A Comparative Study between Wild and Cultivated Varieties of

Adlay Grains for Some Engineering Properties

Raden Cecep Erwan Andriansyah, Dadang D. Hidayat, Seri Intan Kuala, Rohmah Luthfiyanti,

Diki Nanang Surahman and Ashri Indriati

Research Centre for Appropriate Technology, Indonesian Institute of Sciences Jl. KS. Tubun No. 5 Subang,

West Java, Indonesia

Keywords: Adlay Grains, Physical Properties, Mechanical Properties, Angle of Repose, Colour.

Abstract: This study was carried out to complement the database of wild and cultivated Adlay grain varieties and to

identify the similarities and differences between them. Results of the analyses determined that regarding the

polar diameter (D

p

), thickness (T), and coefficient of contact surface (C

cs

), there were not any significant

differences between wild and cultivated varieties (p>0.05); Otherwise there were significant differences on

the properties of equatorial diameter (D

e

), geometric mean diameter (D

gm

), arithmetic mean diameter (D

am

),

frontal surface area (A

fs

), transverse area A

t

), sphericity (ø), shape index I

s

), mass (M), volume (V), particle

density (ρ

p

), bulk density (ρ

b

), and porosity (ε ) (p<0.05). In term of shape, the wild variety tended to be

widened, while the cultivated variety tended to be lengthwise. Based on hardness and stickiness, the wild type

was harder and stickier than the cultivated ones. The emptying angle of repose, filling angle of repose and the

static friction of cultivated variety was relatively higher than that of the wild type. The mean total colour

difference between the wild and cultivated variety was 6.952 ± 0.011.

1 INTRODUCTION

Adlay (Coix lacryma-jobi L. ) is a broad-leaved,

branched grass, a grain-bearing tropical plant of the

family Poaceae. It is indigenous to China but also

cultivated widely in many other Asian countries such

as Philippine, Burma, Sri Lanka and Thailand

(Bender, 1999). According to the previously

published paper (LIPI, 1986), in Indonesia, there are

four varieties of Adlay, namely Agrotis, Ma-yuen,

Palustris and Aquatic which is then categorised into

wild and cultivated types. The grain size of the wild

type usually is about 1 cm in diameter with the form

of roundish, whereas that of the cultivated variety

usually exceeds 2 cm in diameter with the shape of

spheroidal (Arora, 1977). The wild type ( Coix

lacryma-jobi var. lacryma-jobi) has a hard shell,

stony, unbreakable by hand, shining and has various

colours and is often used as ornamental beads for

making rosaries necklaces, and other objects,

Whereas the cultivated types, have a soft shell,

breakable, coarse, not shining, bold and is used as

folk medicine and foodstuffs (Arora, 1977; J.A Duke,

1985).

As medicine Adlay grains are often used as an

antipyretic anodyne, anti-inflammatory, antiseptic,

antispasmodic, hypotensive, hypoglycemic, sedative

and vermifuge, antirheumatic, diuretic, pectoral,

refrigerant and tonic (J.A.Duke, 1985; Chopra, 1986).

The tea from the boiled seeds is used as part of a

treatment to cure warts (Brooklyn Botanical Garden,

1986) and is also used in the treatment of lung

abscess, lobar pneumonia, appendicitis, rheumatoid

arthritis, diarrhoea, oedema and painful urination

(H.Yeung, 1985).

As a stuffed food Adlay grains offer many

opportunities for utilisation in diversified product

such as for soups, porridge, drinks and pastries

(Waraluck, 2007), it was reported that per 100 g,

Adlay grains contain about 380 calories, 11.2 g H2O,

15.4 protein, 6.2 g fat, 65.3 g total carbohydrate, 0.8

g fibre, 1.9 gram ash, 25 mg Ca, 435 mg P, 5.0 mg

Fe, 0.28 mg thiamine, 0.19 mg riboflavin, 4.3 mg

niacin and 0 mg ascorbic acid (Kumar et.all, 2014).

Machine and equipment designing, handling,

harvesting, processing and storing of grains, requires

physical and mechanical properties. The properties of

various grains have been determined by other

researchers, such as finger millet (Ramashia et.all,

104

Andriansyah, R., Hidayat, D., Kuala, S., Luthfiyanti, R., Surahman, D. and Indriati, A.

A Comparative Study between Wild and Cultivated Varieties of Adlay Grains for Some Engineering Properties.

DOI: 10.5220/0010001000002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 104-113

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2018), Kumquat fruits (Jaliliantabar et. all, 2013)],

Coffee fruits (Dario et. all, 2012), Russian olive

fruits (Dario et.all, 2012), tiger nut (Abano, 2011),

Almonds (Loghavi et. all, 2011), finger millet

(Swami, 2010), paddy grains (Zareiforoush, 2009),

Jatropha curcas (Shkelqim, 2008), Date fruit

(Keramat, 2008), and Sesame Seeds (Akintunde,

2004), cocoa beans (Plange and Baryeh, 2003), cumin

seeds (Singh, 1996), and karinga seeds Suthar and

Das, 1996). Concerning the Adlay grain, there is still

lacking information about the physical, mechanical

and colour properties; therefore the study aimed to

characterise the physical, mechanical and colour

properties to complement the database of two Adlay

grain varieties.

2 MATERIALS AND METHODS

The study was taken place in Research Center for

Appropriate Technology, Indonesian Institute of

Sciences, Subang- West Java. The wild type of Adlay

grains samples was taken from Cigadung village

(Latitude 6

0

33’27” S, Longitude 107

0

45’45” E, and

elevation 87 MAMSL), Subang subdistrict, Subang

district, West Java province; and the cultivated type

of Adlay grains samples were taken from Sukajadi

village (Latitude 6

0

59’26” S, Longitude

108

0

06’32”E) , Wado subdistrict, Sumedang district,

West Java province. The measurement of engineering

properties included physical, mechanical and the

colour was conducted at a moisture content of 10.74

% (wb) for wild type and 10.93 % for the cultivated

variety of Adlay grains. The instrument used to

measure the physical properties comprised of digital

vernier calliper, digital balance, analytical balance,

and baker glass. The apparatus used to measure the

mechanical properties was the TA- XT plus Texture

Analyser Stable Micro System and apparatus for

measuring friction, emptying and filling angle of

repose. The colour was observed using colourimeter

NH 310. The collected data were statistically

analysed to assess the minimum, maximum, means,

standard deviation and means were compared using

paired sample t-test.

