Risk Analysis on Offshore Pipeline Installation Delay:

A Case Study for Mahakam Block, Indonesia

Yohana Selliabreint

1

, Silvianita

1

, Daniel M. Rosyid

1

, Wahyudi Citrosiswoyo

1

and Cheng Yee Ng

2

1

Department of Ocean Engineering, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia

2

Department of Civil and Environmental Engineering, Universiti Teknologi Petronas, 32610 Seri Iskandar, Perak,

Malaysia

Keywords: Fuzzy Fault Tree Analysis, Fuzzy Event Tree Analysis, Bowtie Analysis, Project Delay, Offshore Pipeline

Installation.

Abstract: Pipeline has an important role in oil and gas industry to transfer oil or gas that have been discovered to

production station, one of which is pipeline system belong to one of the companies located in Mahakam

Block, East Borneo, Indonesia. Considering its important role, pipeline installation in not allowed for any

delay and needs to operate as planned. However, the said offshore pipeline installation has experienced 21

days of delay, whereby this project started on December 5

th

2018 and finished at February 3

rd

2019. To

analyse the delay of this project, this research uses two methods, namely fuzzy trapezoidal and bowtie

analysis. The fuzzy fault tree analysis (FTA) diagram will generate the probability value of top event project

delay of offshore pipeline installation. The fuzzy event tree analysis (ETA) diagram will generate how much

fine that the contractor has to pay and the risk level from every factor that causes the delay. The results from

bowtie analysis will determine preventive value which will be used as precaution and mitigation which will

be used as reduction due to delays.

1 INTRODUCTION

In this modern era, oil and gas demands continue to

rise, to meet consumer demands oil and gas

companies have to increase their production

performance. In this industry, pipeline has an

important role to transfer crude oil that has been

discovered from well to production station.

This research discuss the project of offshore

pipeline installation belongs to one of the oil and gas

company in Mahakam. This pipeline located in

Mahakam Block, East Borneo, Indonesia. This

pipeline is connecting two wells at a distance of

0.8km.which the installation shall be commenced

from 5th December 2018 to 13th January 2019.

during the execution, this project delayed for 21

days causing the project to be completed on 3rd

February 2019 instead.

Delays on projects can cause losses to both the

owner and the contractor. From ownerpoint of view,

the construction delay eventually will impact on the

progress of the production, in a way affecting the

profit. From contractor point of view, extra cost will

incurred e.g. on equipment rent and fines

(Muhamad, 2016).

To reduce the possibility of delays on offshore

pipeline installation in the future, risk analysis can

be used.Project delay for jacket structure and HRSG

have been reviewed by (Silvianita et al 2017a,

2017b) and another project delay using Fault Tree

Analysis (Silvianita et al 2014). This paper will

examine the most dominant factor causing the delay

on offshore pipeline installation project at the

company. Pipeline specification data can be seen in

Table 1.

Table 1: Pipeline Specification Data.

Description Specification

Pipe Material API 5L X 65

Outside Diameter 8.625 in

Line Pipe

Pipeline Wall Thickness

Pipe Length

12 m

20.6 mm

800m

106

Selliabreint, Y., Silvianita, ., Rosyid, D., Citrosiswoyo, W. and Ng, C.

Risk Analysis on Offshore Pipeline Installation Delay: A Case Study for Mahakam Block, Indonesia.

DOI: 10.5220/0010057601060112

In Proceedings of the 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management (ISOCEEN 2019), pages 106-112

ISBN: 978-989-758-516-6

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 LITERATURE STUDIES

Fault tree analysis (FTA) is a logic and graphical

representation that explores the interrelationships

between a potential critical events in a system and

the reason for event (Mokhtari et al, 2011). FTA

diagram consists of top event and basic events.

Commonly, FTA method is used to find the

probability of top event.

Meanwhile, Event tree analysis (ETA) is a

method to detect and analyze the different events of

pragmatic accidents possibilities with safety features

following an initiating event (Raiyan et al, 2017).

ETA diagram consists of initiating event and pivotal

events, which normally used to analyzeconsequence

that arise from failure or unwanted event.

To covers the loss event scenario uses a Bowtie

diagram that consists of fault tree (FT) and Event

Tree (ET) to identify the causes of top events or loss

events and shows the consequences of unwanted

events.The weakness of bowtie analysis is that the

opinions used in the analysis have uncertainties and

vaguenesses.

