Zinc Doped of CdS Layers Deposited by Chemical Bath Deposition

Method

R. Zellagui

1, 2

, H. Dehdouh

2

, F. boufelgha

2

, A. Boughelout

2

, T. Sahraoui

1

, D. Chaumont

3

, M.

Adnane

1

1

L

aboratory of Electron Microscopy and Materials Sciences, Université des Science et des Technologies d’ Oran, P.O. Box

1505 El-M’naouer, 31000 Oran, Algérie

2

Research Center in Industrial Technologies CRTI, P.O.Box 64, Cheraga 16014, Algiers, Algeria

3

Laboratoire Interdisciplinaire Carnot de Bourgogne, University of Bourgogne France Comté, Dijon, France

Keywords: CdZnS, chemical bath, SEM, Solar Cells, Thin Films.

Abstract: The chemical bath technique (CBD) uses to deposit the thin layers of CdZnS. we study the properties of

CdxZn1-xS layers deposited by chemical bath (CBD) as surface morphology, structural, optical and chemical

properties were studied by spectrophotometer SEM, XRD, EDAX and UV-visible. The transmittance is 80%

in the visible region from 300 nm to 800 nm; the crystalline structure is hexagonal and cubic, the grain size

is between 9.95 and 25.82 nm.

1 INTRODUCTION

In photovoltaic the material most used is silicon. But

the silicon is not the ideal material for solar cells

based on thin films because of their low absorption

coefficient and a high cost of the product it. For these

reasons, there are many researchers on other materials

in order to replace the silicon. Among these materials,

the Semiconductors groups II-VI are the best

candidates. The use of semiconductor thin films have

generated much interest in the development of

various applications in various electronic and

optoelectronic devices (T. Gruszecki, 1993), (D. Xia,

2011). The importance of technology-based thin film

devices is mainly due to their low production costs.

The Cd

x

Zn

1-x

S is a group II-VI important

semiconductor material (T.D. Dzhafarov, 2006, T.

Prem Kumar, 2011), Cd

x

Zn

1-x

S alloy compounds

have attracted technological interest because their

energy gap can be adjusted and network parameters

can be modified (Ng. Gaewdang, 2005, A.

Mukherjee, 2015). Cd

x

Zn

1-x

S ternaries can form a

continuous series of solid solutions, allowing

variation of the band gap of Cd

x

Zn

1-x

S from 2.43 eV

for CdS to 3.7 eV for ZnS by adjusting the

composition. CdZnS thin films were deposited by a

variety of techniques, for example, Chemical Bath

Deposition (CBD) ] (R. Mariappan, 2011, P.B.

Bagdare, 2010), Spray Pyrolysis (Y. Ravi Prakash,

2010, M. Glatettin, 2010), Successive Ion Layer

Adsorption and Reaction (SILAR) (G. Laukaitish,

2000), vacuum evaporation (D. Patidar, 2008, P.

Kumar, 2004), the method Dip Coating (M. Abdel

Rafea, 2009) and the screen printing technique (V.

Kumar, 2012). Chemical deposition processes are the

low-cost process. The layers obtained found to have

comparable quality to those obtained by the more

classy and expensive physical deposition methods.

The Chemical Bath Deposition is an evolution of the

process by controlled precipitation from solution.

This process has recently been developed for the

deposition of thin layers of the metal chalcogenide.

CBD method attracts attention today because they do

not require sophisticated and expensive equipment

(vacuum systems): simple hot plates with a magnetic

stirrer are required. In this work have been

synthesized and studies the proprieties (optics,

morphological and chemical composition) of CdZnS

thin films obtained by Bain chemical deposition, to

replace the CdS in the solar cell.

Zellagui, R., Dehdouh, H., boufelgha, F., Boughelout, A., Sahraoui, T., Chaumont, D. and Adnane, M.

Zinc Doped of CdS Layers Deposited by Chemical Bath Deposition Method.