2.1 Measurement of Physical

Properties

The measurement of physical properties covered

polar diameter (D

p

), equatorial diameter (D

e

),

thickness (T), geometric mean diameter (D

gm

),

arithmetic mean diameter (D

am

), frontal surface area

(A

fc

), transverse area (A

t

), coefficient of contact

surface (C

cs

), shape index (I

s

), sphericity (ø), mass

(M), volume (V), particle density (ρ

p

), bulk density

(ρ

b

), and porosity (ε). Population number of each type

of the sample was 30, except for bulk density the

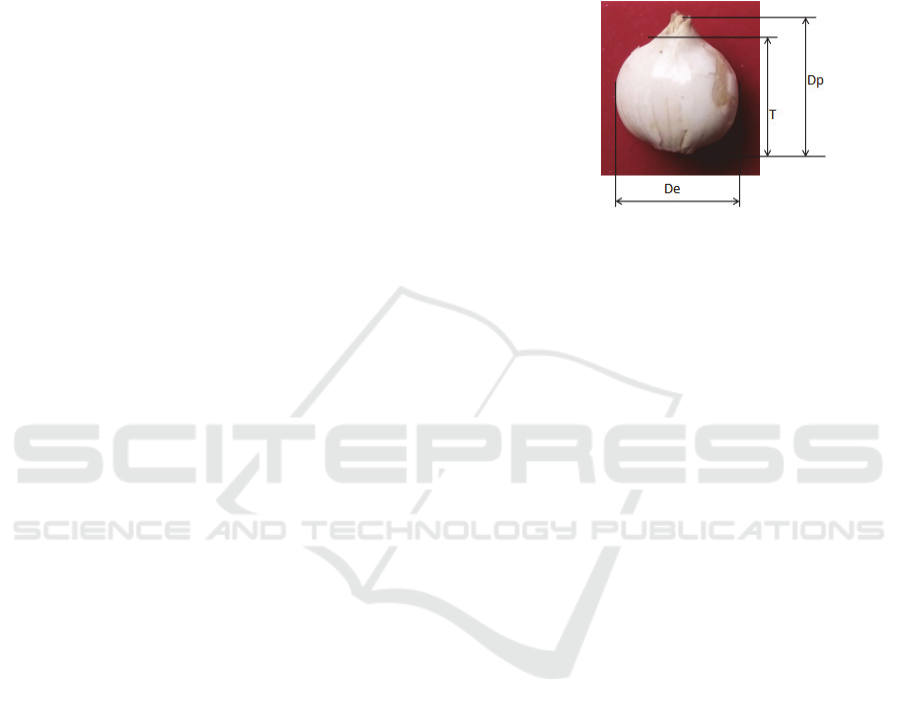

measurement was performed for ten samples. Figure

1 showed the measurement position of polar and

equatorial diameter and thickness of Adlay grains.

Figure 1: Position of Polar diameter, equatorial diameter

and thickness of Adlay grains.

Knowledge of physical characteristics which

composed of sphericity, shape index, polar diameter,

equatorial diameter, surface area, porosity and colour

are essential parameters in designing of the specific

machine and analysing the behaviour of the product

in the handling of materials. The frontal and

transverse area is used to determine the coefficient of

contact surface which is an important parameter to

evaluate the contact surface between the Adlay grain

and the other surfaces such as milling machine

surfaces (El Gendy, et .all, 2011) The grain of Adlay

is considered as an oval if the value of the shape index

is more than 1.50 and as a spherical if that less than

1.50 (El Gendy, et .all, 2011; Bahnasawy et. all, 2004

; Kaveri, 2015)

Density is required in a separation process such as

hulling, quality evaluation, and also in the

determination of thermal diffusivity in heat transfer

problems (Zareiforoush, 2009). The geometric mean

diameter, arithmetic mean diameter, frontal surface

area, transverse area, cross-sectional area, shape

index, sphericity, porosity, volume, particle density

and bulk density were derived by using the following

equations given by Mohsenin (Ramashia et.all, 2018)

and had been used by other researchers (El Gendy, et.

all, 2011; Bahnasawy et. all, 2004 ; Kaveri, 2015;

Mohsenin et.all, 1986; Ismail et. all, 2014; Marioti et.

all, 2006).

A Comparative Study between Wild and Cultivated Varieties of Adlay Grains for Some Engineering Properties

105

2.2 Measurement of Mechanical

Properties

The properties of mechanical measured consisted of

hardness, stickiness, emptying angle of repose, filling

angle of repose and friction. The number of each

samples type was 5 for hardness and stickiness, 10 for

filling angle of repose, emptying angle of repose and

static friction, and 3 for colour analyses. The hardness

and stickiness were measured using TA- XT plus

Texture Analyser Stable Micro System. The hardness

is an essential parameter in designing milling

machine (Jesukristina et. all, 2015).

The angle of repose is an essential parameter in

predicting flow characteristics, for inventorying grain

and designing bins and grain handling systems

(Zareiforoush, 2009; Bhadra,,2016; Tarighi, 2011;

Hamzah, 2018). There are to types of the angle of

repose, i.e. emptying and filling. The emptying angle

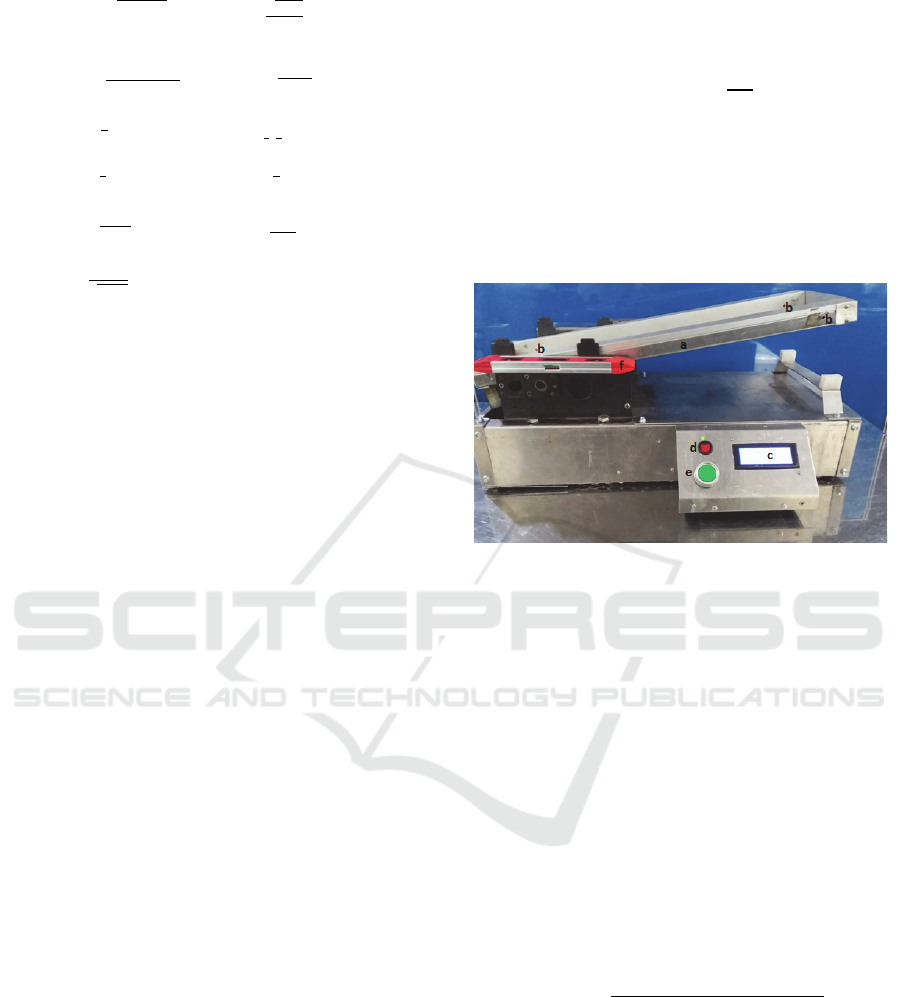

of repose was measured using an electrically inclined

plane supported by the sensor; Figure 2 showed the

apparatus for measuring the emptying angle of

repose. The emptying angle of repose and static

friction coefficients were determined to four surfaces,

i.e., stainless steel, aluminium, acrylic and plywood.

