HACCP Plan Implementation for Food Safety for Startup Business:

Fruit Combining

Kartiko Setiyadi

1

,Tantri Yanuar Rahmat Syah

1

, Semerdanta Pusaka

1

and H. S. Darmansyah

1

1

Master of Management, Faculty of Economics and Business, Esa Unggul University, Jakarta

Keywords: Hazard Analysis, Critical Control Point, Food Production.

Abstract: HACCP is a tool to assess hazards and establish control systems that focus on preventative measures rather

than relying mainly on end-product testing. Seven basic principles underline the concept. These principles

include an assessment of the inherent risk that may be present from harvest through ultimate consumption.

Six hazard characteristics and a ranking schematic are used to identify those points throughout the food

production and distribution system whereby control must be exercised in order to reduce or eliminate

potential risks. A guide for HACCP plan development and critical control point (CCP) identification are

noted. Further, the document points out the additional areas that are to be included in the HACCP plan: the

need to establish critical limits that must be met at each CCP, appropriate monitoring procedures, corrective

action procedures to takes if a deviation is encountered, record keeping, and verification activities.

1 INTRODUCTION

Aware of a large number of deficiencies or

absence of food safety assurance is obtained from

conventional inspection and testing as well as

examples of many products. PT Redceri Indonesia

applies the concept of HACCP (Hazard Analysis

Critical Control Point), i.e. food safety assurance

system based upon a realization that hazard (hazard)

potentially arising at various points or stage

production, and must be controlled to prevent the

occurrence of such hazards. HACCP focuses on

hazards in a food commodity that if not controlled

could affect public health and food product design,

processing, commercialization, provision and the

conditions controlling the hazards.

HACCP systems is not a food safety assurance

systems without the risk or zero-risk. However,

HACCP is designed for minimizing the risk of food

safety hazards in the food production process.

HACCP systems also is a risk management tool that

is used to protect food supply chains and production

processes towards contamination hazards, chemical

and physical purity.

The benefits of the application of the HACCP

system for PT Redceri Indonesia is as follows:

Prevent or detect raw materials or unsafe

ingredient before entering the production system.

Keep the issue not be great and handled by

implementing early detection.

Be aware of the presence of contamination at

facilities that are used together for various

products.

Reduce the detention of products internally and

the destruction of the products.

Prevent dependence testing against a final

product that can cause the issue of unsafe

products.

Application of HACCP in the food industry are

specific for each type of product, every process,

every factory. Besides the basic prerequisite is

required in the form of application of GMP (Good

Manufacturing Practice) and SSOP (Sanitation

Standard Operating Procedures). An important

factor for the success of the application of HACCP

in the food industry is largely determined by the

commitment of management to provide safe food.

In the implementation of HACCP, PT Redceri

Indonesia implementing measures systematically in

the 12 steps, which consists of five initial steps of

preparation followed by seven the next step which is

the seven HACCP principles. As for the stages of

these steps are:

Stage 1 : Drafting HACCP team

Stage 2 : Description of products

Stage 3 : Identifying the purpose of the use of

Setiyadi, K., Yanuar Rahmat Syah, T., Pusaka, S. and Darmansyah, H.

HACCP Plan Implementation for Food Safety for Startup Business: Fruit Combining.

DOI: 10.5220/0009953828652872

In Proceedings of the 1st International Conference on Recent Innovations (ICRI 2018), pages 2865-2872

ISBN: 978-989-758-458-9

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2865

Stage 4 : Compiling flowchart

Stage 5 : Confirm the flowchart in roomy

Stage 6 : Conduct a hazard analysis

Stage 7 : Determine critical control points

(CCP)

Stage 8 : Determine the critical limits for each

CCP

Stage 9 : Specify a monitoring or monitoring

system for each CCP

Stage 10 : Specify the action correction if there is

a deviation from the limit of critical

Stage 11 : Specify the verification procedure

Stage 12 : Specify the system documentation and

record keeping systems or recording

2 THE FORMATION OF THE

HACCP TEAM

The first step in the preparation of HACCP is

forming a team of several members with the

educational background or extensive work

experience (multidisciplinary). The number of

HACCP Team consisting of people from various

parts of 5-6 or academic backgrounds such as

microbiology, sanitation experts, chemists,

engineers, part purchase, part of the QA/QC. People

who are involved in the ideal team is included: (1)

Staff of Quality Assurance or Quality Control Staff;

(2) personnel Production Section (understand the

raw materials and the production process); and (3)

personnel of the technical/Engineering Section; and

(4) Microbiological Experts. One Member is chosen

as the next Chairman of the team. The Chairman of

the team should already understand the preparation

of HACCP plans or between teams already exist that

follow HACCP training and/or auditing HACCP.

The team formed in charge of drawing up an

HACCP plan. For it, teams should meet regularly to

conduct discussions and brainstorming in the

HACCP plan.

For PT Redceri Indonesia, HACCP team consists

of Section Head of Research and Development,

Production Supervisor, QA/QC Supervisor (as

Chairman), Section Head of operations, Purchasing

Staff and some of the employees as members.