DOI: 10.5220/0009771700310035

In Proceedings of the 1st International Conference of Computer Science and Renewable Energies (ICCSRE 2018), pages 31-35

ISBN: 978-989-758-431-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

31

2 EXPERIMENTAL

CdCl

2

, Zn ((C

2

H

3

O

2

)

2

. 2H

2

O) and NH

2

-CS-NH

2

were used as ion source materials for Cd

2+

, Zn

2+

and

S

2

, respectively. The experimental detail located in

reference (R. Zellagui, 2019). The films were

prepared under continuous stirring. The deposition

time was 30 minutes. The deposited films were

cleaned with de-ionized water and alcohol. Cleaning

was necessary to remove the surface impurities and

minimize the particle agglomeration. Deposited films

were dried with N

2

gas. As deposited, Cd

x

Zn

1-x

S thin

films were in golden yellow color. Annealing used

furnace vacuum at temperature was 500 ° C for 1

hour. The performance of the transmittance of visible

light of the sample was measured using a Shimadzu

UV-1800 spectrophotometer. The surface

morphology of the film was carried out using

scanning electron microscopy (SEM) model JEOL

JSM-6610LA. The crystal structure of the samples

was characterized by an X-ray diffractometer Bruker

with a Cu-Kα radiation with wavelength (1.54 Å) and

the Raman spectra were recorded with a Bruker

SENTERRA R200L spectrometer

3

RESULTS AND DISCUSSION

3.1 Morphological Proprieties

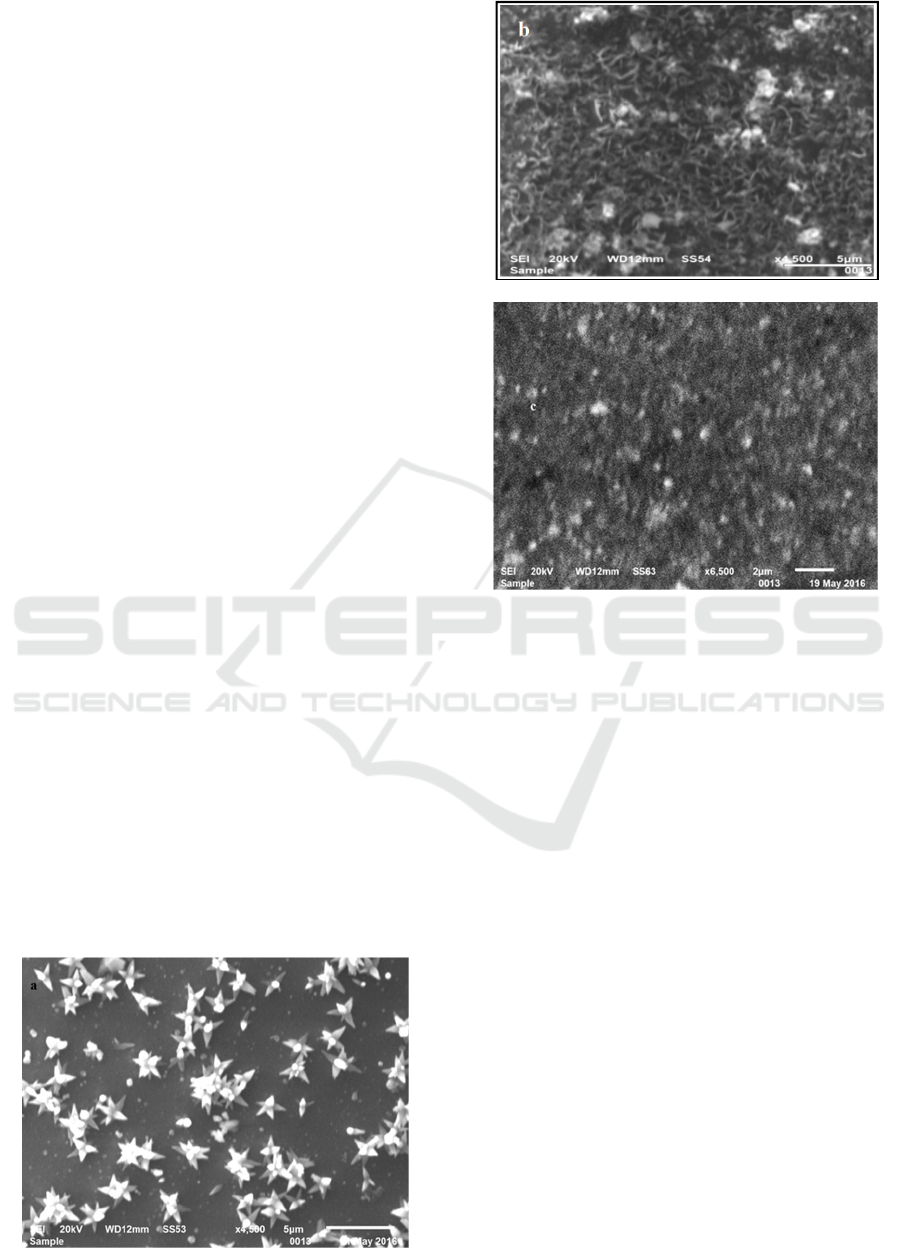

Fig. 1 shows the SEM surface images of Cd

x

Zn

1-x

S

thin films of composition x= 0.7, 0.5, 0.1,

respectively. As the composition (x) increases Zn is

more incorporated into CdS films. Which are

indicated by XRD as well as SEM (S.V. Borse, 2007).

