordering

material

Planning is not

mature enough

p

rocurement

Material provider

negligence

Communication

and coordination

are unclea

r

Material arrived

at the project

site delay

Shipping goods

from abroa

d

Material order

dela

y

The fabrication

process has been

delaye

d

Material delivery

is dela

y

Problems with

p

a

y

ment

Table 7: Basic Event and Intermediate Event FTA

Construction Phase Experienced Disruption.

Intermediate

Event Level 1

Intermediate

Event Level 2

Basic Event

Construction

Phase Has

Disturbances

Problematic

equipment

section

Lack of e

q

ui

p

ment

The equipment is

damage

d

Equipment arrived

dela

y

Low ability of

e

q

ui

p

ment

The labor

force has a

problem

Lack of workforce

Difficulties in labor

mobilization

Labor productivity

is lacking

Absent laborers

Inexperienced

workforce

Problems arise

b

etween workers

Design changes that resulted in the

addition of wor

k

Bad weathe

r

Natural Disaste

r

An accident

occurred

during the

construction

process

Unexpected

accident

Lack of supervisor

and control

Communication and

coordinator are

unclea

r

Problems arise

b

etween workers

Lack of

socialization and

work safet

y

trainin

g

An error

occurred

during the

construction

process

Document/ picture

not detail

Inexperienced

workforce

Communication and

coordination are

unclea

r

4.6 Identifying Problems and

Calculating Probability of

Problems using Six Sigma Analysis

(Analyze): Fault Tree Analysis and

Event Tree Analysis

● Determine top FTA events and ETA initiating

events:

The top event and initiating event that is being

investigated is the delay in the offshore pipeline

replacement project.

DPMO = Lar

g

e Deviation x 1000000

Sigma Number = NORMSINV (1 – Large Deviation + 1.5

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

118

Table 8: The Basic Event and Intermediate Event of the

FTA Installation Stage Are Interrupted.

Intermediate

Event Level 1

Intermediate

Event Level 2

Basic Event

Installation

Phase Has

Interference

Problem in

equipment

section

The equipment is

damage

d

Low standard of

e

q

ui

p

ment

Bad weathe

r

Natural disaste

r

An accident

occurred during

the installation

process

Unexpected

accident

Lack of

supervision and

control

Communication

and coordination

are unclea

r

Problems arise

b

etween workers

Lack of

socialization and

work safety

trainin

g

An error

occurred during

the installation

process

Document/

p

icture not detail

Inexperienced

workforce

Communication

and coordination

are unclea

r

Table 9: Top Event Probability.

No Basic Event Probability

1

Procurement Stage

Experiencing Interference

0,008360286

2

Construction Phase Has

Disturbances

0,022554886

3

Installation Phase Has

Interference

0,021781371

Top Event Probability (Total) 0,052696543

● Determine basic FTA events and ETA pivotal

events:

Basic events and pivotal events are determined by

conducting a literature review of delays in

construction projects and subsea pipeline projects.

The results of the basic event and pivotal event are

obtained after validating to the respondent (client

side).

