Effect of Substrate Concentration Variation on Scleroglucan

Production using Aerobic Fermentation

Nancy Siti Djenar and Bintang Iwhan Moehady

Chemical Engineering Department, Politeknik Negeri Bandung, Jln.Gegerkalong Hilir Ds. Ciwaruga,Bandung, Indonesia

Keywords: S.rolfsii, scleroglucan, liquid sugar, substrate

Abstract: Sclerotium rolfsii is known as one of the pathogenic fungi that causes some diseases in plants. In Indonesia

the various studies that have been conducted on the fungus are still limited to prevention and control to

reduce its pathogenic aspect. Scleroglucan is a biopolymer produced from Sclerotium rolfsii fermentation

and has been used in several industries in various developed countries as both a thickener and emulsifier. In

this study scleroglucan was produced from liquid sugar substrate using S.rolfsii InaCC F-05. The use of

liquid sugar substrate with varying concentration can increase dry cell weight, yield of scleroglucan and

conversion of 73.36%, 3.45% and 3.46% respectively. The acquisition of scleroglucan viscosity was

1.8500 to 2.5713 cP. While low, it can still be applied in chemical industries as a mixture for toothpaste

and mouthrinse formulation.

1 INTRODUCTION

These days exopolysaccharides that were produced

from varieties of microorganisms are widely used in

some industries as emulsifers, gelling, and

thickening agents. Scleroglucan one of the

exopolysaccharides is produced from fermentation

of Sclerotium rolfsii fungal (Survase, 2007). The

properties and characteristics of scleroglucan are

similar to xanthan gum. The difference is that in

Indonesia scleroglucan is not yet well known, while

xanthan gum has been widely used even though it

still has to be imported.

Chemical structure of scleroglucan is depicted in

Figure 1.

Figure 1: Chemical structure of scleroglucan

(https://de.wikipedia.org/wiki/Scleroglucan).

Scleroglucan is composed of (1-3)- β-linked

glucopyranosyl backbone with single (1-6)-β-linked

glucopyranosyl branches on every third subunit.

In Indonesia Sclerotium rolfsii is better known as

one of the pathogenic fungal that causes a number of

diseases in plants such as peanuts, potatoes,

tomatoes, soybeans, cabbage, onions, celery, corn

and lettuce. This limits various studies that have

been carried out regarding the fungal to prevention,

control, and characterization in reducing the

pathogenic properties of Sclerotium rolfsii (Yana,

2011 & Pudjihartati, 2007). The S. rolfsii

metabolism process produces several enzymes

including cellulases, phosphatidase, arabinase,

exogalactanase, polygalacturanase, galactosidase

and exomanase. The enzymes then convert raw

materials into scleroglucan through this fermentation

process (Castillo et.al, 2015).

In an industry that utilizes the fermentation

process, the role of its medium is very important in

increasing the microbial growth rate. PDB (Potato

Dextrose Broth) is one of the medium commonly

used for the growth of S.rolfsii. To support cell

regeneration and productivity, the modified PDB is

one of the best growth medium for S.rolfsii because

it contains beef extract , K

2

HPO

4

and KH

2

PO

4

,

which function as a nitrogen source and buffer

solution to maintain the pH of fermentation broth

(Bhagat.I, 2011).

Djenar, N. and Moehady, B.

Effect of Substrate Concentration Variation on Scleroglucan Production using Aerobic Fermentation.

DOI: 10.5220/0009012504250429

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 425-429

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

425

Temperature is a very important parameter that

affect both culture growth and exopolysaccharide

production. In this case the optimum temperature for

scleroglucan production is in the range of 20-37°C

and at 28

0

C for culture growth. At less than 28°C,

oxalic acid will gradually form which has an adverse

effect on the production of scleroglucan (Survase,

2007).

pH affects the physiology of microorganism such

as its solubility, nutrition and enzyme activity. The

optimum pH for exopolysaccharide production can

differ from the pH for culture growth. Generally the

optimum pH for scleroglucan synthesis is between

4.0 and 5.5 (Castillo et al, 2015). Aeration and

agitation optimization are the most important factors

for controlling cell growth and scleroglucan

production because it can increase the rate of

formation of metabolites and oxygen from liquid

medium to cells.

Substrates used in scleroglucan production are

for example sucrose, condensed corn solubles,

coconut water, molasses, sugar cane juice, and

glucose (J.I Farina.1998, Fosmer.2010). Liquid

sugar syrup produced from tapioca flour can be used

as a substrate because it can shorten the scleroglucan

production chain. Liquid sugar is easy to obtain

even if its utilization is limited only as a raw

material for the food and beverage industry, thus it is

expected a diversification step will emerge from

liquid sugar syrup which is made from local raw

materials and spread throughout Indonesia (Djenar

et al, 2017).

