In Vitro Dissolution Test of Bromelain Isolated from Pineapple Core

Encapsulated in Hydrogel Semi-IPN Methyl Cellulose-Chitosan

Ahmad Aly Irfan, Adinda Azkia, Achmad Buhori, Hegi Adi Prabowo, Elmira Vania, Nathasya

Humaira Adriani, and Siswati Setiasih

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Indonesia, Depok West Java,

Indonesia

Keywords: Bromelain, semi-IPN methyl cellulose-chitosan, encapsulation, dissolution, proteolytic activity

Abstract: One of many sources of bromelain is pineapple core. However, in its application as an enzyme-based oral

drug, its activity can be reduced due to interactions with gastric fluids. The isolated bromelain from the

pineapple core is encapsulated with a hydrogel semi-IPN methyl cellulose-chitosan in order to control its

release and to maintain its activity. Isolation of bromelain was conducted with several stages of

fractionation with ammonium sulfate salt and dialysis. The bromelain in semi-IPN methyl cellulose-chitosan

dissolution capability is evaluated in vitro at artificial gastric fluid pH and artificial intestine environment.

The specific activity of bromelain obtained from several purification steps shows an increment. The crude

enzymes, the ammonium sulfate fraction and the dialysis fractions have specific activity value of 22.39

U/mg, 76.73 U/mg, and 111.72 U/mg, respectively. Hydrogel semi-IPN methyl cellulose-chitosan was used

for encapsulation which has the value of crosslinking degree of 46.63% and swelling ratio of 397.59%,

respectively. Meanwhile, post loading encapsulation efficiency is 89.47%. The dissolution test results shows

proteolytic activity of bromelain can be maintained up to 2.83 U/mL in artificial pH environment. The

release rate of bromelain is relatively larger in artificial intestinal environment than artificial gastric fluid.

1 INTRODUCTION

Indonesia occupied third place in ASEAN as an

exporting country of canned pineapple with an

average contribution of 16.42% in 2009-2013

(Respati, 2016). Pineapple core is the solid waste

from pineapple canning industrial process.

Meanwhile, pineapple core is one of many source of

bromelain that can be utilized in the medical

application such as anti-platelet aggregation agents

and other therapeutic effect (Musfiroh et al., 2018,

Manzoor et al., 2016).

Bromelain is a protein-digesting enzyme, thus

the structure can be destabilized due to the pH

change. Destabilization of enzyme structure leads to

decreasing proteolytic activity of bromelain. Based

on studies with milk clotting assay method in

artificial gastric fluid, proteolytic activity of

bromelain was reduced slowly and relatively stable

only in the first 4 hours (Setiasih et al., 2018).

Castell et al. (1997) states that bromelain can be

absorbed in the human intestine without losing its

biological activity. However, in the human digestive

system, before reaching the intestine, oral

consumption of bromelain passes through the

stomach, which has very acidic environment.

Therefore, bromelain needs to be encapsulated in

order to obtain a controlled delivery release of the

bromelain enzyme.

Encapsulation slows down the release of

bromelain, stabilizes bromelain enzyme in gastric

fluid and maintains the proteolytic activity until it

reaches intestine environment. One of the materials

used for encapsulation is semi-interpenetrating

polymer network (semi-IPN) hydrogel. The

dissolution of bromelain was performed in vitro on

artificial gastric fluid (pH 1.2) for 2 hours and in an

artificial intestinal environment (pH 7.4) in the next

10 hours (Farooq et al., 2017).

Irfan, A., Azkia, A., Buhori, A., Prabowo, H., Vania, E., Adriani, N. and Setiasih, S.

In Vitro Dissolution Test of Bromelain Isolated from Pineapple Core Encapsulated in Hydrogel Semi-IPN Methyl Cellulose-Chitosan.

