Enzymatic Esterification Ethyl Ester Fatty Acid from Hydrolyzed

Castor Oil and its Oxidation Product as Emulsifier and Antimicrobial

Compound Using Candida rugosa Lipase E.C.3.1.1.3

Annisa Khairani

1

, Sumi Hudiyono

1

and Sri Handayani

1

1

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Indonesia, Depok

16424, West Java, Indonesia

Keywords: Castor oil, fatty acid ethyl ester, oxidized fatty acid ethyl ester, lipase, emulsifier, antimicrobial

Abstract: Aim of this study was to synthesis fatty acid ethyl ester compound of hydrolyzed castor oil and its oxidation

product using Candida rugosa lipase. Both of the esterification products were expected to have

antimicrobial activity against Staphylococcus epidermidis and Propionibacterium acnes and may act as

emulsifiers. Optimization of esterification reactions was done by varying the mole ratio between fatty acids

and ethanol, ie 1:1, 1:2, 1:3, and 1:4. The esterification products were then characterized using FTIR.

Conversion percentage was determined by titrimetric method, to calculate the amount of fatty acids that was

converted to ester. The ester product was tested its ability as emulsifier by emulsifier test. The esterification

products were also examined their antimicrobial activity using disc diffusion method. The highest

conversion percentage for fatty acid ethyl ester and its oxidation product were 76 % and 72% respectively.

Characterization using FTIR for both ester showed that the absorption band of C=O ester functional group

at wave number 1731.27 cm

-1

and 1732.15 cm

-1

respectively. The emulsifier test showed that both esters

have ability to stabilize emulsion up to 24 hours for water-in-oil emulsion (w/o) type. Antimicrobial assay

showed that both esters have antimicrobial activity against both bacteria.

1 INTRODUCTION

Indonesia is a tropical country that presents a wide

range of beneficial biological plants that can grow in

it. One of the oil-producing plants that benefit the

wider community is Ricinus communis L. Ricinus

communis L. is an oil-producing plant (castor oil)

which contains triglyceride from a variety of fatty

acids which largest content is risinoleic acid, i.e 85-

95% of the total fatty acids (Gunstone et al.,2007).

Risinoleic acid is a long-chain fatty acid having 18

carbons which the ester form is known to have

strong antibacterial activity against Gram-positive

bacteria (Desbois and Lawlor, 2013) and used as

emulsifier in cosmetic industry (Cavalcante et al.,

2009).

Ricinoleic acid can be obtained by castor oil

hydrolysis in an alkaline solution. Ricinoleic acid

can also be esterified with ethanol (Hykkerud and

Marchetti, 2016). To achieve the equilibrium of an

esterification reaction that is so slow, catalyst is

required to accelerate it. Lipase was used in

enzymatic esterification using ethylene glycol at low

temperature and pressure (Chand et al., 1997).

In this research, the esterification between

ethanol and fatty acid obtained from the hydrolysis

of castor oil used Candida rugosa Lipase as catalyst.

Esterification also conducted between ethanol and

oxidized castor oil fatty acid. The ester products

were then examined as emulsifier and antibacterial

compound.

2 MATERIALS AND METHODS

2.1 Chemicals

The materials used in this study were ethanol, KOH,

ethanol 96%, concentrated HCl, NaOH 0.5 N,

aquades, Na

2

SO

4

anhydrous, n-hexane, phosphate

buffer pH 8, KI 15%, thiosulfate 0.01 N, amilum 1

%, KMnO

4

1M, phenolphthalein indicator, eosin

indicator, clindamycin antibiotics, sterile aquades,

DMSO, nutrient broth and nutrient agar,

Khairani, A., Hudiyono, S. and Handayani, S.

Enzymatic Esterification Ethyl Ester Fatty Acid from Hydrolyzed Castor Oil and Its Oxidation Product as Emulsifier and Antimicrobial Compound Using Candida rugosa Lipase E.C.3.1.1.3.

DOI: 10.5220/0009841800002406

In Proceedings of BROMO Conference (BROMO 2018) - Symposium on Natural Product and Biodiversity, page 1

ISBN: 978-989-758-347-6

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

1

Staphylococcus epidermidis and Propionibacterium

acnes cultures (obtained from Biochemistry Lab

Department of Chemistry, Universitas Indonesia).

