Air-cooling System for a Large Size Photovoltaic Panel

*

Idir Kecili, Sonia Ait Saada and Rezki Nebbali

Laboratoire d’Energétique, Mécanique et Matériaux, LEMM. Université Mouloud Mammeri Tizi-Ouzou, Algeria

Keywords: air-cooling, fan, photovoltaic, radiation.

Abstract: Under extreme climatic conditions, the temperature of a photovoltaic solar panel can increase considerably.

This can alter its performance and contribute to its degradation. To overcome these inconveniences, we

propose to cool this PV panel by the ambient air. To do this, we use fan which blows air on the underside of

the PV panel. For a large size PV panel (commercialized panel) two fans are needed to ensure this cooling.

The judicious arrangement of these two fans makes it possible to reduce the temperature gradient on the PV

panel. At first approach, four cases of positions of the fans were considered. By determining the optimum

position, the influence of the ambient air temperature (T

air

= 25 and 50 ° C) and the intensity of the radiation

(R

G

= 400 W/m² and 1000 W/m²) was studied by varying the air mass flow rate from 200 to 400g/s. The

results obtained show that the average temperature of the silicon varies slightly with the mass flow of air

while it is sensitive to the air temperature and the solar radiation. Moreover, the maximum temperature

gradient on the PV panel is only influenced by solar radiation.

1 INTRODUCTION

The use of renewable energies, especially solar

photovoltaic energy, makes it possible to offset the

depletion of fossil fuels and reduce global warming.

The low efficiency of PV panels has led the research

towards the design of new photoelectric materials

(Sze, 1981), (Koch, Ito and Schubert, 2001) and

(Yoann, 2014), while others are interested in the

cooling of PV panels. (Hasanuzzaman et al, 2016)

reviewed methods of cooling.

(Kaiser et al, 2014) studied the cooling of a PV

panel integrated into the building. This system

allows the cooling of the PV panel and the

preheating of the ventilation air of the building.

Another cooling system uses the ground to cool the

ambient air before blowing it onto the PV panel

(Sahay, Sethi and Tiwari, 2013). (Iqbala et al, 2016)

studied the water cooling effect of a polycrystalline

PV panel; this technique achieves an increase in

conversion efficiency of 7 to 12%.

The homogenization of the temperature on a PV

panel is a very important factor that must be taken

into account to avoid power dissipation and possibly

the degradation of the panel (Royne, Dey and Mills,

2005). (Baloch et al, 2015) analyzes the performance

of a convergent channel heat exchanger to ensure

uniform cooling of PV by water. This system

ensures a temperature reduction of 57 and 32% for

the days of June and December, respectively.

(Bahaidarah, Baloch and Gandhidasan, 2014)

designed a water jet cooling system in order to

ensure a homogenization. (Al Tarabsheh et al, 2013)

designed a water-cooling system to ensure low and

uniform PV panel temperature.

(Amelia et al, 2016) investigated the air cooling

which consists of fans that blows ambient air on the

rear face of the PV panel. As main results, two fans

were enough to reduce the PV panel temperature by

14°C. (D. Nebbali, R. Nebbali and Ouibrahim, 2018)

optimised this cooling system. A new design which

consists of a fan placed underside the PV panel

ensures better cooling. Indeed, under extreme

climatic conditions (50°C of ambient air temperature

and 1000W.m

-

² of solar radiation), the efficiency

improvement reached 29.52% while the PV panel

temperature lowered by 39°C.

The objective of this work is precisely to propose

an air-cooling system that allows a better cooling

with a good homogenization of the temperature. It

consists of use two fans that blow ambient air on the

underside of a PV panel.

Kecili, I., Ait Saada, S. and Nebbali, R.

Air-cooling System for a Large Size Photovoltaic Panel.

DOI: 10.5220/0009773403590364

In Proceedings of the 1st International Conference of Computer Science and Renewable Energies (ICCSRE 2018), pages 359-364

