Utilization of Red Onion Skin Waste as Natural Dyes

Rudi Firyanto,

Soebiyono, and Dian Anung Putri

Department of Chemical Engineering, Universitas 17 Agustus 1945 Semarang, Indonesia

Keywords: Onion skin, Anthocyanin, Experimental design.

Abstract: Red onion skin waste can be used as food coloring. Red onion skin is one source of brownish orange color

derived from anthocyanin compounds and is used as natural dyes for traditional foods. The purpose of this

study was to determine the most influential variables of reaction time, material size, and ratio weight

material to the volume solvent in red onion skin extraction. The research method used is an experimental

design method, where this method means a set of differences designed to obtain evidence of a hypothesis

data. This research was carried out at a temperature of 80

o

C and using 80% ethanol solvent. The results

showed that the most influential was the ratio of weight material to volume solvent. The optimum results

were obtained at a ratio of 1 gr: 14 ml with an extraction time of 2 hours and a size of 60-80 mesh.

1 INTRODUCTION

The addition of food additives, especially food

coloring, aims to provide a more attractive color,

sometimes the use of food coloring agents does not

pay attention to their effects on health. Some parties

use harmful dyes to produce attractive and selling

food products to get the maximum profit.

Dyes commonly used are natural coloring agents

and synthetic coloring agents. Natural coloring

agents, made from extracts of certain plant parts.

Synthetic dyes, made from chemicals. Compared to

natural dyes, synthetic dyes have several advantages,

namely more color choices, easy to store and long

lasting. Some of the weaknesses of synthetic dyes

include carcinogenic and toxic properties (Winarno,

1997).

The use of natural dyes has been widely used by

the community, among others, the yellow color of

turmeric, the green color of the suji leaf, the purple

color of purple sweet potato, the black color of the

straw and others. Onion skin is one of the sources of

brownish orange color derived from anthocyanin

compounds and is used as a coloring agent for

traditional foods (Cahyadi, 2009)

Oancea (2013) conducted a study that found the

highest total Anthocyanin 99.66 mg/100 g of

anthocyanin extract ingredients from the outer skin

part of dried onion grown in Romania. The solvents

used were ethanol/acetic acid/water (50/8/42),

ethanol/acetic acid / water (70/4/26), ethanol/acetic

acid/water (80/1/19); 50% ethanol (v/v); ethanol

70% (v/v), and ethanol 80% (v/v). From the results

of the study, the best type of solvent is 80% ethanol.

Red onion also have high levels of flavonoids,

especially in the form of quercetin. Quercetin is a

flavonoid compound that can reduce blood pressure

and prevent plaque in arteries that can cause strokes.

The content of flavonoids in 1 kg of onion (Allium

ascalonicum) is approximately 415-1917 mg. The

onion skin has more antioxidants than the onion

itself.

Concerns about the safety of the use of synthetic

dyes encourage the development of natural dyes as

food coloring ingredients. The use of synthetic dyes

can be replaced with natural dyes. Red onion skin

can be used as a natural food coloring because it has

a color pigment, namely anthocyanin compounds.

These compounds play a role in the onion skin

coloring (Jackman, 1996).

Red onion skin is commonly found as household

waste and has been underutilized optimally and it's

useless . To be able to utilize the onion skin waste, it

can be used as food coloring. So that the onion skin

waste can be something more economical and has a

selling value.

Hussein and Alhassanen extracted the onion skin

as a dye using the reflux process, this is done so that

the anthocyanin compounds found in the onion skin

are easier to extract. The extraction process is

carried out for 40 minutes. So in this study

variations will be made with the smallest extraction

Firyanto, R., Soebiyono, . and Anung Putri, D.

Utilization of Red Onion Skin Waste as Natural Dyes.

DOI: 10.5220/0009012704350438

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 435-438

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

435

time of 40 minutes and the largest is 120 minutes to

determine the effect of the extraction time. In

addition, variations in material size and comparison

between ingredients and solvents were added to see

which conditions were the most optimum in the

process of taking dyes on the onion skin.

There are a number of extraction methods, the

simplest is cold extraction, in this way the dried

material produced by the mill is extracted at room

temperature in a row with the solvent with the higher

polarity. The advantage of this method is that the

extraction method is easy because the extract is not

heated so it is less possibility that the natural

material will decompose.

The use of solvents with increased polarity of

natural materials will separate natural ingredients

based on solubility. This makes the isolation process

becomes easier (Rodrigues et al., 2003).

