Physical Properties of Edible Film from Tilapia Bones

(Oreochromisniloticus) with Addition of Caragenan

(Kappaphycusalvarezii)

Rr. Dewi Artanti Putri, Maulana Akhsan Yoga Pangestu, and Muhammad Husein

Department of Chemical Engineering,Engineering Faculty, Universitas Negeri Semarang,Semarang 50229,Indonesia

Keywords: Carragenan, Edible Film, Tilapia bones, Thickness, Tensile Strength, Elongation, Elasticity, FTIR, Gelatin,

Solubility, WVP.

Abstract: Tilapia Fish (Oreochromis nilloticus) bone gelatin was potential material for edible film manufacture.

However, it needs some modifications to improve barrier properties. One of the modification is by adding a

cross linking agent. Carragenan (Kappapycus alvarezii) containing phenol which is expected to form cross

linking with gelatin. The purpose of this study was to determine the effect of various weight gelatin by

adding carragenan (Kappapycus alvarezii) toward mechanic, hidrofibility properties and functional groups

on bone tilapia (Oreochromis nilloticus) edible film. Edible film solution was made by extraction of gelatin

and addition of carragenan (Kappapycus alvarezii) at concentration 0%, 3%, 6% for each gelatin were 10

gram, 13 gram, 16 gram into 250 ml destilled water containing 30% glycerol (w/w) of gelatin. The addition

of carragenan (Kappapycus alvarezii) effect on the mechanical properties of edible film include increasing

the thickness of edible fim with the best value of 0.227 mm with a concentration of 10 grams gelatin and 6%

(w / w) carrageenan, reducing tensile strength with the best value of 21.5 MPa which is shown by the

treatment of 10 grams of gelatin was heavy and carrageenan concentration was 6% (w / w), increasing the

elongation value (elongation) with the best value of 39.9% as indicated by the treatment of 16 grams of

gelatin and carrageenan concentration of 0% (w / w), and decreasing elasticity with the best value of 0.547

MPa indicated by the treatment of 10 grams of heavy gelatin and carrageenan concentration of 6% (w / w).

The nature of hydrofibity with the addition of carrageenan (Kappapycusalvarezii) has an effect ondecreased

solubility and water vapor permeability (WVP) of edible film. The lowest solubility and water vapor

permeability shown by gelatin 16 gram and carragenan concentration 6% with value 62,85% and 1,31 x 10

-

12

g/m.s.Pa. Observation FTIR spectra showed indication of cross linking formation at edible film with

addition of carragenan (Kappapycus alvarezii).

1 INTRODUCTION

The high fisheries resources have an impact on the

growth of the fish industry in Indonesia. One type of

fish with the largest population is tilapia. In 2005 the

export of tilapia to America in form of fillets

amounted to 1.146.331 tons of the total export of

tilapia by 37.554.537 tons (Prayitno, 2012). This

indicates the large number of fish processing

industries in Indonesia which cause abundant waste

produced (Julianto, 2011). One of the fishery waste

products is fish bones that have the potential as an

alternative to collagen (Nagai and Suzuki, 2000).

One of the uses of collagen in the food sector is as

an ingredient in making gelatin (Maryani, 2010).

This gelatin can become a solution to replace gelatin

from mammals such as pigs or cattle. The product

that uses gelatin is edible film. So that it is expected

that tilapia bone waste can be used as material for

making edible films. Edible films are plastic or

packaging that are biodegradable so they can reduce

plastic waste and also environmentally friendly

(Fardhyanti, 2015). Some of the advantages of

edible film as a food packaging materials, namely

the film will be stronger, denser, elastic, low steam

transmission rate (Santoso, 2015).

Pranoto (2013) states that edible films from

gelatin fish bones have lower functional properties

than gelatin sourced from mammals (pigs and

cattle), so chemical and physical treatments are often

applied to modify polymeric tissue through cross-

linking on chains. Natural ingredients that can be

Artanti Putri, R., Pangestu, M. and Husein, M.

Physical Properties of Edible Film from Tilapia Bones (Oreochromisniloticus) with Addition of Caragenan (Kappaphycusalvarezii).