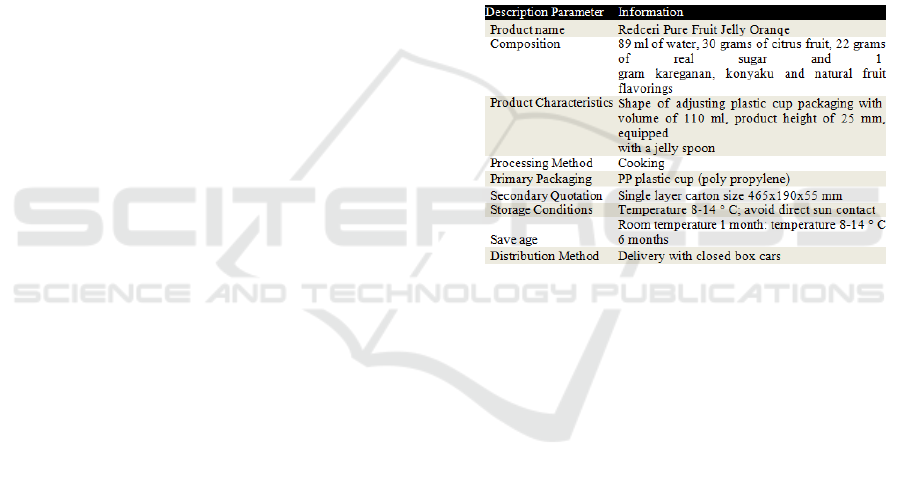

3 PRODUCT DESCRIPTION

The Second Step in the preparation of HACCP

plans are describing the product. HACCP team

should choose which products to be made its

HACCP plan if you have more than one product

type.

The information must exist at the time described

the product include composition, characteristics of

finished products, processing methods are applied to

the product (aw, pH, moisture content), while

preserving the method applied to such products,

primary packaging, packaging for transportation,

storage conditions, method of distribution, the

recommended shelf life, special labeling, usage

instructions, special supervision in the distribution

and where the product will be sold.

One example of PT Redceri Indonesia product

description for product Redceri Puree Fruit Jelly

Orange can be seen in the following table:

Table 1. Description of Product

Redceri Orange

4 THE DETERMINATION OF

THE USE OF THE PRODUCT

At this stage, the team identifies how to use

HACCP products by consumers, serving, as well as

a group of consumers who consume the products.

Important to know whether the product will be

directly consumed (ready to eat) or be cooked

beforehand by the consumer. It must be remembered

there are high-risk consumer groups which include

infants, the elderly, immuno compromised groups

(pregnant women, sick people, people who are

undergoing chemotherapy, AIDS patients).

For product Redceri Puree Fruit Jelly Orange,

descriptions of the users of its products is as follows:

can be in direct consumption by consumers from all

circles of society.

ICRI 2018 - International Conference Recent Innovation

2866

5 PRODUCT FLOW DIAGRAM

Process flow diagram was drawn up with the aim

to describe the entire process of production.

Flowchart of this process in addition to beneficial to

assist in performing the HACCP teamwork, can also

serve as a guideline for other person or institution

who would like to understand the process and

verification.

Flowchart should be covered all the stages in the

process are clearly concerning:

The details of the whole process of activities

including inspection, transportation, storage

and a delay in the process,

The materials to be included in such a process

of raw materials, packaging materials, water,

air and chemicals,

The output of the process such as waste:

packaging, raw material, product, product

reprocess in progress (rework), and products

that are disposed of (rejected).

6 VERIFY THE FLOWCHART IN

PLACE

In order for a process flowchart is made more

complete, and by the implementation on the ground,

then the HACCP team should review the operations

to test and prove the accuracy as well as the

perfection of the process flow diagram. When it

turns out that the process flow diagram is not right

or less than perfect, then to do modifications.

Flowchart of the process that have been made must

be documented and verified.

Flowchart process verified available, it can be done

by:

Observe the flow of the process.

Sampling Activities.

Interview.

Observe routine operations/non-routine.

7 THE ANALYSIS DANGER

Hazard Analysis include activity:

Identify hazards.

Determine the significance.

Identify precautions.

8 IDENTIFICATION OF DANGER

By referring to the flowchart process, HACCP

team lists all dangers real or potential that might be

worth is estimated to occur at each stage of the

process. Such dangers include the danger of

biological or chemical purity, dangers and physical

danger.

Study of the risk (the significance of) the dangers

a. The possibility of danger will occur

This is usually called the chance of danger will

occur. HACCP team needs to consider the likelihood

(odds) for any hazards that have been identified.

This inspection can be based on knowledge of

HACCP team; the literature on food microbiology,

HACCP, food products, and food processing,

scientific research papers; the journal; supplier; food

producers or processors; information regarding the

withdrawal of products; consumer complaints; the

areas of process, raw materials, or product that has

been identified is problematic. The possibility of

harm occurring in a simple can be rated as high,

medium, or low.

b. The level of seriousness of the Danger

Level of the seriousness of the danger can be

grouped as follows:

The seriousness of the hazard can be established

by looking at its effect on the health of the

consumer and also impact on the reputation of

the business.