2 EXPERIMENTAL DETAILS

2.1 Microbial Preparation

At this stage regeneration of fungal S.rolfsii on :

a) Potato dextrose Agar (PDA) medium

containing potato, dextrose and agar ,

incubated at 28°C for 5-7 days.

b) Modified PDA medium containing potato,

dextrose, beef extract, KH

2

PO

4

, K

2

HPO

4

and

agar, incubated 28°C for 5-7 days.

2.2 Production of S.rolfsii Inoculum

2.2.1 Production of S.rolfsii inoculum in

Potato Dextrose Broth (PDB)

Potato Dextrose Broth medium was prepared by

dissolving 1.0 g potato, 0.1 g dextrose, 0.1 mg

CaCO

3

, 0.1 mg MgSO

4

7H

2

O in erlenmeyer

containing 5 mL of distilled water. The medium then

sterilized for 20 minutes at 121°C and 1.4 atm. The

stock culture S.rolfsii in PDA was inoculated to the

PDB medium and incubated at 28°C for 48 hours

and stirred at 150 rpm. Furthermore, this active

inoculum will be used to make S. rolfsii growth

medium.

2.2.2 Production of S.rolfsii inoculum in

modified Potato Dextrose Broth (PDB)

Potato Dextrose Broth medium was prepared by

dissolving 1.0 g potato, 0.1 g dextrose, 0.1 mg

CaCO

3

, 0.1 mg MgSO

4

7H

2

O, 0.0115 g K

2

HPO

4

,

0.0591 g KH

2

PO

4

and 0.005 g beef extract in

erlenmeyer containing 5 mL of distilled water. The

medium then sterilized for 20 minutes at 121°C and

1.4 atm. The stock culture S.rolfsii in PDA was

inoculated to the PDB medium and incubated at

28°C for 48 hours and stirred at 150 rpm.

Furthermore, this active inoculum will be used to

make S. rolfsii growth medium.

2.3 Experimental Work

In this step, aerobic fermentation was done in

variation of growth medium at 170 rpm, pH 5, at 30-

35 °C using 5% and 7% liquid sugar as substrate

(Table 1)

Table 1: Variation of growth medium and substrate

concentration on scleroglucan production.

No

Growth

medium

Substrate

concentration

1

PDB

5% Liquid sugar

2

PDB

7% Liquid sugar

3

Modified PDB

5% Liquid sugar

4

Modifiied PDB

7% Liquid sugar

Pasteurization. The pasteurization was done at 90°C

for 25 minutes. The pasteurized fermentation was

separated between scleroglucan solution and its

cells using centrifugation.

Purification and precipitation. Precipitation of

scleroglucan was done by adding an organic solvent

of isopropyl alcohol (IPA) with a ratio of 3: 1 (v / v)

to the supernatant. The obtained precipitate was

then dried in an oven at 50°C, weighed, and the

yield and % conversion were calculated.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

426

Scleroglucan testing is done by measuring its

viscosity. While the functional groups analysis uses

FT-IR.

3 RESULT AND DISCUSSION

In this batch-based S.rolfsii fermentation the oxygen

was produced from air which exists in the

bioreactor by using a ratio of 1:5 between

fermentation medium and the bioreactor (v/v)

(Standbury P.F et al, 2000). At this stage curves

were made to determine the production time of

scleroglucan for this process, with pH between 4.0-

5.5, temperature 30-35

o

C with stirred at 170 rpm.

The time needed to produce the maximum amount

scleroglucan is shown in Table 2 below.

Table 2: The time needed to produce scleroglucan using

liquid sugar substrate.

Growth

medium

Substrate

The time needed to

produce

scleroglucan (hour)