DOI: 10.5220/0009841700002406

In Proceedings of BROMO Conference (BROMO 2018) - Symposium on Natural Product and Biodiversity, page 1

ISBN: 978-989-758-347-6

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

1

2 METHODS

2.1 Isolation, Ammonium Sulfate

Precipitation and Dialysis of

Bromelain

In the cold condition, pineapple core was crushed

into juice using blender. The juice was filtered and

centrifuged at ±4 °C for 45 min with rotor spinning

at 6000 rpm (rotation per minute), the supernatant

obtained was called crude enzyme. Then, protein in

the crude enzyme was precipitated using (NH

4

)

2

SO

4

with interval concentration variation of 0-20%; 20-

50%; and 50-80%. The mixture was centrifuged at

±4 °C for 25 min and 6000 rpm. The precipitate

obtained (pellet) from each fraction was dissolved in

0.20 M phosphate buffer pH 7 solution which had

been cooled. Then, dialysis with cellophane sac in a

0.05 M phosphate buffer pH 7 with continuous

stirring at ±4 °C was done in the fraction with

highest specific activity. The dialysis buffer solution

was replaced every 2 hours and tested with BaCl

2

in

acidic condition. If there is no a white precipitate of

BaSO

4

, thus dialysis process has been completed.

2.2 Determination of Enzyme Specific

Activity

The specific activity of the enzyme was obtained by

dividing total number of the units of enzyme activity

(U) from Kunitz method with total protein (mg) of

Lowry method for each enzyme fraction (Setiasih,

2018).

(2.1)

A and B are the total proteolytic and total protein,

respectively.

2.3 Synthesis of Chitosan and Semi-

IPN Methyl Cellulose-Chitosan

Hydrogel

The synthesis of non-covalent chitosan hydrogel was

carried out by dissolving 2 g chitosan into 2% acetic

acid as much as 50 mL until homogenous. Then, the

mixture was molded and dried at 60 °C with an oven

until the hydrogel is completely dry. Furthermore,

synthesis of semi-IPN methyl cellulose-chitosan was

carried out by adding 1.33 g methyl cellulose into

the homogenous mixture of non-covalent chitosan

and stirred for 24 hours at room temperature until

homogeneous. Then the crosslinking agent as much

as 10% (w/w) to chitosan weight of glutaraldehyde

0.10 M was added to the mixture and stirred for 2

hours. Hydrogels were shaped in a molding

container and dried at 60 °C using an oven for 24

hours. Hydrogels were stored in desiccators for

further testing and characterization (Rokhade et al.,

2007).

2.4 Swelling Ratio and Degree of

Crosslinking Determination

Hydrogels were immersed in 0.20 M phosphate

buffer pH 7 at room temperature for 60 minutes, and

removal of water remains on the hydrogel surface

was conducted using filter paper. The percentage of

swelling ratio was determined by the equation

(Katime and Mendizábal, 2010):

Swelling Ratio (%)=

x100%

(2.2)

Where, m

o

and m are the weights of dry hydrogel

and swollen hydrogel, respectively. Dry hydrogel

(m

o

) weight was measured and then the hydrogel

was immersed into 2% acetic acid for 24 hours.

Then, the hydrogel was grounded and stirred at 60

°C to a fixed weight (Wg). The degree of

crosslinking was determined by the following

equation (Abdel-Mohzen et al., 2011):

Degree of Crosslinking (%) =

x 100%

(2.3)

2.5 Bromelain Encapsulation into

Hydrogel

Dried semi-IPN methyl cellulose-chitosan hydrogel

was spilled with bromelain and incubated for up to

24 hours. Then, the hydrogel was rinsed with cold

phosphate buffer pH 7. The amount of encapsulated

bromelain and encapsulated activity can be

determined by the following formula (Croisfelt et

al., 2015):

Encapsulated Bromelain = [C]

1

– [C]

0

(2.4)

Activity Loading = A

1

– A

0

(2.5)

Efficiency

(2.6)

BROMO 2018 - Bromo Conference, Symposium on Natural Products and Biodiversity

2

[C]

1

and [C]

0

are the bromelain before encapsulation

and bromelain rinsed. A

1

and A

0

are Activity before

encapsulation and activity rinsed.