Candida rugosa Lipase obtained from Sigma-

Aldrich.

2.2 Hydrolysis of Castor Oil

To get hydrolized castor oil fatty acid 100 g of

castor oil and 100ml KOH 5 M solution in 96%

were mixed. The mixture was heated in oil bath for 1

hour at 70

o

C with magnetic stirrer and was cooled

at room temperature. HCl 5M was added until pH 5-

4 (± 55 mL). The mixture was then allowed to stand

for 24 hours and will formed 2 phases. The upper

phase (organic phase) were separated and called

hydrolized fatty acids.

2.2.1 Oxidation of Fatty Acids

To 10 ml of hidrolyzed fatty acid 5 mL NaOH 0.5 M

and 2 mL of KMnO

4

was added and stir for 90 min

at 25

o

C. The solution was then left for 24 hours,

then filtered. The filtrate was added by 4 mL of

sulfuric acid. The Na

2

SO

4

anhydrate was added to

the organic phase of oxidized sample, and decanted.

2.2.2 Iod Numbers Test

Before and after oxidized, 0.3-0.4 g fatty acid was

mixed with 10 mL of chloroform and 10 mL of

Hanus solution. The solution was stored for 30

minutes in dark place. Furthermore, 10 mL of 15%

KI solution and 100 mL of aquadest were added.

The solution was titrated using 0.1 N sodium sulfate

solution to a yellow colour. The solution was added

1-2 mL of 1 % amilum solution and re-titrated with

0.1 N sodium sulfate solution until the colour turned

clear (Goud, 2006).

2.3 Esterification

2.3.1 Synthesis of Ethyl Ester Hydrolyzed

Castor Oil Fatty Acid and Its

Oxidation Products Using Candida

Rugosa Lipase

To get ester products fatty acid and the n-hexane,

Candida rugosa lipase as catalyst and ethanol were

mixed. Before mixing Candida rugosa was

dissolved with pH 8 phosphate buffer solution. The

mol ratio of fatty acid to etanol (respectively)

varians were 1: 1, 1: 2, 1: 3 , and 1: 4 (mol/mol). The

amount of solvent were used are 1:1 (v/v substrate in

each ratio). The 5% of the substrate total mass was

used as enzyme mass (w/w of each substrate ratio).

The incubation was conducted using horizontal

incubator shaker at 250 rpm and 37 °C for 18 hours.

To terminate the reaction, the mixture was heated in

a water bath at temperature of ± 80

o

C for 1-3

minutes. The same treatment was applied for

oxidized fatty acid ethyl ester.

2.3.2 Conversion Percentage Determination

Conversion percentage was calculated by using

titration method. Titrations were performed on an

organic phase (upper phase) which is a residual fatty

acid dissolved in n-hexane. 1 mL the organic phase

that has been separated after the centrifugation

process is transferred into a 10 mL measuring flask

and adjusted its volume with n-hexane. Then as

much as 1 mL aliquot was titrated with 0.1 N NaOH.

2.3.3 Identification Product Using FTIR

Esterification products, hydrolyzed castor oil fatty

acid, and oxidized fatty acids were identified using

FTIR.

2.4 Emulsifier Test and Determination

of Emulsion Type

Emulsifier test was carried by mixing water and oil

with a certain ratio according to Table 1. A total of

0.1 g of fatty acid ester were added into each

mixture, then shaken using a vortex for 30 seconds

to form an emulsion. Then the stability emulsion

was observed.

Table 1 : Oil and water composition for emulsions

Emulsion

Type

Water (ml)

Oil (drop)

Type 1

1

1

1

1

1

2

4

6

8

10

Water(drop)

Oil (ml)

Type 2

2

4

6

8

10

1

1

1

1

1

To determine the emulsion type, a drop of

emulsion and eosin was mixed on object glass. The

observation of emulsion type was performed under

microscope to determine an oil-in-water (o / w) oil

or water in oil (w / o) emulsion type.