The seriousness of the danger can also be

assessed: low, medium or high.

By combining opportunities with heavy and light

danger will be able to set the level of risk (the

SIGNIFICANCE of) the danger of being revealed as

high, medium or low. Such an approach can be used

to specify the type of control measures a must-have

in place and the higher the risk of danger, then the

higher the specified monitoring frequency

Thus the danger that there may also be classified

based on their significance, as shown in the table

below. The significance of the danger can be

decided by the team with the opportunity to consider

the occurrence of (reasonably likely to occur) and

severity (severity) of a danger.

c. Determination of Precautions

The next step after analyzing the dangers is to

identify the possible precautions to control any

hazards. The team then had to consider whether

precautionary measures, if any, can be applied to

any danger.

HACCP Plan Implementation for Food Safety for Startup Business: Fruit Combining

2867

LMH

L LL ML HL

M LM MM HM*

H LH MH* HH*

Peluang Terjadi

(

Reasonably like to occur

)

Tingkat Keparahan

(

Severity

)

Table 2. Determination Of The Significance Of Risk

Or Hazard Categories

Remarks:

L = Low, M = Medium, H = High

* Generally considered significant and will be considered

in the determination of the CCP

Precautions are all activities and activities that

are needed to eliminate hazards or minimize its

effects or its existence at an acceptable level. More

than one precautionary measures may be needed to

control the specific hazards, and more than one

hazard may be controlled by specific precautions.

Precautionary measures may include actions

which are chemical, physical or other controlling

food safety hazards. Precautionary measures in

tackling the danger can be more than one if needed.

This stage is an important stage after analysis of the

danger. Precautions are defined as any action that

may inhibit the incidence of danger into products

and refers to operating procedures are applied at

each stage of processing. Due to the nature of the

HACCP concept of prevention, then the HACCP

system in designing precautionary measures should

always be a concern. Here are a few examples of

precautions:

The separation of raw materials with a finished

product in storage.

Use a water source that already has security

requirements.

Calibration of the scales and gauges of

temperature.

using trucks that offer temperature control, etc.