2.6 In Vitro Release Study of

Bromelain

In vitro release study was carried out by adding a

bromelain encapsulated in semi-IPN hydrogel into a

container containing 10 mL buffer solution of pH

1.2 at a temperature of 37 °C, stirred at a rotational

speed of 100 rpm. After 2 hours, a hydrogel was

transferred into 10 mL phosphate buffer of pH 7.4 to

a total of 12 hours. Then the release solution was

tested for activity by Kunitz method and protein

content by Lowry method.

2.7 Hydrogel Characterization

Chitosan hydrogel, semi-IPN chitosan-methyl

cellulose and encapsulated bromelain in semi-IPN

methyl cellulose-chitosan were characterized using

FT-IR instrumentation, and optical microscope.

3 RESULTS

3.1 Isolation, Ammonium Sulfate

Precipitation and Dialysis of

Bromelain

Proteolytic activity of isolation product of bromelain

was determined by Kunitz method with modification

at its optimal condition (pH 8; 37 °C; 30 min). In

this method casein was used as substrate, where

casein will be dispart into tyrosine and measured by

UV-Vis. Meanwhile, the total protein content was

determined by the Lowry method. The principle of

this method is to sharpen the colors produced on the

Biuret method. After reacting with the Biuret

reagent, the system was added with

phosphomolibdate-phosphotungstate reagent.

Reduction-oxidation reactions will occur at the

tyrosine and tryptophan groups of proteins.

Bromelain is further purified to enhance its

specific activity by ammonium sulfate precipitation.

Ammonium sulfate precipitation method works by

using the salting out principle, in which the salt will

be solvated by the solvent so that the interaction

between proteins is stronger and forming aggregates

(pellets) with low solubility. After precipitation, the

dialysis process was done to remove the content of

excess salt. Dialysis works by the principle of

diffusion, in which smaller molecules of the

membrane pores will go out to a buffer whose

concentration is lower than the buffer to dissolve the

bromelain pellets. Data of total proteolytic activity

and total protein content of bromelain can be seen in

Table 1.

Based on these data, it can be seen that from each

stage of purification causes an increase in the

specific activity of bromelain. The highest specific

activity was found in dialysis fraction of bromelain

(F2D) with value of 111.72 U/mg, with purity level

5 times its crude enzyme, and yield percentage of

39.81%.