Opportunities for each basic event were obtained

with a questionnaire from 7 respondents experienced

in underwater piping projects. After that, do the

calculations to get the probability of intermediate

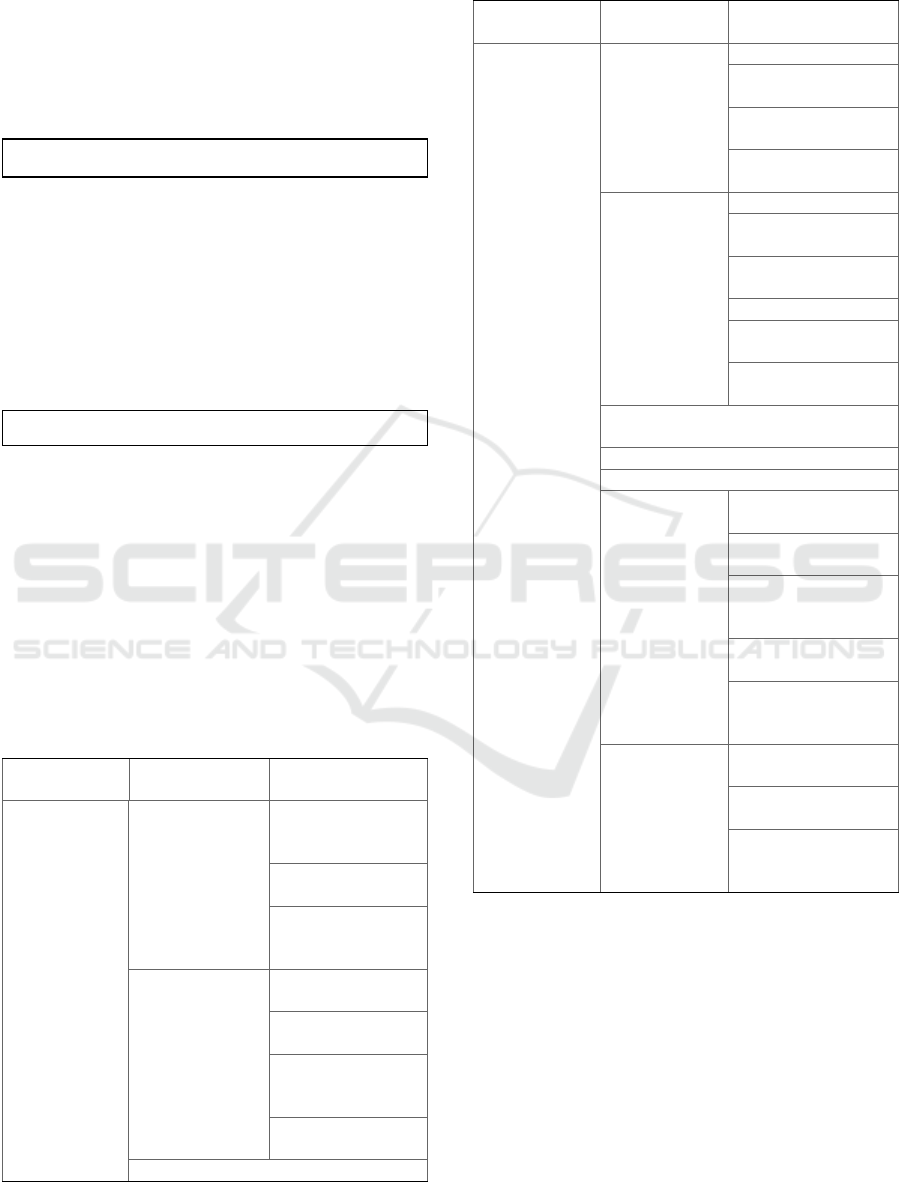

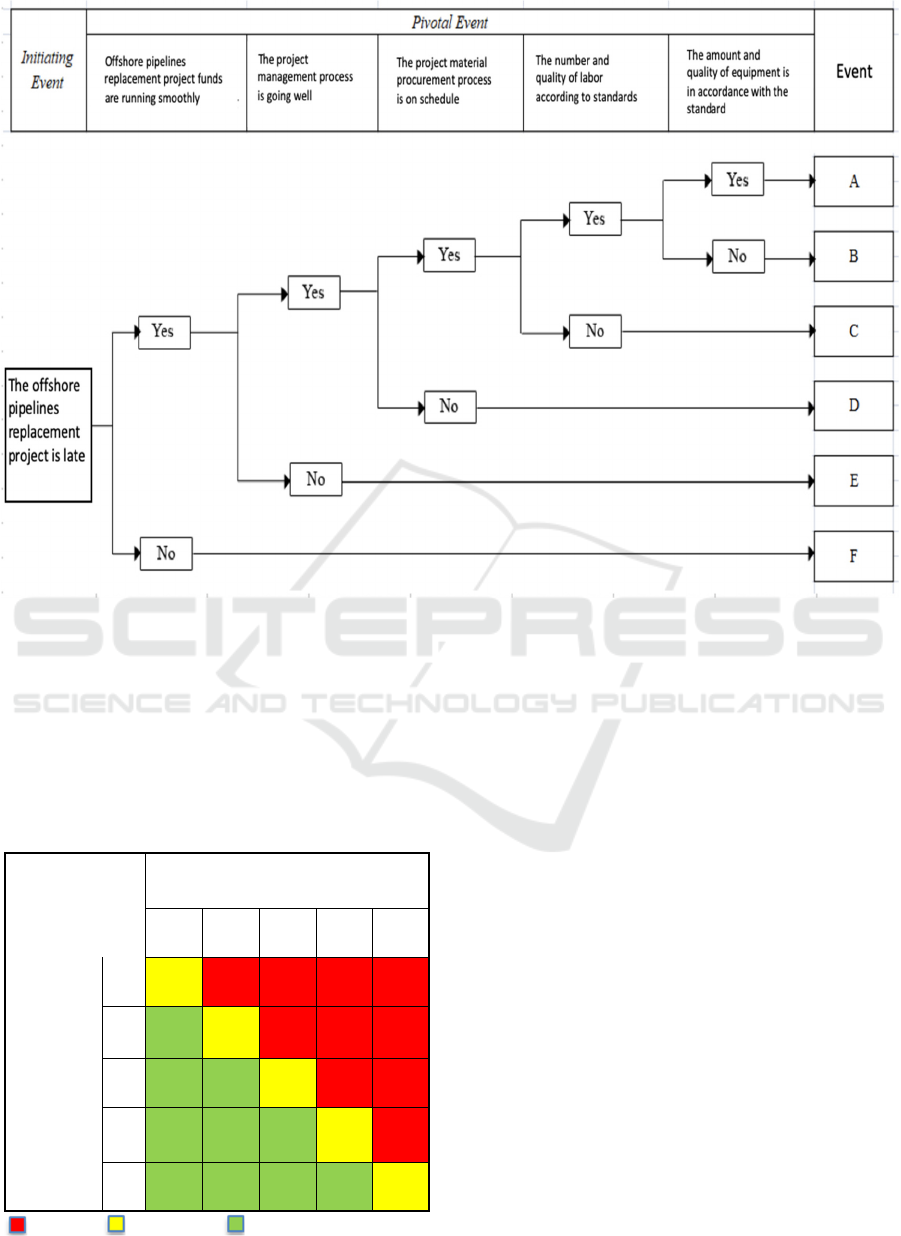

events and top event. The event tree diagram shows

that the initiating event of this research is that the

delay offshore pipelines replacement project has 6

probability events A, B, C, D, E, and F.

(a) Event A

Replacement of the underwater pipeline is completed

on time because it runs smoothly and there is no

problem in one of the pivotal events. The probability

of Event A is 0.05270 x 0.83 x 0.77 x 0.80 x 0.69 x

0.71 = 0.0132

(b) Event B

Replacement of underwater pipelines is complete but

can be delayed for 5-6 weeks due to shortages and

conditions of available equipment. The probability of

Event B is 0.05270 x 0.83 x 0.77 x 0.80 x 0.69 x 0.29

= 0.0053

(c) Event C

Replacement of underwater pipelines is complete but

can be delayed for 3-4 months due to lack of

manpower and inexperience. The probability of Event

C is 0.05270 x 0.83 x 0.77 x 0.80 x 0.31 = 0.0085.

(d) Event D

Replacement of underwater pipelines is complete but

can be delayed for 4-5 months due to delays in

procurement. The probability of Event D is 0.05270

x 0.83 x 0.77 x 0.20 = 0.0067

(e) Event E

Replacement of subsea pipelines is complete but can

be delayed for 5-6 months due to lack of

implementation and supervision of project

management. The probability of Event E is 0.05270 x

0.83 x 0.23 = 0.0100

(f) Event F

Replacement of subsea pipelines cannot be resolved

due to cost issues during the project, considering costs

are the main thing of the project's success. The

probability of Event F is 0.05270 x 0.17 = 0.0090

The next step is to determine the risk categories of

each event into the risk matrix. The probabilities of

each output are matched into the Frequency Index

(FI) table and the consequences of each output are

matched into the Severity Index (SI) table. The FI and

SI tables are referenced from DNV RP F107 (Pipeline

Risk Assessment).

