Characterization of Activated Carbon Prepare from Low-rank Coal

of East Kalimantan by using Acid and Base Activation

Yuli Patmawati

1

, Alwathan

1

and Nurkholis Hadi Ramadani

1

1

Department of Chemical Engineering, Politeknik Negeri Samarinda

Jl.Dr.Cipto Mangunkusumo, Kampus Gn.Lipan Po.Box 1341 Samarinda, Kalimantan Timur - Indonesia

Keywords: Activated Carbon, Activation, Low Rank Coal.

Abstract: Indonesia is one of the countries that has large coal reserves in the world. Low rank coal in Indonesia

reached 28.4% of coal reserves, 67,198,300,021 tons/year of low-rank coal production in East Kalimantan.

Despite their vast reserves, low-rank coals are considered undesirable because has less economic value;

their high moisture content, entails high transportation costs, potential safety hazards in transportation

and

storage and the low thermal efficiency obtained in combustion of

such coals. Besides improving its

economic and usage values, processing low-rank coal into activated carbon becomes alternative way of

utilization of abundant amount of low-rank coal. The aim of this research is to determine the characteristics

of activated carbon produced from low rank coal of East Kalimantan by using acid and base activation with

different activators : HCl,

H

3

PO

4

and NaOH. Low rank coal which has been prepared -100 +120 mesh is

carbonized at 600

0

C for 3 h, then after cold it was activated using 2.5 M concentration of HCl, H

3

PO

4

and

NaOH for 8 h. Furthermore proximate analysis were used to

investigate the characteristics of activated

carbon produced such as moisture content, ash content, volatile matter and fixed carbon. Meanwhile, the

adsorption capacity of activated carbon is determined through the iodine adsorption number. The quality

requirements for activated carbon refers to Indonesian National Standard (SNI 06-3730-1995). The best

results were obtained by using HCl with activated carbon characteristics such as a moisture content, ash

content, volatile matter, fixed carbon and iodine absorption number respectively as follows 5.23%, 11.72%,

8.85%, 74.2% and 660.40 mg/g. Activated carbon

is one of the mostly widely used adsorbents

.

In the

treatment

of wastewater, it is usually employed for purification, decolorization and the removal

of

toxic heavy metal ions and organic pollutants.

1 INTRODUCTION

Coal was formed by the decomposition of plant

matter , and

it is a complex substance that can be

found in many forms. Coal is divided into four

classes: lignite/low-rank coal, sub-bituminous,

bituminous and anthracite. Low-rank coal in

Indonesia reached 28.4% of coal reserves,

67,198,300,021 tons/year of low-rank coal

production in East Kalimantan (Demirbas, 2007).

Activated carbon is mainly composed of

carbonaceous material with various

porous

structures and it is one of the mostly widely used

adsorbents

(Bilal, 2016). Activated carbons have

been widely employed in water and wastewater treat-

ment processes for removing organic contaminants,

because they generally have

large adsorption

capacity (Tsai, 2001). This activated carbon has a

specific affinity for non-polar

compounds, such as

organics (Dong Su Kim, 2004).

Activated carbon

can be produced from different sources, such as

lignocellulosic materials, coal, bagasse ash, asphalt

and oil, waste tyre rubber, activated sludge and

others (Shawabkeh and Ghamdi, 2014).

Coal has the

potenti al as a raw material to produce activated

carbon because it has a high carbon content

(Speight, 1994).

The production process of activated carbon

mainly consists of three steps:

dehydration,

carbonization, and activation. Dehydration is a

drying process to

remove moisture content

from the raw material. During carbonization,

organics

contained in the raw material are

converted into primary carbon, which is a

mixture of amorphous, crystalline carbon, tar,

and ash. Activation is the main step in the

178

Patmawati, Y., Alwathan, . and Ramadani, N.

Characterization of Activated Carbon Prepare from Low-rank Coal of East Kalimantan by using Acid and Base Activation.

DOI: 10.5220/0010021900002905

In Proceedings of the 8th Annual Southeast Asian International Seminar (ASAIS 2019), pages 178-181

ISBN: 978-989-758-468-8

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

whole process and is usually carried out in two

ways:

physical and chemical activation

.