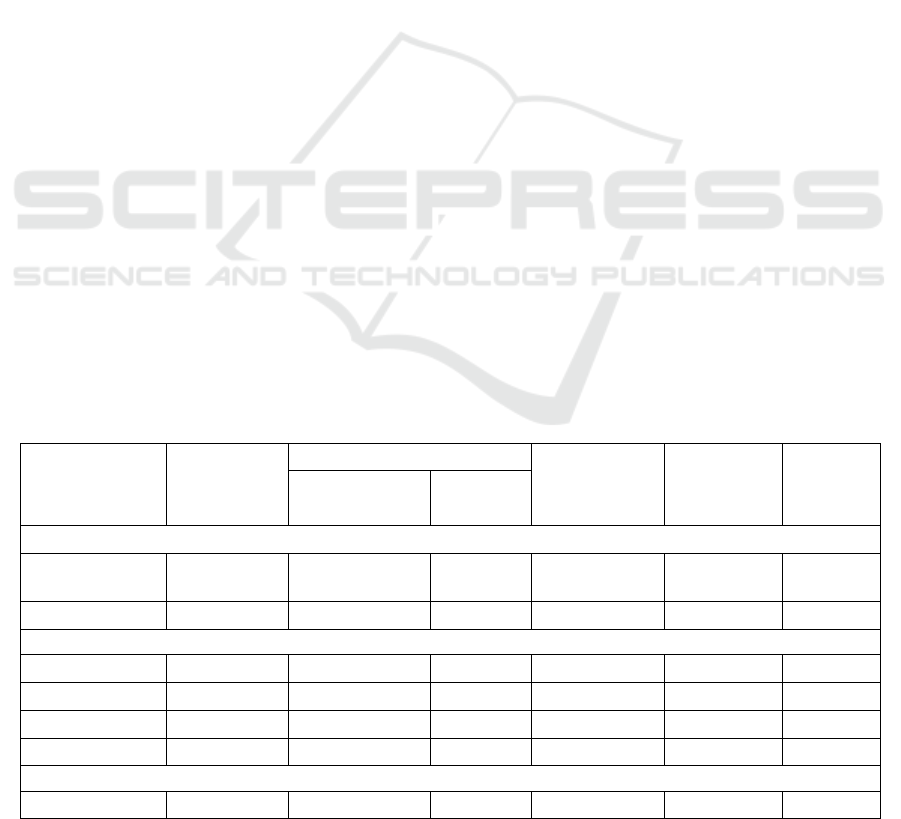

Table 1: Bromelain Activity from each Purification Process

Sample

Volume (mL)

Total

Specific

Activity

(U/mg)

Purity

(times)

% Yield

Proteolytic

Activity (U)

Protein

(mg)

Isolation Process

Pineapple Core

Juice

150

275.00

23.28

11.82

-

-

Crude Enzyme

65

256.75

11.47

22.39

1

100

Ammonium Sulfate Precipitation

F1 (0-20%)

5.4

59.31

1.05

56.34

2.52

23.10

F2 (20-50%)

11.1

137.09

1.79

76.73

3.43

53.39

F3 (50-80%)

3.4

9.01

0.59

15.38

0.69

15.19

F4 (remaining)

55

2.75

4.94

0.56

0.03

2.01

Dialysis

F2D

12

102.20

0.92

111.72

5.00

39.81

In Vitro Dissolution Test of Bromelain Isolated from Pineapple Core Encapsulated in Hydrogel Semi-IPN Methyl Cellulose-Chitosan

3

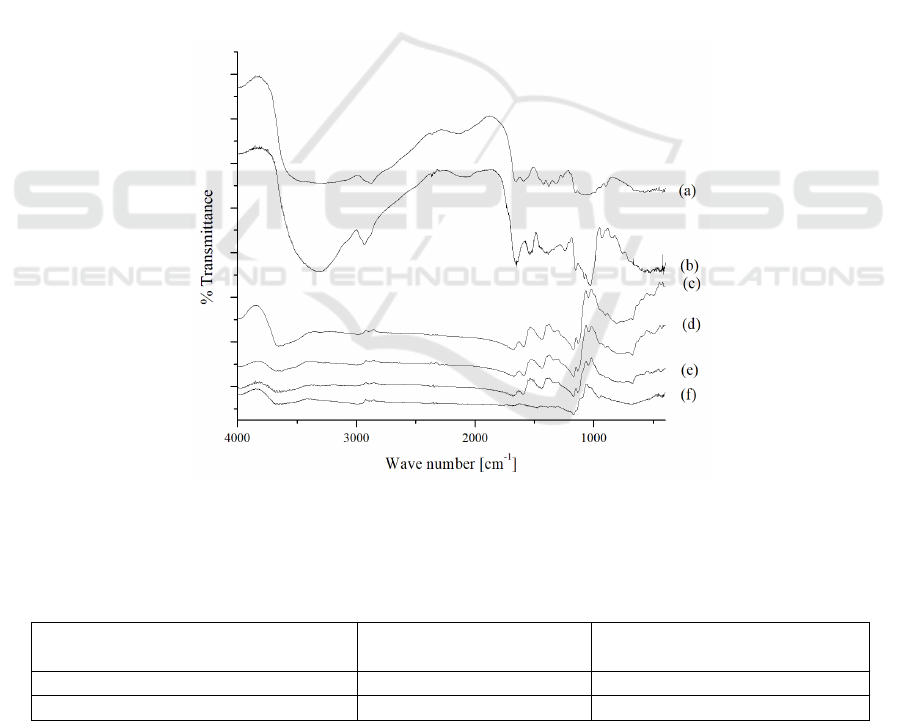

3.2 Semi-IPN Methyl Cellulose-

Chitosan Hydrogel

Visually, semi-IPN methyl cellulose-chitosan

hydrogel has brown color, in contrast to its control

(chitosan non-covalent) that has yellow color. FTIR

characterization of bromelain, chitosan powder and

hydrogel were shown in Figure 1. FTIR spectrum of

powder chitosan can be seen in Figure 1a, where

there is a wide band of uptake at 3568-3003 cm

-1

for

N-H and O-H which overlap each other.

