Simulation Study of Thorium Separation from Monazite Mineral

Megawati

1

, Haniif Prasetiawan

1

, Bayu Triwibowo

1

and Anwaruddin Hisyam

2

1

Chemical Engineering Department, Faculty of Engineering, Universitas Negeri Semarang, Semarang, Indonesia

2

Faculty of Chemical and Natural Resources Engineering, Universiti Malaysia Pahang, Pekan, Malaysia

Keywords: Rare Earth, Thorium, Separation, Simulation

Abstract: Growth of electricity demand is rapidly increasing. Several method to supply electricity such as utilizing

renewable energy has been used. Nuclear energy is still the best choice to produce electricity. Instead of

using uranium as a fuel, utilization of thorium as a nuclear power plant fuel has been investigated since

1950. Thorium is much safer than uranium since it does not produce hazardous by product which can be

used as an explosive material. Thorium can be found widely in Indonesia together with uranium and many

other rare earth material such as lanthanides group. Separation is needed before thorium can be used as a

fuel. In this article, preliminary study of thorium separation from monazite mineral has been conducted.

The end product of this study is a plant design for thorium separation process. This study used secondary

data which has been lab scale experimental. The data was then predicted by using mathematical model,

calculated data were then compared to the experimental data. The model used in this study was in

accordance with the experimental data, where R

2

for thorium, uranium and rare earth element are 0.9591,

0.7591 and 0.9889 respectively. The developed model in this study then can be used for thorium separation

process modelling using METSIM.

1 INTRODUCTION

In 2018, the growth of electricity demand in the

world is increasing twice as the global demand of

energy which is 900 TWh. From overall electricity

generation, gas and coal are still have the biggest

contribution. While, the generated electricity from

renewable energy resources only able to supply less

than 10%. More than 90 TWh of electricity

generation contributed by nuclear energy (IEA,

2019). As a promising alternative energy in the

world, there are 450 nuclear reactors in total which

is operated in over 30 countries around the world.

There are six type of different reactor which are used

in the nuclear power plant namely Boiling Light-

Water Cooled and Moderated Reactor (BWR), Fast

Breeder Reactor (FBR), Gas Cooled, Graphite

Moderated Reactor (GCR), Light-Water Cooled,

Graphite Moderated Reactor (LWGR), Pressurized

Heavy-Water Moderated and Cooled Reactor

(PHWR) and Pressurized Light-Water Moderated

and Cooled Reactor (PWR). PWR reactor type is the

most popular in the world which is being used by

more than 60% of nuclear power plant around the

world (PRIS, 2019).

The electricity of nuclear plant was obtained

from spin large turbines which is operated by the

steam from water heating process. The water heating

process is utilizing a heat produced during nuclear

fission process to convert the water into a steam.

uranium oxide (UO

2

) is commonly used as a fuel of

nucler reactor, meanwhile not all of the uranium

product can be used as fuel. There are only 0.7% of

of natural uranium can undergo a fission process and

produce high energy. Naturally, mined uranium

consist of 0.7% uranium-235 (U-235) and 99.2% of

uranium-238 (U-238) (WNA, 2018). In the other

hand, uranium have some disadvantages which are

having deleterious health effect and also create a

radioactivity waste issue. The leaked radiation from

nuclear power plant can last for centuries and create

a problem for the next generations. U-238 also very

dangerous since during the fission process it can

transmute into neptunium and then into plutonium-

239 which is a byproduct that can be used as a

weapon.

Thorium has become an alternative nuclear

power plant fuel to replace U-235. In nature,

thorium is more abundant rather than uranium, Its

oxide form, ThO

2

also relatively inert compared to

Megawati, ., Prasetiawan, H., Triwibowo, B. and Hisyam, A.

Simulation Study of Thorium Separation from Monazite Mineral.

DOI: 10.5220/0009013104550459

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 455-459

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

455

UO

2

which is easily oxidised into a more dangerous

byproduct (Dewita, 2012). Thorium can be found

easily in a mineral monazite which is the second

most important rare earth (RE) mineral source

containing thorium and uranium in associated metals

(Amaral and Morais, 2010). Studies on the thorium

fuel cycle had been started from 1950 and still

continuing until recent centuries (Oettingen and

Skolik, 2016).