ISBN: 978-989-758-431-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

359

2 PROBLEM POSITION

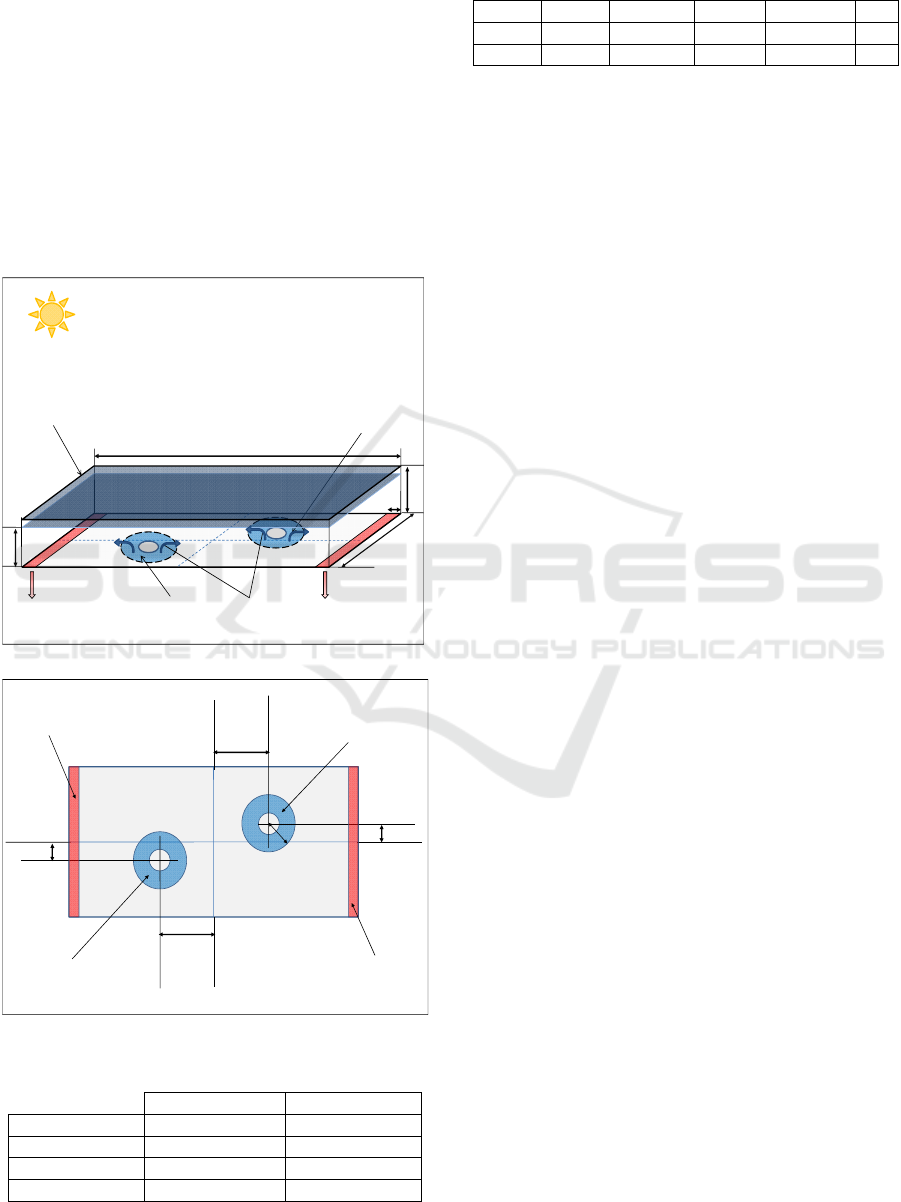

In figure 1 we describe the sketch of the PV panel

cooling system. As the first step, the positions of the

two fans must be determined to ensure a well

cooling of the PV panel. For this purpose, four

positions of the fans were considered (Figure 2 –

Table 1). Then, under extreme climatic conditions of

air temperature and solar radiation characterised by:

T

air

= 50°C and R

G

=1000Wm

-

², we studied the

influence of air flow, air temperature and the solar

radiation is then considered to evaluate the

efficiency of this cooling system.

Fan

L

w

t

T

air outlet air outlet

Fan

glass exposed

to the sun

air inlet

d

Geometric data:

t = 3.8 cm L = 158 cm d = 3.5 cm

T= 4.5 cm w= 80.8 cm

Figure 1: Sketch of the PV with the cooling system.