2 MATERIALS AND METHOD

2.1 Material

In this study the material used is dry onion skin on

the market regardless of its type. Another supporting

material used in this study is 80% ethanol as a

solvent

2.2 Experimental

2.2.1 Sample Preparation

Red onion skin is cleaned from dirt by rinsing use

running water. Dry under the sun and oven at 50°C

until dry. After drying and mashed with blending

and then sieved with a 40-60 mesh and 80-100 mesh

sieve.

Research methodology used is Experimental

design. Experimental design is a set of data designed

to obtain concrete data to prove a hypothesis.

Experimental design method with two-level factorial

design, low level (-) and high level (+) is used for

reasons because a little run for each variable is

investigated, so it can save time, cost, and material.

In this study using a fixed variable: temperature

80

o

C and 80% ethanol solvent, while the variable

changed: extraction time (t) 40 and 120 minutes, the

ratio of ingredients solvent (R) was 1:10 and 1:15,

the size of the material (N) was 40-60 and 80-100

mesh.

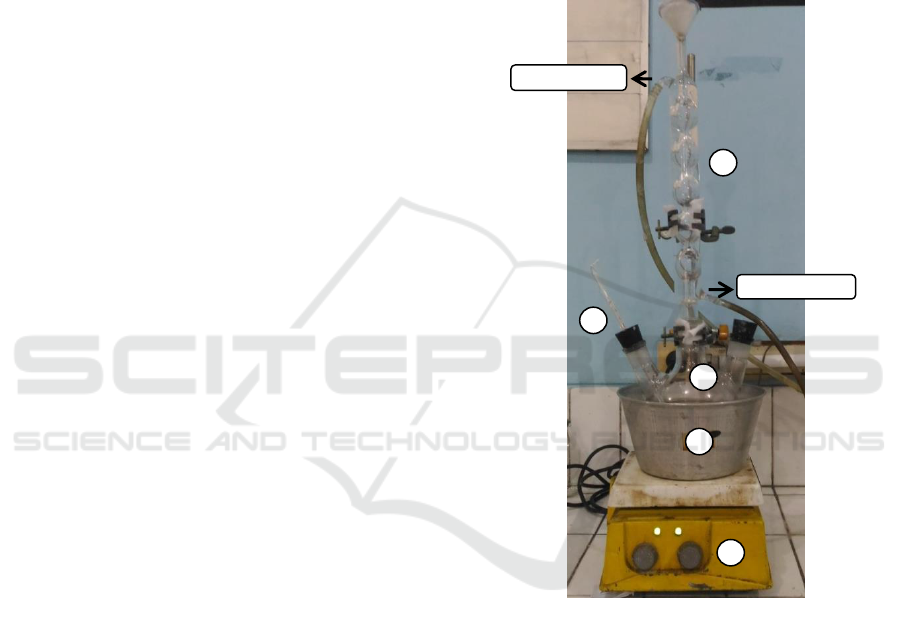

The tool used is an extraction tool (reflux)

consisting of three neck flasks, condensor, hot

plates, magnetic stirrers, ovens, thermometers, water

bath.

2.2.2 Extraction Process

The onion skin is weighed as needed, put in a three-

neck flask. 80% ethanol is put into a three-neck

flask, then assemble the appliance and attach a hose

that connects the condenser and water tap as shown

in Figure 1.

(1) Condensor, (2) three neck flasks, (3)

thermometers, (4) water bath, (5) hot plate

Figure 1: Extraction tool.

Extraction is done by varying the extraction time,

material:solvent ratio and material size. The

extraction results obtained were then concentrated in

a waterbath at 50

o

C. Then weighed and calculated

the resulting dyes content.

Anthocyanin testing was carried out by 2 mL red

onion skin extract added with 2 mL HCl 2 M. Then

it is heated at 100 ° C for 5 minutes, if it appears red

then the result is positive.

5

Water

inlet

Water

outlet

4

3

2

1

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

436

3 RESULTS AND DISCUSSION

The results of the research that have been carried out

are obtained shown in Table 1.

Table 1: Results observations of yield.

t

(minutes)

R

(rasio)

N

(mesh)

Yield

(%)

40

1 : 10

40-60

5.52

120

1 : 10

40-60

5.68

40

1 : 15

40-60

6.63

120

1 : 15

40-60

7.38

40

1 : 10

80-100

6.66

120

1 : 10

80-100

6.80

40

1 : 15

80-100

8.92

120

1 : 15

80-100

10.61

The yield results from Table 1 are included in the

calculation formula for the effect, to find the most

influential variables using chart % P vs Z (Normal

Probability Curve) and % P vs I.