There are numerous research have been

conducted to separate thorium from mineral

monazite/monazite sands. Hughes and Singh (1980),

introduced solvent extraction process of monazite

sulphate solution by using secondary amine Adogen

283. A maximum thoria concentration of 18 g/l was

obtained by using ammonium carbonate solution as

a stripping agent in the 9-10 pH range. Ali et al.

(2007) develop a process to obtain the thorium from

the hydrous oxide cake from which uranium has

been removed. It was found that Aliquat-336 can be

prefentially extract thorium from HNO

3

solutions.

The extraction efficiency was found to be 80% and

the stripping process efficiency was 82%. Amaral

and Morais (2010) investigation, stated that four

stages of extraction step, five stages of stripping

process and one stage of solvent generation able to

separate 99.9% of thorium and 99.4% of uranium

from aquaeous solution with only less than 0.001

g/L metal contents in the extract phase.

Further process of thorium separation from

uranium has been investigated by Trinopiawan and

Sumiarti (2012). Two different solvent were used to

precipitate the thorium from uranium, it gave a

satisfying results where sulfuric acid able to obtain

96.99% while chloride able to obtain 98.05%.

Simulation study in the research of rare earth

elements especially in nuclear power plant is very

impoertant. It might help the researcher on

predicting the separation process of thorium to

obtain an advance and optimum process. Larochelle

and Kasaini (2016) were presenting an alternative

model for designing and optimizing rare earth

element solvent extraction process using METSIM.

The simulation results has been compared to pilot

plant and it shows a good accordance with the real

solvent extrction process. Advantages of process

simulation in rare earth process are able to minimize

the complexity of the design by only using a simple

batch extraction data and also able to optimize the

process theoretically based on existing variables and

parameters.

This research will discuss on the preliminary of

simulation study of thorium separation process plant.

In the future, this study might have a worth

contribution for the thorium separation process

plant.

2 RESEARCH METHODOLOGY

2.1 Thorium Separation Process Flow

Diagram

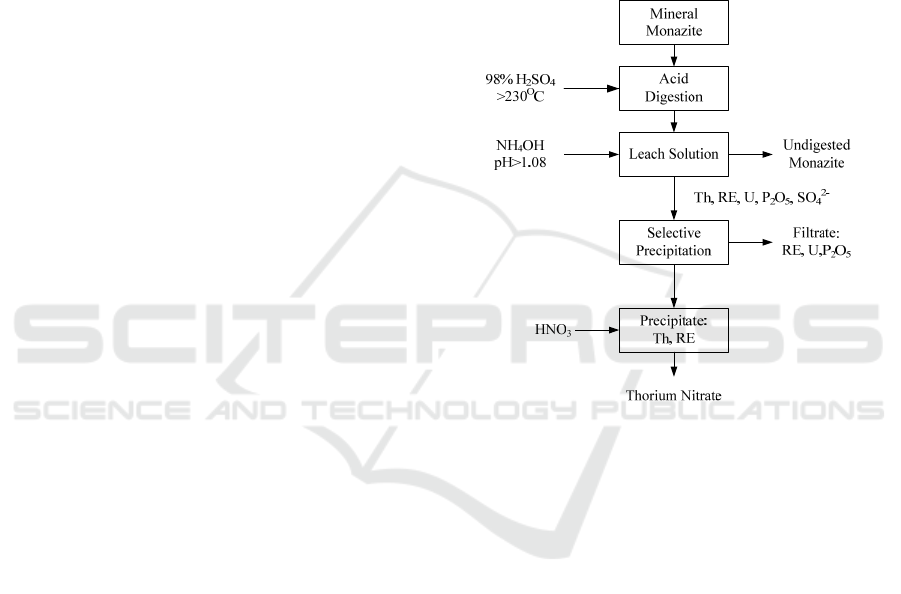

The flow diagram process for thorium separation

process is shown in Figure 1.