The static friction (μ) was calculated by using the

following equation (Zareiforoush, 2009; Plange,

et.all, 2003; Singh, 1996)

μ = tan θ

e

The filling angle of repose was determined by

using a PVC of 100 mm diameter and 100 mm height.

The PVC cylinder was placed on four types of

surfaces, i.e. stainless steel, aluminium, acrylic and

plywood; the filled PVC was raised until it formed the

cone and the mean diameter (D) and height of pile (H)

were recorded to calculate the filling angle of repose.

The following formula was employed to determine

the filling angle of repose (Zareiforoush, 2009,

Tarighi, 2011; Hamzah, 2018).

𝜃

tan

2𝐻

𝐷

Where:

θe: Emptying angle of repose

θf: Emptying angle of repose

H: Height of cone

D: Diameter of the cone

μs: Static Friction

Figure 2: The angle of repose measuring instrument.

(a: Adjustable Plane, b: Sensor 4 units; c: Display;

d: ON/OFF Button; e: Start button, f: Water level).

2.3 Colour

The colour of wild and cultivated Adlay grains

samples was determined using a colourimeter NH

310. The analysis methods used were CIE

(Commission Internationale de L'Eclairage) L* a* b*

and CIE L* c* h* coordinates (Ruiz et.all, 2012) The

value of L*, a* b* and L* c* h*obtained was used to

determine the total colour difference between each

group of samples; the measurements were performed

on three-grain samples which randomly taken from

each type of Adlay grains samples. The entire colour

difference was calculated using the following

equation (Ruiz et.all, 2012; Pathare et.all, 2013)

ΔE*

A-B

=

ΔL

∗

Δa

∗

Δb

∗

The colour of the sample principally can be

described using three specific qualities of visual

sensation, i.e. tonality, luminosity, and chromatism.

Tonality (h*) is the characteristics of the colour, i.e.

red, yellow, green, and blue. The clarity is the

attribute of the visual sensation according to the

appearance of the sample whether less or more

luminous. The chromatism (c*) is the level of colour

D

gm

D

e

D

p

T

3

D

am

D

e

D

p

T

3

A

fs

π

4

D

e

D

p

A

t

π

4

T D

e

C

cs

𝐴

𝑓𝑠

𝐴

𝑡

𝐴

𝑓𝑠

x 100

I

s

D

e

D

p

T

2

Ø

D

e

D

p

T

3

D

e

ε

𝝆

𝑝

𝝆

𝑏

𝜌

𝑝

100 %

V =

1

4

[

𝜋

6

D

p

(D

e

+t)

2

]

ρ

p

M

v

ρ

b

M

v50 0

V

500

16th AFC 2019 - ASEAN Food Conference

106

related to a lower or higher intensity of the colour.

Coordinate L* represents the clarity, in which L=0 is

black, and L*= 100 is colourless. Coordinate a*

represents the shade of red and green, in which a*> 0

indicates red colour and a*< 0 indicates green colour.

