Direct Shear Strength Improvement through Soil Stabilization using

Dry Dust Collector and Silica Sand from Industrial Waste

Anita Setyowati Srie Gunarti

1*

, Irwan Raharja

2

, Hermanto

3

1

Department of Civil Engineering, Universitas Islam 45, Jl. Cut Meutia No. 83, Bekasi, Indonesia

2

Departement of Computerized Accounting, AMIK Bina Sarana Informatika,

Jl. Banten No. 1, Karangpawitan, Karawang Barat, Indonesia

3

Departement of Geography Education, Universitas Islam 45, Jl. Cut Meutia No. 83, Bekasi, Indonesia

Keywords: Direct Shear, Soil Stabilization, waste, silica sand, dry dust collector

Abstract. Nowadays, Green technology call for research on the utilization of industrial waste to solve civil construction

problems, e.g. broken roads, foundation crack, etc. This study aims to analyze the characteristics of clay after

soil stabilization using Dry Dust Collector (DDC) and Silica Sand (SS) from industrial waste. Laboratory test

was employed for finding the parameters, i.e. water content, specific gravity, plasticity index, and mechanical

test (proctor compaction standard and direct shear strength). The result showed the best friction angle for mix

soil with SS and DDC with 5 percent of SS. Cohesion number increased for the mix soil which contained

only one type of waste. The shear strength increased 32.26 percent for the mix soil with 1.5 percent DDC and

5 percent SS. This study showed mechanical characteristic improvement of clay after DDC and SS addition.

1 INTRODUCTION

Industries often generate much waste when

producing any goods. Coloring and compounding

plastic resin industries in EJIP industrial park in

Cikarang, West Java, give three ton of dry dust

collector waste (DDC) every month. In the other

hand, mineralogy industries create 50 ton silica sand

waste (SS) every month. DDC and SS have chemical

characteristics which are useful for soil stabilization.

But there is a problem to implantation this method

related to high cost in collecting DDC and SS.

Therefore some innovations and infrastructure in

managing industrial waste are emerged. Factory

owners need a lot of collectors with very high cost.

Therefore, some researches on industrial waste

utilization are needed.

The novelty of this study is in stabilizing the

clay using DDC and SS which is useful to support

building constructions as well as roads. Two kinds of

stabilization, i.e. physical and chemical stabilizations,

were used for increasing the strength, decreasing the

swelling potential, and improving physical and

mechanical of clay. This study is useful in Indonesia

since industrial waste increase every year, and adhere

green technology by utilizing the waste for

infrastructure development.

Many studies have been conducted to utilize

industrial waste for additive in construction. Wardana

(2009) proposed soil stabilization through the use of

marble powder and other stabilizers. This research

shows that testing result showed decreasing of soil

swelling and rising the compression strength, but the

stabilizers use showed better in decreasing soil

swelling and the compression strength similar to lime

addition. This research also recommended the soil

depth and optimum composition of stabilizers. In

addition, it is recommended to test the performance

not only based on soil plasticity, but also the

allowance of soil swelling, so soil will have the ability

to support the foundation as well as the vehicles on

the road although in expansion. Paddle only affected

at the surface of the soil as well.

Aulia (2006) proposed to use the waste of

pulp and paper industry as clay stabilizer. The result

showed the clay from Grobogan regency with specific

gravity of 2.68 and solid paper-waste addition up to

15% showed the decreasing of liquid limit up to

58.40%, increasing of plasticity limit up to 44.74%,

decreasing of plasticity index by 13.66%, increasing

of shrinkage limit up to 17.16%, and decreasing of

clay fraction by 71.40%. Solid pulp and paper waste

addition up to 15% could change soil unified system

from class H to MH or OH which there is no class

change based on AASHTO. Cohesion value (c) for all

addition of solid pulp and paper waste up to 10% with

7 days aging are decreased, but the shear angles (ϕ)

are increased. For pulp and paper addition greater

than 10% and 7 days aging, the shear angle (ϕ) tends

to decreased again. Umam (2017) studied about sand

gradation and clay ratio influence on soil’s shear

2990

Setyowati Srie Gunarti, A., Raharja, I. and Hermanto, .