Physical

activation usually involves the carbonization of

pre-cursor followed by the gasification of the

resulting char or direct CO

2

/steam activation of

the starting material. Chemical activation involves

the impregnation of the given precursor with

activation agent such as phosphoric acid (H

3

PO

4

),

chloric acid (HCl), nitrit acid

(HNO

3

), zinc

chloride (ZnCl

2

), and alkaline

metal compounds

(Dong-Su Kim, 2004).

The

adsorption performance of activated carbon, to a

large extent, depends on the choice of activators

(Fen Li, Bo Yan and Tao Lei, 2014).

The adsorption capacity of activated carbon is

very important because this property determines

how much of the substance can be absorbed per

gram of carbon (Demirbas, 2007). This capacity is

related to the pore structure and chemical nature of

the carbon

surface in connection with preparation

conditions (Pehlivan and Cetin, 2008). The quality

requirements for activated carbon refers to

Indonesian National Standard (SNI 06-3730-1995)

with max.15% moisture content, max.10% ash

content, max. 25% volatile matter, min. 65% fixed

carbon and min. 750 mg/g iodine absorption number

(Departemen Perindustrian and Perdagangan, 2003).

Lots of research has been

reported on the

preparation of activated carbon from different

sources and on the effects of diferrent preparation

condition on the characteristics of the activated

carbon. Research conducted by Maulana et.all

(2017) “Activation Process of Candlenut Shell Use

Different Activators (

H

3

PO

4

, CaCl

2

, NaOH) a n d

Concentration”

The best result were obtained at 15%

concentration of NaOH, produce activated carbon

with characteristics of moisture content, ash content,

volatile matter, fixed carbon and iodine absorption

number respectively as follows 5.55%, 7.65%,

65.54%, 27.80% a n d 663.82 mg/g. Another study

was making of activated carbon from sub-

bituminous coal with chemical activation using

H

3

PO

4

and combination of

H

3

PO

4

-NH

4

HCO

3

activators

.

Sub-bituminous is carbonized at 600

o

C

for 3 h, continued by chemical activation for 8 h and

drying process at 600

o

C for 2 h. The best result were

obtained on the concentration

H

3

PO

4

-NH

4

HCO

3

2.5

M with moisture content of 7.4%, ash content of

10%, volatile matter of 39.1%, fixed carbon of 43.5

% and iodine absorption number of 1238.554 mg/g

(Kusdarini and Ghafarunnisa, 2017).

The aim of this research is to determine the

characteristics of activated carbon produced from

low rank coal of East Kalimantan by using acid and

base activation with different activators such as HCl,

H

3

PO

4

and NaOH.

2 METHODOLOGY

Low rank coal which has been prepared -100

+120 mesh is carbonized at 600

0

C for 3 h, then after

cold it was activated using 2.5 M concentration of

HCl,

H

3

PO

4

and NaOH for 8 h. Furthermore, an

analysis of activated carbon refers to Indonesian

National Standard SNI 06-3730-1995 was carried

out including moisture content, ash content, volatile

matter, fixed carbon and iodine absorption number.

Coal to be processed into activated carbon is

determined by parameters of moisture content, ash

content, volatile matter, fixed carbon, iodine

absorption number and calorific value respectively

as follows 37.86%, 5.53%, 25.06%, 31.55%, 215.75

mg/g and 3665 cal/g.