The CdZnS layer constituted of a dense layer of small

crystallites and few large particles are embedding in

the surface. These particles are quite likely Cd

x

Zn

1-x

S

colloidal particles formed on the substrate during film

growth. The shape of particle is changing with

increases of Zn concentration.

Fig. 1 Typical SEM images of nanostructured

Cd

x

Zn

1-x

S thin films (a=Cd

0.1

Zn

0.9

S, b= Cd

0.5

Zn

0.5

S,

c= Cd

0.7

Zn

0.3

S) annealed at 500 °C.

3.2 Optical Properties

The optical transmission of CdZnS thin films with

different concentrations is using the

Spectrophotometer UV-visible (Shimadzu UV-

1800). We observe that the transmittance of our

samples is varied between 60 and 80% in visible

region this variation due to the decrease in Zinc

concentration. Whereas in the region <450 nm

fundamental absorption therefore, our thin films

possess transparency performance in the 450-800 nm

region, the latter gives them great importance in solar

cells as a buffer layer.

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

32

Fig. 2 Transmission spectra of Cd

x

Zn

1-x

S thin films.

The optical band gap Eg was obtained by

extrapolating the linear portion of the plot (αhν)

2

versus (hν) to α = 0, according to the following

equation (Y. Bakha, 2011):

α = A (hν − Eg)

n

(1)

Where hν is the photon energy, Eg is the band gap, A

is the edge parameter and n = 1/2 for direct gap

material.

The values of optical band gap Eg of thin films

(Cd

0.7

Zn

0.3

S, Cd

0.5

Zn

0.5

S and Cd

0.1

Zn

0.9

S) are (3.5,

3.61 and 3.8 eV) respectively, we find that the gap

energies of our thin layers are closer to that of ZnS

(K. Nagamani, 2012, T. Ben Nasr 2006).

Fig. 3 Extrapolations of E

g

for Cd

x

Zn

1-x

S thin films.