DOI: 10.5220/0009012304130420

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 413-420

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

413

added to edible film from gelatin to form cross

linking are carrageenan (Pranoto, 2006). According

to Athukorala (2003) carrageenan contains phenol

compounds that can bind to the side chains of

polypeptides from gelatin, so they can form denser

and stronger matrices. It also can improve the

mechanical and hydrofibility properties of edible

films and maintain the quality of the packaged

material. Research on edible film synthesis from

tilapia bone with the addition of carrageenan is

expected to improve the mechanical properties and

hydrofibity of edible films.

2 EXPERIMENTAL

2.1 Materials

In this study, raw materials of tilapia bones were

obtained from tilapia fish ponds in Kayen

subdistrict, Pati, Indonesia. Other materials are

99.9% purity technical glycerol that were obtained

from Merck, carrageenan (kappa) that obtained from

Pesona Green, Depok, Indonesia, also aquades from

the Indrasari chemical store, and 5% hydrochloric

acid obtained from the Integrated Chemical

Engineering Laboratory, Universitas Negeri

Semarang.

2.2 Experimental Procedures

2.2.1 Gelatin Extraction of Tilapia Bones

Gelatin extraction of tilapia bones refers to the

method of Rahayu (2015) by using hydrochloric

acid. Tilapia bones are cleaned using clean water

until the dirt is removed, then the bones are boiled

for 10 minutes using water at a temperature of 70

o

C

and then left to dry. The stew bone is cut to a

uniform size then soaked for 36 hours using 5%

hydrochloric acid with a ratio of 1: 5 (w / v) until

ossein is formed. After that the softened fish bone is

washed until the pH becomes 4-5. The fish bones

that have reached pH are then extracted using

distilled water with a ratio of 1: 3 (w / v) at 55

o

C for

5 hours. Collagen converted into gelatin by

hydrolysis will dissolve in distilled water. Then the

gelatin solution was dried with a rotary evaporator

then in the oven at 55

o

C for 24 hours until a gelatin

sheet was formed. The gelatin sheet is blended to

become gelatin powder.

2.2.2 Edible Film Synthesis

The edible film synthesis was made by using the

method of Pranoto (2013). Fish gelatin with a

variable of 10, 13 and 16 g was added with

carrageenan at several concentration (0%, 3%, 6% w

/ w gelatin) and dissolved with distilled water. The

solution was added by glycerol as much as 30% w /

w gelatin and stirred by heating to 55

o

C and distilled

water was added to a volume of 150 ml. The edible

film solution was stirred for 30 minutes. Edible film

solution was poured on a 20x20 cm glass plate and

then the solution was dried in oven at 55

o

C for 24

hours to form a stable layer.

2.2.3 Thickness Test

Film thickness was measured using a micrometer

with accuracy of 0.001 mm at 5 different points.

Then the measurement results averaged as the result

of film thickness (Nofiandi et al., 2016). According

to Japanese Industrial standard for edible film, the

maximum thickness is 0.25mm (Ariska and Suyatno,

2015).

2.2.4 Tensile Strength Test

Tensile strength is the maximum stress that an object

can hold when it is stretched or pulled before the

film breaks or tears (Fatma et al., 2016). The tensile

strength testing process is carried out in the

Diponegoro University Integrated laboratorium

using texture analyzer Brookfield CT 03 4500.

Tensile strength (Mpa) =

A

F

where: F = Maximum stress (N)

A = Cross-sectional area (mm

2

)

(Rusli et al., 2017)

2.2.5 Elongation Test

Elongation is a measure of the ductility of a material

as determined by a tension test. It is the increase of

the gauge-length of a test specimen after fracture is

divided by its original gauge-length. Higher

elongation means higher ductility. Elongation is

expressed as a percentage, and it is calculated by:

Elongation (%) = (b - a) / (a) × 100%

Description: a = Initial length of edible film

b = The final length of the edible film

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

414

2.2.6 Modulus Young

Lengthening values indicate the elasticity of a

material. The higher the elongation value of the

material, the more elastic the material will be. The

standard value of the minimum lengthening of edible

films is 0.35 Mpa (Ariska and Suyatno, 2015). The

amount of elasticity is obtained from the ratio of

tensile strength to elongation of a material (Setiani et

al., 2013).