FTA and ETA considered probability value to

determine cost of delaying fortop event of FTA and

initiating event of ETA respectively. But in the

execusion, these methods will produce unrealistic

outcome as the probability values are solely depend

on assumptions and lead to erroneous conclusion.

Fuzzy logic was introduced to overcome the

ambiguity of human judgement as it can change the

probability value to possibility number within the

scale of 0-1. According to Aqlan et al (2014), fuzzy

logic is used to find aggregates or the value of the

word variable (linguistics) of the respondent, which

are converted into a collection of numbers. The scale

used in fuzzy logic is more flexible, making it easier

to assess linguistic variables according to condition

Table 2: Fuzzy Likelihood of an Event (Zarei et al, 2019).

Grade Likelihood

Membership

Function

1 Very High (VH) (0.8,1,1,1)

2

High-Very High

(HVH)

(0.7,0.9,1,1)

3 High (H) (0.6,0.8,0.8,1)

4 Fairly High (FH) (0.5,0.65,0.65,0.8)

5 Medium (M) (0.3,0.5,0.5,0.7)

6 Fairly Low (FL) (0.2,0.35,0.35,0.5)

7 Low (L) (0,0.2,0.2,0.4)

8 Low-Very Low (LVL) (0,0,0.1,0.3)

9 Very Low (VL) (0,0,0,0.2)

in the field (Shahriar, 2012). In this research, the use

of linguistic variables and fuzzy numbers are as

follow (Zarei et al, 2019).

This research using the trapezoidal fuzzy number

to determine the possibility value from respondents

assumptions based on interview. Trapezoidal fuzzy

number can be defined as:

(1)

The formula can be defined as follows :

𝑋

∗

=

𝑥𝑑𝑥 +

𝑥𝑑𝑥+

𝑥𝑑𝑥

𝑑𝑥+

𝑑𝑥 +

𝑑𝑥

𝑋

∗

=

1

3

×

(

𝑎

+𝑎

)

−𝑎

𝑎

−

(

𝑎

+𝑎

)

+𝑎

𝑎

(

𝑎

+𝑎

−𝑎

−𝑎

)

(2)

According to Clemen et al (1999) to change the

linguistic variable to fuzzy number and combine the

value of experts assumption to one fuzzy number,

the formula can be defined as follows:

𝑀

=𝑊

𝐴

,𝑗=1,2,…,𝑛

(3)

Where :

Aij = Linguistic expression of basic event by j

M = Number of basic events

n = Number of experts

W = Weighting factor of j and M

Representing the combined Fuzzy number of basic

event i.

According to Lavasani et al (2012) the value of

experts assumption can be determined by this

following formula :

Experts value = PP + ET + EL + A (4)

Wj=

value o

f

expert

∑

value o

f

expert

(5)

Where:

PP = Professional Position

ET = Education Level

EL = Experience Time (year)

A = Age (year)

Wj = weighting factor of experts

Risk Analysis on Offshore Pipeline Installation Delay: A Case Study for Mahakam Block, Indonesia