Figure 1: Flow diagram process for monazite digestion

and thorium recovery (Al-Areqi, 2016).

2.2 Data Observation

The secondary data was obtained from the previous

work related to thorium separation process. Data set

of monazite digestion process was obtained from

Anggraeni et al. (2015). While data for thorium

separation from uranium by using precipitation

process were obtained from Trinopiawan & Sumiarti

(2012).

2.3 Simulation Study

This simulation study was conducted by using

METSIM software with licensed owned by

Universiti Malaysia Pahang.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

456

3 RESULTS AND DISCUSSION

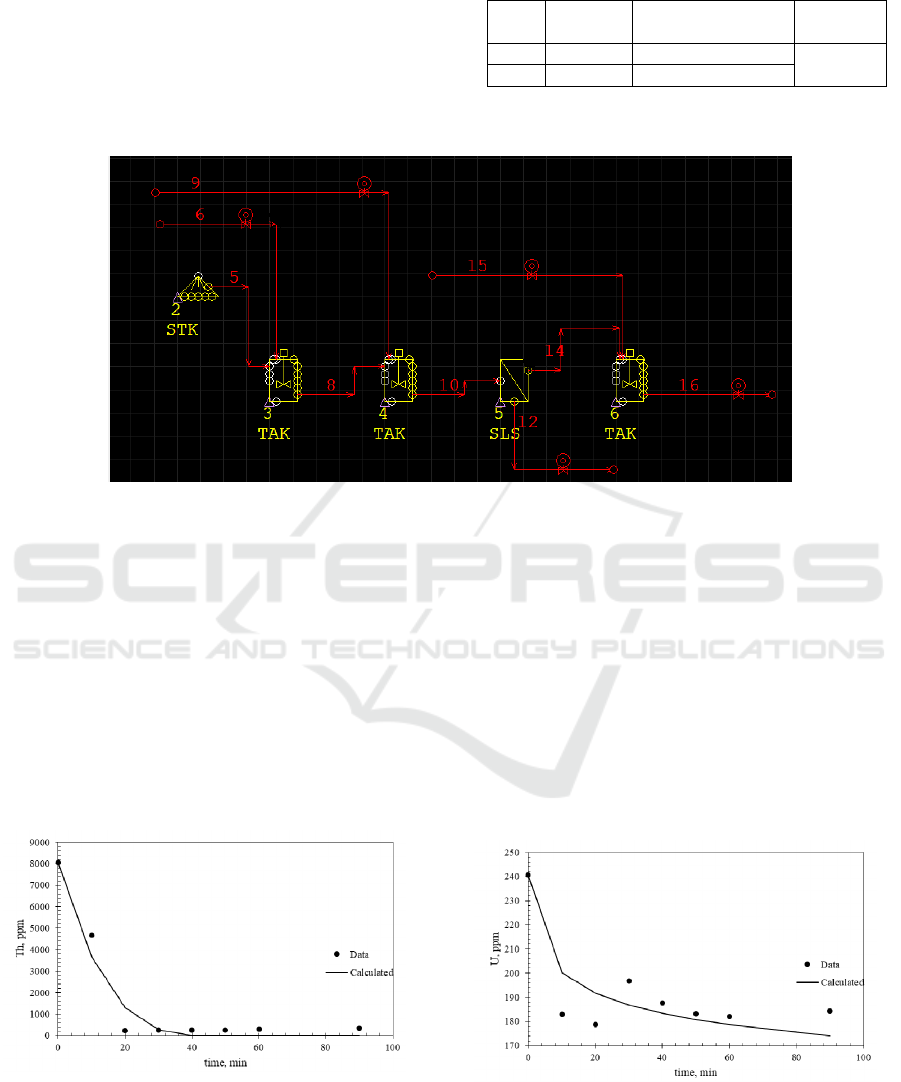

Based on Figure 1, the flow sheet of thorium

separation process was created in METSIM

Software. The detail of the flow sheet is shown in

Figure 2.

Table 1: Kinetic constant for thorium concentration data

regression analysis.