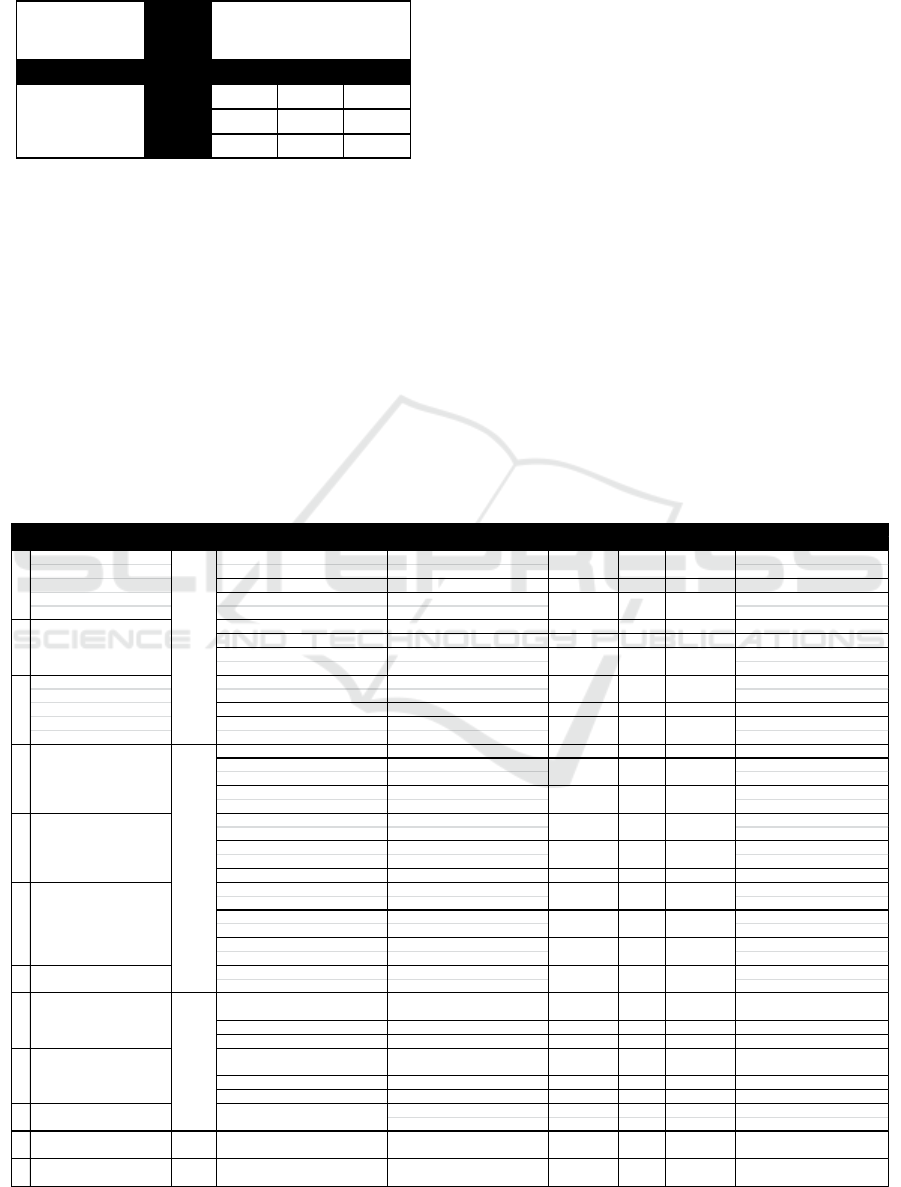

Hazard analysis results poured in the table

analysis of hazards. In the case of the production of

Redceri Pure Fruit Jelly danger analysis table can be

seen in the following table :

Table 3. Hazard Production Analysis

OPPORTUNITY SEVERITY SIGNIFICANCE

AcceptanceofRawMateri al s B:Destructivemicrobes Storage StorageSOP

(peeledfruit,sugar, (Amylolytic)

carrageenan,flavoring) K:Heavymetals Takenfromsuppl ie r

L

L

TN Supplierguarantee

F:Gravel,Insects,Frui t Takenfromsuppli er Supplierguarantee

rotten,fruitsize

B:Coliform,E.Coli Factorywatersource M H N Tre atmentofWaterSanitation

K:Heavymetals Factorywatersource M

L

TN WaterAnalysis

F:Gravel,Insects,Objects Factoryenvironment TreatmentofWaterSanitation

foreign

ReceptionSupplie s (cup B:Microbes Storage SOPforStorageand

plastic,spoonjelly,lid, Supplierguarantee

cardboard) K:Heavymetals,migration Takenfromsupplier

L

L

TN Supplierguarantee

F:Brokenness,Clarity, Takenfromsuppli er Supplierguarantee

Perforated,cut

B:Microbe s,sporebacteria Directcontactofworker H H N GMP,SSOP(workerhygiene)

K:Chemicalcontamination, Air,workenvironment GMP,SSOP(areahygiene

Dust [work)

F:Gravel,Insects,Objects Air,workenvironment GMP,SSOP(areahygiene

foreign,rottenfruit [work)

B:Bacteria,Coliform,E.Coli Temperatureandcookingtime GMP,

SSOP(hygiene

notenough worker),CookingSOP

K:Dust,dirt Air,workenvironment GMP,SSOP(areahygiene

[work)

F:Mix er,Piping ToolsandPlantInstallation

L

MN[GMP,Mai ntenance

B:Bacteria,Molds Dirtycontainer [GMP,SSOP(areahygiene

[work)

K:Dirt,Dust Air,workenvironment GMP,SSOP(areahygiene

[work)

F:Rottenfruit,roomtemperature ToolsandPlantInstallation [GMP,SSOP,Timecontrol

>18°C,Insects andtemperature

F:Forei gnobjects Dirtyscales, Scal e ssani tation

Environment

|B:Bacteria(Salmonella) Insuff icie nttemperatureand

cookingtime|

HHNGMP,SSOP

(workerhygiene),

CookingSOP

|K:Dust,Dirt Air,workenvironment

L

L

TN GMP,SSOP(workareahygiene)j

F:Mix er,Piping ToolsandPlantInstallation

L

MNGMP,Mainte nance

B:Bacteria,Coliform,E.Coli,^

Salmonella

Dirtymachine H H N GMP,SSOP(workhygiene),SOP

Filling

|K:Dust,Dirt Air,workenvironment

L

L

TN GMP,SSOP(workareahygiene)j

F:Piping,Presssealing ToolsandPlantInstallation

L

MNGMP,Mainte nance

Dirtyscales,

L

L

TN Sanitationscales

Environment

11 Packing Packing F:Foreignbodycontamination,Leaking Worker L L TN GM P,SSOP(workerhygiene)

12 Storage Logistics F:Pests,Roomtemperature|>18°C,

Insects

Workers,factoryenvironment L M N GMP,SSOP,Timeandtemperature

control

8

Filling9

Weighing10

HAZARDIDENTIFICATION PREVENTIONACT

DANGERSIGNIFICANCE

JUSTIFICATIONOFCAUSES

JellyCooking Productio

n

F:Forei gnobjects

Preparati

on

SugarWaterCooking5

AREAINPUT/PROCESSSTAGENO

Fruitpreservation6

Weighing7

L

H

L

L

H

Warehou

se

1

Inputofcleanwater2

3

FruitSort4

TNL

M

L

L

H

L

L

L

L

LLTN

TN

H

LTN

N

HN

NM

LTN

TNL

LTN

LTN

TNL

LTN

ICRI 2018 - International Conference Recent Innovation

2868

Remarks :

B (biological hazards), K (chemical hazards), F (physical

hazards), L (low), M (medium), H (high), TN (not real

danger), N (real / significant hazard).