2.5 Antimicrobial Activity Assay

Disc diffusion method was used as antimicrobial

activity assay. Aliquot 200 μL of P.acnes and

S.epidirmidis suspension with cell density 1x10

8

BROMO 2018 - Bromo Conference, Symposium on Natural Products and Biodiversity

2

cells/mL was mixed with 20 mL nutriet agar in

sterile petri dish aseptically. The media was then

allowed to harden. Sterile disc paper with diameter

of 6 mm was placed on top of the medium and

dropped by 4 μL on sample. The incubation was

performed at 37 °C for 24 hours. Clindamycin

(0.5%) was used as positive control while DMSO as

negative control. The clear area around disc paper

was measured to determine antimicrobial activity.

The assay was performed on ethyl ester fatty acid

product with concentrations of 20%, 40%, 60%, and

80%.

3 RESULT AND DISCUSSION

3.1 Hydrolysis of Castor Oil

The hydrolysis process in this study was carried out

using an alkaline as catalyst in order to obtain fatty

acids from castor oil. The hydrolysis reaction with

an alkaline catalyst is irreversible, thereby resulting

in a higher fatty acid yield than the reversible acid

catalyst (Rifqy, 2016). To obtain free fatty acids, the

resulting soap was added by HCl. The fatty acid

obtained from this process was about 83.5%. The

hidrolized castor oil fatty acid was identified using

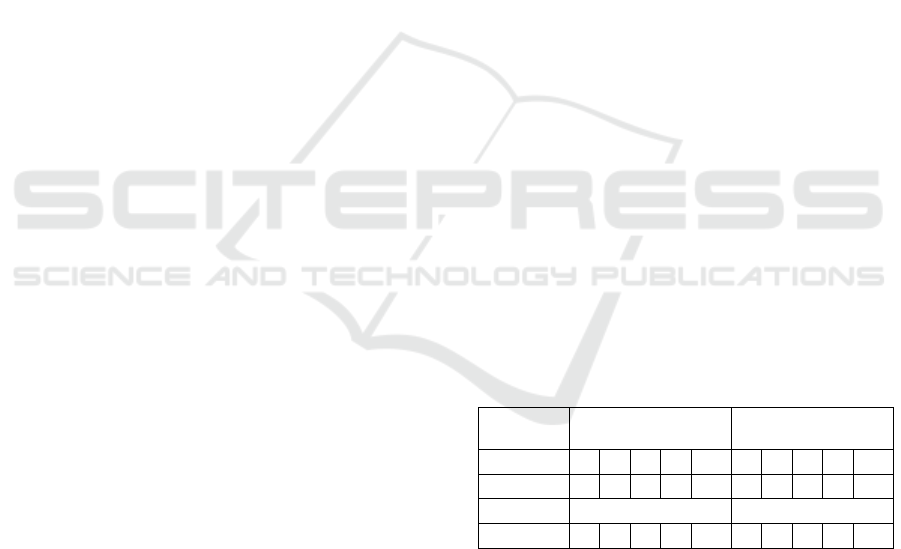

FTIR and the spectrum can be seen in Figure 1.

Figure 1: Castor oil hydrolyzed fatty acid spectrum.

The figure showed absorbsion at wave numbers

1725-1700 cm

-1

which indicate C=O carbonyl

uptake bands of carboxylic groups after hydrolysis

process. At wave number 1800-1650 cm

-1

appears

the absorption band for C=C accompanied by the

appearance of absorption band CH sp

2

vinyl at wave

number 3150-3000 cm

-1

(Janice, 2011).