3 RESULTS AND DISCUSSION

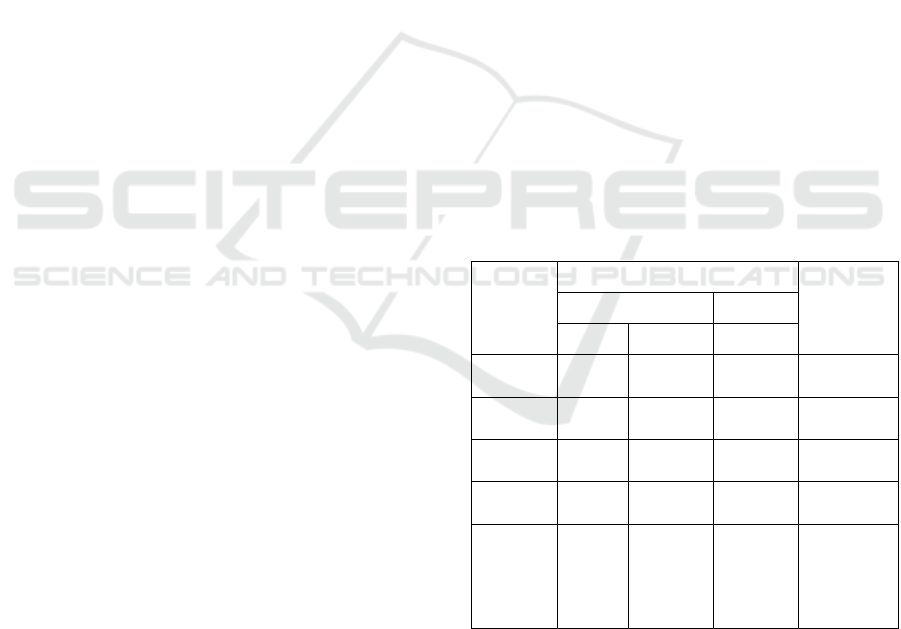

Table 1 summarizes the results of activation low-

rank coal using acid and base activators.

Table 1: Characteristics of Activated Carbon after

Activation Low-Rank Coal.

Parame

ter, %

Activators

SNI

Standard

Acid Base

HCl H

3

PO

4

NaOH

Moist.

Content

5.23 3.42 4.67 Max. 15%

Ash

Content

11.72 13.25 13.64 Max. 10%

Volatile

Matter

8.85 10.13 10.61 Max. 25%

Fixed

Carbon

74.20 73.20 71.08 Min. 65%

Iodine

Adsorpti

on

Number,

mg/g

660.4 469.53 479.11 Min. 750

Characterization of Activated Carbon Prepare from Low-rank Coal of East Kalimantan by using Acid and Base Activation

179

Figure 1: Characteristic of Low Rank Coal at Initial

Condition and After the Activation Process with Different

Activators.

In Figure 1 can be seen that moisture content of

low rank coal has decreased from 37.86% to 3.42 –

5.23%. The lowest moisture content produced by

coal activated by H

3

PO

4

is 3.42% while the highest

moisture content produced by coal activated by HCl

is 5.23%. Acid activators cause complex damage to

oxygen during the activation process so that the

moisture content in activated carbon is less than base

activators (Erawati and Fernando, 2018). But it does

not happen to HCl activators because the pH

produced is so small that it requires more water in

the neutralization process. This causes activated

carbon to absorb more water. Refers to Indonesian

National Standard (SNI 06-3730-1995), allowable

moisture content max. of 15%.

The ash content of the activated carbon has

increased from 5.53% to 11.72 – 13.64%. The

increase in ash content was due to the carbonization

process at high temperatures cause the oxidation of

most volatile substances including carbon. Whereas

ash is not oxidized because it is not a volatile

substance. Based on Figure 1, the use of acid

activators produces lower ash content compared to

alkaline/base activators. This is because the acid

activators of HCl and H

3

PO

4

bind together with the

alkaline elements in activated carbon and form salts

that dissolve easily in water. Conversely, the base

activators such as NaOH, contain the mineral

element (sodium, Na) will be absorbed in the pores

of activated carbon thereby increasing ash content in

activated carbon (Rahim and Indriyani, 2010). Based

on Indonesian National Standar (SNI 06-3730-

1995), allowable ash content max. of 10%.

The use of activators in the activation process is

able to reduce component of non-carbon compounds

found on the surface of activated carbon and enlarge

the surface pores of activated carbon (Maulina and

Iriansyah, 2018). Figure 1 shows acid and base

activators able to degrade organic matter that is

present on the surface of carbon and also release

volatile materials. The lowest volatile matter

produced by coal activated by HCl is 8.85% while

the highest volatile matter produced by coal

activated by NaOH is 10.61%. Refers to Indonesian

National Standard (SNI 06-3730-1995), max. 25%

volatile matter allowed.

The fixed carbon of low-rank coal was 31.55%,

it has increased after the activation process to 71.08

– 74.2%. This can be seen in Figure 1. The increased

in fixed carbon was due to decrease in moisture

content and volatile matter of activated carbon.

Refers to Indonesian National Standard (SNI 06-

3730-1995), allowable fixed carbon of min. 65%.