Coordinate b* represents the tone of blue and yellow,

in which b*> 0 shows the intensity of yellow and b*<

0 means the hue of blue. The total colour difference

(ΔE*) is the difference between the two colours of the

samples

3 RESULTS AND DISCCUSSION

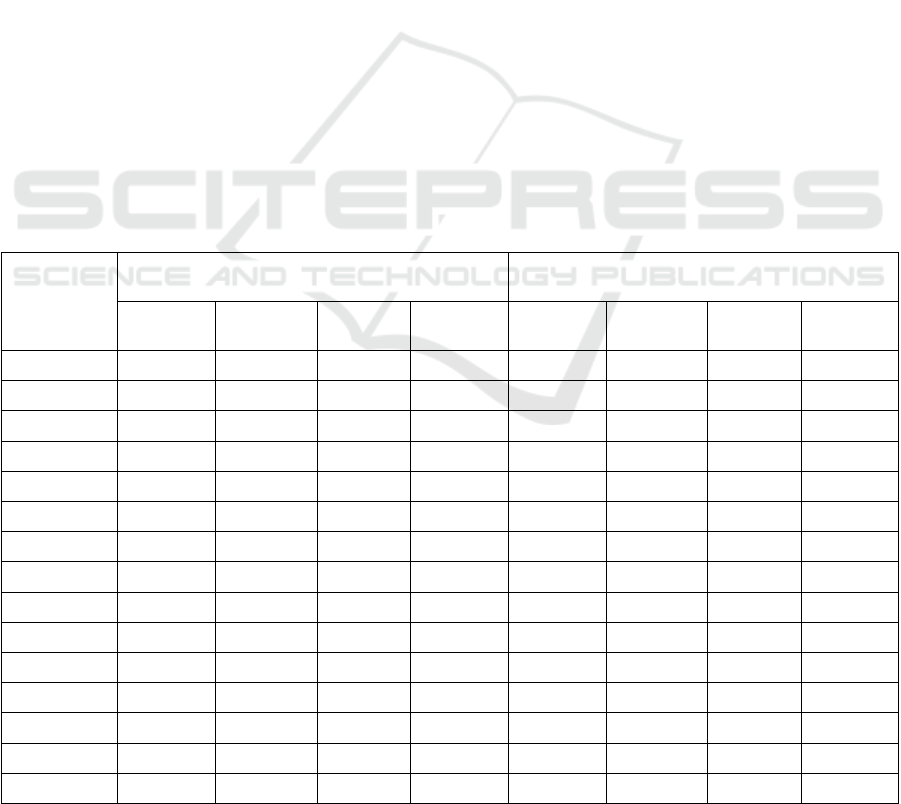

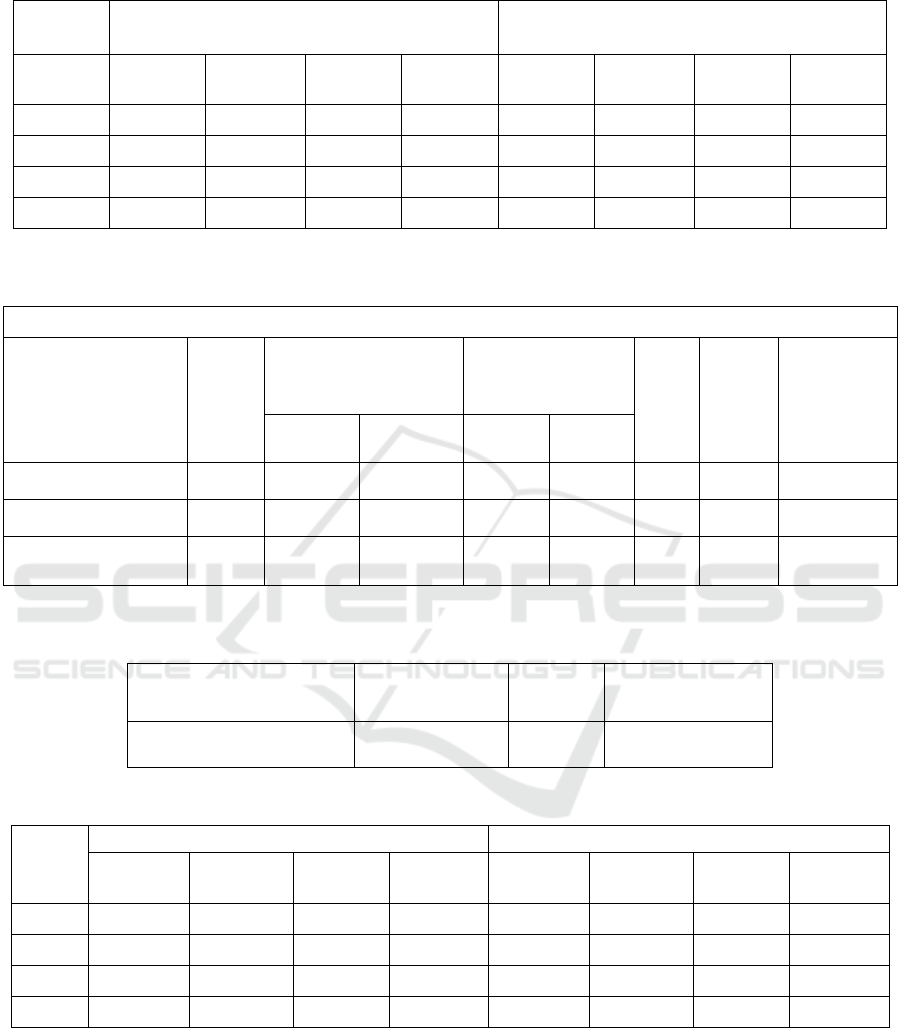

Table 1 showed the minimum, maximum, average

and standard deviation of wild and cultivated varieties

of Adlay grains. The polar diameter of wild and

cultivated varieties ranged from 9.40 ± 0.35 mm and

9.42 ± 1.67 mm respectively and the equatorial

diameter of those ranged from 8.32 ± 0.30 and 7.02 ±

0.38 mm respectively; it meant that the shape of wild

Adlay variety tended to be widened, whereas that of

cultivated ones tended to be lengthwise. The density

of wild type was more significant than that of

cultivated ones; these results were found to be in close

agreement with the past researchers (Jesukristina et.

all, 2015; Gruben and Partohardjono, 1996; Agripina

et.all. 2018). The porosity associated inversely with

the sphericity; the higher the sphericity, the smaller

the porosity.

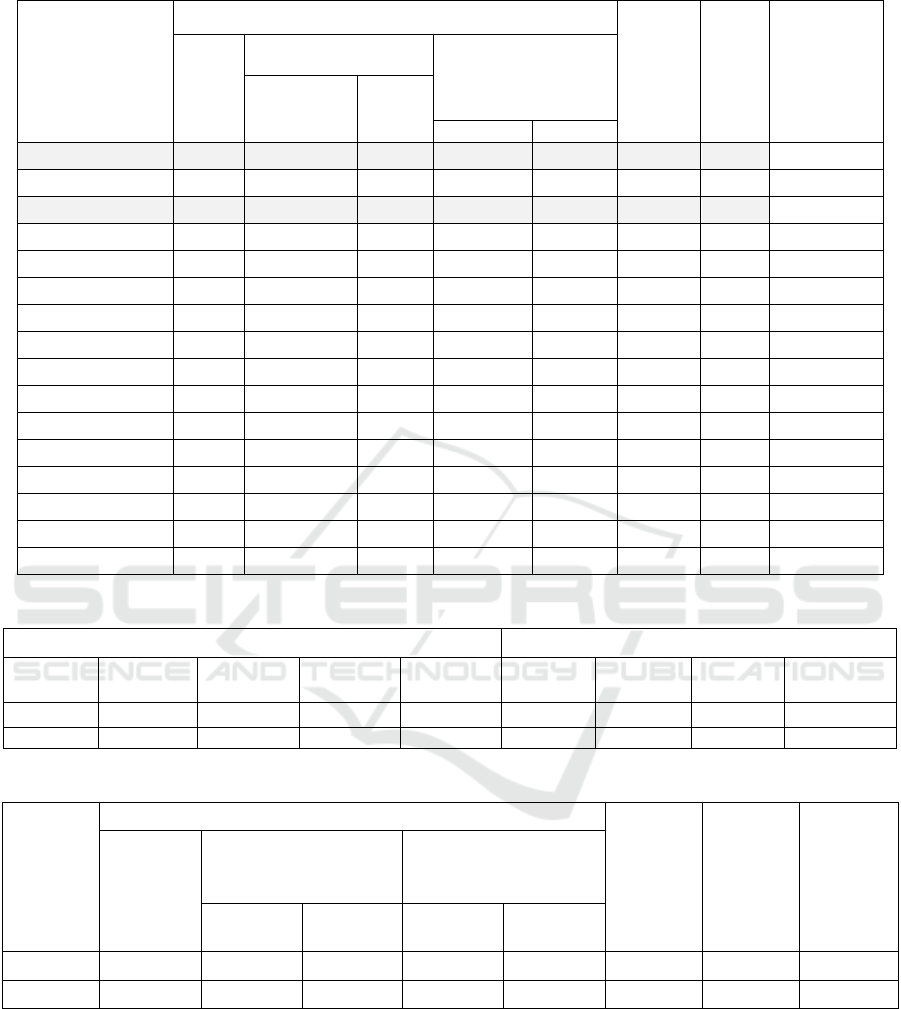

In term of polar diameter (D

p

), thickness (T), and

coefficient of contact surface (C

cs

), table 2 showed

that results of paired sample t-test analysis

determined that there were not any significant

differences between wild and cultivated varieties

(p>0.05); Otherwise there were significant

differences on the properties of equatorial diameter

(D

e

), geometric mean diameter (D

gm

), arithmetic

mean diameter (D

am

), frontal surface area (A

fs

),

transverse area At), sphericity (ø), shape index I

s

),

mass (M), volume (V), particle density (ρ

p

), bulk

density (ρ

b

), and porosity (ε ) (p<0.05).

Table 2 showed the hardness and stickiness of

wild and cultivated varieties of Adlay grain. Results

of measurement indicated that the hardness of wild

type was relatively stronger than that of cultivated

ones, as well as for stickiness. The average hardness

of wild variety was about eight times compared to that

of cultivated ones; it meant that the wild type was

stony, in the other hand the cultivated variety was

breakable. This result was found under that of the

earlier researchers (Jesukristina, 2015); Grubben and

Partohardjono, 1996).

Table 1: Physical properties of wild and cultivated varieties of Adlay grain.

Physical

Properties

WILD CULTIVATED

Minimum Maximum Mean

Std.

Deviation

Minimum Maximum Mean

Std.