Calculation of the main effects:

I

0

= ⅛ (Y

1

+ Y

2

+ Y

3

+ Y

4

+ Y

5

+ Y

6

+ Y

7

+ Y

8

)

I

t

= ¼ (-Y

1

+ Y

2

– Y

3

+ Y

4

– Y

5

+ Y

6

– Y

7

+ Y

8

)

I

R

= ¼ (-Y

1

– Y

2

+ Y

3

+ Y

4

– Y

5

– Y

6

+ Y

7

+ Y

8

)

I

N

= ¼ (-Y

1

– Y

2

–Y

3

– Y

4

+ Y

5

+ Y

6

+ Y

7

+ Y

8

)

Calculation of interaction effects:

I

t.R

= ¼ (Y

1

– Y

2

– Y

3

+ Y

4

+ Y

5

– Y

6

– Y

7

+ Y

8

)

I

t.N

= ¼ (Y

1

– Y

2

+ Y

3

– Y

4

– Y

5

+ Y

6

– Y

7

+ Y

8

)

I

R.N

= ¼ (Y

1

+ Y

2

– Y

3

– Y

4

– Y

5

– Y

6

+ Y

7

+ Y

8

)

I

t.R.N

= ¼ (-Y

1

+ Y

2

+ Y

3

– Y

4

+ Y

5

– Y

6

– Y

7

+ Y

8

)

The results of the calculation of effects are

presented in Table 2.

Table 2: The results of the calculation of the effect value.

No.