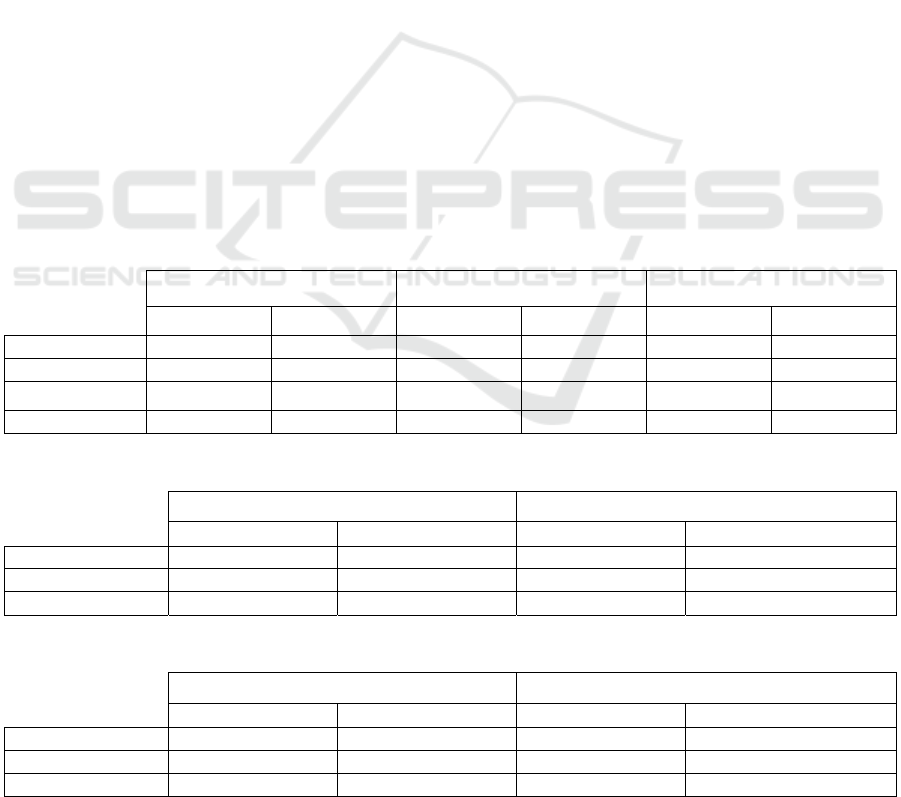

H

h

h

Fan

Fan

Air outlet

Air outlet

H

R

R = 15.25 cm

Figure 2: Bottom view of the cooled PV panel.

Table 1: Positions of the fans.

H (cm) h (cm)

Case 1

39.5 0

Case 2

39.5 10

Case 3

29.5 10

Case 4

19.5 10

Table 2: Material properties of a PV panel (Armstrong and

Hurley, 2010).

Layer e(mm)

λ(W/m.K)

ρ(kg/m

3

)

C

P

(J/kg.K)

ε

Glass

3.2 1.8 3000 500

0.7

Silicon

0.3 148 2330 677

0.7

3 METHOD

3.1 Associated Equation

3.1.1 Thermal Balance of the Solar Panel

The thermal balances performed on the PV panel are

expressed for the solid media of glass and silicon

(Table 2), by:

ΔT + Q / λ = 0 (1)

Where:

heat source of the glass layer (W/m

3

):

Q

g

= [α

g

R

G

– ε σ (T

p

4

– T

v

4

)] / e

g

(2)

Where:

T

v

= 0.0552 T

ai

r

1.5

(3)

heat source of the silicon layer (W/m

3

):

Q

si

= α

si

τ

g

R

G

/ e

si

(4)

Where T

p

is the PV panel temperature; T

v

the

temperature of the sky; α

g

the absorption coefficient

of the glass; α

si

is the

absorption coefficient of the

silicon; ε is the emissivity of the surface of the PV; σ

is the Boltzmann constant and τ

g

is the

transmissivity of the glass.

3.1.2 Thermal Balance of the Cooling Fluid

As for the forced circulation air on the lower side of

the panel, the distributions of the velocity and

temperature field are determined by solving the

coupled equations of continuity, momentum and

energy. To do this, CFD-Fluent code was used.

3.1.3 Convective Exchange between the

Panel and the Ambient Air

Moreover, the upper face of the panel exchanges, by

natural convection, heat with the ambient

environment. The convective exchange coefficient

was evaluated by the following correlations

(Holman, 1997).

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

360

N

u

= 0.54 (R

a

)

0.25

for 10

4

< R

a

< 10

6

(5)

N

u

= 0.15 (R

a

)

0.33

for 10

6

< R

a

< 10

11

(6)

Where:

Nu and R

a

are, respectively, the Nusselt and the

Rayleigh numbers.

3.2 Boundary Conditions

3.2.1 Positions of the Fans

In order to determine the optimal position of the

fans, four cases (Table 1) were considered under air

temperature T

air

= 50°C, solar radiation

R

G

=1000W/m² and air mass flow rate varying from

200 g/s, 300 g/s and 400 g/s.