Direct Shear Strength Improvement through Soil Stabilization using Dry Dust Collector and Silica Sand from Industrial Waste.

DOI: 10.5220/0009947429902993

In Proceedings of the 1st International Conference on Recent Innovations (ICRI 2018), pages 2990-2993

ISBN: 978-989-758-458-9

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

strength. This result concluded that clay addition to

the sand would increase internal shear angle of the

soil and decrease cohesion value. Cohesion value was

not influenced by granules size of sand but influenced

by small granules of sand. Stabilization method was

also developed through the use of waste from

PERTAMINA, i.e. spent catalyst RCC 15 (Gunarti,

2014), which showed the significant increase of

clay’s carrying capacity. These result that showing

carrying capacity improvement will be used as

preliminary data of this study. Another result was the

increase of constrained compressive strength (qu)

compared to the original soil from the stabilization of

soil using spent catalyst RCC 15 and lime because the

soil did chemical process that create the bond among

granules that change particles size into the sandy and

non-cohesive.

This paper proposed the soil stabilization

using dry dust collector (DCC) and silica sand (SS)

from industrial waste. This first time research also

utilized the industrial waste for improving capability

and strength for construction development that adhere

the green technology concept.

2

METHODS

2.1 Kind of Test and Location

The laboratory test for physical and mechanical

characteristic was done at Soil Mechanic laboratory

in Universitas Islam 45 Bekasi to find direct shear

strength, water content, specific gravity, and

plasticity index.

2.2 Materials

For laboratory tests, this study used some materials,

i.e. clay (disturbed and not disturbed clay in

Universitas Islam 45 Bekasi), Dry Dust Collector

(null and 1.5 percent composition compared to clay

dry weight), and silica sand (null, 2.5, and 5 percent

composition compared to clay dry weight). A direct

shear test tool was used with JIS standard (Figure 1).