107

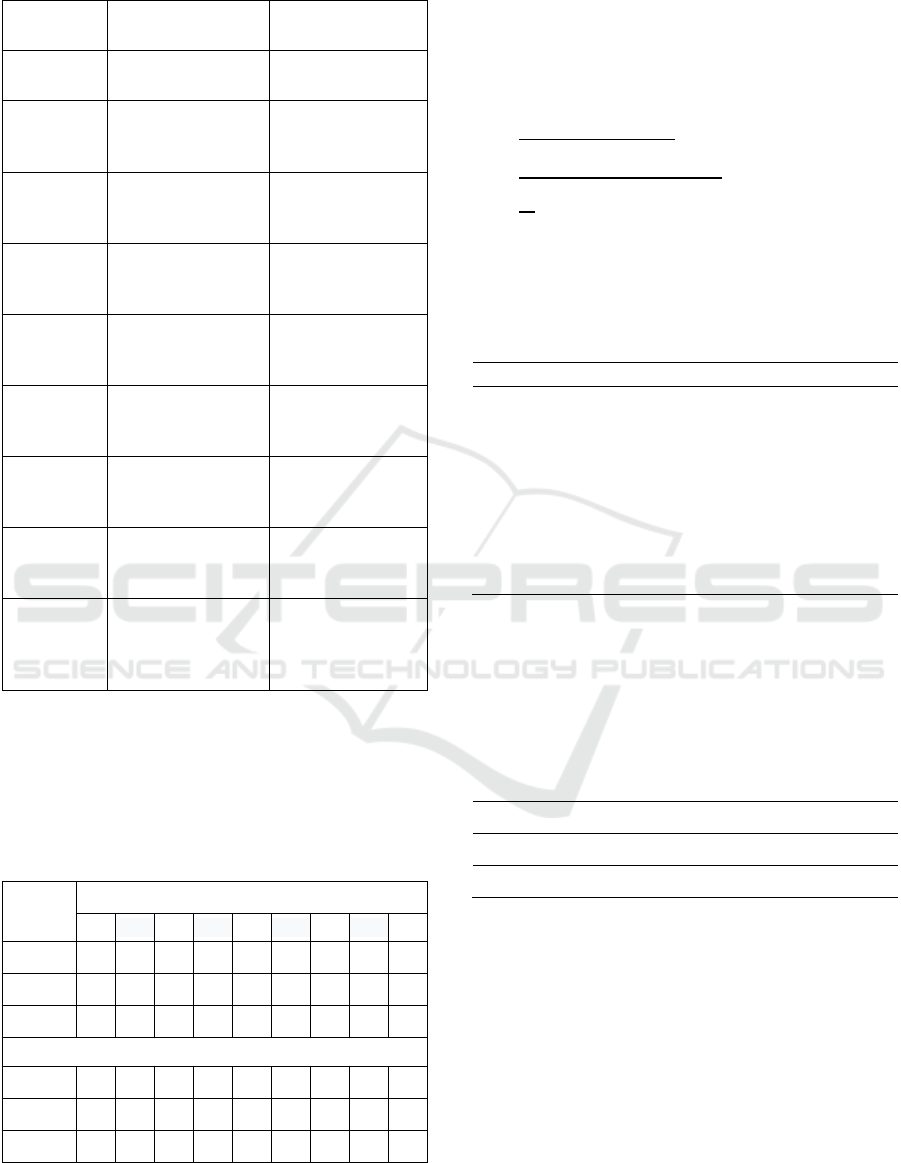

Table 3 shows the value of experts (Ramzali et al,

2015).

Table 3: Value for Experts.

Constitution Classification Score Constitution Classification Score

Professional

Position

Senior

academic

5

Education

Level

PhD 5

Junior

academic

4 Master 4

Engineer 3 Bachelor 3

Technician 2

Higher

National

Diploma

(HND)

2

Worker 1 School Level 1

Experience

Time (year)

≥30 5

Age (year)

≥50 4

20-29 4 40-49 3

10-19 3 30-39 2

6-9 2

<30 1

≤5 1

According to Onisawa (1998) to change the

fuzzy possibility score (FPs) by summing the three

fuzzy number parameters and the dividing by three.

For the last step, change the FPS to fuzzy probability

score (FPr) using the following formula:

FPr=

1

10

if FPs ≠0

0 if FPs =0

K

=

1−FPs

FPs

× 2.301

(6)

Where :

FPr = Fuzzy Probability Score

FPs = Fuzzy Posibilatas Score

K = Constant Numbers

The probability will be used to calculate the

possibility on ETA fuzzy diagrams. To change the

probability to possibility by using the following

formula (Onisawa, 1988):

FPs=f

(

FPr

)

FPs=

1

1 + k × log

,FPr≠0

0, FPr=0

(7)

Where :

FPr = Fuzzy Probability Score

FPs = Fuzzy Posibilatas Score

k =

(/(×

))

3 METHODOLOGY

Figure 1: Flowchart.

Start

data collection

Problem definition

and literaturestudies

Determine Risk

Value and Risk

Matrix

Generate Bow-Tie

Analysis

Finish

YES

YES

NO

Determine

Initiating Event

Determine Top

Event

Determine Pivotal

Event

Determine Basic

Event

CalculateFPs

InputFPs

InputFPs

ChangeFPsintoFPr

ChangeFPs

intoFPr

FTA

acceptable

ETA

acceptable

NO

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

108

The procedures of the research are as follow:

1. Formulations of Problems

The formulations of the problems are decided

as the purpose or the goal of the research.

2. Literature Studies

3. Data Collection

The data used in this research are:

a. Pipeline installation project master schedule

data

b. Actual pipeline installation project data

schedule

c. Contract data

d. General data about the pipeline installation

project

e. Make a questionnaire to look for the

probability

of basic FTA events, pivotal ETA events,

determination of risk matrices, barriers and

escalation factors in a bow-tie diagram.