Furthermore, at the wave number of 1653 cm

-1

there

is an absorption for C=O amide stretch of residual

acetyl in chitosan. Furthermore, the N-H stretch of

the primary amine was identified at 1592 cm

-1

and

the C-O-C bridge at 1037 cm

-1

. FTIR spectrum from

bromelain showed several absorption bands for C-N

stretch bands at wave number 1540 cm

-1

, absorption

band with strong intensity for C=O stretch (amide)

at 1653 cm

-1

, at 2933 cm

-1

for C-H stretch and at

wave number 3317 cm

-1

for N-H stretch (Figure 1b).

The difference between the two hydrogels (Fig. 1c

and d) lies in the intensity of the C = N imine band

uptake at the wave number 1596 cm

-1

. The imine-

absorbing bands arise because of a Schiff base

occurs from a crosslink reaction.

The physical parameters of semi-IPN methyl

cellulose-chitosan hydrogel were compared with

non-covalent hydrogels (as control) to ensure that

crosslinking with glutaraldehyde have been

successfully performed. Physical parameters test

including the determination of swelling ratio and

degree of crosslinking. The test results of hydrogel

physical parameters are presented in Table 2. The

semi-IPN hydrogel has a higher crosslinking degree

and relatively smaller swelling. This indicates that

the crosslink reaction has reacted well. Visual

appearance of hydrogel has been shown at Figure 2.

Figure 1: FTIR Spectra a) chitosan powder, b) bromelain, c) chitosan non-covalent hydrogel, d) semi-IPN methyl-cellulose

chitosan hydrogel, e) semi-IPN methyl cellulose-chitosan hydrogel after encapsulation, f) semi-IPN methyl-cellulose

chitosan hydrogel after in vitro release study

Table 2: Result of Swelling Ratio & Degree of Crosslinking Determination (n=3)

Hydrogel

Degree of Crosslinking

(%)

Swelling Ratio (%)

Chitosan non-covalent

0.50 ± 0.03

2627.58 ± 89.75

Semi-IPN Methyl cellulose-chitosan

46.63 ± 2.92

397.59 ± 8.66

BROMO 2018 - Bromo Conference, Symposium on Natural Products and Biodiversity

4

Figure 2: Visual appearance of a) chitosan non-covalent, b) semi-IPN methyl cellulose-chitosan, c) semi-IPN hydrogel

swollen, d) semi-IPN after crosslinking degree test.

3.3 Bromelain Encapsulation into the

Hydrogel

Post loading encapsulation method is chosen to

make the encapsulation process more efficient and

fewer bromelain of dialysis fraction are being used.

The post loading efficiency can be determined

indirectly by washing the encapsulated hydrogel

with phosphate buffer pH 7, the results was

tabulated in Table 3.

Furthermore, the hydrogel after encapsulation is

characterized by FTIR and the spectra was presented

in Figure 1e. From the comparison of hydrogel

absorption spectra before and after encapsulation,

bromelain does not resulting a new absorption band.

This indicates that the interaction that occurs is only

physical interactions in the form of hydrogen bonds

which is characterized by changes in intensity at

3568-3003 cm

-1

. In addition, there was also a shift of

absorption bands from 1683 cm

-1

to 1672 cm

-1

.

Table 3: Post Loading Efficiency of Bromelain into the Hydrogel

Material

Protein Content of

Encapsulated

Bromelain (µg/mL)

Proteolytic Activity of

Encapsulated

Bromelain (U/mL)

Post Loading

Efficiency

(%)