3.3 Chemical Composition

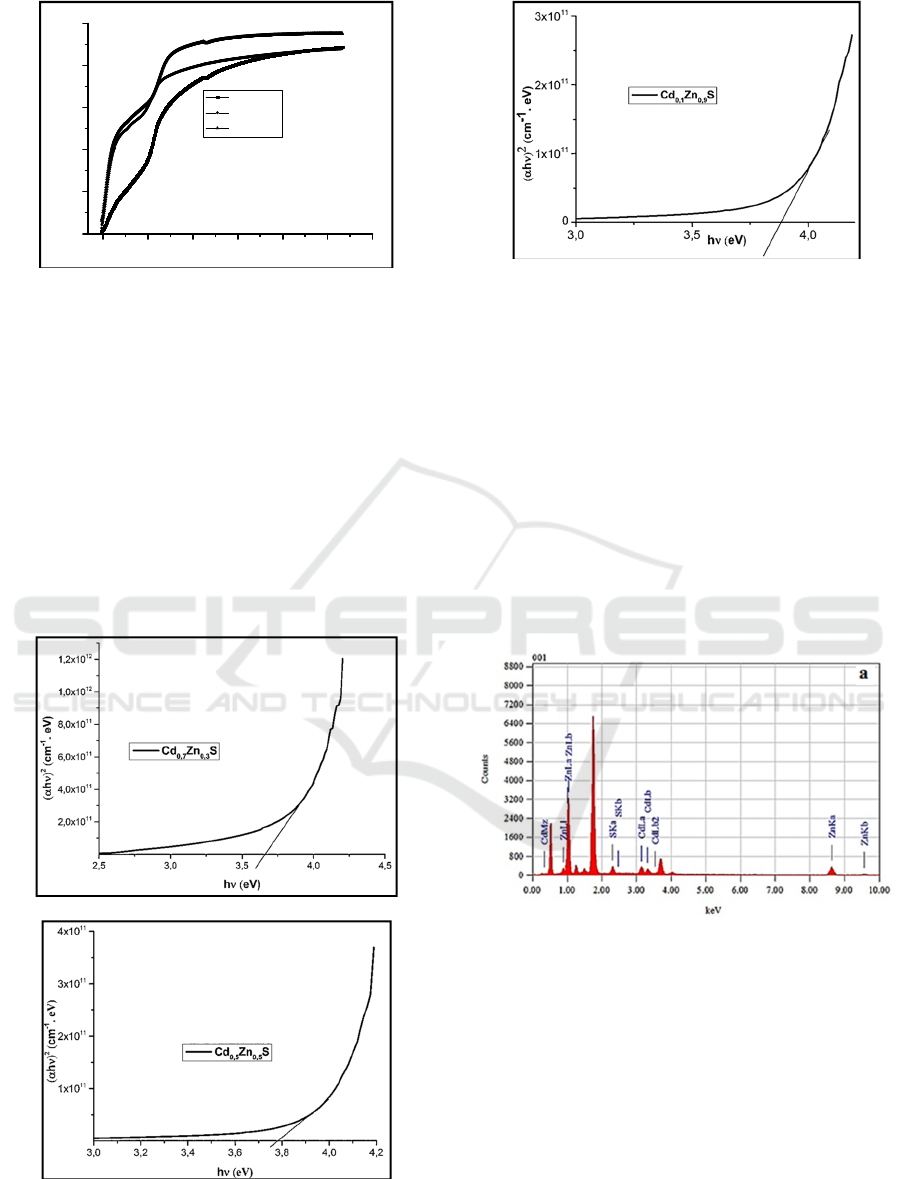

Quantitative analysis by EDX mines layers of CdZnS

was carrying out to investigate the stoichiometry. The

results are present Fig.4, which confirms the presence

of Cd, Zn and S, with atomic percentages of Cd / Zn

/ S: 19.36 /60.43 /20.20, 42.69/19.08/38.23 and

40.41/23.35/36.23 for three concentrations of

Cd

0.1

Zn

0.9

S, Cd

0.7

Zn

0.3

S, and Cd

0.5

Zn

0.5

S (A.

Abdolahzadeh Ziabari, 2013), (] S.D. Chavhan,

2008).

300 450 600 750 900 1050 1200

0

20

40

60

80

100

Cd

0.7

Zn

0.3

S

Cd

0.5

Zn

0.5

S

Cd

0.1

Zn

0.9

S

Intensity (u.a)

Wavelength (nm)

Zinc Doped of CdS Layers Deposited by Chemical Bath Deposition Method

33

Fig. 4 EDX spectra for CdZnS thin films (a

=Cd

0.1

Zn

0.9

S, b= Cd

0.7

Zn

0.3

S, c= Cd

0.5

Zn

0.5

S)