PDB

5% liquid

sugar

57

PDB

7% liquid

sugar

68

Modified

PDB

5% liquid

sugar

76

Modified

PDB

7% liquid

sugar

65

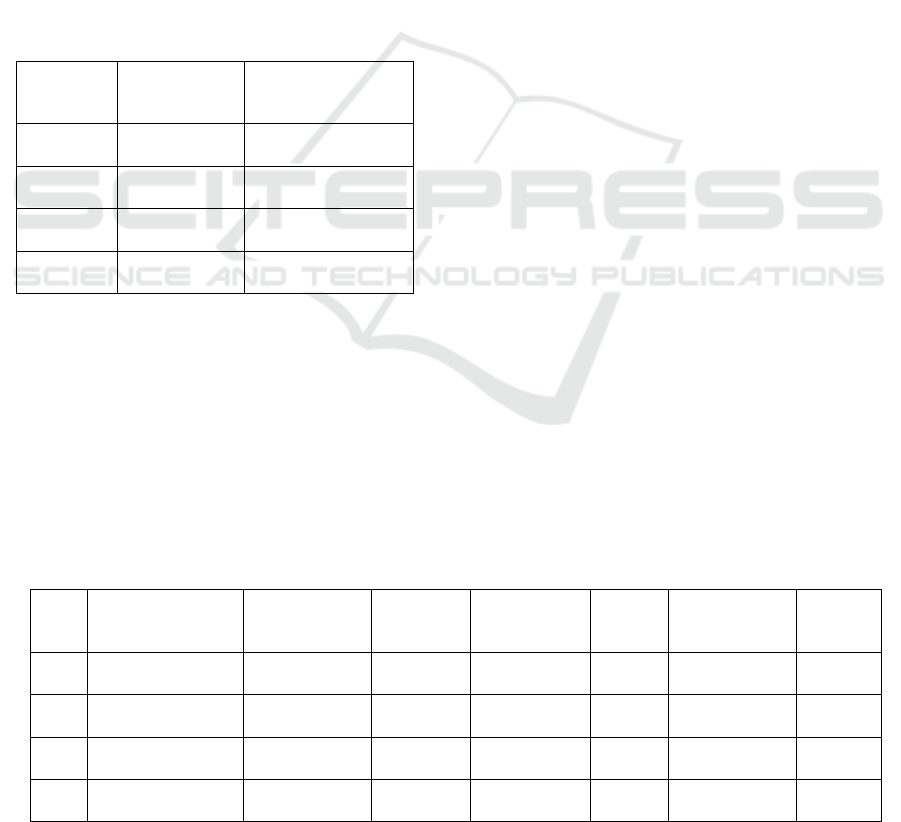

In Table 3 It was shown that S.rolsii grown in

PDB produced both low yield and conversion. The

PDB only contains potatoes and dextrose which

functions as carbon source. However, to increase the

productivity, nitrogen source and others are

required. In this PDB, an increase in substrate

concentration causes a decrease both of yield and

conversion. This happened as a result of the

fermentation that was carried out in batch. This

condition causes substrate repression to often occurs.

In this experiment, 7% liquid sugar substrate

repressed S.rolfsii metabolism, thus disrupting the

enzyme synthesis (Egli, 2009).

A modified PDB is different in that changes in

liquid sugar substrate with 5% to 7% concentration

can increase yield and conversion about 3.45% and

3.46% respectively. Overall, when compared to

PDB, there is an increase in yield and conversion of

17-18 g/L and 35-36% respectively. This is because

the modified PDB contains beef extract as a source

of nitrogen and K

2

HPO

4

and KH

2

PO

4

. Nitrogen is a

major component of amino acids, and these amino

acids will form the proteins needed for cell

metabolism – namely the growth and synthesis of

enzymes, so as to increase the production of

biopolymers (Survase,2007). Phosphorus is an

important element for secondary cell metabolism. In

fermentation medium, phosphorus is in the form of

phosphate salts such as K

2

HPO

4

or KH

2

PO

4

which

serve as a pH buffer. Potassium is the main

inorganic cation in cells and is usually added as an

inorganic salt. Potassium is a cofactor for several

enzymes needed for carbohydrate metabolism. The

results of scleroglucan production are as shown in

the following Table 3.

As shown in Table 3 the value of scleroglucan

viscosity was still low which was around 0.9585 -

2.5713 cP. However, according to Castillo, N. A., et

al, (2015), scleroglucan with viscosity of 1.5-3 cP

can still be applied in the chemical industries as a

mixture for toothpaste and mouthrinse formulation.

The viscosity of an exopolysaccharide is affected

by fermentation conditions such as temperature, pH,

and oxygen content (Garcia-Ochoa, 2000).

According to Castillo.A.N et al. (2015) and Survase

S.A, et al. (2007), the rate of aeration used is usually

at 2 vvm at a stirring speed of 180-600 rpm using air

bubbles. In this study aeration was carried out by

utilizing oxygen in the bioreactor with a ratio

between fermentation medium with bioreactor of 1:5

(v/v) (Standbury,2000).

Table 3: Scleroglucan research result.