Deviation

D

p

8.71 10.14 9.40 0.35 7.51 17.30 9.42 1.67

D

e

7.59 8.85 8.32 0.30 6.12 7.88 7.02 0.38

T

6.05 8.71 10.14 0.41 6.02 8.38 7.18 0.53

D

gm

7.76 7.59 8.85 0.25 6.81 8.97 7.77 0.48

D

am

7.82 8.83 8.32 0.25 6.87 10.08 7.87 0.61

A

fs

54.93 68.48 61.41 3.37 39.39 94.11 51.95 9.73

A

t

38.85 55.37 47.34 3.75 30.30 48.68 39.60 4.19

C

cs

12.06 35.84 22.87 5.09 12.25 65.20 22.35 9.40

ø

0.82 0.95 0.88 0.03 1.01 1.29 1.11 0.06

I

s

0.81 0.97 0.89 0.04 0.40 0.90 0.76 0.09

M

0.24 0.38 0.33 0.04 0.08 0.12 0.10 0.01

V

0.26 0.37 0.32 0.03 0.17 0.38 0.25 0.05

ρ

p

0.86 1.23 1.03 0.10 0.30 0.58 0.42 0.08

ρ

b

0.53 0.61 0.58 0.02 0.20 0.31 0.29 0.03

ε

33.70 49.79 42.21 5.99 19.60 46.74 33.82 9.06

A Comparative Study between Wild and Cultivated Varieties of Adlay Grains for Some Engineering Properties

107

Table 2: Physical properties comparison between wild and cultivated of Adlay grains.

Pairs

Paired Differences

t df

Sig

(2-tailed)

Mean

Standard

95% Confidence

Interval of the

Difference

Deviation

Error

Mean

Lowe

r

U

pp

e

r

D

pw

- D

pc

-0.02 1.66 0.30 -0.64 0.60

-0.08 29.00 0.94

D

ew

- D

ec

1.31 0.41 0.07 1.15 1.46

17.44 29.00 0.00

t

w

- t

c

0.06 0.72 0.13 -0.21 0.33

0.46 29.00 0.65

D

gmw

- D

gmc

0.50 0.49 0.09 0.31 0.68

5.59 29.00 0.00

D

amw

- D

amc

0.45 0.60 0.11 0.22 0.67

4.11 29.00 0.00

A

sw

- A

sc

24.41 24.04 4.39 15.43 33.39

5.56 29.00 0.00

A

fsw

- A

fsc

9.47 9.26 1.69 6.01 12.92

5.60 29.00 0.00

A

tw

-A

tc

7.75 5.55 1.01 5.67 9.82 7.64 29.00 0.00

C

scw

-C

scc

0.52 11.38 2.08 -3.73 4.77 0.25 29.00 0.80

ø

w

- ø

c

-0.23 0.07 0.01 -0.25 -0.20

-17.85 29.00 0.00

I

sw

- I

sc

0.13 0.10 0.02 0.09 0.17

6.76 29.00 0.00

M

w

- M

c

0.23 0.04 0.01 0.21 0.24

33.84 29.00 0.00

V

w

- V

c

0.07 0.05 0.01 0.05 0.09

7.75 29.00 0.00

ρ

pw

- ρ

pc

0.62 0.13 0.02 0.57 0.67

25.87 29.00 0.00

ρ

bw -

ρ

bc

0.29 0.04 0.01 0.27 0.32

23.37 9.00 0.00

ε

w

- ε

c

0.08 0.11 0.04 0.00 0.16

2.32 9.00 0.05

Table 3: Hardness and stickiness of wild and cultivated varieties of Adlay grain.

WILD CULTIVATED

TA-

Profile

Minimum Maximum Mean

Std.

Deviation

Minimum Maximum Mean

Std.

Deviation

Hardness 28466.73 40546.65 35584.70 4966.19 3544.07 5049.88 4426.05 614.97

Stickiness -5.40 -3.64 -4.5300 0.63 -1.29 -0.94 -1.15 0.13

Table 4: Hardness and stickiness comparison between wild and cultivated varieties of Adlay grain.

Pairs

Paired Differences

t df

Sig

(2-tailed)

Mean

Standard

95% Confidence

Interval of the

Difference

Deviation

Error

Mean

Lower Upper

H

w

-H

cul

31158.65 4594.85 2054.88 25453.38 36863.91 15.16 4.00 0.00

S

w

-S

cul

-3.38 0.75 0.34 -4.31 -2.44 -10.03 4.00 0.00

Results of paired sample t-test analysis which

could be seen in table 4, determined that there were

significant differences of hardness and stickiness

between wild and cultivated varieties (p<0.05).

Table 5 showed the emptying angle of repose on

a different type of surfaces. The highest angle of

repose occurred on the surface of plywood;

otherwise, the smallest of that happened on the

aluminium surface.

Results of paired sample t-test analysis, which

could be seen in table 6, showed that there were not

any significant differences of emptying angle of

repose on aluminium and acrylic surfaces of wild and

cultivated

varieties (p>0.05); otherwise, there was

16th AFC 2019 - ASEAN Food Conference

108

Table 5: The emptying angle of repose of wild and cultivated varieties of Adlay grains on a different type of surfaces.

WILD CULTIVATED

Minimum Maximum Mean

Std.

Deviation

Minimum Maximum Mean

Std.

Deviation

θ

eSS

28,10 34,02 31,56 1,94 29,60 35,52 33,06 1,94

θ

eAL

28,10 38,28 31,42 2,84 28,89 37,18 34,12 2,77

θ

eACRY

29,28 36,86 32,62 1,99 29,13 39,31 33,96 2,84

θ

ePLYWD

32,13 39,23 35,80 2,26 35,52 50,91 41,17 4,01

Table 6: The emptying angle of repose comparisons between wild and cultivated of Adlay grains on the surface of aluminium,

acrylic and plywood.

Paired Differences

Pairs Mean

Standard

95% Confidence

Interval of the

Difference

t df

Sig

(2-tailed)

Deviation

Error

Mean

Lower Upper

θ

eALW

- θ

eALCUL

-2.70 4.35 1.37 -5.82 0.41 -1.97 9.00 0.08

θ

eACRYW

- θ

Eacryw CUL

-1.33 3.56 1.13 -3.88 1.22 -1.18 9.00 0.27

θ

ePLYWDW

- θ

ePLYWD

CUL

-5.37 4.00 1.26 -8.23 -2.51 -4.25 9.00 0.00

Table 7: The emptying angle of repose comparisons between wild and cultivated of Adlay grains on the surface of stainless

steel.

Chi-Square df Asymp. Sig.

θ

eSS

W

- θ

eSS

CUL

0.800 8 0.999

Table 8: Filling angle of repose of wild and cultivated varieties of Adlay grains on a different type of surfaces.

WILD CULTIVATED

Minimum Maximum Mean

Std.

Deviation

Minimum Maximum Mean

Std.

Deviation

θ

fSS

68.29 73.38 70.88 1.52 73.06 77.83 75.75 1.37

θ

fAL

65.51 72.80 70.53 2.35 74.22 78.83 76.40 1.56

θ

fACRY

70.76 74.76 73.06 1.35 75.30 79.41 76.90 1.43

θ

fPLYWD

68.50 73.55 71.79 1.63 75.77 79.00 77.71 0.89

a considerable difference of that on the surface of

plywood (p<0.05).