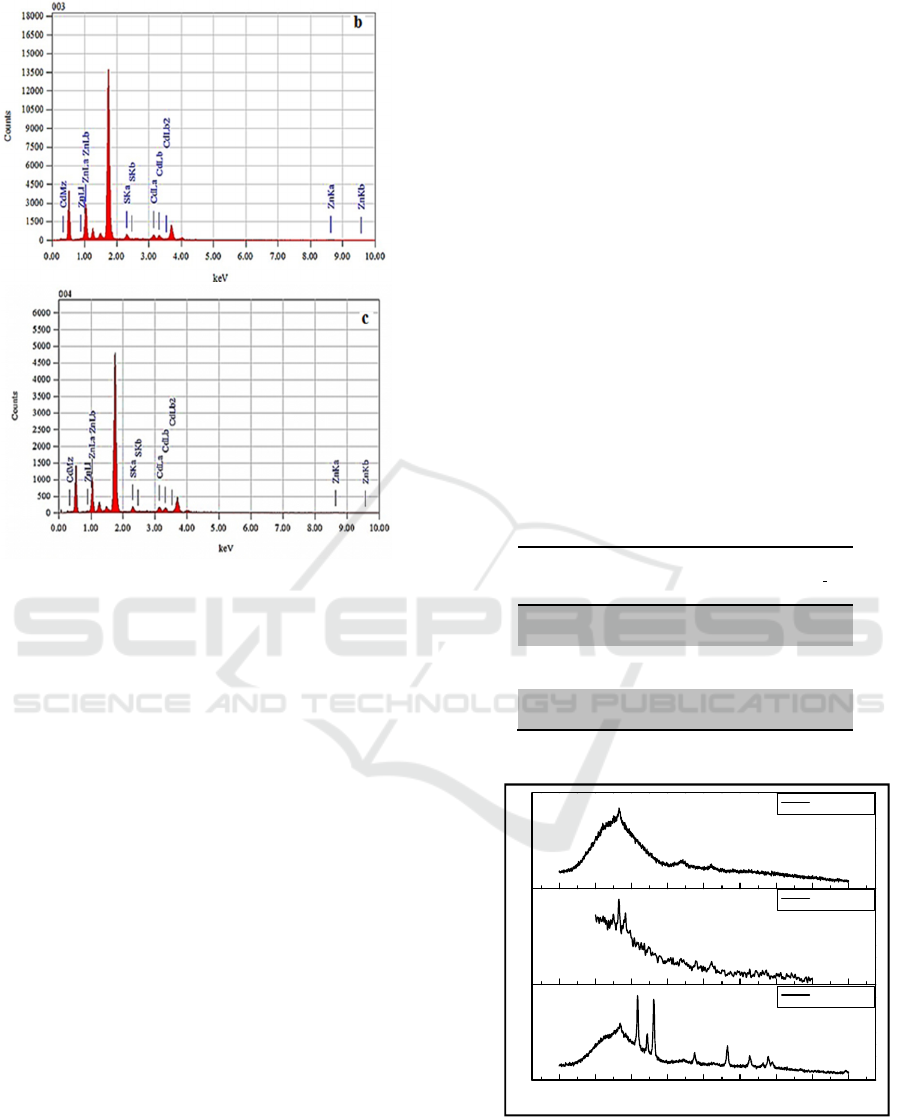

3.4 Structural Proprieties

X-ray diffraction (XRD) spectra give information on

the nature of structure and the composition of a thin

film. These XRD diagrams confirm the formation and

composition of the alloys of the ternary system

Cd

x

Zn

1-x

S with x = (0.1, 0.5, 0.7) are present in FIG.

5 Peaks: (100), (002), (101), (110), (103), (200) and

(201) correspond to the hexagonal structure of the

thin films of Cd

0.7

Zn

0.3

S and Cd

0.5

Zn

0.5

S (ASTM

JCPDS File No. 491302 and 241136). The peak (002)

is the most intense for Cd

0.7

Zn

0.3

S and Cd

0.5

Zn

0.5

S.

But for Cd

0.1

Zn

0.9

S the peaks are (111), (200), (210),

(211), (300), (222), (321) and (400), the most intense

peak is (200) correspond to the cubic structure

(JCPDS file No. 079-6257 and 6259 of ASTM). The

average size of the crystallites of CdZnS estimated

according to the formula of Debye-Scherer’s [23].

0.9/2 (2)

Where D is the crystallite size, λ = 0.154 nm the mean

wavelength of Cu Kα radiation and β = (Δ2θ) is the

full-width half maximum (FWHM) of Bragg peak

observed at Bragg angle θ (rad), K = 0.9, the values

of D obtained. The grain size values, of Cd

x

Zn

1-x

S

thin layers deposited at bath temperature 80 ± 5 ° C

and annealed at 500 ° C are shown in Table 1. From

the table it can be seen that the size of the crystallites

increases with increasing zinc compositions (x) (R.

Mariappan, 2011).

The lattice parameter values were calculated using the

formula (3) and (4):

1/

2

= 4/3 ((

2

+ +

2

)/

2

) +

2

/

2

(3)

1/

2

= (

2

+

2

+

2

)/

2

(4)

Moreover, the obtained values are compiled in Table

1 (D. Patidar, 2008), the lattice parameter is decreased

when the zinc concentration increases, when the zinc

concentration is greater than 0.5 M the crystal

structure changes from hexagonal to cubic.

Tab.1 XRD results of CdZnS thin films.

(hkl) D

(nm)

Lattice parameter Å

Cd

0.7

Zn

0.3

S

(002) 9.95 c= 6.62, a= 4.08

Cd

0.5

Zn

0.5

S

(002) 20.66 c= 6.42, a= 3.95

Cd

0.1

Zn

0.9

S

(200) 25.82 a= 5.73

Fig. 5 XRD pattern of Cd

x

Zn

1-x

S thin films.

10 20 30 40 50 60 70 80 90

2

Cd

0,1

Zn

0,9

S

C (111)

C(200)

C (210)

C(211)

C(300)

C (222)

C (321)

C(400)

Intensity (a. u.)