Semi-IPN methyl cellulose-chitosan

68.00 ± 3.46

8.30 ± 0.03

89.47 ± 4.56

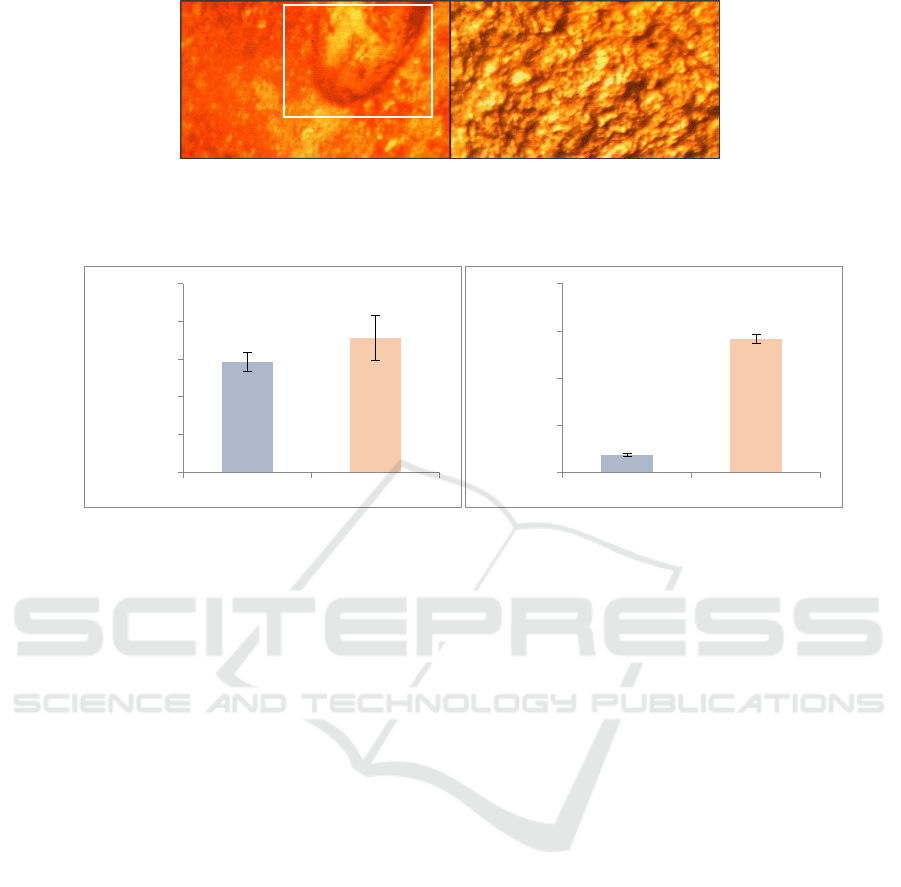

3.4 In Vitro Release Study of

Bromelain

Dissolution is also referred as a release process that

aims to determine the protein content of bromelain

coming out of the hydrogel matrix and monitored its

proteolytic activity. The visual appearance of the

hydrogels before and after the dissolution test is

shown in Figure 3a-d.

Hydrogel after dissolution test are also

characterized using the FTIR presented in Figure 1f.

In the FTIR results, it appears that there are some

absorption bands that missing from the matrix, such

as C=N and C=O. This is due to damage to the

matrix network due to dissolution process. The

damage is also morphologically identified using the

optical microscope presented in Figure 4a and b.

Meanwhile, the encapsulated bromelain release

profile and its proteolytic activity are shown in

Figure 5a and b.

Figure 3: Visual appearance of semi-IPN methyl cellulose-chitosan hydrogels a) before and b) after encapsulation, c)

dissolution process, d) after dissolution test.

a)

d)

c)

b)

a)

d)

c)

b)

In Vitro Dissolution Test of Bromelain Isolated from Pineapple Core Encapsulated in Hydrogel Semi-IPN Methyl Cellulose-Chitosan

5

Figure 4: Morphological structure of semi-IPN methyl cellulose-chitosan hydrogels characterized by Boeco Germany

optical microscope with 45 times magnification a) before and b) after dissolution

Figure 5: In Vitro release study of bromelain, a) dissolution percentage of bromelain and b) proteolytic activity of

dissolution result.

The apparent release in the artificial gastric fluid

(29.27 ± 2.53) was smaller than in the artificial

intestinal environment (35.61 ± 5.91). In line with

this, the proteolytic activity of bromelain in the

artificial intestinal environment (2.83 ± 0.10) is also

greater than in the artificial gastric fluid (0.36 ±

0.03).