No

Growth Medium

Substrate

Concentration

Fermentat

ion time

(hour)

Scleroglucan

produced (g)

Yield

(g/L)

Conversion

(%)

Viscocit

y (cP)

1

PDB

5% liquid

sugar

57

0.3785

1.893

3.785

0.9585

2

PDB

7% liquid

sugar

68

0.2892

1.446

2.066

1.9358

3

Modified PDB

5% liquid

sugar

76

3.5017

17.505

35.017

1.8500

4

Modified PDB

7% liquid

sugar

65

3.6228

18.114

36.228

2.5713

Effect of Substrate Concentration Variation on Scleroglucan Production using Aerobic Fermentation

427

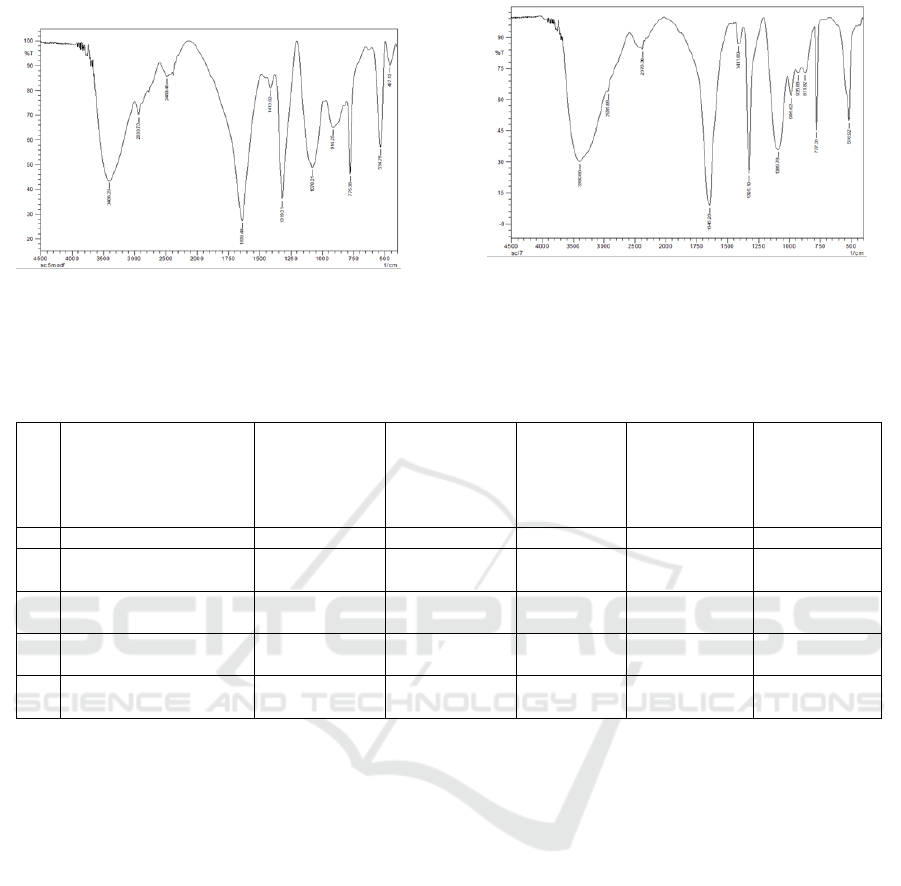

Figure 2: FTIR spectrum of scleroglucan from S.rolfsii

fermentation using a modified PDB medium with a

substrate of 5% liquid sugar.

Figure 3. FTIR spectrum of scleroglucan from S.rolfsii

fermentation using a modified PDB medium with a

substrate of 7% liquid sugar.

Table 4: The comparison of functional groups between literature scleroglucan obtained using two types of substrates

concentration.

No

Annotation

OH Stretching

and Bending

(cm

-1

)

CH Stretching

and Bending

(cm

-1

)

CH (cm

-1

)

CH Bending

(cm

-1

)

GOC

Glycosidic

and CCOH

Stretching

(cm

-1

)

1

Farina, J.I. et. al, 2015

3400

2937

-

1475 – 1250

1000 – 1200

2

Casadei, M.A. et al,

2007

3422

-

1636

1420 – 1395

1079

3

Moehady, B. I et. al,

2016

3392

2933

-

1409 – 1382

1026 – 1153

4

Scleroglucan (using 5%

liquid sugar)

3406

-

1639

1413 – 1319

1078

5

Scleroglucan (using7%

liquid sugar)

3390

2935

1645

1411 –1325

1089

Based on the results of FTIR analysis, the

presence of functional groups in the scleroglucan

obtained from various fermentation process

conditions can be recognized. Figure 2 and 3 showed

the FTIR spectrum of scleroglucan using modified

PDB with 5 and 7% liquid sugar substrate

respectively.

The compatibility of functional groups between

literature scleroglucan and scleroglucan of the study

is shown in Table 4 below. Overall, this suggests

that the fermentation of S.rolfsii using two types of

the liquid sugar substrate concentration can produce

scleroglucan.