4. Data Analysis and Discussion

a. Analysis of the results of the interview to

determine the work items that are

experiencing problems, thefactors that

cause delays in the project and

theconsequences caused by delays. At this

stage a weighting is carried out for each

respondent withequations 4 and 5

b. Fuzzy FTA stage

c. Fuzzy ETA stage

d. Determine the Risk Matrix

e. Bowtie Analysis

5. Conclusions and Suggestions

After all the results are obtained, conclusions

are then drawn up containing the answers to the

formulation of the existing problems and

suggestions for further research, especially in

the field of Risk Assessment.

4 RESULT AND DISCUSSION

4.1 Data Management Factors

Delaying Offshore Pipeline

Installation using Fault Tree

Analysis and Fuzzy Logic

Fault tree analysis (FTA) is a method used to find

therootcauses of a top event or peak failure

event.Thisresearch explained the factors that cause

the delay in the offshore pipeline installation project.

The basic causes of delays and the probability of

each basic event were illustrated through a fault tree

diagram. The basic events can be seen in Table 4.

Table 4: Basic Event of FTA Diagram.

No. Code Name of Event

1 A111

Equipment / machinery not

available

2 A112

Equipment / machinery is being

used in another location

3 A121

Poor equipment / machinery

maintenance

.....

25 B11

Miscommunication between

owner supervisor and contractor

26 B12

Workers do not understand the

work items to do

27 B2

The process is not according to

the initial plan

Meanwhile, the respondent's personal data can be

seen in Table 5, and the respondents involved in the

offshore pipeline installation were selected:

Table 5: Respondent Profile.

Expert

Category

Age Experiences Postion Education

1 34 12

Site

Planner

S2

2 29 11 Engineer S1

3 40 17 Supervior S1

4 26 5 Engineer S1

5 29 6 Engineer S1

6 32 8

Site

Manager

S1

7 26 5 Engineer S1

8 39 12 Supervisor S2

9 28 5 Engineer S1

Probability of each basic FTA was obtained

throughinterviewing the respondents. the frequency

of basic fuzzy FTA events was referred to the scale

proposed by Zarei, et al. (2019), as listed in Table 6.

Risk Analysis on Offshore Pipeline Installation Delay: A Case Study for Mahakam Block, Indonesia

109

Table 6: Scale Fuzzy Likelihood of an Event.

Linguistic

Variabel

Defenition

Membership

Function

Very High

(VH)

It happened every

pipeline installation

(0.8,1,1,1)

High-Very

High

(HVH)

It happened in a

span of 3 times the

pipeline installation

(0.7,0.9,1,1)

High (H)

It happened in a

span of 5 times the

pipeline installation

(0.6,0.8,0.8,1)

Fairly High

(FH)

It happened in a

span of 15 times the

pipeline installation

(0.5,0.65,0.65,0.8)

Medium

(M)

It happened in a

span of 25 times the

pipeline installation

(0.3,0.5,0.5,0.7)

Fairly Low

(FL)

It happened in a

span of 50 times the

pipeline installation

(0.2,0.35,0.35,0.5)

Low (L)

It happened in a

span of 75 times the

pipeline installation

(0,0.2,0.2,0.4)

Low-Very

Low (LVL)

It happened in a

span of 90 times the

pipeline installation

(0,0,0.1,0.3)

Very Low

(VL)

It happened in a

span of 100 times

the pipeline

installation

(0,0,0,0.2)

4.1.1 Calculating Fuzzy Possibility (FPs)

From the results of interviews and questionnaires, a

recapitulation of data for linguistic variable scales

were compiled in Table 7.

Table 7: Questionnaire Results from Experts.

Activity

Category

1 2 3 4 5 6 7 8 9

A111

VL VL H LVL LVL VL L M L

A112

L VL HVH L FL M L M M

A121

L LVL VH LVL FL L LVL M LVL

.....

B11

LVL LVL FL LVL M VL LVL H FL

B12

LVL FH FL VL L L VL M LVL

B2

LVL FH L M M L VL M FL

To determine the possibility of each basic event,

the first step to identify the weight for each

respondent adopting equations 4 and 5, while the

scores for respondents based on Table 3.