4 CONCLUSIONS

Bromelain is successfully encapsulated in semi-IPN

methyl cellulose-chitosan hydrogel. The release rate

of bromelain in the artificial intestinal environment

is greater than in the artificial gastric fluid.

Furthermore, the activity of dissolved bromelain in

the artificial intestinal environment is greater than in

the intestinal environment. This suggests that the

activity of bromelain can be maintained up to the

intestine.

ACKNOWLEDGEMENTS

This research was financially supported by Program

Kreativitas Mahasiswa (PKM) 2018 with contract

number 136/SPK/KM/IV/2018 from Ministry of

Research, Technology and Higher Education of the

Republic of Indonesia.

REFERENCES

Abdel-Mohzen AM, Aly AS, Hrdina R, Montaser AS,

Hebeish A., 2011. Eco-synthesis of PVA/Chitosan

Hydrogels for Biomedical Application. J.Polym.

Environ. 19: 1005-1012.

Castell JV, Friedrich G, Kuhn CS, Poppe GE., 1997.

Intestinal absorption of undegraded proteins in men:

presence of bromelain in plasma after oral intake.

American Journal of Physiology 273(1): G139–G146.

Croisfelt F, Martins BC, Rescolino R, Coelho DF,

Zanchetta B, Mazzola PG, Goulart LR, Pessoa AJr,

Tambourgi EB, Silveira E., 2015. Poly(N-

Isopropylacrylamide)-co-Acrylamide Hydrogels for

the Controlled Release of Bromelain from

Agroindustrial Residues of Ananas comosus. Planta

Med. 81: 1719-26.

Farooq U, Khan S, Nawaz S, Ranjha NM, Haider MS,

Khan MM, Dar E, Nawaz A., 2017. Enhanced gastric

retention and drug release via development of novel

floating microspheres based on eudragit E100 and

polycaprolactone: synthesis and in vitro evaluation.

Designed Monomers and Polymers 20: 419-433.

0

10

20

30

40

50

1,2 7,4

Dissolution

Percentage (%)

pH

a)

0

1

2

3

4

1,2 7,4

Proteolytic Activity

(U/mL)

pH

b)

a)

b)

BROMO 2018 - Bromo Conference, Symposium on Natural Products and Biodiversity

6

Katime I and Mendizábal E., 2010. Swelling properties of

new hydrogels based on the dimethyl amino ethyl

acrylate methyl chloride quanternary salt with acrylic

acid and 2-methylene butane-1,4-dioic acid monomers

in aqueous solutions. Materials Sciences and

Application 1: 162-167.

Manzoor Z, Nawaz A, Mukhtar H, Haq I., 2016.

Bromelain: Methods of Extraction, Purification and

Therapeutic Applications. Brazilian Archives of

Biology and Technology 59 pp.1–16.

Musfiroh FF, Setiasih S, Handayani S, Hudiyono S, Ilyas

NM., 2018. In vivo antiplatelet activity aggregation

assay of bromelain fractionate by ethanol from extract

pineapple core (Ananas comosus [L.] Merr). IOP

Conf. Ser.: Mat. Sci. Eng. 299 (0122017): 1-4.

Respati E., 2016. Outlook nenas. Jakarta, Indonesia: Pusat

Data dan Sistem Informasi Pertanian Sekretariat

Jenderal Kementerian Pertanian 2016.

Rokhade AP, Shelke NB, Patil SA, Aminabhavu TM.,

2007. Novel Interpenetratung Polymer Network

Microspheres of Chitosan and Methylcellulose for

Controlled Release of Theophylline. Carbohydrate

Polymers, 678-687

Setiasih S, Darwis AAC, Dzikria V, Hudiyono S., 2018.

Stability test of partially purified bromelain from

pineapple (Ananas comosus (L.) Merr) core extract in

artificial stomatch fluid. IOP Conf. Ser.: Mater. Sci.

Eng. 299: 1-7.

In Vitro Dissolution Test of Bromelain Isolated from Pineapple Core Encapsulated in Hydrogel Semi-IPN Methyl Cellulose-Chitosan

7