9 DETERMINATION OF

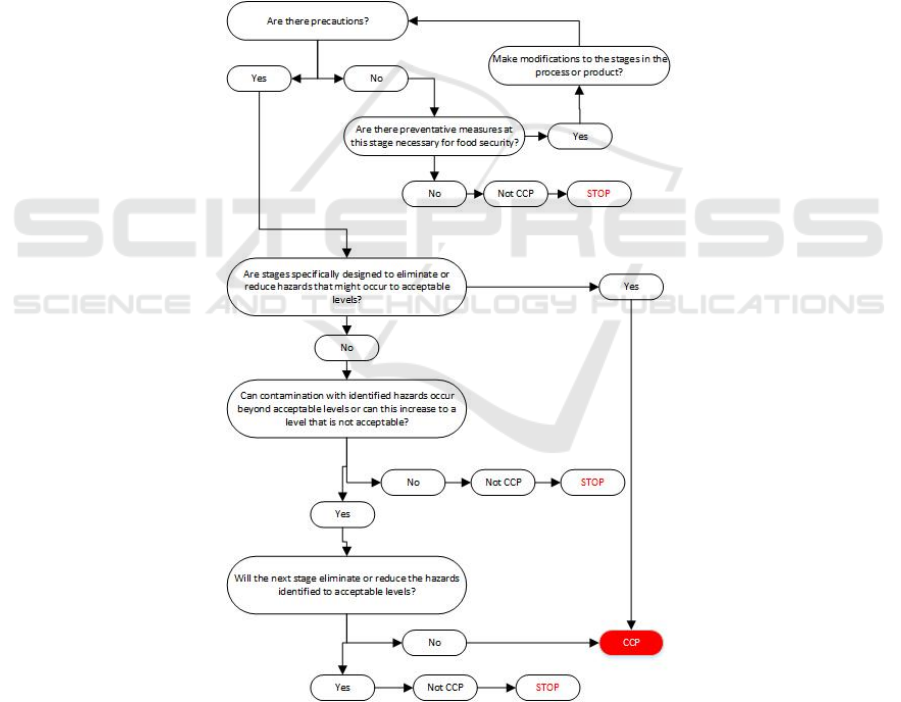

CRITICAL CONTROL POINTS

OR CCP

For each significant hazard then it must be

specified whether or not included in the Critical

Control Point or not. A critical control point is a

stage or procedure where control can be applied and

a food safety hazard can be prevented, eliminated or

reduced to an acceptable level so that the risks can

be minimized. In this stage can not controlled then it

can cause hazard food safety HACCP team establish

where the dangers are high risks can be controlled.

CCP can be identified by using knowledge of the

production process and all potential hazards and

dangers of an analysis of the hazards and

precautions. To help find where it should be true,

CCP can use decision tree Diagram of CCP (CCP

Decision Tree).

Decision tree diagram is a logical question series

asking every danger. The answer to each question

will facilitate HACCP team and bring the logically

decide whether CCP or not.

In addition to decision tree diagram process, to help

set can also be used decision tree CCP for raw

materials and formulations.

Figure 1. Decision Tree Diagram Process CCP

Examples of the results of the determination of

the CCP by the HACCP team PT Redceri Indonesia

Redceri on the production of Pure Fruit Jelly can be

seen in the following table:

HACCP Plan Implementation for Food Safety for Startup Business: Fruit Combining

2869

Table 4. The result of the determination CCP

10 THE DETERMINATION OF

CRITICAL LIMITS

For each CCP identified critical limits should be

determined then. Critical limit shows the difference

between products that are safe and not safe so that

the production process can be managed in a secure

level. These critical limits should not be passed to

ensure that the CCP is effectively in control of the

dangers of purity, chemical and physical. The

common criteria is used to determine the critical

limit is the physical criteria such as temperature,

time, humidity levels, and viscosity, as well as

chemical criteria such as pH, free chlorine residual,

acid levels. Microbiological criteria are not used as a

critical limit due to these measures take a long time.

In addition to physical and chemical measurements

can be used as indicators of measurement or control

of purity.

To set a critical limit can use data sources from

articles in the journal, regulations and Government

documentation, the guidelines of the Association,

publications of research at universities,

manufacturers, consultants and maker of the

equipment used.

11 SETTING PROCEDURE

MONITORING

Monitoring procedures (Monitoring) is a stage of

the observation or measurement of critical limits are

planned generate the proper recording and is

intended to ensure that the critical limit was able to

maintain the security of the product. HACCP team

set a series of monitoring procedure for each critical

limits are set that covers the what, who, where, when

and how the monitoring was done.

What question is answered with what should be

monitored, that is based on a critical limit is defined

as the temperature, time, size and so on. Answered

the question why the reason that if it not monitored

and the critical limit will cause certain dangers and

not allow cause insecurity products. The question

which should be answered at which point or at a

location where the monitoring should be done. The

question of how the ask method of monitoring,

whether in remote, chemistry or specific

measurements. Next is the question of when doing

monitoring, ideally a minimum which occurs in the

flow of production interruptions, or a lot, or other

data which establishes a period of monitoring. Last

is the question of who is doing the monitoring,

which ideally is the personnel who have access to a

very easy on the CCP, have the skills and knowledge

of the CCP and ways of monitoring, highly trained

and experienced.