Figure 1: Direct Shear Test

2.3 Methods

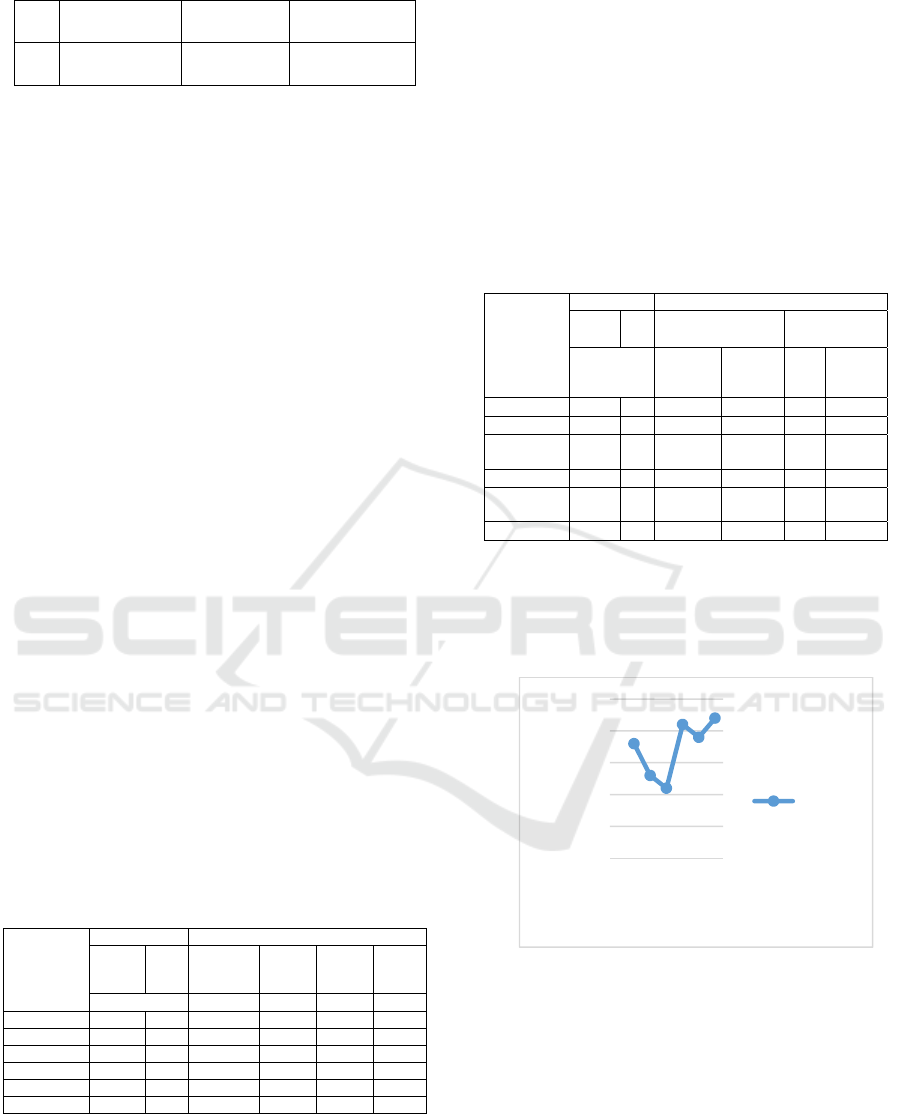

Figure 2 shows the research framework. Two separate

materials (original and stabilized through the use of

DDC and SS). Each material was tested to find:

atterberg limit, water content, specific gravity, sieve

analysis, Proctor standard compaction, and shear

strength. After testing and validation, the results were

concluded and discussed.

Figure 2: Research Framework

3 RESULT AND DISCUSSION

3.1 Physical Characteristics of the

Original Clay

3.1.1 Undisturbed Clay’s Characteristics

Table 1 shows the five physical test results of undisturbed

clay.

Table 1: Physical test result of undisturbed clay

No Soil Description

Kind of Test

U

ndisturbed

S

oil depth

1

.00-1.50m

Undisturbed

Soil Depth

1.50-2.00m

1 Specific

Gravity

2.603 2.691

2 Water

Content

58.51 48.72

3 Liquid Limits 87.65% 74.80%

Direct Shear Strength Improvement through Soil Stabilization using Dry Dust Collector and Silica Sand from Industrial Waste

2991

4 Plasticity

Limits

31.02% 28.36%

5 Plasticity

Index

56.63 46.44

Plasticity index can be used as a base to

identify soil expansion. Fathani (1994) study, based

on Chen criteria gives an expansive criterion if PI

greater than 35%. If pass filter number 200 greater

than 95% and liquid limit > 60%, then the soil has a

very high expansive criterion. Table 1 shows

undisturbed soil has PI of 56.63% for 1.00 – 1.50

meters depth and 46.44% for 1.50 – 2.00 meters

depth. Percent of pass sieve fraction number 200 is

85.538% for 1.00 – 1.50 meters depth and 62.716%

for 1.50 – 2.00 meters depth. Liquid limits is 87.65%

for 1.00 – 1.50 meters depth and 74. 80% for 1.50 –

2.00 meters depth. The tests showed that soil has high

expansive criterion. Hardiyatmo (1994) said that soil

will degrade if having gradation coefficient (Cc) of 1

and 3, with uniformity coefficient (Cu) greater than

15. In this study, both Cc and Cu is null because none

of the samples has pass sieve below 10 percent.

Therefore, this kind of soil is categorized as bed in

degradation which is not pass for gradation and

uniformity coefficient. Based on unified criteria and

the liquid limits, it was found that the soil has liquid

limits of 87.65 for 1.00 – 1.50 meters depth and 74.

80% for 1.50 – 2.00 meters depth (greater that 50%).

Therefore, the soil is categorized as CH (organic clay

with high in plasticity).

3.1.2 Disturbed Clay’s and Stabilized Clay’s

Characteristics

Testing results for disturbed and stabilized clay are

shown in Table 2.

