Structural Study of Al-doped ZnO Thin Films Produced by the

Sol-

g

el Techni

q

ue

F. Boufelgha

1,2

, N. Brihi

2

, A. Bouaine

2

, R. Zellagui

1

, N. Ouafak

1

and A. Boughelout

1

1

Research Center in Industrial Technologies CRTI, P. O. Box 64, Cheraga 16014, Algiers, Algeria

2

Laboratory of Condensed Matter and Nanomaterials Physics (LPMCN), Department of Physics, Faculty of Exact

b

oufel

g

halem

@y

ahoo.f

r

Keywords: thin films, spin coater, ZnO / Al, XRD, SEM, UV-Visible

Abstract: In this work we studied the effect of aluminum doping concentration on the structural properties of zinc

oxide thin films, we deposited samples of ZnO and aluminum doped ZnO with a doping rate of 1, 2, 3, 4

and 5%, on glass substrates by the spin coating technique. The structural characterization of the samples is

done by the XRD and SEM techniques, the XRD spectra show that the layers are polycrystalline with a

hexagonal würtzite structure, and a preferred orientation in the plane (002), and for the doping 5% the

structure is almost monocrystaline (002). SEM images are used to confirm grain sizes and surface

conditions. Optical characterization is done by UV-visible spectroscopy, gives a good visible transmittance

up to 80% and exceeds 90% for 2% doping, and the gap varies with the doping variation with a small gap

for the same doping (2%).

1 INTRODUCTION

In recent years, transparent and conductive

oxides (TCO) such as ZnO, find important

applications in new technologies. Since the

discovery at the beginning of the century of duality:

good electrical conductivity and good optical

transparency in the visible, research in the field of

TCO are really intensified from the 80s. Non-

toxicity and this great existence on earth are the

main advantages of ZnO, these advantages give the

possibility of reducing the manufacturing costs of

ZnO-based composites, in the massive state the ZnO

has several structures, among its structures, the

Würtzite structure is the most stable for ZnO, these

lattice parameters of the latter are: a = 0.3296 nm

and c = 0.5207 nm. It does not have a center of

symmetry. It can be deduced that this structure is an

insertion of two HC networks (the O2- and Zn2 +

network), with the displacement of the oxygen

network by a fraction of 0.38 the size of a unit cell

relative to ZnO is a degenerate semiconductor with

n-type conductivity, this conductivity is due in

particular to excess zinc in interstitial positions, with

a large direct gap (3.436 to 0 K and 3.2 eV at room

temperature). ). Its electrical properties can be

changed by heat treatment, or by appropriate doping,

the conductivity of ZnO can be increased by the

substitution of trivalent atoms for the positions of

the Zn atoms, and to reduce the conductivity the Zn

atoms can be substituted by monovalent atoms.

The methods of elaboration of the thin layers are

classified in two big categories: Physical methods

(Sputtering, Laser ablation, Evaporation under

vacuum), and Chemical methods (Spray pyrolysis,

Sol gel), in this work we prepared our layers by the

Sol-Gel method associated with spin coater.

2 EXPERIMENTAL PART

The ZnO layers are deposited based on a

solution that prepares as follows: zinc acetate

dihydrate [Zn (CH

3

COO) 2. 2H2O] (a concentration

of 0.4M / L) dissolved in a mixture of isopropanol,

ethanol and monoethanolamine, this mixture and

heated stirring with a temperature of 60 ° C for a

period of 2 hours. The dopant source (Aluminum) is

aluminum chloride (AlCl

3

). The deposit is made by

Boufelgha, F., Brihi, N., Bouaine, A., Zellagui, R., Ouafak, N. and Boughelout, A.

Structural Study of Al-doped ZnO Thin Films Produced by the Sol-gel Technique.

DOI: 10.5220/0009772001290132

In Proceedings of the 1st International Conference of Computer Science and Renewable Energies (ICCSRE 2018), pages 129-132

ISBN: 978-989-758-431-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

129

the spin-coating technique (rotation of about 2500

rpm) for 30s, and drying between each 2 layers at

200 ° C for 10 minutes, and a final annealing at 600

° C for 3 hours.