Vari

able

Value 95% confidence

interval

R

2

k 0.6933 ± 0.0039124

0.9591

n 1.1009 ± 0.0357526

Figure 1: Flowsheet of Thorium Separation Process.

Each of the simulated equipment, required a specific

input equation to represent the current process. Acid

digestion process of a monazite, requires a kinetic

parameter to simulate the rare earth material

separation from monazite mineral. The data was

obtained from Trinopiawan and Sumiarti (2012).

The predicted model of ihorium in acid digestion are

shown in Figures 2 and Table 1. While the kinetic

model used is shown in Equation 1.

,

1

/

(1)

Figure 2: Simulation result of thorium concentration

over digestion time.

Based on the R

2

value, the simulated result of

Thorium concentration was in accordance with the

data experiment.

In the digestion process of monazite, besides

thorium there is also uranium which already

commonly used in nuclear power plant as a fuel. The

model for uranium separation during digestion

process also predicted using Equation 1 and the

results are shown in Figure 3 and Table 2.

Figure 3: Simulation result of uranium concentration

over digestion time.

Simulation Study of Thorium Separation from Monazite Mineral

457

Table 2: Kinetic constant for uranium concentration data

regression analysis.

Vari

able

Value 95% confidence

interval

R

2

k 16.38806 ± 3.583056

0.7591

n 2.38E-38 ± 4.48E-37

A scattering data experiment used in this

simulation caused a slight value of deviation and

affect the R

2

value.

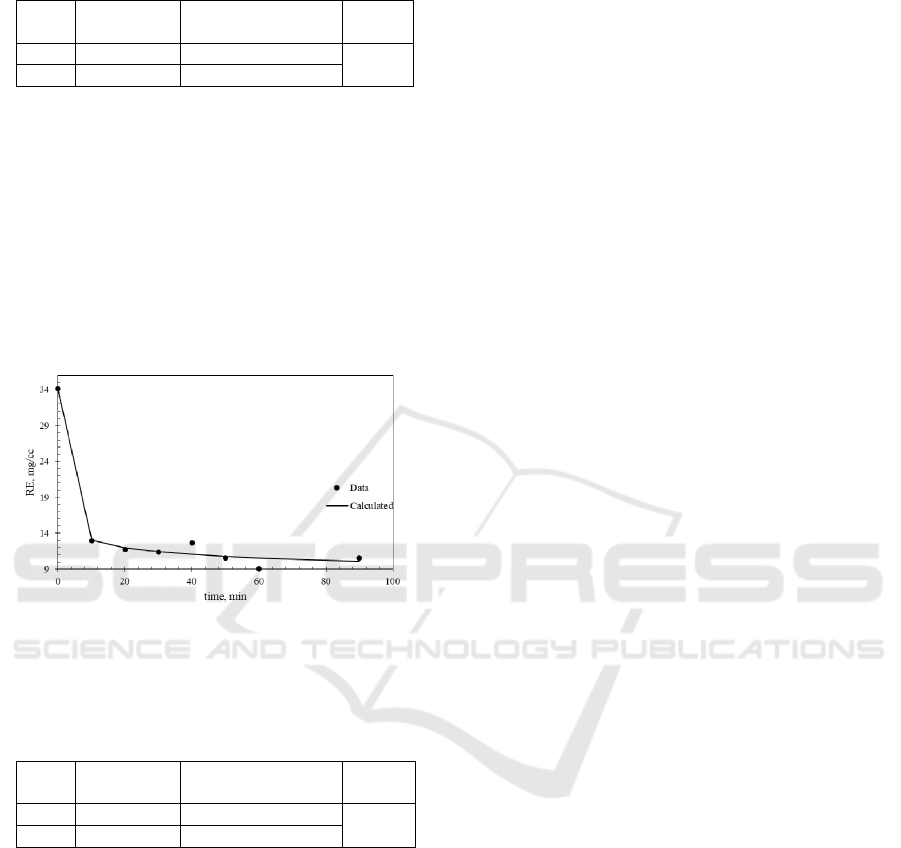

The other components inside monazite mineral

were analyzed as a total Rare Earth Element (REE)

concentration. This component can not be eliminated

during the simulation due to its existence is very

large in monazite mineral. The predicted model of

REE concentration are shown in Figure 4 and Table

3.