Project Planning of Offshore Pipelines Replacement: Study Case at Offshore North West Java

119

Figure 2: Event Tree

Diagram

.

Table 10 explains that event A is categorized as

moderate risk while events B, C, D, E, and F are

categorized as high risk due to high probability and

high severity. In this result, there is no low risk result

because the lowest probability of event is categorized

as high probability (4) and very high (5).

Table 10: Risk Matrix.

Severity

1 2 3 4 5

Frequency

5

A E F

4 B C, D

3

2

1

High Risk Medium Risk Low Risk

4.7 Determination of Problems using

Six Sigma Analysis (Improve)

It is known that in that month there are material

delivery activities, the likelihood of this happening is

that the material delivery is delayed in view of the

large probability at the basic event. Delay material

delivery has a probability of 0.007389714.

The step that can be taken is to complete all

material financing because monitoring of funding in

ordering materials is important because in the

absence of funds the goods cannot be ordered or

delivered on time. For the next project, it is expected

that the procurement plan can be planned as well as

possible so that there are no more errors in the

delivery of materials and the project is running

optimally.

5 CONCLUSIONS

Based on discussion in the previous chapter, these are

the conclusion of the study:

1. The offshore pipelines replacement project has

19 critical activities created from 38 project

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

120

activities.

2. Many factors cause project delay. These factors

are divided into 3 intermediate event branches,

namely the procurement, construction and

installation stages.

3. The offshore pipelines replacement project using

Fault Tree Analysis (FTA) obtained the results of

the top event probability on this project of

0.05270.

4. Offshore pipelines replacement project using

Event Tree Analysis (ETA) obtained 6 events with

different probabilities and consequences.

REFERENCES

Baccarini, David., 1996. The Concept of Project Complexity

– a review. International Journal of Project

Management, volume 14, I(4), pp. 201-204.

Brue, G., 2002. Six Sigma for Managers, McGraw-Hill

Publishing. New York, 1

st

Edition.

Ericson, C. A., 2005. Hazard Analysis Techniques for

System Safety. A John Wiley & Sons, Inc., New Jersey.

ISO 31010, 2009.Risk Management – Risk Assessment

Techniques. British Standard Institution.

Heizer, J. & Render, B., 2014. Operation Management

Sustainability and Supply Chain Management, Pearson,

11

th

Edition.

Larasati, Dea P., 2019. Improvement of Bottle Production

Quality with Six Sigma Method and Data Mining

Method at PT. Bumi Mulia Indah Lestari. Jakarta:

Industrial Engineering, Trisakti University.

PMBOK, 2008. A Guide to Project Management Body of

Knowledge. Newton Square: Project Management

Institute.

Samad, F., 2019.Analysis of Schedule and Delay Risk of

Onshore Pipeline X Project in Melaka. Surabaya:

Department of Ocean Engineering Sepuluh Nopember

Institute of Technology.

Silvianita., Redana, F. , Rosyid, DM., Chamelia, DM .

2017a. Applied Mechanics and Materials 862, 315-320.

Silvianita Daniel M Rosyid, Anantya Novega S. 2017b.

Project Delay Analysis of HRSG. In, 79:12036. IOP

Conference Series: Earth and Environmental Science.

Silvianita, Robby Guntara, Daniel M. Rosyid, and Wahyudi

Citrosiswoyo. 2018. Occupational Risk Analysis Using

Bowtie Method on Mooring Change Replacement

Production Barge Ocean X Project. International

Journal of Civil Engineering and Technology 9 (13):

356–65.

Szymanski, P., 2017. Risk Management in Construction

Projects. Procedia Engineering, I(208), pp. 174-182.

Project Planning of Offshore Pipelines Replacement: Study Case at Offshore North West Java

121