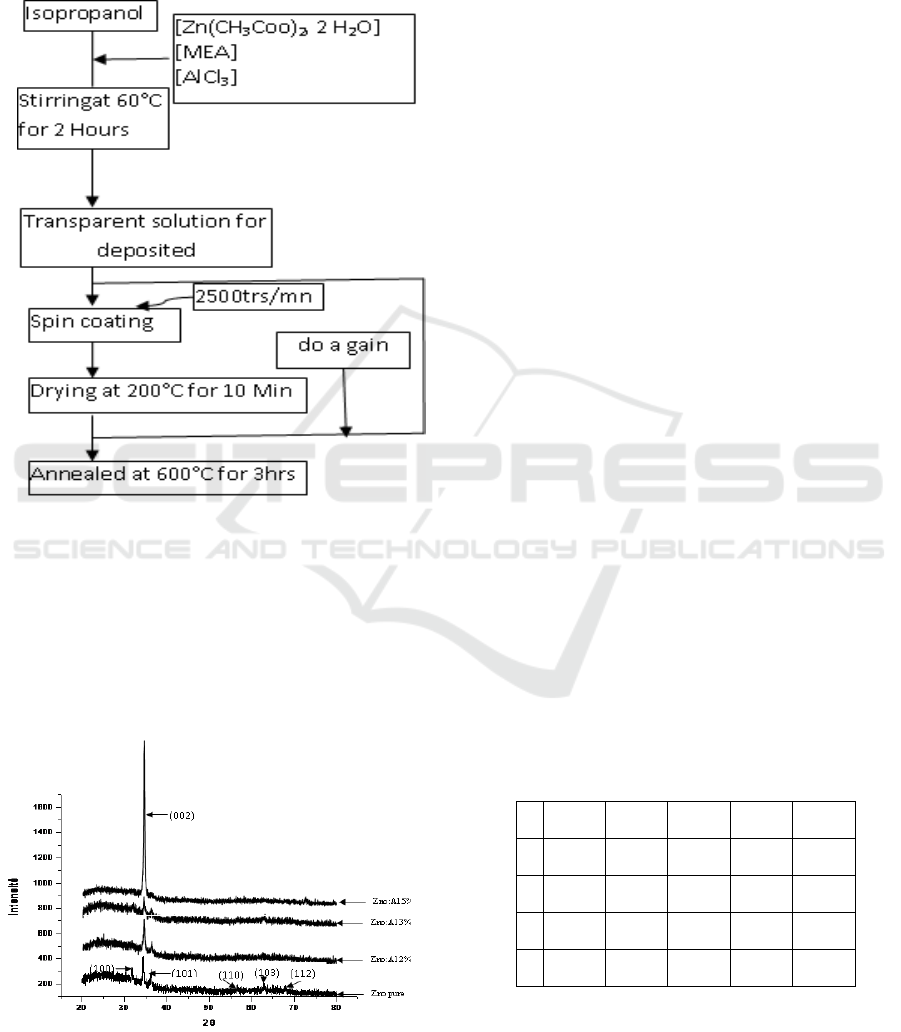

We can schematize the steps followed for the

preparation of our samples as follows:

Fig.1 Schematization of the steps followed for the

elaboration of our samples.