Cd

0,5

Zn

0,5

S

H (100)

H(002)

(101)

H (110)

H (103)

H (201)

Cd

0,7

Zn

0,3

S

H (002)

H (110)

H (200)

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

34

4 CONCLUSIONS

Synthesis CdZnS thin films by chemical bath

deposition (CBD) were easy and feasible for

deposition on large-area glass substrates. The study

of the characterizations showed that the morphology

of the surface and the transmittance are modified with

respect to the zinc concentration. The energy of the

interval is of the order of 3.5 to 3.8 eV. The crystalline

structure is hexagonal for (Cd

0.7

Zn

0.3

S and

Cd

0.5

Zn

0.5

S) and cubic for Cd

0.1

Zn

0.9

S. and the grain

size is between 9.95 and 25 nm.

REFERENCES

T. Gruszecki, B. Holmstrom, Sol. Energy Mater. Sol.

Cells31 (1993) 227–234.

D. Xia, T. Caijuan, T. Rongzne, L. Wei, F. Lianghuan, Z.

Jingquan, W. Lili, L. Zhi, J. Semicond.32 (2011)

22003.

T.D. Dzhafarov, F. Ongul, I. Karabay, J. Phys. D Appl.

Phys. 39 (2006) 3221.

T. Prem Kumar, S. Sarvana Kumar, K. Sankaranarayanan,

Appl. Surf. Sci. 257(2011) 1923–1927.

Ng. Gaewdang, T. Gaewdang, Materials Letters 59 (2005)

3577 – 3584.

A. Mukherjee, M. Fu, P. Mitra, Journal of Physics and

Chemistry of Solids 82(2015)50–55.

R. Mariappan, M. Ragavendar, V. Ponnuswamy, J. Alloys

Compd. 509 (2011)7337–7343.

P.B. Bagdare, S.B. Patil, A.K. Singh, J. Alloys Compd.

506(2010) 120–124.

Y. Ravi Prakash, K.V. Bangera, G.K. Shivakumar, Growth,

Appl. Phys. 10 (2010) 193–198.

M. Glatettin Baykul, Nilgun orhan, Thin Solid Films 518

(2010) 1925–1928.

G. Laukaitish, S. Lindroos, S. Tamulevicius, M. Leskela,

M. Rackaitis, Appl. Surf. Sci. 161 (2000) 396–405.

D. Patidar, N.S. Saxena, T.P. Sharma, J. Mod. Opt. 55

(2008) 79–88.

P. Kumar, A. Misra, D. Kumar, N. Dhama, T.P. Sharma,

P.N. Dixit, Opt. Mater. 27 (2004) 261–264.

M. Abdel Rafea, A.A.M. Farag, N. Roushdy, J. Alloys

Compd. 485 (2009) 660–666.

V. Kumar, S.K. Sharma, D.K. Dwivedi, J. Alloys Compd.

512 (2012) 351–354.

R. Zellagui, H. Dehdouh, F. Boufelgha, A. Boughelout, T.

Sahraoui, D. Chaumont, M. Adnane, Effect of

zinc/cadmium proportion in CdS layers deposited by

CBD method, International Multidisciplinary Research

Journal 2019, 9: 8-12.

S.V. Borse, S.D. Chavhan, Rampha Sharma, Journal of

Alloys and Compounds 436 (2007) 407–414

Y. Bakha, K.M. Bendimerad, and S. Hamzaoui, Eur. Phys.

J. Appl. Phys. 55, 30103 (2011)

K. Nagamani, N. Revathi, P. Prathap, Y. Lingappa, K.T.

Ramakrishna Reddy, Current Applied Physics 12

(2012) 380-384

T. Ben Nasr, N. Kamoun, M. Kanzari, R. Bennaceur, Thin

Solid Films 500 (2006) 4 – 8.

A. Abdolahzadeh Ziabari, F.E.Ghodsi, Materials Science

in Semiconductor Processing 16 (2013) 1629–1636.

S.D. Chavhan, S. Senthilarasu, Soo-Hyoung Lee, Applied

Surface Science 254 (2008) 4539–4545.

D. PATIDAR , N. S. SAXENA, T. P. SHARMA, Journal

of Modern Optics, Vol. 55, No. 1, January 10, 2008, 79-

88

.

Zinc Doped of CdS Layers Deposited by Chemical Bath Deposition Method

35