3.2.2 Influence of the Air Temperature and

the Intensity of the Solar Radiation

For the optimal position retained, we studied the

influence of the variation of the temperature of the

air (T

air

= 25 and 50°C) associated with the variation

of the intensity of solar radiation (R

G

= 400 and

1000 W/m²).

4 RESULTS

4.1 Influence of Flow and Positions of

Fans

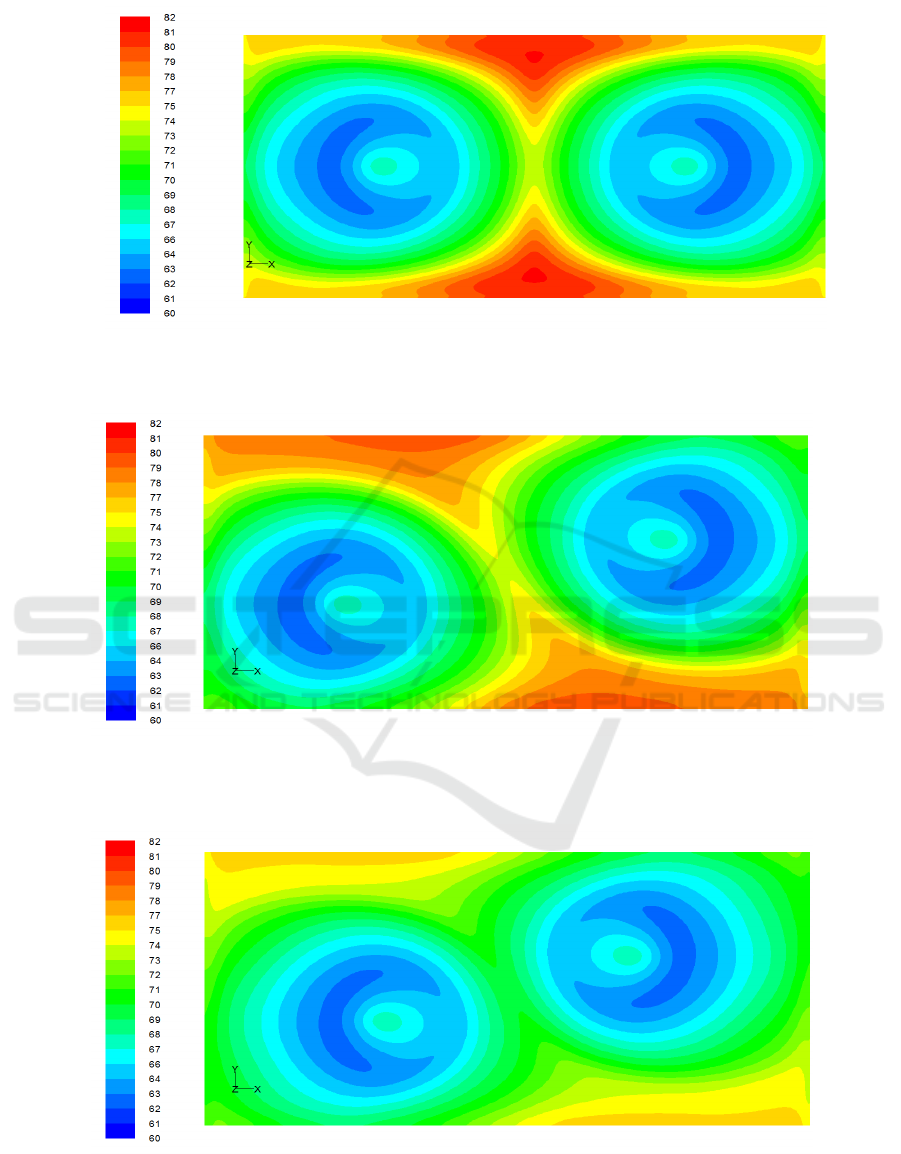

The maximum temperature gradient ΔT prevailing

on the PV panel highlight the influence of the fans

positions. Indeed, as shown in figures 3, 4, 5 and 6,

for an air flow of 400 g/s the distribution of the

temperature field is almost homogeneous for case 3

with an average silicon temperature T

si

= 69.1°C and

a maximum gradient temperature T = 13.3°C

(Figures 3-6, Table 3).

4.2 Influence of Air Temperature and

Global Radiation

By adopting the positions of the fans selected for the

case 3, we studied the influence of T

air

and R

G

at

different mass air flows.

It appears from Table 4 that the average silicon

temperature increases significantly with T

air

and R

G

,

whereas it varies slightly when the air flow increases

from 200 to 400 g/s.