Results of Chi-square analysis of emptying angle

of repose on the stainless steel surface for wild and

cultivated varieties as could be seen in table 7, did not

show any significant difference (p>0.05).

Table 8 showed that the highest a filling angle of

repose occurred on the surface of plywood;

otherwise, the smallest of that happened on the

surface stainless steel.

The result of paired sample t-test as shown in Table

9 indicated that there were significant differences

A Comparative Study between Wild and Cultivated Varieties of Adlay Grains for Some Engineering Properties

109

Table 9: Filling angle of repose comparisons between wild and cultivated of Adlay grains.

Pairs

Paired Differences

t df

Sig

(2-tailed)

Mean

Standard

95% Confidence

Interval of the

Difference

Deviation

Error

Mean

Lower Upper

θ

fSS W

- θ

fSS CUL

-5.87 2.89 0.91 -7.94 -3.80 -6.43 9.00 0.00

θ

fal W

– θ

fal CUL

-4.87 2.23 0.71 -6.46 -3.27 -6.90 9.00 0.00

θ

facry W –

θ

facry CUL

-5.92 1.16 0.37 -6.75 -5.09 -16.14 9.00 0.00

θ

fplywd W

– θ

fplywd CUL

-3.84 1.80 0.57 -5.13 -2.55 -6.72 9.00 0.00

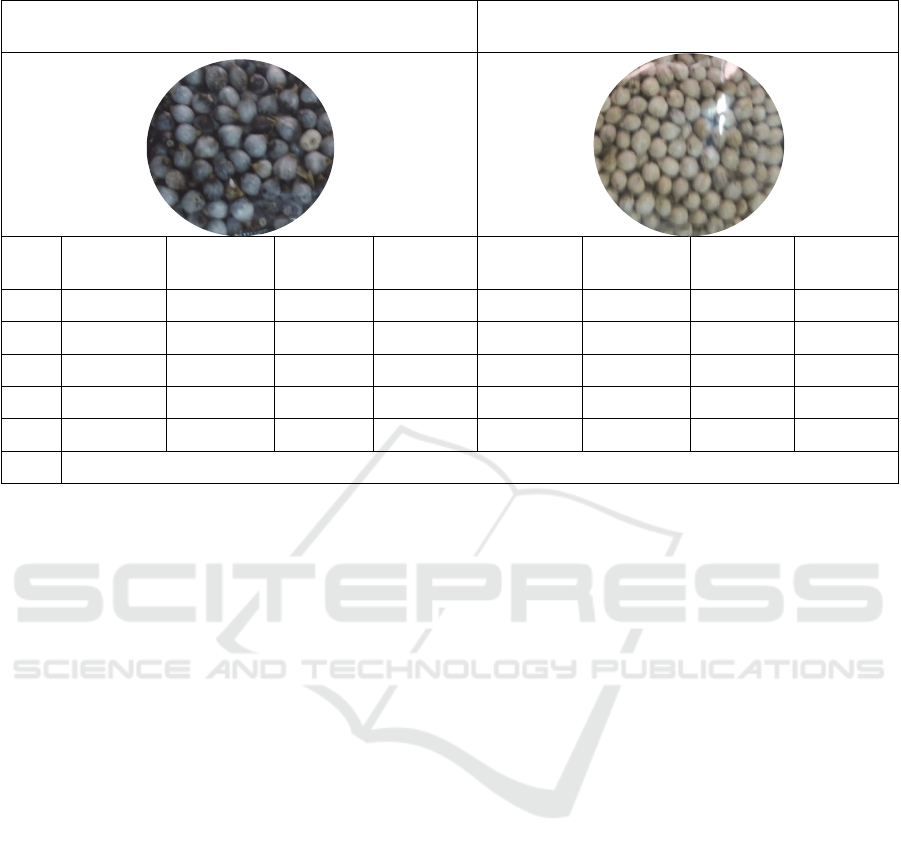

Table 10: The friction of wild and cultivated varieties of Adlay grains on a different type of surfaces.

WILD CULTIVATED

Minimum Maximum Mean

Std.

Deviation

Minimum Maximum Mean

Std.

Deviation

μ

SS

0.53 0.68 0.62 0.05 0.57 0.71 0.66 0.05

μ

AL

0.53 0.79 0.61 0.07 0.55 0.76 0.69 0.07

μ

ACRY

0.56 0.75 0.64 0.05 0.56 0.82 0.66 0.08

μ

PLYW

0.63 0.82 0.72 0.06 0.71 0.91 0.83 0.05

Table 11: Friction comparisons between wild and cultivated of Adlay grains.

Pairs

Paired Differences

t df

Sig

(2-tailed)

Mean

Standard

95% Confidence

Interval of the

Difference

Deviation

Error

Mean

Lower Upper

μ

SSW

-

μ

SS CUL

-0.04 0.03 0.01 -0.06 -0.02 -4.00 9.00 0.00

μ

ALW

-

μ

AL CUL

-0.07 0.11 0.04 -0.15 0.01 -2.02 9.00 0.07

μ

ACRYW

-

μ

ACRY CUL

-0.02 0.10 0.03 -0.09 0.05 -0.72 9.00 0.49

μ

PLYWW

-

μ

PLYW CUL

-0.11 0.07 0.02 -0.16 -0.06 -4.83 9.00 0.00

between one surface and the others (p<0.05).

Comparisons between emptying and filling angle

of repose on different surfaces, it was found that the

filling angle of repose had a higher value than the

emptying angle of repose.

Table 10 showed the static friction of wild and

cultivated varieties of Adlay grains. As it was

presented in the table, the highest static friction

occurred in the surface of plywood, for both wild and

cultivated varieties; Otherwise, the lowest of that

happened in aluminium surface for wild type, and on

the acrylic surface for cultivated ones.

Result of paired sample t-test as shown in table 11

pointed out that there were significant differences

between wild and cultivated varieties in static friction

on the surfaces of stainless steel and plywood

(p<0.05), on the other hand, there were not any

significant differences of that on the surfaces of

aluminium and acrylic (p>0.05).