By setting the critical limit is then obtained data

and information for the underlying decisions, got

early warning if there are any irregularities, to

prevent or minimize loss of product, indicating the

reasons for the problem and provide a document that

the product has been produced in accordance with

the HACCP plan. All documents related to record-

keeping and monitoring the CCP must be signed by

a person who does the monitoring and by the person

in charge.

12 SET THE ACTION OF THE

CORRECTIONS

Act Corrections is all the action taken if the

monitoring results on CCP deviations of critical

limits (losing control) because if control is lost, then

the product is not eligible. In practice, there are two

levels of correction actions, namely:

immediate action (Immediate Action), i.e. the

adjustment process to be controlled again and

deal with the suspected products affected by

the irregularities.

the precautionary measures (Preventive

Action), i.e., accountability for the action

recording and action correction.

INPUT/PROCESSSTAGE HAZARDIDENTIFICATION P1 P2 P3 P4 STATUS

Destructivemicrobes

Y

Y

CCP

Gravel,Insects,Fruitrotten,fruitsize

Y

Y

CCP

Inputofcleanwater Coliform,E.Coli

Y

NN NOTCCP

ReceptionSupplies(cup Mi crobes

Y

Y

CCP

plastic,spoonjelly,

lid,cardboard)

Brokenness,Clarity,Perforate d,cut Y N N NOTCCP

Microbes,sporebacteria

Y

Y

CCP

Dust

Y

N

Y

Y

NOTCCP

Gravel,Insects,Objects,foreign,

rottenfruit

Y Y CCP

Bacteria(Salmonella)

Y

Y

CCP

Dust,dirt

Y

N

Y

Y

NOTCCP

Mix er, Piping

Y

N

Y

Y

NOTCCP

Bacteria,Mol ds

Y

Y

CCP

Dirt,Dust

Y

N

Y

Y

NOTCCP

Rottenfruit,roomtemperature

Y

N

Y

N CCP

Bacteria,Coliform,E.Coli,Salmonella

Y

Y

CCP

Dust,Dirt

Y

N

Y

Y

NOTCCP

Piping,Pressseali ng

Y

N

Y

Y

NOTCCP

Bacteria(Salmonella)

Y

Y

CCP

Dust,Dirt

Y

N

Y

Y

NOTCCP

Mix er, Piping

Y

N

Y

Y

NOTCCP

Weighing Foreignobjects

Y

NN NOTCCP

Packing Foreignbodycontamination,Leaking

Y

N

Y

Y

NOTCCP

Storage Pests,Roomtemperature

Y

N

Y

N CCP

AcceptanceofRaw

Mate ri als(peeledfruit,

JellyCooking

Filling

Fruitpreservation

SugarWaterCooking

FruitSort

ICRI 2018 - International Conference Recent Innovation

2870

13 SET OF PROCEDURES

VERIFICATION

HACCP Team devised a procedure to assure that

the HACCP plan is already valid and that the

HACCP plan drawn up has been implemented as

planned. Verification is the application of a method,

procedures, tests or other evaluation to determine the

suitability of implementation with the HACCP plan.

Verification gives assurances that the HACCP plan

has complies with daily operations and will result in

the product Redceri Puree Fruit Jelly with good

quality and/or safe to consume. Specifically, the

verification procedure must ensure that:

The HACCP plan are applied absolutely right to

prevent the danger of the process and product

hazards.

Monitoring Procedures and corrective actions

still applied.

Internal audit, microbiology or chemical testing

on the final product.

14 DOCUMENTATION AND

RECORDINGS

Either documents or data records is written

evidence that an action has been performed. These

documents can be used (1) for inspection and (2) to

the study of lapses that resulted in the damage and

find the appropriate correction action. Type of

document (data records) that must be present in the

preparation of HACCP plans are:

HACCP plan and all supporting material.

Document monitoring.

Document Action correction.

Document verification.

He arranges with the system documentation, then

it was the preparation of HACCP plans the

production of PT Redceri Indonesia. HACCP plans

are subject to change in case of a change in raw

materials, the layout of the factory, equipment

replacement, cleaning or sanitation program

changes, the application of the new procedures,

changes in consumer products group and the

presence of new information about a hazard.