4 CONCLUSION

The FTIR analysis, showed the compatibility of

functional groups between literature scleroglucan

and scleroglucan of the study. This suggests that the

fermentation of S.rolfsii using two types of the liquid

sugar substrate concentration will produce

scleroglucan. The use both of 5% and 7% liquid

sugar in modified PDB can increase yield and

conversion about 3.45% and 3.46% respectively.

The acquisition of scleroglucan viscosity was 0.

9585 to 2.5713 cP. While low, it can still be

applied in chemical industries as a mixture for

toothpaste and mouthrinse formulation.

.REFERENCES

Anisa, Yana, Nawangsih, & Abdjad Asih, 2011.

Pengaruh mulsa dan PGPR terhadap insidensi

penyakit busuk pangkal batang (S.rolfsii) pada

tanaman kedelai (glysine max (L) Merill). Institut

Pertanian Bogor, Bogor

Bhagat, I., 2011. “Factors influencing mycelial growth of

Sclerotium rolfsii”, Nepalese Journal of Biosciences,

Vol. 1, pp. 26-31.

Casadei, M.A., Matricardi P , Fabrizi G, Feeney M , &

Paolicelli P, 2007. “Physical gels of a carboxymethyl

derivative of scleroglucan: synthesis and

characterization”, European Journal Of

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

428

Pharmaceutics and Biopharmaceutics, Vol. 67, pp.

682-689.

Castillo, N. A., Valdez, A. L., & Fariña, J. I., 2015.

“Microbial production of scleroglucan and

downstream processing”, Frontiers In Microbiology,

Vol. 6, pp. 1106.

Djenar N.S and Wahyu. E., 2017. “The Effect of

Substrate Modification on Xanthan Gum Production

by Aerobic Fermentation Method”. Advanced Science

Letters, Vol. 23, No. 6, pp. 5678-5680

Egli, T., 2009. “Growth kinetics, bacterial”. In M.

Schaechter (Ed.), Encyclopedia of Microbiology, pp.

180-193.

Fariña, J.I., Siñeriz, F., Molina, O.E. & Perotti, N.I.

1998. “High scleroglucan production by Sclerotium

rolfsii: Influence of medium composition”. Journal Of

Biotechnology Letters, Vol. 20, Issue 9, pp 825–831.

Fariña, J.I., Viñarta, S.C., Cattaneo, M., & Figueroa,

L.I.C., 2008. “Structural stability of Sclerotium rolfsii

ATCC 201126 β‐glucan with fermentation time: a

chemical, infrared spectroscopic and enzymatic

approach”. Journal Of Applied Microbiology, Vol.106,

pp. 221-232.

Fosmer, A, Gibbons, W. R. & Heisel, N. 2010.

“Reducing the Cost of Scleroglucan Production by

Use of a Condensed Corn Solubles Medium,” Journal

of Biotechnology Research, Vol. 2, 2010, pp. 131-143.

García-Ochoa F, Santos VE, Casas JA, & Gómez E.,

2000. “Xanthan gum: production, recovery, and

properties”. Biotechnology Advances, Vol. 18, pp.

549-579.

https://de.wikipedia.org/wiki/Scleroglucan.

Moehady, B. I., Djenar, N. S., Widyanti, E. M., 2016.

“Produksi scleroglucan dari S.rolfsii menggunakan

media gula cair”, Prosiding Seminar Nasional

Teknik Industri, Universitas Gajah Mada, pp M2-M9.

Peter F Stanbury, P. F., Whitaker, A, Hall, S., J. 2000.

Principles of Fermentation. Butterworth-Heinemann,

Oxford, Melboune.

Prasetyoningrum, Adnan, T, & Muin, A., 2012. “Potensi

seduhan kompos untuk pengendalian penyakit layu

S.rolfsii pada tanaman kedelai”. Institut Pertanian

Bogor, Bogor.

Pudjihartati, Sudarsono, E., Ilyas, Satriyas, & S,

Siswanto, R., 2007. “Ketahanan kacang tanah dan

tembakau terhadap infeksi S.rolfsii Sacc. dengan

ekspresi enzim kitinase tinggi”, Pusat Pelatihan

Agrobisnis, Bioteknologi dan Sarana Industri, Bogor.

Survase, S. A., Saudagar, P. S., Bajaj, I. B., & Singhal,

R. S. 2007. “Scleroglucan: Fermentative Production,

Downstream Processing and Applications”, Food

Technol.Biotechnol. Vol. 45, No. 2, pp. 107-118.

Effect of Substrate Concentration Variation on Scleroglucan Production using Aerobic Fermentation

429