3 RESULTS AND DISCUSSIONS

3.1 Structural Properties

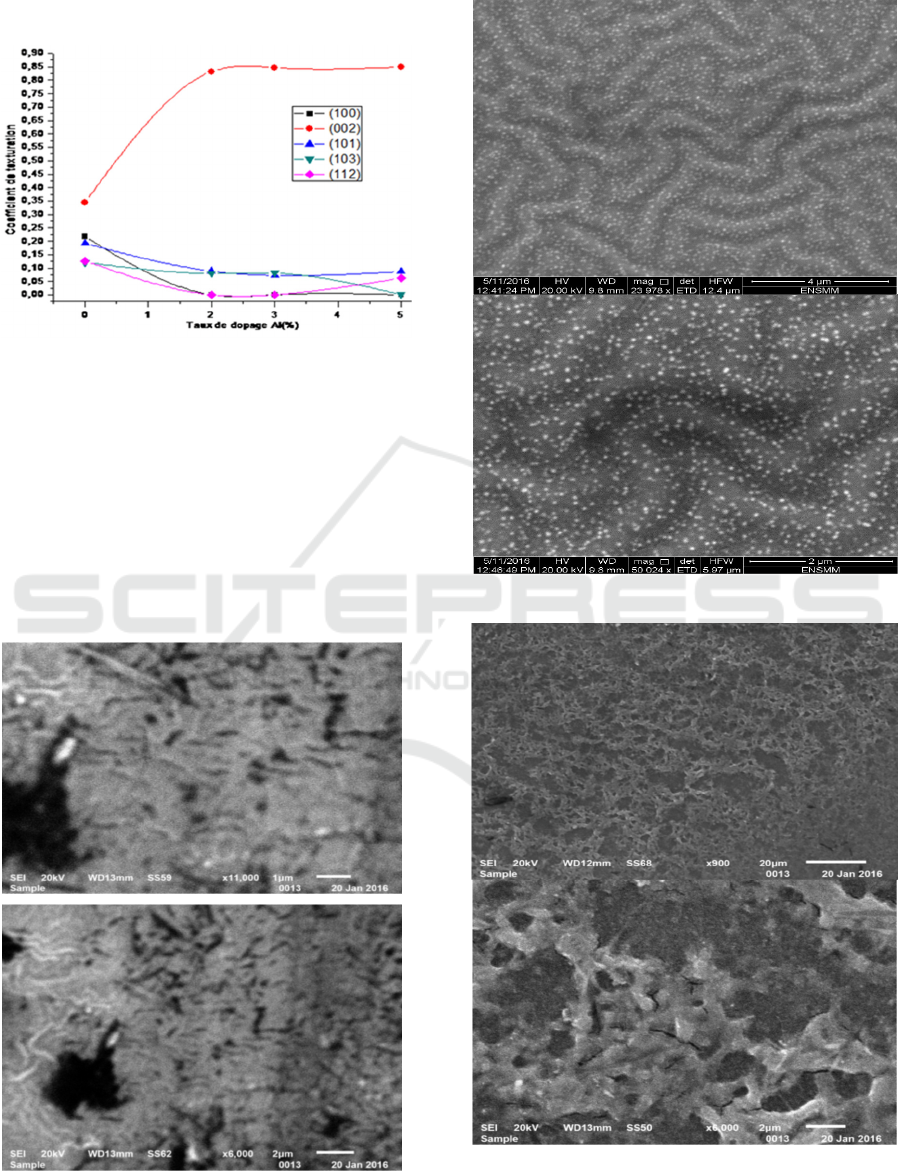

Fig.2 ZnO DRX Spectra: Pure, Doped Aluminum 2, 3 and

5%

Fig.2 shows the X-ray spectra of thin layers of

zinc oxide, deposited by the sol-gel method (spin-

coating technique), pure samples, doped with

aluminum with different concentrations 2, 3 and 5%.

The identification of the peaks is made by

comparing them with the diffraction angles found on

ASTM sheets 36-1451 (American Society for

Testing and Materials). The spectra affirm a

crystallization. For the ZnO which one can not speak

about a growth in a preferential direction (the

appearance of 3 peaks of the same intensity) almost:

(100), (002) and (101), in the case of ZnO doped on

speaks of growth in a preferential orientation

according to the direction (002). One can speak to

almost total growth in the (002) direction for the 5%

concentration. These results confirm the results

found by F. Chouikh for pure and Al doped ZnO

samples deposited by the pyrolysis spray technique.