Table 2: Physical Test Result of Disturbed and Stabilized

Clay

Additive

Compositi

on

Code

Additive Kind of Test

DDC SS SG LL PL PI

% % % %

A

0 0 2.6232 58.10 31.54 26.55

B

1,5 0 2.5469 57.35 27.21 30.14

C

0 2,5 2.5767 55.50 27.62 27.87

D

0 5 2.6208 51.40 27.53 23.87

E

1.5 2.5 2.5642 52.75 27.60 25.15

F

1.5 5 2.5766 53.42 26.78 26.63

Table 2 shows the mix of DCC and SS decreased

Plasticity of 23.87 for original and disturbed soil from

26.55 (Code D). PI value for some composition code

were both decreased and increased because there is a

characteristic change of the granules as the result of

physical characteristic of granules change from clay

to sandy soil after chemical and aging of stabilized

clay.

3.1.3 Mechanical Characteristics of

Disturbed and Stabilized Clay

Table 3 shows testing of direct shear results for

disturbed and stabilized clay.

Table 3: Direct Shear Test for Disturbed and Stabilized

Clay

Additive

Compositi

on Code

Additive Kind of Test

DD

C

S

S

Compaction Direct Shear

%

d

(t/m3)

Wopt

(%)

(

o

)

C

Kg/cm

2

A

0 0 1,380 30,50 18 0,0115

B

1,5 0 1,372 31,80 13 0,0415

C

0 2,

5

1,375 31,62 11 0,0440

D

0 5 1,384 31,00 21 0,0225

E

1,5 2,

5

1,364 30,75 19 0,0280

F

1,5 5 1,384 30,00 22 0,0255

Compaction value, d, for Code A is 1.380t/m

3

with

optimum water content (Wopt) of 30.50% for

disturbed clay. The highest d value is shown for code

D and F (1.384 t/m3 for 5% DDC and SS addition).

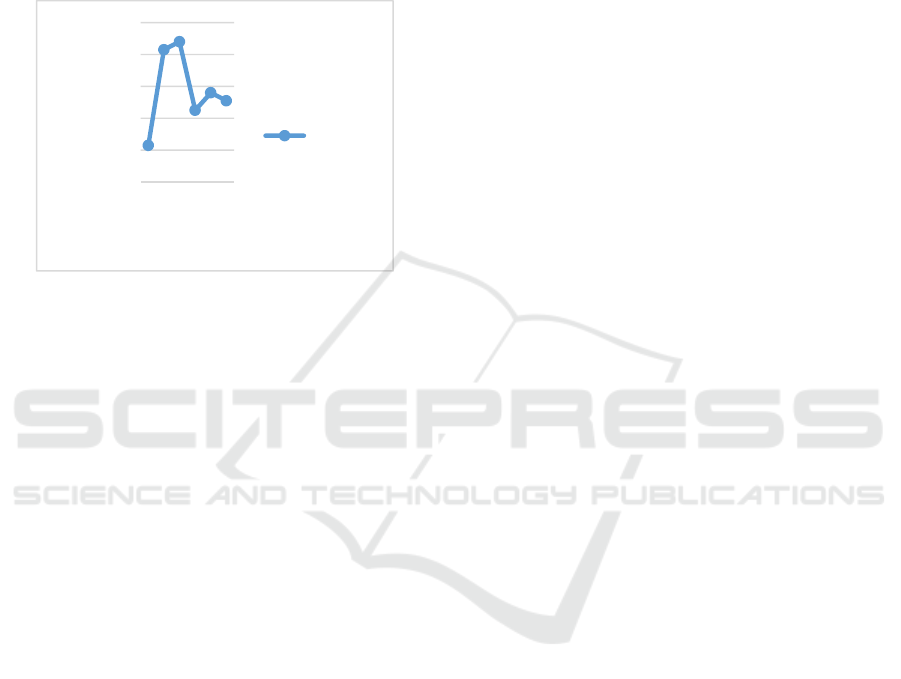

Figure 3: Friction Angle Chart

Figure 3 shows a fluctuation of friction angles. The

highest friction angle is code F (increased 22.22%

compared to original clay) with the composition of

DDC and SS are 1.5% and 5% respectively. SS

addition, physically, made clay more sandy, whereas

DDC addition made the clay more sticky. The

increase of friction angle for stabilized clay improve

the soil compactness because SS could change a

particle size, makes the soil more heterogeneous, and

the cavities are filled. Soil compactness of stabilized

0

5

10

15

20

25

ABCDEF

FrictionAngle

AdditiveCompositionCode

Friction

Angle

ICRI 2018 - International Conference Recent Innovation

2992

clay (code F) can be seen by comparing the d

max

value that is higher than the original clay.