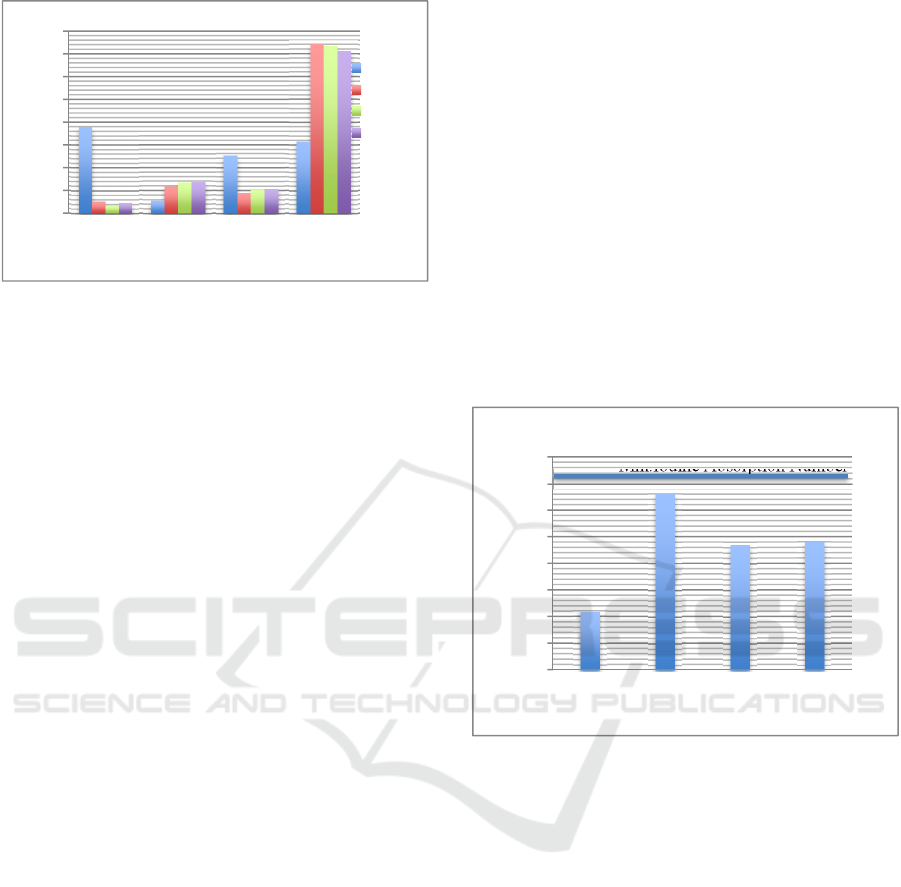

Figure 2: Iodine Absorption Number of Low-Rank Coal at

Initial Condition and After the Activation Process with

Different Activators.

The iodine adsorption number reflected the

adsorption per-formance of activated carbon, as

shown in Figure 2. It tends to increase from 215.75

mg/g to 469.53 mg/g – 660.40 mg/g. The iodine

absorption number of H

3

PO

4

and NaOH activators is

lower than HCl because some of minerals element

such as sodium (Na) in NaOH is absorbed in the

pores of activated carbon. It causes the micropore

structure that has been formed to be covered again

by the Na element, thereby reducing the absorption

capacity of activated carbon. The highest iodine

absorption number were obtained by using HCl

activators was 660.40 mg/g. Refers to Indonesian

National Standard (SNI 06-3730-1995), allowable

iodine adsorption number of min.750 mg/g. The

iodine absorption number of activated carbon in this

research still below the standards referred to.

0

10

20

30

40

50

60

70

80

Persentage, %

Parameters

Initial

HCl

H3PO4

NaOH

Moisture Ash Vol.Matter Fixed Carbon

0

100

200

300

400

500

600

700

800

Initial HCl H3PO4 NaOH

Iodine Absorption Number, mg/g

Initial and with Activators

Min.Iodine Absorption Number

ASAIS 2019 - Annual Southeast Asian International Seminar

180

4 CONCLUSIONS

1. Activation of low-rank coal of East

Kalimantan was evaluated by taking

different activators. The best result

were

obtained by using HCl with activated

carbon characteristics such as a moisture

content, ash content, volatile matter, fixed

carbon and iodine absorption number

respectively as follows 5.23%, 11.72%,

8.85%, 74.2% and 660.40 mg/g.

2.

Ash content and iodine absorption number

still below the standards referred to

Indonesian National Standard (SNI 06-

3730-1995).