Figure 4: Simulation result of rare earth (RE)

concentration over digestion time.

Table 3: Kinetic constant for rare earth (RE) concentration

data regression analysis.

Vari

able

Value 95% confidence

interval

R

2

k 9.57258 ± 7.307524

0.9889

n 3.33E-12 ± 6.21E-11

From Figure 4 and Table 3, it can be seen that

the equation able to represents the rare earth material

digestion process over acid condition. The R

2

value

is close to 1 indicated that the model is fit enough

with the experimental data.

In the future, this model is going to be used in

the METSIM simulation to predict the thorium

separation process from monazite mineral.

4 CONCLUSION

In this study, the flow sheet of thorium separation

from monazite mineral has been prepared. All the

model have been developed by using secondary

data. The result shows that model for thorium and

RE digestion process is in accordance with the

experimental data, while model for uranium

digestion process is quite far from the data but it still

manageable to be used in the upcoming simulation.

ACKNOWLEDGEMENTS

The authors would like to thank the grant project of

DIPA UNNES with reference number

042.01.2.400899/2018 for sponsorship.

REFERENCES

Al-Areqi, W. M., Aniza, C. N., Majid, A. A. & Sarmani,

S., 2016. “Separation and Radiological Impact

Assessment of Thorium In Malaysian Monazite

Processing”, Malaysian Journal of Analytical Science.

Vol. 20, No. 4, pp. 770 – 776.

Ali, A. M.I, Daoud, j. A. & Aly, H. F., 2007. “Recovery of

thorium ( IV ) from leached monazite solutions using

counter-current extraction”, International Journal of

Mineral Processing, Vol. 81, pp. 217 – 223.

Amaral, J & Morais, C., 2010. “Thorium and uranium

extraction from rare earth elements in monazite

sulfuric acid liquor through solvent extraction”,

Minerals Engineering, Vol. 23, No. 6, pp. 498 – 503.

Amaral, J. C. B.S. & Morais, C. A., 2010. “Thorium and

uranium extraction from rare earth elements in

monazite sulfuric acid liquor through solvent

extraction”, Minerals Engineering, Vol. 23, No. 6, pp.

498 – 503.

Anggraini, M., Sarono, B., Waluyo, S., Rusydi, R.,

Sujono, S. 2015. “Pengendapan Uranium dan Thorium

Hasil Pelarutan Slag II”, Vol. 36, No. 2, pp. 125 – 132.

Dewita, E., 2012. “Analisis Potensi Thorium Sebagai

Bahan Bakar Nuklir Alternatif PLTN”, Jurnal

Pengambangan Energi Nuklir, Vol. 14, No. 1, pp. 45 –

56.

Hughes, K. & Singh, R., 1980. “The Isolation of Thorium

from Monazite by Solvent Extraction : Part 1”,

Hydrometallurgy, Vol. 6, pp. 25 - 33

IEA, 2019. Global Energy and CO

2

Status Report: The

Latest Trends in Energy and Emmisions in 2018,

International Energy Agency, France.

Oettingen, M & Skolik, K., 2016. “Numerical design of

the Seed-Blanket Unit for the thorium nuclear fuel

cycle”, E3S Web of Conference, Vol. 10, pp. 00067-1

– 00067-5.

PRIS, 2019. Operational & Long-Term Shutdown

Reactors, https://pris.iaea.org/PRIS/WorldStatistics/

OperationalReactorsByType.aspx, accessed at 31

st

March 2019.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

458

Trinopiawan, K. & Sumiarti, S., 2012. “Pemisahan

Thorium Dari Uranium Pada Monasit Dengan Metode

Pengendapan”, Vol. 33, No. 1, pp. 55 – 62.

WNA, 2018. Nuclear Power Reactors, World Nuclear

Association, London, United Kingdom.

Simulation Study of Thorium Separation from Monazite Mineral

459