3.3.1 Oxidation of Fatty Acids

The fatty acids obtained from castor oil hydrolized

have a double bond (C=C) which may undergo a

oxidation reaction. The oxidation process was

performed to increase the hydroxyl group into the

molecule by breaking the double bond (Pierre,

1994). The oxidation reaction using KMnO

4

at an

alkaline condition provides the oxidation product of

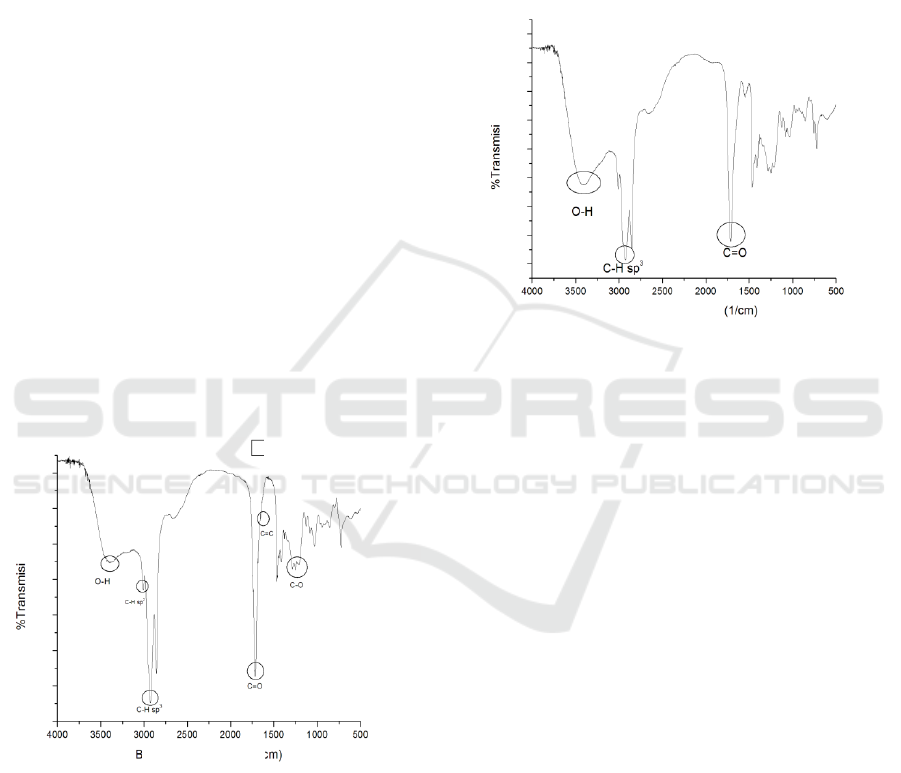

a diol compound (Marlina, 2004). The spectrum of

oxidized can be seen in Figure 2.

Figure 2: Oxidized fatty acid spectrum.

The loss of the absorption band for C=C and the

CH sp

2

absorption bands indicated that the fatty

acids had been oxidized to diols . The presence of

hydroxyl group of diols were shown with sharper

and wider absorbing bands for O-H.

The determination of the iodine is performed to

prove that the fatty acid had been oxidized. In this

study showed that iodine number on hydrolyzed

fatty acid is 10 mg/g while the oxidized fatty acids

of 1.5 mg/g. It indicated that the oil has lost its

C=C and the oxidation was successful.

3.2 Esterification

Candida rugosa Lipase can catalyze the

esterification reaction under a slight water condition,

called essential water. Enzyme need water to

perform its catalytic activity called essential water

(Zaks and Klibanov, 1988). The essential water in

this study was obtained from pH 8 phosphate buffer.

The use of alcohol in larger quantities may induce a

reaction towards ester formation (Pandey et al.,

1999). In order to optimize the esterification

reaction, the reaction equilibrium is shifted to the

right direction to the formation of ester. In this

research, ethanol was used in excess amount. The

ester was identified using FTIR and the spectrum

can be seen in Figure 3.

Wavenumbers

Wavenumber

s

Enzymatic Esterification Ethyl Ester Fatty Acid from Hydrolyzed Castor Oil and Its Oxidation Product as Emulsifier and Antimicrobial

Compound Using Candida rugosa Lipase E.C.3.1.1.3

3

Figure 3 : Esters spectrum.

The figure shows the presence of the C = O ester

absorption bands at the wave numbers 1735-1750

cm

-1

for both types of esters. This bands shows a

shift to greater wave numbers than fatty acid and

oxidized fatty acid form, this wave number is also

the typical wave number for C=O groups of ester.

The differences between these two spectrum are the

absence of C=C and C-H vinyl absorbtion bands for

oxidized fatty acid esters that appear at wave

numbers of 1652.48 cm

-1

and 3009.73 cm

-1

(Janice,

2011).