Effect

Efffect

Identity

%P=

%100

5

n

i

1

0,2281

I

t.N

7,14

2

0,2381

I

t.R.N

21,43

3

0,5367

I

t.R

35,71

4

0,6867

I

t

50,00

5

0,8127

I

R.N

64,28

6

1,9427

I

N

78,57

7

2,2189

I

R

92,86

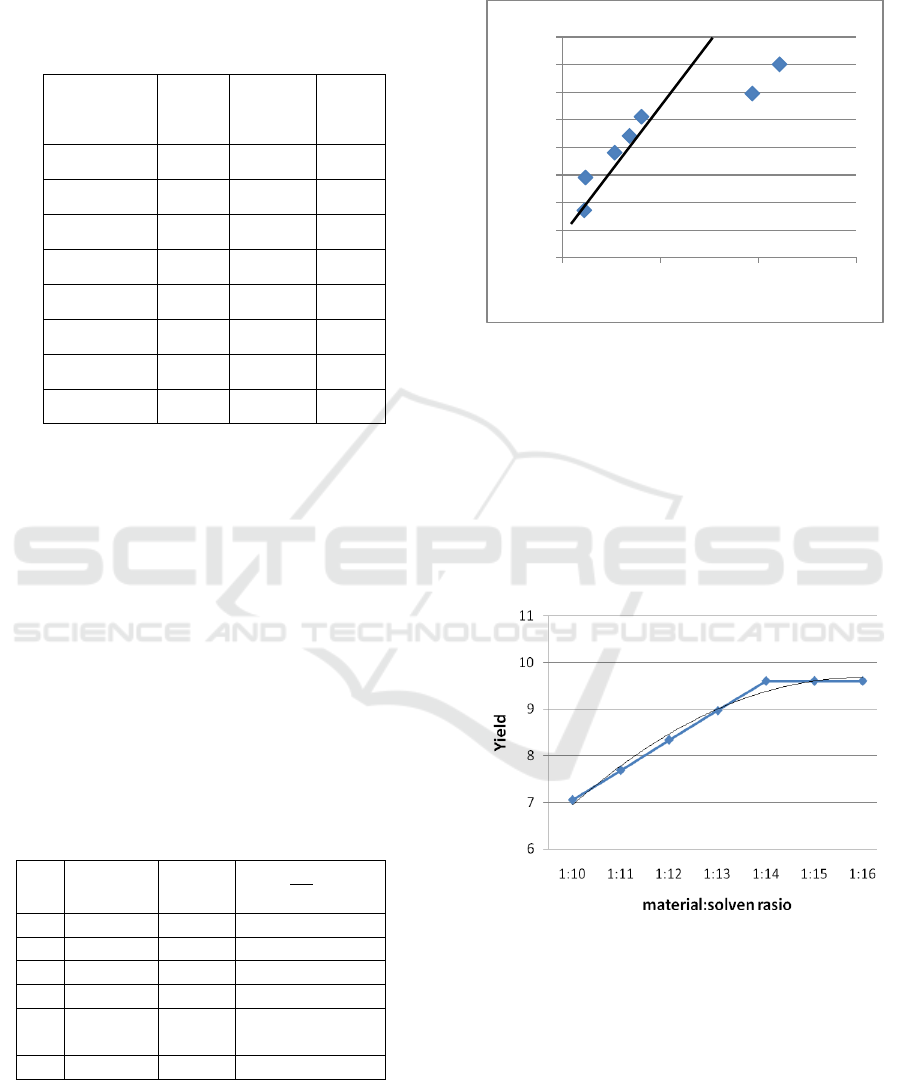

Based on the chart % P vs Z and % P vs I, the

most influential variable is I

R

(variable ratio of

materials and solvents). This can be seen from chart

%P vs I (Figure 2), which is the farthest point from

the „approach line‟

Figure 2: %P vs I.

After analyzing using the factorial design

method, the material and solvent ratio (R) is the

most influential variable, because it is located

farthest from the approach line on the distribution

curve.

Next, optimization of various material:solvent

ratios under operating conditions 120 minutes (t) and

material size 80-100 mesh (N) as shown in Figure 2.

Figure 3: Optimization material:solven ratio.

Figure 3 shows clearly that the greater the

amount of solvent than the amount of material, the

greater yield will be produced. The greater dyes

yield is obtained because the solvent's solubility

ability to extract dyestuffs in the onion skin is better

and provides greater opportunities between solvents

and ingredients to touch.

0

10

20

30

40

50

60

70

80

0.0 1.0 2.0 3.0

%P

I (Efect Interaction)

IR

IN

It

It,R

It,N

It,R,

N

IR,

N

Utilization of Red Onion Skin Waste as Natural Dyes

437

The solubility of dyes will continue to increase

with the amount of the material ratio and the

extraction solvent until saturation occurs in the

solvent. Material and solvent ratio of 1:14 (50

grams: 700 ml), yield has not increased again. This

is due to saturation of the solvent concentration so

that the diffusion process between the material and

the solvent occurs very slowly. So that the addition

of a larger solvent will not add to the extraction

power of the dyes in the extraction process.

Another factor that influences the high and low

yield produced in this extraction process is the size

of the material. In this study using the material size

of 40-60 and 80-100 mesh, after the experiment it

was seen that the use of material sizes with 80-100

mesh gives higher yields compared to the use of

material sizes with 40-60 mesh. This is because the

surface area of the extracted material is getting

larger so the greater the chance for the material to

interact with the solvent, so that the solvent can

extract more.

4 CONCLUSIONS

The results of the study and observations concluded

that the variables that most influence the yield of

dyes from onion skin waste are the ratio of materials

and solvents. The greater the ratio of materials and

solvents, the greater the yield value. The optimum

ratio value is 1:14 with extraction time of 120

minutes, particle size of 80-100 mesh and a yield of

9.6%.

REFERENCES

Cahyadi, W., 2009. Analisis & Aspek Kesehatan Bahan

Tambahan Pangan. Bumi Aksar. Jakarta, Edisi Kedua.

Hussein, I, & Alhassanen Y, 2013. Protection of Humans

From Ultraviolet Radiation (UVR) Through the Use of

Cotton Clothes Dyed With Aqueous Extracts of Onion

Skin as the Natural Colorant, Minouviya University:.

Egypt.

Jackman, R. L., & Smith, J. L. 1996 Anthocyanin and

Batalains. Natural Foods Colourants. Blackie

Academic and Professionals. London, Second Edition.

Oancea, S. & Drághici O., 2013. “pH and Thermal

Stability of Anthocyanin-Based Optimised Extracts of

Romanian Red Onion Cultivars” Czech J. Food Sci.,

Vol. 31, pp. 283–291.

Rodrigues, A., S., Fogliano V., Graziani G., Mendes, S.,

Vale, A. & Goncalves, C., 2003., “Nutrition Value of

Onion Regional Varieties in Northwest Portugal”,

Electronic Journal of Environmental, Agricultural and

Food Chemistry, Vol. 2, No. 4, pp. 519-524.

Winarno, F., G., 1997. Kimia Pangan dan Gizi, PT.

Gramedia. Jakarta.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

438