Moreover, the maximum temperature gradient

remains only sensitive to variations in solar radiation

(Table 5).

Table 3: Average silicon temperature and maximum temperature gradient on the panel.

200g/s 300g/s 400g/s

T

si

ΔT T

si

ΔT T

si

ΔT

Case 1 76,9 19,9 72,9 18,8 70,5 18

Case 2 75,9 18,4 72,7 17,4 70,3 16,6

Case 3 74,3 13,9 71,3 13,3 69,1 13,3

Case 4 76,9 16,3 73,2 15,3 70,5 14,9

Table 4: Average silicon temperature (°C).

T

air

=25°C T

air

=50°C

R

G

=400 (W/m²)

R

G

=1000 (W/m²) R

G

=400 (W/m²)

R

G

=1000 (W/m²)

200g/s 33,7 48,9 59,8 74,3

300g/s 32,6 45,8 58,6 71,3

400g/s 31,7 43,5 57,6 69,1

Table 5: Maximum temperature gradient on the panel (°C).

T

air

=25°C T

air

=50°C

R

G

=400 (W/m²)

R

G

=1000 (W/m²) R

G

=400 (W/m²)

R

G

=1000 (W/m²)

200g/s 5,5 14,3 5,9 13,9

300g/s 5,1 13,4 5,6 13,2

400g/s 5 13,2 5,6 13,3

Air-cooling System for a Large Size Photovoltaic Panel

361

Figure 3: Temperature distribution on the PV panel (°C) at T

air

=50°C, R

G

=1000W/m

2

and 400g/s of air mass flow rate -

Case 1.

Figure 4: Temperature distribution on the PV panel (°C) at T

air

=50°C, R

G

=1000W/m

2

and 400g/s of air mass flow rate -

Case 2.

Figure 5: Temperature distribution on the PV panel (°C) at T

air

=50°C, R

G

=1000W/m

2

and 400g/s of air mass flow rate -

Case 3.

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

362

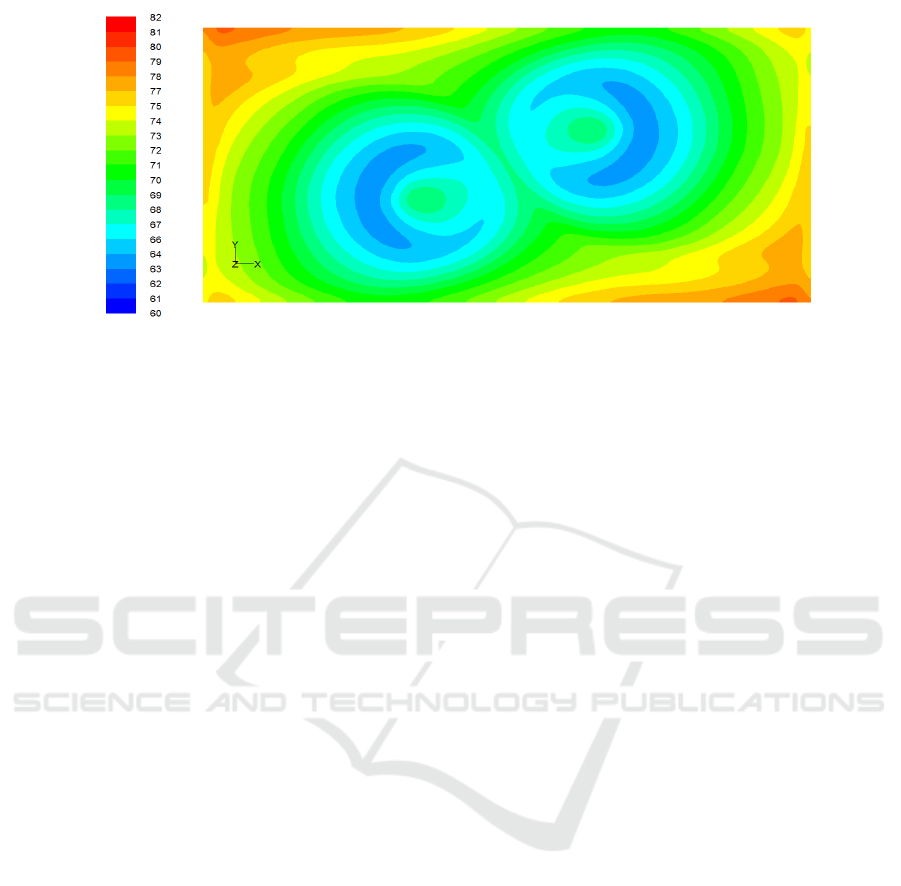

Figure 6: Temperature distribution on the PV panel (°C) at T

air

=50°C, R

G

=1000W/m

2

and 400g/s of air mass flow rate -

Case 4.