3.2.1 Conversion Percentage

For the castor oil hydrolyzed fatty acids has the

highest convertion value at 1:3 composition with

conversion percentage value of 76.31% and the

oxidized fatty acid has the highest conversion

percentage value at 1:2 composition with the value

of 72% (Figure 4).

Figure 4 : Konversion percentage ester fatty acid

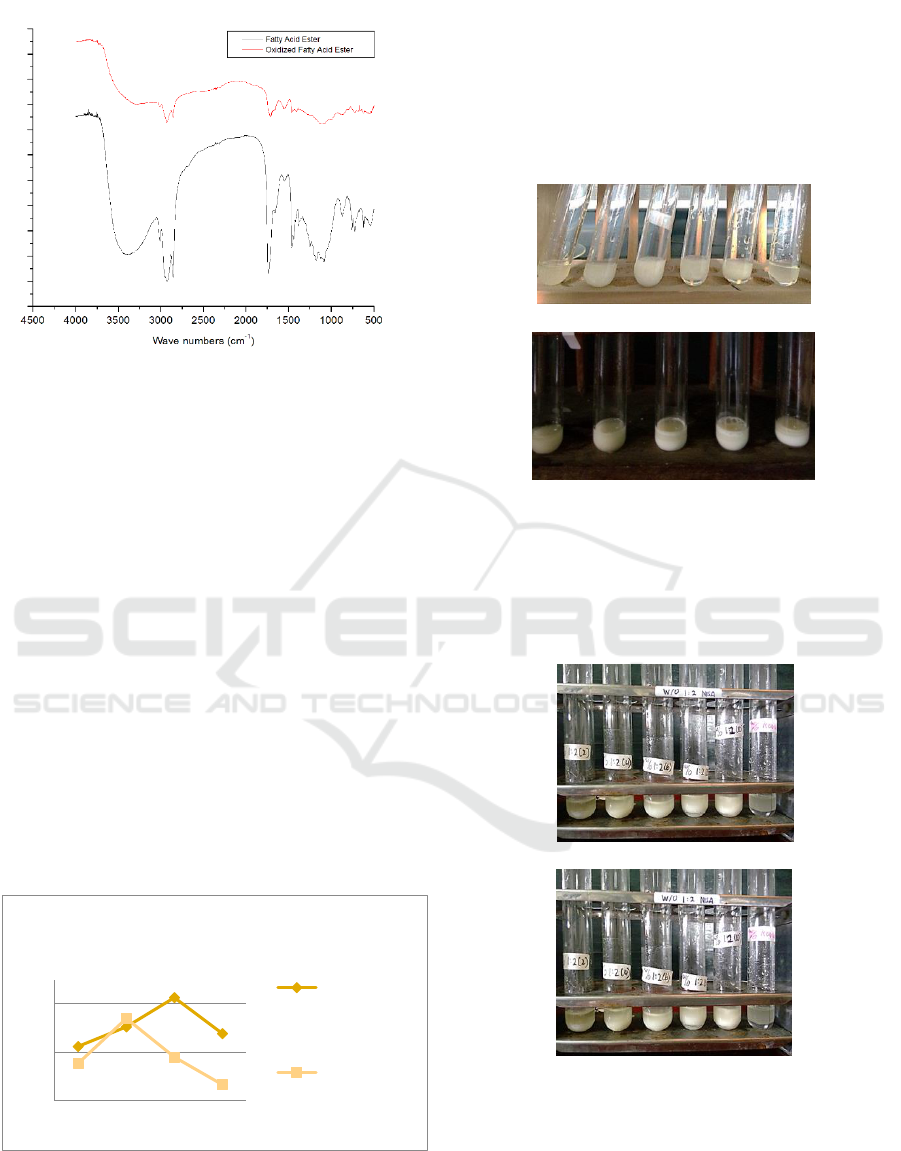

3.3 Emulsifier Test

The ester product has a polar group on one side and

a non-polar group on the other side, allowing the

ester to have properties as an emulsifier. Emulsifier

test for castor oil hydrolyzed fatty acid did not

produce emulsifier properties, whereas for its

oxidation product it gives properties as emulsifier

after 24h. This emulsifiers can be seen in Figure 5.