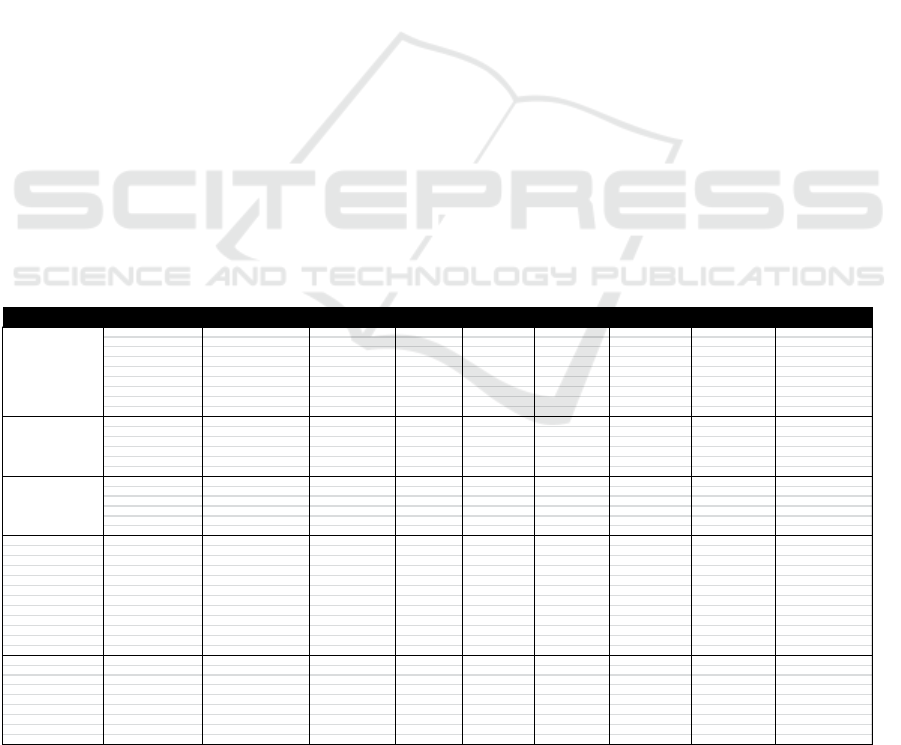

Determination of the CCP, the determination of

critical limits, designation procedures monitoring,

the setting of the correction action, determination of

procedures verification and documentation is good

next pour in the HACCP Plan table.

As for the HACCP Plan table for the production of

Redceri Pure Fruit Jelly was as follows:

Table 5. HACCP Plan PT. Redceri Indonesia

PROCESSSTAGE DOCUMENTATION

OFCCP WHAT HOW WHERE WHO WHEN ANDRECORD

Thereisnodirt Physicalconditionoffrui t Do Theplace Empl oye e Every 1.Contactstaff Reviewtheform recordof

(forei gnmaterial), peeland examination reception warehouse arrivaland QC/QAanddecide everyreceipt rawmaterialacceptance

standardsize, Certificateof visualand rawmaterial rece ption acceptedor

rejected month

notrottenand Analysis(CoA) check 2.Complainingto

smelling,guarantee supplierguaran tee supplier

supplier(CoA throughCoA

basedonSNI

3165:2009or

4230:2009)

Thereisnodirt Physicalconditionand Do Theplace Employe e Every 1.Contactstaff Reviewtheform recordof

(forei gnmaterial), Certificateof examination reception warehouse arri valand

QC/QAanddecide everyreceipt materialacceptance

supplierguarantee Analysis(CoA) visualand rawmateri al reception acceptedorrejected month raw

(CoAbasedonSNI) check 2.Complainingto

supplierguarantee supplier

throughCoA

Thereisnodirt Physicalconditionand Do Theplace Employe e Every 1.Contactstaff Reviewtheform recordof

(forei gnmaterial), Certificate

of examination reception warehouse arrivaland QC/QAanddecide everyreceipt receptionsuppl ies

contamination,NG Analysis(CoA) visualand rawmateri al reception acceptedorrejected month

product,guarantee check 2.Komplainto

supplier(CoA supplierguarantee supplier

basedonSNI) throughCoA

Inputofcleanwater 1.Clarity,color, Physicalconditi onofwater 1.Do Bak QA/

QCinspector 1.Everystart 1.Contactstaff Reviewtheform recordof

odorandcontaminati on input examination shelter Spv. productionprocess QC/QAanddecide rawwaterchecking rawwaterchecking

(attribute) visual rawwater Mai ntenance 2.Periodic6 qualify daily

2.Standardvariable 2.Periodictest onceamonth forprocess

cleanwater watercontent productionornot

input 2.Contacttheteam

maintenancefor

checkingconditions

watertreatment

factory

3.Complainingto

supplier

Sortfruit Thereisnodirt Physicalconditionoffruit Do Fruitsortingarea QA/QCinspector Everyprocess 1.Contactstaff Reviewthe sortform Sortingrecord

(forei gnmaterial), pee l and examination Spv.Production production QC/QAanddecide

dailyfruit fruit

notcontaminated, suitability visualand takeplace qualify

standardsize, internalstandard suitability forprocess

notrottenand standard productionornot

smells 2.Complaintsand

returntosection

warehouse

3.Accost

VERIFICATION

MONITORINGPROCEDURE

CORRECTION

MEASURES

Sugar,carrageenanand

flavori ngacceptance

Cup,plastic,jelly

spoon,lidandcarton

acceptance

Peelfruitacceptance

CRITICALLIMITS

HACCP Plan Implementation for Food Safety for Startup Business: Fruit Combining

2871

Table 5. HACCP Plan PT. Redceri Indonesia (Continued)

REFERENCES

Graham Friend and Stefan Zehle, Guide To Business

Planning, The Economist Newspaper

Porter, Micheal E. (1980). Competitive Strategy. New

York: Free Press.