16th AFC 2019 - ASEAN Food Conference

110

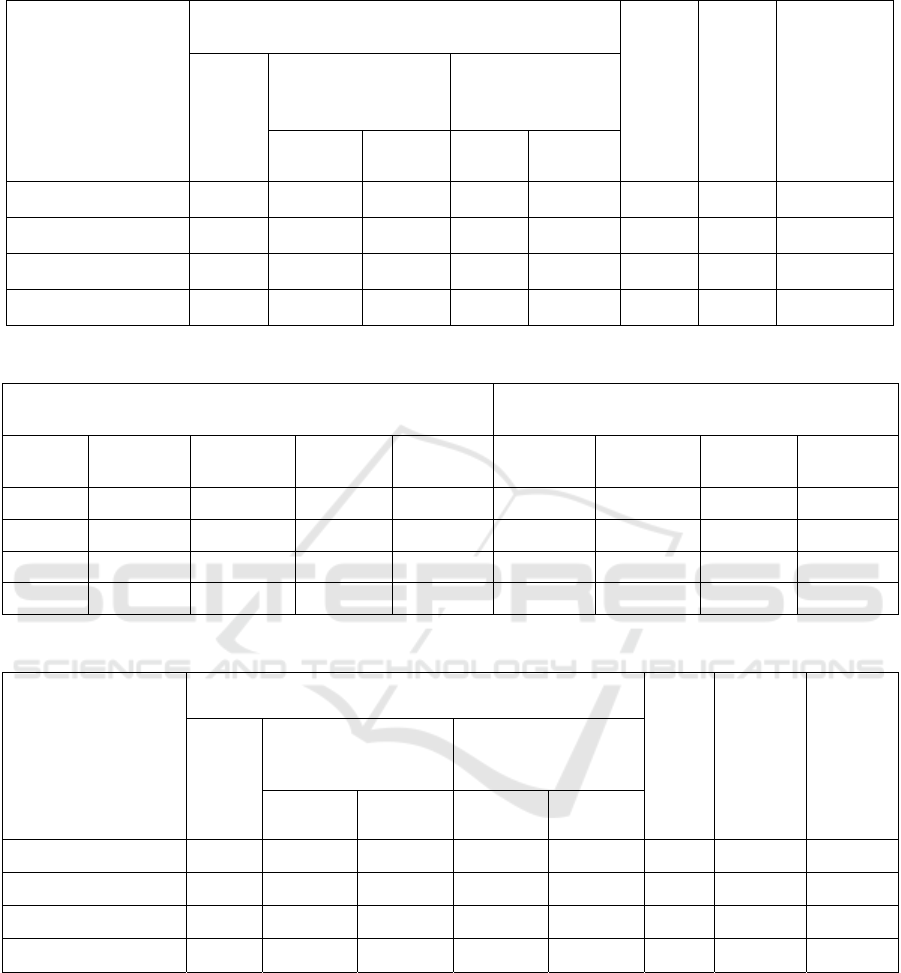

Table 12: Colour of Wild and Cultivated Varieties of Adlay Grains.

WILD CULTIVATED

Minimum Maximum Mean

Std.

Deviation

Minimum Maximum Mean

Std.

Deviation

L* 39.769 39.777 39.773 0.004 41.950 41.953 41.951 0.002

a* 0.015 0.041 0.030 0.013 3.024 3.055 3.037 0.016

b* 0.866 0.894 0.881 0.014 6.749 6.769 6.758 0.010

c* 0.867 0.895 0.882 0.014 7.399 7.414 7.409 0.009

h* 0.000 0.001 0.000 0.000 0.001 0.002 0.001 0.001

ΔE* 6.952 ± 0.011

Visually a wild Adlay was shiny and had a various

colour, i.e. grey, yellow-brownish, purplish and

blackish, while the cultivated one was not shiny and

had a uniform colour of white-brownish. These

findings were relatively under that of the previous

study (Grubben and Partohardjono, 1996). The

geometrical CIE L*a*b*c*h* coordinates of wild

and cultivated Adlay grains were (39.773±0.004;

0.030±0.013; 0.881±0.014; 0.882±0.014;

0.000±0.000) and (41.951±0.002; 3.037±0.016;

6.758±0.010; 7.409±0.009; 0.001±0.001)

respectively. Results of the calculation determined

that the total colour difference between wild and

cultivated variety (ΔE*w-cul) was 6.952±0.011.

4 CONCLUSION

Results of the study found that the polar diameter,

equatorial diameter and thickness of wild Adlay grain

varieties were 9.40 ± 0.35 mm, 8.32 ± 0.30 mm and

7.24 ± 0.41 mm respectively, and those for cultivated

variety were 9.42 ± 1.67 mm, 7.02 ± 0.38 mm, and

7.18 ± 0.53 mm respectively.

There was not any significant difference in the

polar diameter, thickness and coefficient of contact

surface between wild and cultivated varieties of

Adlay grains; otherwise there were significant

differences in equatorial diameter, geometric mean

diameter, arithmetic mean diameter, frontal surface

area, transverse area, sphericity, shape index, mass,

volume, particle density, bulk density and porosity.

The shape of wild Adlay tended to be widened,

whereas that of cultivated ones tended tobe

lengthwise. The particle density, bulk density and

porosity of wild Adlay were bigger than that of

cultivated ones. The particle density, bulk density

and porosity of wild Adlay were 1.03 ± 0.10 gr/cm3,

0.58 ± 0.022 gr/cm3, and 42.21 ± 5.99 %

respectively, and those of cultivated ones were 0.42 ±

0.08 gr/cm3, 0.29 ± 0.03 gr/cm3, and 33.82 ± 9.06 %

respectively.

Concerning the texture profile, the wild Adlay

grain was harder and stickier than the cultivated ones.

The hardness and stickiness for wild Adlay grain

were 35 584.70 ± 4 966.19 g-force and -4.53 ± 0.63

g-forces respectively and those for cultivated ones

were 4 426.05 ± 614 ± 614.97 g-force and -1.15 ±

0.13 g-force respectively. The emptying angle of

repose, filling angle of repose and static friction of

wild Adlay grain was smaller than that of cultivated

ones.

The geometrical CIE L*a*b*c*h* coordinates of

wild and cultivated Adlay grains were

(39.773±0.004; 0.030±0.013; 0.881±0.014;

0.882±0.014; 0.000±0.000) and (41.951±0.002;

3.037±0.016; 6.758±0.010; 7.409±0.009;

0.001±0.001) respectively, and the total colour

different of them was 6.952±0.011.

A Comparative Study between Wild and Cultivated Varieties of Adlay Grains for Some Engineering Properties

111

ACKNOWLEDGMENTS

The authors would like to acknowledge the Research

Centre for Appropriate Technology which provided

facilities in carrying out this study. We would also

like to thank everyone who provided us with

assistance throughout our works. We want to thank

Dadang Gandara, Iman Rusim, Sutrisno, Sukwati,

Neneng K. and S. Khudaifanny for their help in

carrying out this study.

REFERENCES

Agripina R., Aradilla. Phenology, Growth and Yield

Performance of Adlay (Coix lacryma-jobi L.) Grown in

Adverse Climatic Conditions. International Journal of

Research & Review. 2018; 5 (3).

Arora, R. K. Job's-tears (Coix lacryma.jobi) a Minor Food

and Fodder Crop of Northeastern India. ECONOMIC

BOTANY. 1977;31: 358—366.

Bahnasawy A H. Z A El-Haddad. M Y El-Ansary and H M

Sorour. Physical and mechanical properties of some

Egyptian onion cultivars. J. of Food Eng. 2004;62: 255-

261.

Bart-Plange A. and Edward A. Baryeh. The physical

properties of Category B cocoa beans. Journal of Food

Engineering. 2003;60: 219–227.

Bender, D.A., and Bender A.E. Benders’ Dictionary of

Nutrition and Food Technology. Woodhead Publishing,

Abington 1999.

Bhadra, Rumela & Bhadra, R & E. Casada, M &

Thompson, Sidney & Boac, Josephine & Maghirang,

Ronaldo & Montross, Michael & Mcneill, Samuel &

Turner, Aaron. Technical Note: Field-Observed Angles

Of Repose For Stored Grain In The U.S. Applied

Engineering in Agriculture. 2016;33(1): 131-137 2017

American Society of Agricultural and Biological

Engineers ISSN 0883-8542 DOI 10.13031/aea.11894.