(a)

(b)

Figure 5 : Emulsifiers, (a) Castor Oil Hidrolized Fatty

Acid ; (b) oxidized fatty acid

In this study, these two fatty acid esters provide

properties as emulsifiers but for the oxidized fatty

acid ethyl ester provide more stable emulsion for

48h. This emulsifier test can be seen in Figure 6.

(a)

(b)

Figure 6 : Emulsifiers ester, (a) castor oil hidrolized fatty

acid ; (b) oxidized fatty acid

This indicated that ester of oxidized fatty acid

has stronger ability as emulsifier, due to addition of

hydroxyl groups to the fatty acid structure that

increase its polarity. The increasing polarity is able

to reduce the surface tension between 2 types of

66,22

70,26

76,31

68,9

62,7

72

64

58,3

55

65

75

1;1 1;2 1;3 1;4

%Konversion

Hidrolyzed

Castor Oil

Fatty Acid

Oxidized

Fatty Acid

BROMO 2018 - Bromo Conference, Symposium on Natural Products and Biodiversity

4

polar and non-polar solutions (in this case water and

oil) (Arbianti, et al., 2009).

The type of emulsion was determined

qualitatively under microscope observation. Figure 7

shows microscopic photograph of emulsion. The red

part is eosin dissolved in water while the yellow part

is the oil phase. In this study, the esters has water in

oil emulsion type.