ACKNOWLEDGEMENTS

The authors would like to acknowledge the

Department of Chemical Engineering, Polytechnic

State of Samarinda and PT.Sucofindo Samarinda for

the Proximate and Iodine Adsorption Number

Analysis.

REFERENCES

Bilal Khalid et.al., 2016. Effects of KOH Activation on

Surface Area, Porosity and Desalination

Performance

of Coconut Carbon Electrodes. Desalination and

Water Treatment Journal

57. pp. 2195–2202.

Demirbas, A., 2007. Utilization of Coal as a Source of

Chemical. Energy Sources : Part A : Recovery,

Utilization Environmental Effects. Sila Science,

Universite Mahallesi Trabzon, Turkey.

Dong-Su Kim, 2004.

Activated Carbon from Peach

Stones Using Phosphoric

Acid Activation at Medium

Temperatures.

Journal of Environmental Science

and Health Part A—Toxic/Hazardous Substances

& Environmental Engineering

Vol. A39. No. 5. pp.

1301–1318.

Department of Environmental Science

and Engineering

.

Ewha Womans University.

Korea.

Departemen Perindustrian dan Perdagangan, 2003. Syarat

Mutu dan Uji Arang Aktif SNI No. 06-3730-1995.

Balai Perindustrian dan Perdagangan.

Erawati and Fernando, 2018. Pengaruh Jenis Aktivator

dan Ukuran Karbon Aktif Terhadap Pembuatan

Adsorbent dari Serbuk Gergaji

kayu Sengon

(Paraserianthes Falcataria). Jurnal Integrasi Proses

Vol. 7. pp.

58-66. Unversitas Muhammadiyah

Surakarta.

Fen Li, Bo Yan, Yanping Zhang, Linhuan Zhang and Tao

Lei, 2014. Effect of activator on the structure and

desulphurization efficiency of sludge-activated carbon.

Environmental Technology. 35:20. pp. 2575-2581.

Kusdarini, E., Budianto, A. and Ghafarunnisa, 2017.

Produksi Karbon Aktif dari Batubara Bituminus

dengan Aktivasi Tunggal H

3

PO

4

, Kombinasi H

3

PO

4

-

NH

4

HCO

3

, dan Termal. Jurnal Reaktor UNDIP.

Maulana, G.G.R., Agustina, L. and Susi, S., 2017. Proses

Aktivasi Arang Aktif dari

Cangkang Kemiri

(Aleurites Moluccana) dengan Variasi Jenis dan

Konsentrasi Aktivator Kimia. Universitas Lambung

Mangkurat, Teknik

Industri Pertanian.

Maulina, S. and Iriansyah, M., 2018. Characteristics of

Activated Carbon Resulted From Pyrolysis of The Oil

Palm Fronds Powder. Universitas Sumatra Utara.

Teknik Kimia.

Muthusamy Karthikeyan, Wu Zhonghua and Arun S.

Mujumdar, 2009. Low-Rank Coal Drying

Technologies. Current Status and New Developments,

Drying Technology: An International Journal. 27:3. pp.

403-415.

Pehlivan, E. and Cetin, S., 2008. Application of Fly Ash

and Activated Carbon in the Removal of Cu

2+

and

Ni

2+

Ions from Aqueous Solutions. Energy Sources,

Part A: Recovery, Utilization, and Environmental

Effects. 30:13. pp. 1153-1165.

Rahim, M. and Indriyani, O.S., 2010. Pembuatan

Karbon Aktif dari Batubara Peringkat Rendah.

Jurnal Teknologi Media Perspektif. pp. 40-44.

Shawabkeh, R.A., Al-Harthi and Al-Ghamdi, 2014. The

Synthesis and Characterization of Microporous,

High

Surface Area Activated Carbon from Palm Seeds.

Energy Sources. Part A. 36:93–103.

Speight, J.G., 1994. The Chemistry and Technology of

Coal. Marcel Dekker. Inc. New York.

Tsai, et al., 2001. Characterization of Activated Carbons

Prepared From Sugarcane Bagasse By ZnCl

2

Activation. J.Environ.Sci.Health. B36(3). pp. 365 –

378.

Characterization of Activated Carbon Prepare from Low-rank Coal of East Kalimantan by using Acid and Base Activation

181