The example of value calculating of aexpert:

Value of expert = PP + ET + EL + A

= 3 + 3 + 4 + 2

=12

Wj =

∑

ί

Wj =

Wj =

Wj = 0,13

From the calculations above, we get the value of

each respondentas written in Table 8.

Table 8: Value of Each Experts.

Respondent Final Score

1 0.13

2 0.11

3 0.13

4 0.09

5 0.11

6 0.12

7 0.09

8 0.13

9 0.09

After knowing the weight of each respondent,

then determined possibilities (FPs) of each basic

event using equation 2 and 3.

We used Basic Event code A111 from the

questionnaire results as an example to calculate the

possibility (FPS).

Table 9: Questionnaire Results A111.

Experts

1 2 3 4 5 6 7 8 9

VL VL H LVL LVL VL L M L

Table 9 shows the outcome of questionnaire

survey. Then fuzzy numbers as in table 6 were

converted to calculate the possibility (FPs). The

results can be seen as below:

Expert 1 = (0, 0, 0, 0.2)

Expert 2 = (0, 0, 0, 0.2)

Expert 3 = (0.6, 0.8, 0.8, 1)

Expert 4 = (0, 0, 0.1, 0.3)

Expert 5 = (0, 0, 0.1, 0.3)

Expert 6 = (0,0, 0, 0.2)

Expert 7 = (0, 0.2, 0.2, 0.4)

Expert 8 = (0.3, 0.5, 0.5, 0.7)

Expert 9 = (0, 0.2, 0.2, 0.4)

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

110

using equation 3, by multiplying the following fuzzy

number with the weight of each respondent defined

in Table 8.The following results were derived:

Expert 1 = (0, 0, 0, 0.2) x 0.13

= (0, 0, 0, 0.026)

Expert 2 = (0, 0, 0, 0.2) x 0.11

= (0, 0, 0, 0.022)

Expert 3 = (0.6, 0.8, 0.8, 1) x 0.13

= (0.078, 0.104, 0.104, 0.13)

Expert 4 = (0, 0, 0.1, 0.3) x 0.09

= (0, 0, 0.009, 0.027)

Expert 5 = (0, 0, 0.1, 0.3) x 0.11

= (0, 0, 0.011, 0.033)

Expert 6 = (0,0, 0, 0.2) x 0.12

= (0, 0, 0, 0.024)

Expert 7 = (0, 0.2, 0.2, 0.4) x 0.09

= (0, 0.018, 0.018, 0.036)

Expert 8 = (0.3, 0.5, 0.5, 0.7) x 0.13

= (0.039, 0.065, 0.065, 0.091)

Expert 9 = (0, 0.2, 0.2, 0.4) x 0.09

= (0, 0.018, 0.018, 0.036)

The fuzzy numbers isthen summed, to obtain the

ultimate fuzzy number, as follows:

M = R1 + R2 + R3 + R4 + R5 + R6 +

R7 + R8 + R9

= (0 + 0+ 0.078 + 0 + 0 + 0 + 0 + 0.039 + 0 ;

0 + 0 + 0.104 + 0 + 0 + 0 + 0.018 + 0.065

+ 0.018 ; 0 + 0 + 0.104 + 0.009 + 0.011 + 0

+ 0.018+ 0.065 + 0.018 ; 0.026 + 0.022 +

0.130 + 0.027 + 0.033 + 0.024 +0.036 +

0.091 + 0.036)

= (0.12 ; 0.21 ; 0.23 ; 0.43)

Considering Eq (2), the Fuzzy Probability Score for

event A111 can beobtained as follows:

FPs =

×

(..)

(.×.)

(

..

)

(.×.)

(....)

=

×

.

.

= 0.25

Similar procedure was repeated for the rest of the

events and the results are as shown in Table 10.

Table 10: Calculation Results of Fuzzy Possibility (FPs).

No Code

Fuzzy Number

FPs

a b c d

1 A111 0.12 0.21 0.23 0.43 0.25

2 A112 0.22 0.39 0.40 0.57 0.39

3 A121 0.17 0.29 0.32 0.49 0.32

.... ... .... .... .... .... ....

25 B11 0.16 0.24 0.28 0.47 0.29

26 B12 0.12 0.23 0.25 0.44 0.27

27 B2 0.17 0.32 0.33 0.52 0.34

After finding the FPs of each basic event from

the Fuzzy FTA Diagram, were thenconverted the

possibility (FPs) to probability (FPr) using equation

6. The results of FPr are shown in Table 11.

Table 11: Calculation Results of Fuzzy Probability (FPr).