2.2.7 Solubility Test

The solubility test follows the procedure of

Ghanbarzadeh (2011). The film is stored in a

desiccators containing silica gel until it reaches a

constant weight. After that, around 500 mg of film is

soaked in a glass containing 50 ml of distilled water

at 23

o

C for 24 hours by gentle agitation periodically.

Next, the film was taken and placed in the

desiccators to get the final dry weight of the film.

2.2.8 Water Vapor Permeability Test

Water vapor permeability test is carried out by

following the ASTM (1996) E96 procedure with

several modifications. The film is stretched over the

permeation cell tube in a circle with a diameter of 4

cm. In this permeation cell, silica gel is added (0%

RH). After being covered with film, the permeation

cell is inserted into the desiccators which has been

filled with saturated NaCl solution (70% RH) at 30

o

C. The rate of water vapor transfer can be

determined from the weight of the permeation cell

weight every 1 hour until several points are

obtained. Then film thickness measurements were

carried out at several points with a micrometer

(Wirawan, 2012).

2.2.9 FTIR analysis

Functional group analysis with FTIR aims to

determine whether the process of synthesizing edible

film runs physically or chemically. To find out about

this, one sample of edible film was taken to be

analyzed using FTIR. Firstly the sample is placed in

the set holder, then the appropriate spectrum is

searched. The result will be obtained by

diffractogram relationship between wave number

and intensity. The FTIR spectrum was recorded

using a spectrophotometer at room temperature

(Setani, 2013).

3 RESULT AND DISCUSSION

In this study, the effect of gelatin and carrageenan

concentration on the addition of glycerol as a

plasticizer as much as 30% v / w with coding as

follows:

G1 : 10 g gelatin ; C1 : 0% carrageenan w/w gelatin

G2 : 13 g gelatin ; C2 : 3% carrageenan w/w gelatin

G3 : 16 g gelatin ; C3 : 6% carrageenan w/w gelatin

3.1 Thickness

Film thickness is an important characteristic in

determining the feasibility of edible film as a food

product packaging. It is because thickness greatly

influences the physical and mechanical properties of

other edible films, for example tensile strength,

elongation (Ariska and Suyatno 2015).

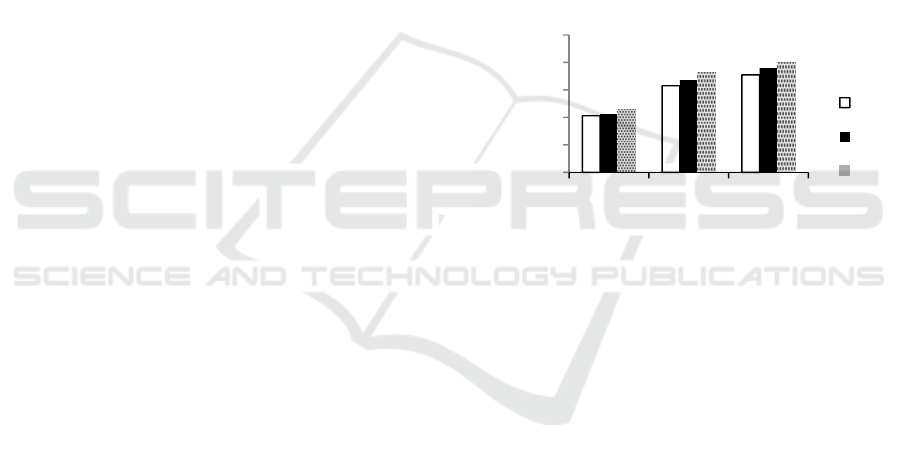

Figure 1: This Effect of gelatin and carrageenan

concentration on the thickness of edible film

As seen in Figure 1, it shows that along with the

increase in gelatin and carrageenan concentration,

the result of the thickness is also increased. The

Increasing thickness of edible film is also related to

the nature of colloidal compounds that are unique as

thickener and suspending, as well as the interaction

between the constituent components of edible films

(Handito, 2011). In addition thickness is also

influenced by the concentration of glycerol that

occupies the cavity in the edible film matrix and

interacts with carrageenan molecules to form

polymers which cause an increase in the distance

between the carrageenan molecule polymers thereby

increasing the thickness of the edible film (Rusli et

al., 2017). The best thickness value for tested edible

film from the gelatin of tilapia bone is 0.227 mm

with a concentration of 10 grams of gelatin, 6%

carrageenan w / w, and 30% glycerol v / w which

0

0.1

0.2

0.3

0.4

0.5

G1 G2 G3

Thickness (mm)