Figure 7 : The observed emulsion type with microscope

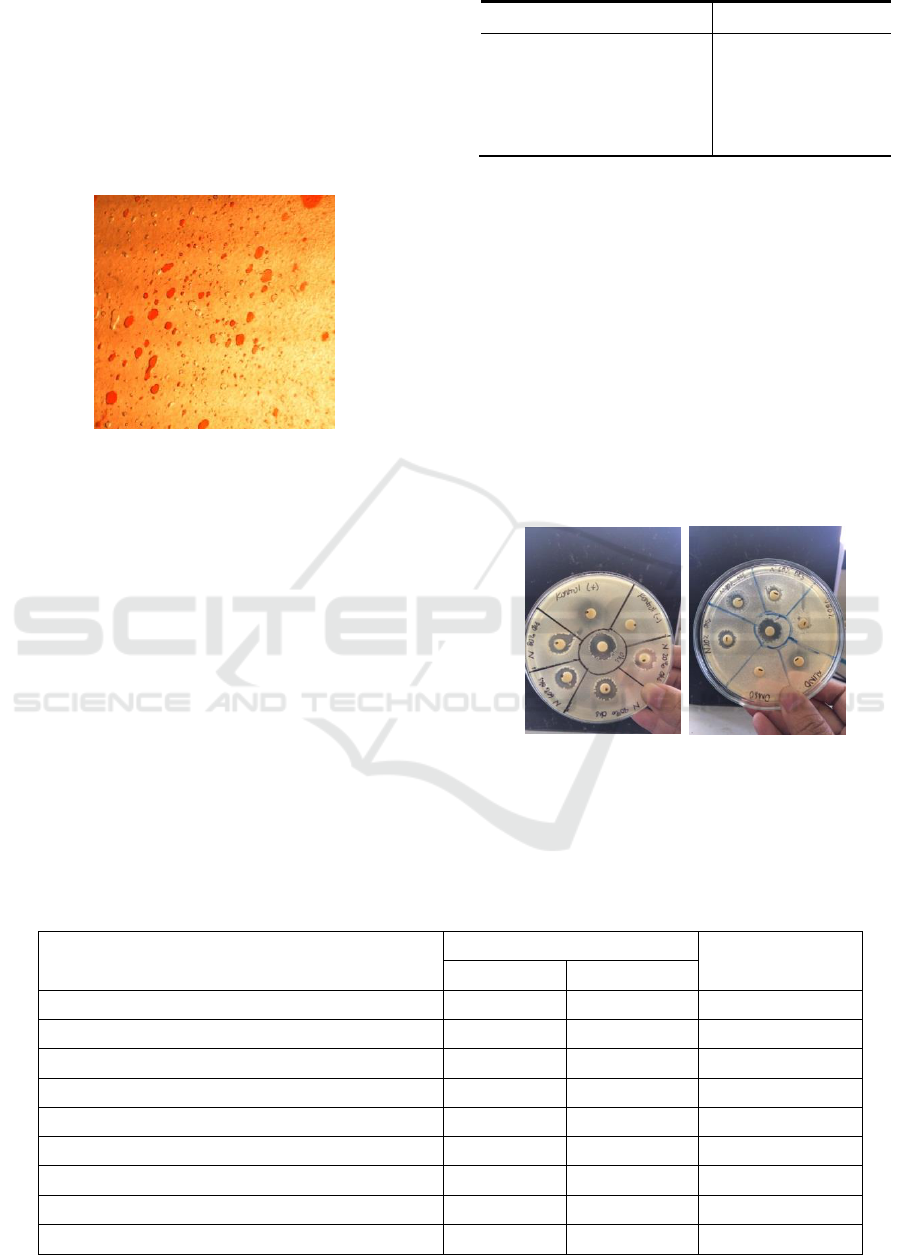

3.4 Antimicrobial Activity Assay

Antimicrobial activity is shown by clear areas

around paper disc that indicate the inhibition of

microorganism growth by antimicrobial agents

(Pratiwi, 2008). The stronger the antibacterial

activity of the compound, the greater the diameter of

clear zone. Based on this research, it was shown that

the oxidized fatty acid, the oxidized fatty acid etyl

ester at concentration of 40% and 80% had the

highest antibacterial activity. All the data of

antibacterial activity assay can be seen in Table 3.

Table 2 show effectivity parameters for

antimicrobial compound.

Table 2: Effectivity parameters for antimicrobial

compound (Greenwood, 1995)

Diameter of clear zone

Classification

> 20mm

Strong

16-20 mm

Medium

10-15 mm

Weak

< 10 mm

No Effective

The ability of a monoglyceride as an

antimicrobial agent is related to the level of

solubility of the compound in water so that it can

dissolve in an aqueous environment, and its

hydrophobicity properties so as to interact with the

cell membrane structure composed of lipid bilayer.

The longer the chain of C atoms, the more non polar

the compound, so the solubility in the water

decreases (Widiyarti et al, 2009). The oxidized fatty

acid has a polar group at the diol group when it

oxidizes the C=C chain. Oxidized fatty acids and its

ester product showed greater activity than its fatty

acid form because they have a stronger polar side

and a longer non-polar side. The antimicrobial

activity assay can be seen in Figure 8.

(a) (b)

Figure 9 : Antimicrobial, (a) Staphylococcus epidermidis ;

(b) Propionibacterium acnes

Table 3 : Inhibition Zone

Sample

Inhibition Zone (mm)

Classification

P. acnes

S. epidirmidis

Ethyl Ester Hidrolyzed Castor Oil Fatty Acid (20%)

3

10

Weak

Ethyl Ester Hidrolyzed Castor Oil Fatty Acid (40%)

X

7

No Effective

Ethyl Ester Hidrolyzed Castor Oil Fatty Acid (60%)

X

8

No Effective

Ethyl Ester Hidrolyzed Castor Oil Fatty Acid (80%)

X

X

No Activity

Oxidized Fatty Acid Ethyl Ester (20%)

12

13

Weak

Oxidized Fatty Acid Ethyl Ester (40%)

17

13

Medium

Oxidized Fatty Acid Ethyl Ester (60%)

14

12

Weak

Oxidized Fatty Acid Ethyl Ester (80%)

12

17

Medium

Oxidized Fatty Acid

15

17

Medium

Enzymatic Esterification Ethyl Ester Fatty Acid from Hydrolyzed Castor Oil and Its Oxidation Product as Emulsifier and Antimicrobial

Compound Using Candida rugosa Lipase E.C.3.1.1.3

5

Ethanol

11

14

Weak

Hidrolyzed Castor Oil Fatty Acid (50%)

12

14

Weak

Hidrolyzed Castor Oil Fatty Acid (100%)