Hakam et al (2010) said that in direct shear strength

test, the more compact the clay, the higher its friction

angle (), and vice versa. In addition, the higher the

clay added, the higher cohesive (c) value but the

smaller of its friction angle.

Figure 4: Cohesive Value Chart

Figure 4 shows the change of cohesive value. The

highest cohesive value is code C (0% DDC and

2.5%SS) which increased 282.62% from its original

value. Large number SS addition (code D and F with

5% addition) affect sandy characteristic of the clay.

Therefore, decreasing the cohesive force between

particles. The increase of cohesive, significantly

showed at clay with only one additive as shown in

table 3 (code B and C). However, the addition of DDC

and SS still increase the cohesive value and stabilized

the original clay.

Maximum shear strength value was found at

composition of 1.5% DDC and 5% SS (code F) which

improve 32.36% compared to the original clay. It

implies that the stabilization through addition of DDC

and SS improve the mechanical characteristics

.

4 CONCLUSIONS

Clay in Universitas Islam 45 Bekasi has high

expansion and bed degradation which does not follow

the gradation and uniformity coefficient. This soil is

categorized as CH (un-organic clay with high

plasticity). Friction angle is increased for clay with

5% silica sand (with or without DDC). But, cohesion

value increased for only one additional stabilizer

(silica sand or dry dust collector). Best shear strength

found at composition of 1.5% DDC and 5% SS (code

F). This composition increase the shear strength of

32.26% compared to the original clay. This study

concludes that a mix clay with additional DDC and

SS has better mechanical characteristics.

ACKNOWLEDGEMENTS

This research was supported by ministry of research,

technology, and higher education of Indonesia

(RISTEK-DIKTI). We thank our colleagues from

Universitas Gadjah Mada who provided insight and

expertise that greatly assisted the research.

REFERENCES

Aulia,K., 2006. Stabilisasi Tanah Lempung menggunakan

Limbah Padat Pabrik Kertas Terhadap Kuat Geser

Tanah, Jurnal Universitas Negeri Semarang, Semarang.

Fathani, T.F., dan Adi, D.A.1994. Perbaikan Sifat Lempung

Expansif dengan Penambahan Kapur, Prosiding

Seminar Nasional Geoteknik, Jurusan Teknik Sipil

UGM, Yogyakarta.

Gunarti, A.S.S, 2014. Daya Dukung Tanah Lempung yang

Distabilisasi dengan Spent Catalyst dan Kapur,

BENTANG Jurnal Teoritis dan Terapan Bidang

Rekayasa Sipil,Vol 2 No 1 Januari 2014, Program Studi

Teknik Sipil Universitas Islam 45, Bekasi.

Hakam, A., Yuliet, R., Donal, R. 2010. Pengaruh

Penambahan Tanah Lempung pada Tanah Pasir Pantai

Terhadap Kekuatan Geser Tanah, Jurnal Rekayasa Sipil

Vol 6 No 1 Februari 2010, Universitas Andalas,

Padang.

Hardiyatmo, H.C, 1994. Mekanika Tanah 1, Gadjah Mada

University Press, Yogyakarta, 1994.

Umam, K., Nugroho, S.A., Wibisono, G., 2017. Pengaruh

Gradasi Pasir dan Kadar Lempung terhadao Kuat Geser

Tanah, Jom FTEKNIK Vol 4 No 1 Februari 2017,

Universitas Riau, Riau.

Wardana, IGN, 2009. Kelakuan Tanah dengan Sifat

Kembang Susut yang Tinggi Pada Stabilisasi Tanah

Dengan Bahan Serbuk Marmer dan Bahan Stabilia,

Jurnal Teknik Sipil Universitas Udayana, Denpasar

0

0.01

0.02

0.03

0.04

0.05

ABCDEF

Cohesion

AdditiveCompositionCode

Cohesion

Direct Shear Strength Improvement through Soil Stabilization using Dry Dust Collector and Silica Sand from Industrial Waste

2993