Texture

For the purpose of checking the preferred

orientation, the ratio R

xi

which is given by:

∑

For pure ZnO: there are 5 peaks with the

concentrations: I

(100)

=283, I

(002)

=450, I

(101)

=251,

I

(103)

=258, I

(112)

=164,

R

(100)

= I

(100)

/[ I

(100)

+ I

(002)

+ I

(101)

+ I

(103)

+

I

(112)

]=283/1306=0.217

R

(002)

= I

(002)

/[ I

(100)

+ I

(002)

+ I

(101)

+ I

(103)

+

I

(112)

]=450/1306=0.344

R

(101)

= I

(101)

/[ I

(100)

+ I

(002)

+ I

(101)

+ I

(103)

+

I

(112)

]=251/1306=0.192

R

(103)

= I

(103)

/[ I

(100)

+ I

(002)

+ I

(101)

+ I

(103)

+ I

(112)

]=158/1306=0.121

R

(112)

= I

(112)

/[ I

(100)

+ I

(002)

+ I

(101)

+ I

(103)

+

I

(112)

]=164/1306=0.126

in the same way, we find:

Table 1: Texturing variation of orientations for each

doping rate.

(100) (002) (101) (103) (112)

0 0.217 0.344 0.192 0.121 0.126

2 0.000 0.832 0.088 0.080 0.000

3 0.000 0.847 0.072 0.081 0.000

5 0.000 0.850 0.087 0.000 0.063

For the undopedZnO, the growth does not have a

preferential direction, we notice the appearance of

the peaks (lines): (100), (002), (101), (103) and

(112) with almost the same concentrations

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

130

(intensities), this non-texturing is similar to the

surface energies of the three lines.

Fig.3 Variation of texture coefficients according to doping

rates.

In the case of doped ZnO, an increase in the

texture coefficient of the line (002) as a function of

ZnO doping rate with Al is observed, a maximum

texturing (R (002)) is observed on the line (002) for

the concentration 5%.

3.2 Morphology of the Layers

Fig 4, 5 and 6 show the SEM images of aluminum

doped ZnO samples by percentages 2%, 3% and 5%

respectively.

Fig.4 ZnO/Al 2%

Fig.5 ZnO/Al 3%

Fig.6 ZnO/Al 5%

The SEM images show a homogeneity of the

morphology of the surface of all the samples.

Structural Study of Al-doped ZnO Thin Films Produced by the Sol-gel Technique

131

Fig.4 (2% doping) has a homogeneous can with

the presence of rod-shaped relief.

Fig.6 (5% doping) has a melted and porous

layer showing the presence of some microcracks at

the surface.

For Fig.5 (3% doping) has a completely

homogeneous layer, with the presence of shape

grains.