13

15

Weak

Klindamisin (500ppm)

11

20

High

N- Heksane

X

X

No Activity

Castor Oil (50%)

X

X

No Activity

Castor Oil (100%)

X

X

No Activity

DMSO

X

X

No Activity

4 CONCLUSIONS

The synthesis of etyl ester castor oil hydrolyzed fatty

acid and its oxidation product using Candida

rugosa lipase was successfully performed. It was

shown by the presence of C=O ester group band of

FTIR spectra. Etyl ester castor oil hydrolyzed fatty

acid and its oxidation product have activity as

emulsifier with water in oil emulsion type. Oxidized

fatty acid ethyl ester at concentration of 40% has the

highest antimicrobial activity against

Propionibacterium acne bacteria and oxidized fatty

acid ethyl ester at 80% has the highest antimicrobial

activity againts Staphylococcus epidermidis bacteria.

ACKNOWLEDGEMENTS

This work was funded by Hibah Kompeteni

Publikasi Internasional Terindeks Untuk Tugas

Akhir Mahasiswa (PITTA), Universitas Indonesia

2018

REFERENCES

Arbianti, R., Utami, T dkk. (2009). Transesterifikasi

Parsial Minyak Kelapa Sawit dengan Etanol pada

Pembuatan Digliserida sebagai Agen Pengemulsi.

Jurnal Teknik Kimia Indonesia, Vol. 8 No. 1 April

2009, 33-37

Cavalcante, K.S.B. et al., (2009). Optimization of

tranesterification of castor oil with ethanol using

central composite rotatable design

Chand, Subhash et al . (1997). Lipase-catalyzed

esterification of ethylene glycol to mono- and diesters.

The effect of process parameters on reaction rate and

product distribution. J . Enzyme and microbial

Technology Elsevier

Desbois, A., Lawlor, K. (2013). Antibacterial Activity of

Long-Chain Polyunsaturated Fatty Acids against

Propionibacterium acnes and Staphylococcus aureus.

Mar. Drugs 2013, 11, 4544-4557;

doi:10.3390/md11114544

Goud, V.V et al., (2006). Epoxidation of Karanja

(pongamia glabra) Oil by H

2

O

2

, J. of the American Oil

Chemists’ Society

Greenwood. (1995). Antibiotic susceptibility (sensitivity)

test, antimicrobial and chemotherapy. USA: Mc

Graw Hill Company.

Gunstone, F.D., Harwood, J.L., Dijkstra, A.J., (2007). The

Lipid handbook, third ed. CRC Press,Boca Raton

Hykerud, A., Marchetti, J.M., (2017). Esterification of

oleic acid with ethanol in the presence of Amberlyst

15. J. of Supercritical Fluids 126 (2017) 25-36

Janice. (2011). Organic Chemistry Third Edition. The

McGraw-Hill Companies Inc, New York

Marlina, N dkk. (2004). Pengaruh Konsentrasi Oksidator

pada Proses Hidroksilasi Minyak Jarak (Castor Oil)

Dengan atau Tanpa Proteksi Gugus Hidroksi. PROC.

ITB Sains & Tek. Vol. 36 A, No. 1, 2004, 33-43

Pandey A, Benjamin S, Soccol CR, Nigam P, Krieger N,

Soccol VT. (1999). Review: the realm of microbial

lipases in biotechnology. Biotechnol Appl Biochem

Pierre L., (1994). Organic Reaction, Simplicity, and Logic,

Wiley and Son, Singapore (1994).

Pratiwi S.T. (2008). Mikrobiologi Farmasi.Penerbit

Erlangga.Jakarta

Widiyarti, Galuh; Hanafi, Muhammad; Soewarso,

Wahyudi.(2009). Kajian Awal Sintesis Monolaurin

sebagai Antibakteri Staphylococcus aureus. Indo. J.

Chem., 2009, 9 (1), 99 - 106

Zaks, Aleksey; Klibanov, Alexander.(1988). Enzyme-

catalyzed processes in nonaqueous solvents. Vol. 263,

pp. 3194-3201, 1988. USA

BROMO 2018 - Bromo Conference, Symposium on Natural Products and Biodiversity

6