Porter, Micheal E. (1985). Competitive Advantage. New

York: Free Press.

Osterwalder, Alexander & Pigneur, Yves. (2010).

Business Model Generation. New Jersey: John Wiley

& Sons Inc.

Jacobs, F. Robert & Chase, Richard B. (2011). Operations

and Supply Chain Management. Singapore: McGraw-

Hill.

Welsc, Glenn A. Budgeting: Profit Planning And Control,

Fourth Edition, Prentice Hall Inc., New Jersey, 1976.

Mulyadi, Sistem Perencanaan dan Pengendalian

Manajemen, Edisi Ketiga, Salemba Empat, Jakarta,

2007

PROCESSSTAGE DOCUMENTATION

OFCCP WHAT HOW WHERE WHO WHEN ANDRECORD

Fruitpreservation Thereisnodirt Tubcondition 1.Examination Area QA/QCinspector Faithfulprocess 1.Contactstaff 1.Reviewtheform 1.Recording

(foreignmaterial), prese rvation, bakandroutine prese rvation Operator producti on QC/QAanddecide fruitpreservation fruitpreservation

notcontaminated, temperature temperature preservation takeplace qualify daily 2.Checklistrecord

standardsize, preservative

room, 2.Do forprocess 2.Reviewtheform 3.Checkl istrecord

notrotten,smelling, physical conditionoffruit standardandmedia producti onornot sanitationchecklist roomtempe rature

roomtemperature peeland preservation 2.Productthatfailedequipment

<18°C,cleanliness cleanliness 3.Observe annihilated preservation

preservative, theworker hygieneconditions 3.Re viewtheform

workersanitationand

theworker temperaturechecklist

GMPissatisf ying room

Sugarwatercooking Thereisnodirt Tubcondition 1.Examination Cookingarea QA/QCinspector Faithfulprocess 1.Contactstaff 1.Reviewtheform 1.Recording

andjelly (foreignmaterial), prese rvation, temperatureandtime sugarwate randj

e

Operator production QC/QAanddecide 2.Reviewtheform cookingsugarwate r

notcontaminated, temperatureandtime 2.Do cooking takeplace qualify sanitationchecklist andjelly

standardbucket cookingand 3.Examination forprocess cookingequipment 2.Checklistrecord

rawmaterial, cleanliness scales producti onornot 3.Reviewtheform 3.Checklistrecord

tubcleanliness theworker theingredients 2.

Productthatfailedtemperaturecheckli st roomtemperature

preservative,sanitation used annihilated cookingtime 4.Records

worker,temperature 3.Observe 3.Accost 4.Reviewtheform useofmaterials

90°C, time hygieneconditions useofmaterials

workersandGMP theworker

satisfying

Filling Sanitationworkers, cleanliness 1.Examination Areafilli ng QA/QCinspector Faithful process 1.Contactstaff 1.Reviewthe

form 1.Producti onrecord

sanitaryfillingmachines, environment, cleanlinessofthearea Spv.Production production QC/QAanddecide dailyproduction 2.Checkl istrecord

andGMP cleanliness filling takeplace qualify 2.Reviewtheform 3.Checklistrecord

satisfying fillingmachine, 2.Do forprocess sanitationchecklist

andcleanliness 3.Examination productionornot fillingmachine

theworker cleanliness 2.Accost 3.Reviewtheform

4.Observe 3.

Productthatfailed workersanitation

hygieneconditions annihilated

theworker

Packing Sanitationworkers, cleanliness 1.Examination Packingarea QA/QCinspector Faithfulprocess 1.Contactstaff 1.Reviewtheform 1.Productionrecord

sanitarypacki ngarea, environment, cl eanlinessof thearea Spv.Producti on producti on QC/QAanddecide dailyproduction 2.Checklistrecord

andGMP andcleanliness packing takeplace qualif y 2.

Reviewtheform 3.Checkl istrecord

satisfying theworker 2.Do forprocess sanitationchecklist roomtemperature

3.Observe productionornot packingarea

hygieneconditions 2.Accost 3.Reviewtheform

theworker 3.Productthatfailed workersanitation

annihilated

Storage Sanitationarea cleanliness 1.Examination Area Logisticsstaff Every 1.Contactstaff 1.Reviewtheform 1.Recording

storage, environment, cleanlinessofthe

area storage Spv.Logisti cs acceptanceof QC/QAanddecide FGreceipts FGreceipts

roomtemperature andtemperature storage QA/QCinspector finishe dgoods qualify daily 2.Checklistrecord

storageand 2.Do tobesentor 2.Re viewtheform storage

GMPissatisf ying 3.Observe not sanitationchecklist 3.Checkl istrecord

temperature 2.Accost storagearea roomtemperature

storage 3.Theproduct 3.Reviewthe

form

defe ctindicated tempe raturechecklist

destroyed,after room

reworked

CRITICALLIMITS

MONITORINGPROCEDURE

CORRECTION

MEASURES

VERIFICATION

ICRI 2018 - International Conference Recent Innovation

2872