5 CONCLUSION

This work proposes a new design of a PV panel

cooling system. It consists of two fans that blow

ambient air on the rear face of the PV panel. In order

to ensure a good cooling of the PV panel with a

better homogenization of the distributed temperature

on the PV panel, it was necessary to determine the

optimal position of these two fans.

By varying the air mass flow rate from 200 to

400g/s, we observed that:

The PV panel temperature was very sensitive

to changes in air temperature and solar

radiation.

The heterogeneity of the temperature field on

the PV panel increases with the rise of solar

radiation.

REFERENCES

Sze, S.M., 1981. Physics of Semiconductor Devices, John

Wiley& Sons, New York.

Koch, C, Ito, M, Schubert, M., 2001. ‘Low-temperature

deposition of amorphous silicon solar cells’, Solar

Energy. Mater. Solar Cells, vol. 68, pp. 227-236.

Yoann, R., 2014. Croissance et Physique de structure

Photovoltaïque CuInSe2, Ph.D. thesis, The University

of Montpellier 2 Sciences et Techniques, France.

Hasanuzzaman, M, A.B.M.A. Malek, Islam, M.M,

Pandey, A.K, Rahim, N.A., 2016. Global advancement

of cooling technologies for PV systems, A review

Solar Energy, Vol. 137, pp. 25-45

Kaiser, A.S, Zamora, B, Mazón, R, García, J.R, Vera, F.,

2014. Experimental study of cooling BIPV modules

by forced convection in the air channel, Applied

Energy, vol. 135, pp. 88–97.

Sahay, A, Sethi, V.K, Tiwari, A.C., 2013. Design,

optimization, and system integration of low cost

ground coupled central panel cooling system (GC-

CPCS). (ISSN 2277-4106). International Journal of

Current Engineering and Technology, vol. 3(4), pp.

1473-9.

Iqbala, S, Afzalb, S, Mazharc, A.U, Anjumd, H, Diyyane,

A., 2016. Effect of Water Cooling on the Energy

Conversion Efficiency of PV. American Scientific

Research Journal for Engineering, Technology and

Sciences (ASRJETS), vol. 20, No 1, pp. 122-128.

Royne, A, Dey, C, Mills, D., 2005. Cooling of

photovoltaic cells under concentrated illumination: a

critical review. Sol Energy Mater Sol Cells, vol. 86(4),

pp. 451–83.

Baloch, A.A.B, Bahaidarah, H.M.S, Gandhidasan, P, Al-

Sulaiman, F.A., 2015. Experimental and numerical

performance analysis of a converging channel heat

exchanger for PV cooling, Energy Conversion and

Management, vol. 103, pp. 14-27.

Bahaidarah, H.M.S, Baloch, A.A.B, Gandhidasan, P.,

2014. Modeling and comparative analysis of jet

impingement cooling and conventional channel

cooling for photovoltaic strings, In: 2014 IEEE 40th

photovoltaic specialist conference (PVSC). IEEE; p.p.

748–53.

Al Tarabsheh, A, Voutetakis, S, Papadopoulos, A.I,

Seferlis, P, Etier, I, Saraereh, O., 2013. Investigation

of Temperature Effects in Efficiency Improvement of

Non-Uniformly Cooled Photovoltaic Cells. Chemical

enginerieng transactions, vol. 35.

Amelia, A.R, Irwan, Y.M, Irwanto, M, Leow, W.Z,

Gomesh, N, Safwati, I, Anuar, M.A.M., 2016. Cooling

on Photovoltaic Panel Using Forced Air Convection

Induced by DC Fan, International Journal of

Electrical and Computer Engineering (IJECE), Vol. 6,

No. 2, pp. 526-534.

Nebbali, D, Nebbali, R, Ouibrahim, A., 2018. Improving

photovoltaic panel performance via an autonomous air

Air-cooling System for a Large Size Photovoltaic Panel

363

cooling system –experimental and numerical

simulations, International Journal of Ambient Energy.

Armstrong, S, Hurley, W.G., 2010. A thermal model for

photovoltaic panels under varying atmospheric

conditions, Applied Thermal Engineering, vol. 30, pp.

1488-1495.

Holman, J.P., 1997. Heat Transfer, McGraw-Hill, 8th

edition.

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

364