W Gelatin (g)

C1

C2

C3

Physical Properties of Edible Film from Tilapia Bones (Oreochromisniloticus) with Addition of Caragenan (Kappaphycusalvarezii)

415

according to Industrial Javanese Standard maximum

thickness of edible film is 0.25mm (Ariska and

Suyatno, 2015).

3.2 Tensile Strength

Tensile strength is one of the important mechanical

properties of edible film, because it is related to the

ability of edible film to protect coated products.

Edible films that have high tensile strength will be

able to protect the products they pack from

mechanical disturbances (Rusli et al., 2017).

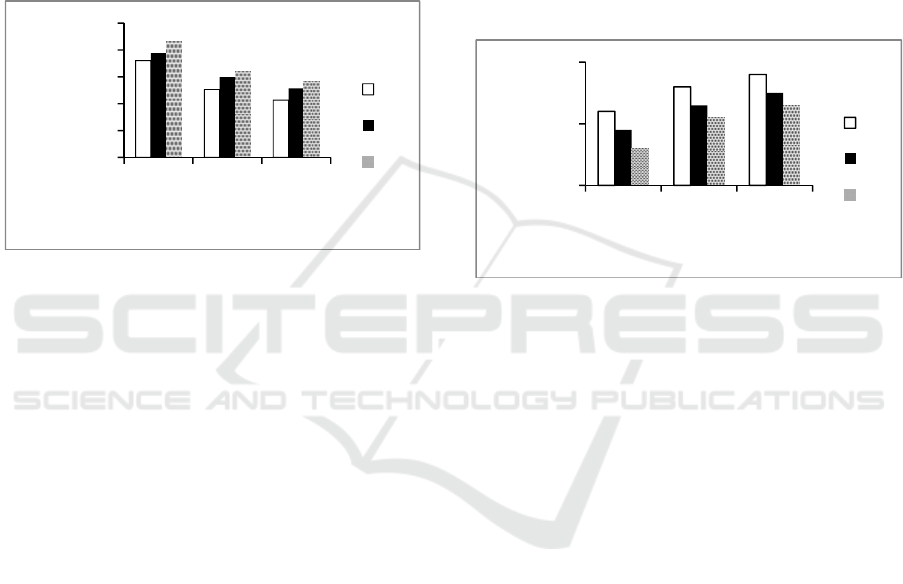

Figure 2: Effect of gelatin and carrageenan concentration

on the tensile strength of edible films

Figure 2. shows that an increase in carrageenan

concentration tends to increase the tensile strength of

edible films. This shows that the increase in the

amount of carrageenan in the synthesis of edible

film causes the bond between the constituent

molecules of edible film to increase resulting in an

increasingly compact edible film (Rusli et al., 2017).

These results are also supported in the study of

Ariska and Suyatno (2015) stating that the more the

concentration of carrageenan added in the synthesis

of edible films will form a stronger matrix of films,

so the force needed to decide edible film is also

getting bigger.

The tensile strength of edible films that get

additional glycerol has a tendency to decrease, this is

due to a decrease in the interaction between

molecules of edible film constituents. This decrease

is caused by glycerol which can reduce internal

hydrogen bonds which causes the weakening of the

intermolecular polymer chain forces that are close

together, thereby reducing breaking strength (Putra

et al., 2017). This is consistent with research from

Sinaga et al. (2013) which states that the higher the

concentration of glycerol will cause a decrease in the

tensile strength of edible film. This is due to the

reduction of intermolecular interactions in the

protein chain so that the film matrix formed will be

less.