Brooklyn Botanic Garden, “Oriental herbs and vegetables”,

1986;39 (2), New York.

Chopra, R. N., S. L. Nayar, and I. C. Chopra, “Glossary of

Indian medicinal plants” (including the supplement),

Council of Scientific and Industrial Research, New

Delhi. 1986.

E.E. Abano and K.K. Amoah, Effect of Moisture Content

on the Physical Properties of Tiger Nut (Cyperus

esculentus). Asian Journal of Agricultural Research.

2011;5:56-66.

DOI: 10.3923/ajar.2011.56.66.URL: https://scialert.net

/abstract/?doi=ajar.2011.56.66

El- Gendy H. A., A. I. Elrayes and SH. F. Abdel-Hammed.

Engineering Properties Of Some Arabian Coffee

Varieties. Egypt. J. Agric. Res., 2011;89 (2), 2011 615.

Engineering Research. 64: 93-98

FAO. Coix lacryma-jobi L. Grassland Species Profiles.

FAO/CIAT Collaboration on Tropical Forages.

http://www.fao.org/ag/AGP/AGPC/doc/Gbase/DATA/

PF000205.HTM.

Grubben, G.J.H. & Soetjipto Partohardjono (Editors). Plant

Resources of South-East Asia No 10. Cereals.

Backhuys Publishers, Leiden. 1996. 199 pp.

H. Yeung, “Handbook of Chinese herbs and formulas”,

Institute of Chinese Medicine, Los Angeles. 1985.

H. Zareiforoush, M.H. Komarizadeh and M.R. Alizadeh.

Effect of Moisture Content on Some Physical

Properties of Paddy Grains. Research Journal of

Applied Sciences, Engineering and Technology.

2009;1(3): 132-139, ISSN: 2040-7467.

Hamzah M. Beakawi Al-Hashemi, Omar S. Baghabra Al-

Amoudi. A review on the angle of repose of granular

materials. Powder Technology. 2018;30: 397–417.

Ismail, L., Anuar, M.S., Shamsudin, R. Physical properties

of liberica coffee (Coffea liberica) berries and beans.

Pertanika J Sci Technol. 2014;22: 65–79.

Iván Darío. I.A.T. José Jaime. C.H. Carlos. E.O.T. Physical

And Mechanical Properties Correlation Of Coffee Fruit

(Coffea Arabica) During Its Ripening. Dyna.

2012.;79(172):148-55.

J. A. Duke and E. S. Ayensu, “Medicinal plants of China”,

Reference Publications, Michigan, 1985.

Jaliliantabar. F. Ali N. L. R. GholamiPhysical properties of

kumquat fruit. International Agrophysics. 2013. DOI:

10.2478/v10247-012-0074-y.

Karaj. Shkelqim*. Huaitalla. Roxana Mendoza. Müller.

Joach. Physical, mechanical and chemical properties of

Jatropha curcas. Open tag Stuttgart-Hohenheim.

Conference on International Agricultural Research for

Development. 2008.

Kaveri. G and Thirupathi. V. Studies On Geometrical And

Physical Properties Of Co 4 Onion Bulb (Allium Cepa

Lvar. Aggregatum Don.). International Journal of

Recent Scientific Research. . 2015;6(3): 2897.

Keramat JM. Rafiee S. Jafari A. Ghasemi Bousejin MR.

Mirasheh R. Mohtasebi SS. Some physical properties

of date fruit (cv.Dairi). Int Agrophys. 2008;22:221–224.

Kumar, R., N. Kumawat and U.N. Shukla. Job's tears: An

unexploited multipurpose shrub in North Eastern hilly

region of India. Popular Kheti, 2014;2: 118

LIPI. Low Land Grass Types. Research Centre for Biology.

Indonesian Institute of Sciences, Bogor. 1986.

Loghavi M. Souri S. Khorsandi F. Physical and mechanical

properties of Almond (Prunus dulcis l. cv. 7

Shahrood).Annual International Meeting. Shiraz.

Iran.ASABE. 2011.

Ma Jesukristina C. M. Design and Development of Milling

Machine for the Production of Adlai (Coix lacryma jobi

L) Grains. Asia Pacific Journal of Multidisciplinary

Research. 2015;3(4): 93-99. P-ISSN 2350-7756 E-

ISSN 2350-8442.

Mariotti, M., C. Alamprese, M.A. Pagani, M. Lucisano.

Effect of puffing on ultrastructure and physical

characteristics of cereal grains and flours. Journal of

Cereal Science. 2006;43: 47–56.

Mohsenin, N.N. Physical properties of plant and animal

materials. Gordon and Breach Updated Edition. 1986.

16th AFC 2019 - ASEAN Food Conference

112

Pankaj B. Pathare, Umezuruike Linus Opara, Fahad Al-

Julanda Al-Said. Colour Measurement and Analysis in

Fresh and Processed Foods: A Review. Food

Bioprocess Technol. 2013;6:36–60. DOI

10.1007/s11947-012-0867-9.

Ramashia, S.E., E.T. Gwata, S. Meddows-Taylor, T.A.

Anyasi, A.I.O. Jideani. Some physical and functional

properties of finger millet (Eleusine coracana) obtained

in sub-Saharan Africa. Food Research International.

2018;104: 110–118.

Ruiz. F. Agell. N. Angulo. C. Sanchez. M. A qualitative

learning system for human sensory abilities in

adjustment tasks. 2012.

S.S. SWAMI AND S.B. SWAMI. Physical properties of

finger millet (Eleusine coracana). International

Journal of Agricultural Engineering. 2010; 3(1): 156-

160.

Singh. K. K. and Goswami. T. K. Physical properties of

cumin seed. Journal of Agricultural. 1996.

Singh. K. K. and Goswami. T. K. Physical properties of

cumin seed. Journal of Agricultural. 1996.

Suthar. S. H. and Das. S. K. Some physical properties of

karinga seeds. Journal of Agricultural Engineering

Research. 1996;65:15-22.

Tarighi, J., Asghar Mahmoudi, and Naser Alavi. Some

mechanical and physical properties of corn seed (Var.

DCC 370). African Journal of Agricultural Research.

2011; 6(16): 3691-3699. DOI: 10.5897/AJAR10.521.

ISSN 1991-637X.

Tunde-Akintunde. T.Y. and Akintunde. B.O. 2004. Some

Physical Properties of Sesame Seed. Biosystems

Engineering. 88. 127-129.

Waraluck, K., W. Wangcharoen, S. Pimpilai and W. Daeng.

Preference direction study of Job’s-tears ice cream.

Maejo International Journal of Science and

Technology. 2007:01(2):137-144. ISSN 1905-7873.

Zare. D. Salmanizade. F., H. Safiyari. Some Physical and

mechanical properties of Russian olive fruit. World

Academy of Science. Engineering and Technology.

International Journal and Bological, Biomolecular,

Agricultural, Food and Biotechnological Engineering.

2012;6(9):668-671.

A Comparative Study between Wild and Cultivated Varieties of Adlay Grains for Some Engineering Properties

113