No. Code FPs K FPr

1 A111 0.25 3.30 0.0005

2 A112 0.39 2.66 0.0022

3 A121 0.32 2.,95 0.0011

.... ... .... .... ....

25 B11 0.29 3.09 0.0008

26 B12 027 3.23 0.0006

27 B2 0.,34 2.88 0.0013

The next step is calculating the minimum cut set

by input the Fuzzy probability from each basic event

to Top Event FTA software.

Calculations using the software will produce the

Top Event Probability and Intermediate Event

Probability values shown in Figure2.

Figure 2: Minimum cut set results from Fuzzy FTA.

Figure 2 showed the minimum cut sets of fuzzy

fault tree analysis (FFTA). The minimum cut set for

project delay of offshore pipeline installation are due

to disruption of pipeline installation process with a

probability 0.04135065 and inefficient management

project has a probability of 0.00130048. So the

minimum total cut set for the top event is 0.0426069.

Risk Analysis on Offshore Pipeline Installation Delay: A Case Study for Mahakam Block, Indonesia

111

5 CONCLUSION

Based on discussion in the previous chapter, it can

be conclude that the most dominant factor causing

delays in offshore pipeline installation projects is

Disruption of Pipeline Installation Process with a

probability of 0.0413 and Inefficient Management

Projectwith a probability of 0.0013.

REFERENCES

Aqlan, F., and Ali, E. 2014. Integrating lean principles

and fuzzy bowtie analysis for risk assessment in

chemical industry. Jurnalinternasional: www.elsevier.

com/locate/jlp.

Clemen, R.T., Winkler, R.L. 1999. Combine Probability

Distribution from Experts in Risk Analysis. Risk

Analysis. Vol 19, 187–203.

Lavasani, S.M.M., Wang, J., Yang, Z., and Finlay, J.

2012. Application of MADM in a Fuzzy Environment

for Selecting the Best Barrier for Offshore Wells.

Expert Syst. Appl. 39, 2466–2478.

Mokhtari, K., Ren, J., Roberts, C., and Wang, J. 2011.

Application of a Generic Bow-tie Based Risk

Analysis Framework on Risk Management of Sea

Ports and Offshore Terminals. Jurnalinternasional:

www.elsevier.com/locate/jhazmat.k

Muhamad, P. 2016. Analisa Faktor Penyebab

Keterlambatan Proyek Topside Platform ONE OF

THE COMPANYYZ. Surabaya: TugasAkhir.

Departement Teknik Kelautan Institut Teknologi

Sepuluh Nopember.

Onisawa, T. 1988. An Approach to Human Reliability in

Man-Machine Systems Using Error Possibility. Fuzzy

sets Syst. Vol. 27, 87–103.

Ramzali, N., Lavasani, M.R.M., Ghodousi, J. 2015. Safety

Barriers Analysis of Offshore Drilling System by

Employing Fuzzy Event Tree Analysis. Saf. Sci. Vol.

78, 49–59.

Raiyan, A., Das, S., Islam, M. R. 2011. Event

Tree Analysis of Marine Accidents in

Bangladesh. Jurnalinternasional: www.elsevier.com/

locate/ procedia.k

Shahriar, A., Sadiq, R., and Tesfamariam, S. 2012. Risk

analysis for oil & gas pipelines: A sustainability

assessment approach fuzzy based bowtie analysis.

Journal of Loss Prevention in the Process Industries.

Vol 25, 505-523.

Silvianita., Daniel M Rosyid, Dirta M Chamelia, Firza

Redana. 2017. “Project Delay Analysis on Jacket

Structure Construction.” Applied Mechanics and

Materials 862: 315–20.

Silvianita., Daniel M Rosyid, Anantya Novega S. 2017.

“Project Delay Analysis of HRSG.” In 79:12036. IOP

Conference Series: Earth and Environmental Science.

Silvianita., Daniel M Rosyid, Dirgha S Mahandeka. 2014.

“Fault Tree Analysis for Investigation on The Causes

of Project Problems.” Second International Seminar

on Ocean and Coastal Engineering Environment and

Natural Disaster Management 2014. Surabaya.

Zarei, E., Khakzad, N., Cozzani, V., Reniers, G. 2019.

Safety Analysis of Process Systems Using Fuzzy

Bayesian Network (FBN). Jurnalinternasional:

www.elsevier.com/locate/jlp. K

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

112