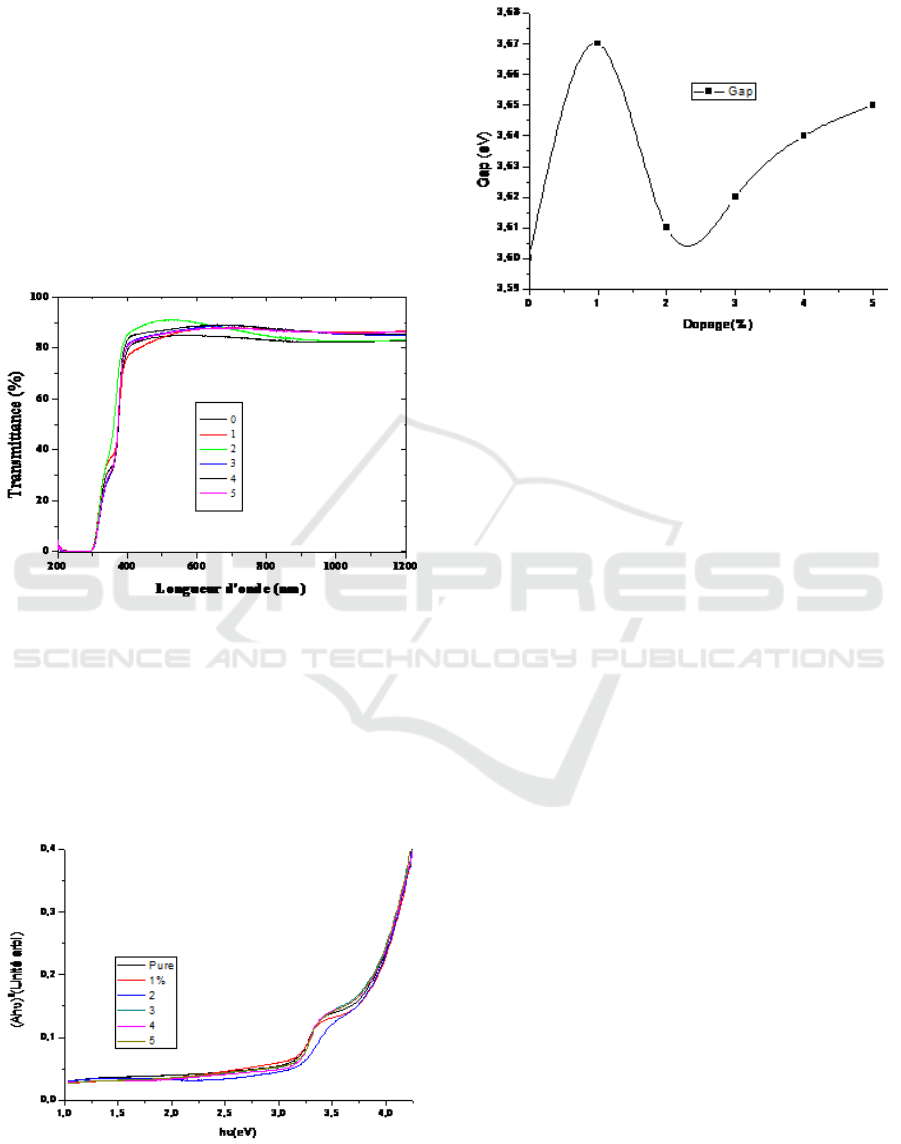

3.3 Optical Properties

Fig.7 represents the UV-visible spectra of

aluminum doped ZnO samples (Al) in percentages 1,

2, 3, 4 and 5%.

Fig.7 Transmittance spectra of ZnO and ZnO / Al (1,

2, 3, 4 and 5%)

The UV spectra show a transmittance higher

than 80% in the visible for all the samples, the

transmittance exceeds the 90% for the 2% doping,

one can hard that the latter to a better transmittance

compared to the others.

Fig.8 shows the optical Gaps of ZnO and ZnO /

Al (1, 2, 3, 4 and 5%).

Fig.8 ZnO and ZnO / Al Optical Gap (1, 2, 3, 4 and 5%)

Fig.9 shows the variation of the ZnO / Al gaps

Fig.9 optical Gap variation of ZnO and ZnO / Al (1, 2, 3, 4

and 5%)

4. CONCLUSION

The thin layers of undoped and Al doped ZnO

were developed by spin-coater-associated sol-gel

methods on glass substrates. Aluminum doping

changes the properties of our layers (structural and

optical). the results of the XRD show a preferential

orientation according to the plan (002). The UV-

Visible results show a transmittance of over 80%.

Note for concentration 5% the crystal and almost

mono

.

REFERENCES

Chouikh Fathi et al, paperexposed on Vème Congrès

International sur les Energies Renouvelables et

l’Environnement, Sousse ,Tunisie,04-06 Novembre,

E.Heredia et al, Applied Surface Science 317 (2014) 19-25

M. Sahal and al, Afrique SCUENCE 02(3)(2006) 245-154

N.JabenaBegum et al. Superlattices and Microstructures

53 (2013) 89-98

R. Sankarganesh et al, Journal of Alloys and Compounds

698 (2017) 555-564

S.Fernandez et al, Thin Solid Films 517 (2009) 3152-3156

Youssef Ammaihet al.Opt Quant Electron (2014) 46:229–

234

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

132