3.3 Elongation

Elongation is the maximum increase percentage of

film length when obtaining tensile forces until the

film breaks compared to the initial length

(Fardhyanti and Julianur, 2015). Elongation test is

done by comparing the length increments that occur

with the length of the material before the tensile test

is carried out (Arini et al., 2017).

Figure 3: Effect of gelatin and carrageenan concentration

on elongation of edible film

In figure 3, it can be seen that the result of the

extension show that with the addition of the

concentration of gelatin and carrageenan does not

show a significant difference. The extension value

produced in this study ranged from 39.3 - 39.9%.

This value tends to increase due to the addition of

glycerol in the manufacture of edible films. This is

because glycerol can increase the stretch of

intermolecular space in the matrix structure of edible

film and increase flexibility, and reduce the number

of hydrogen bonds so that it can reduce fragility and

not break easily (Ningsih, 2015). The extension

value of edible film produced in this study is quite

good because it is above the Japanese Industrial

Standars which stipulates that percent elongation is

categorized as bad if it is less than 10% and

categorized very well if more than 50% (Ariska and

Suyanto, 2015).

0

5

10

15

20

25

G1 G2 G3

Tensilestrength

(MPa)

WGelatin(g)

C1

C2

C3

39

39.5

40

G1 G2 G3

Elongation(%)

WGelatin(g)

C1

C2

C3

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

416

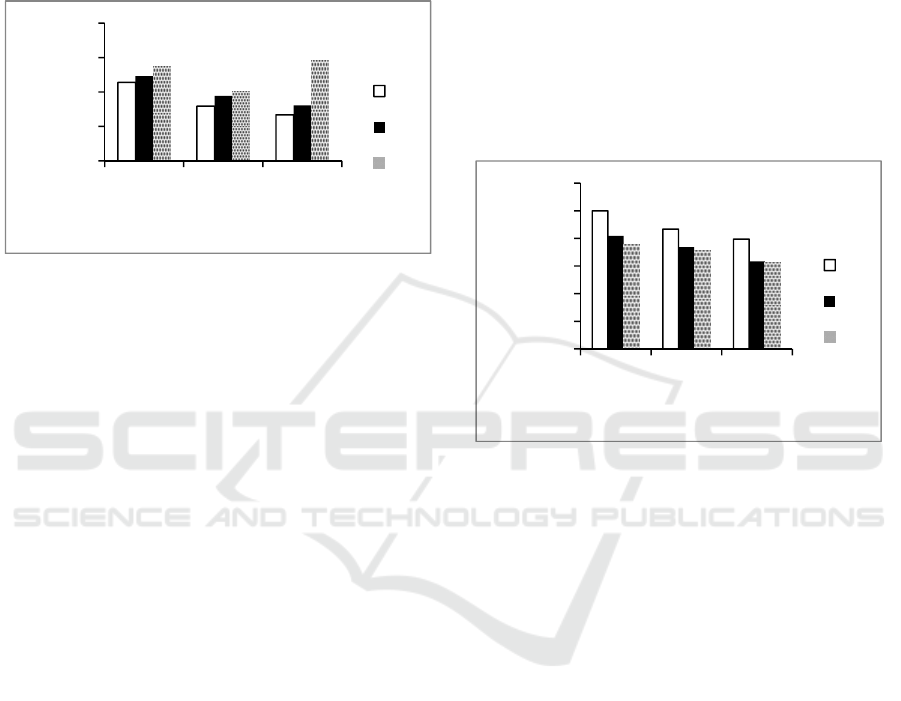

3.4 Modulus Young

Young modulus is done to determine the size of the

stiffness of the material produced. Modulus young

can be known by comparing the tensile strength

value with the extension value (elongation) (Febianti

et al., 2015).

Figure 4: Effect of gelatin and carrageenan concentration

on Modulus Young of edible film

In Figure 4 the value of elasticity produced tends

to decrease with increasing concentration of gelatin

and carrageenan. This decrease in elasticity

(modulus young) is caused by increasing the

concentration of gelatin and glycerol. The greater

the concentration of gelatin and glycerol added, the

greater the number of polymers making up the film

matrix, which increases the value of tensile strength

and decreases the value of elongation (Ariska and

Suyatno, 2015). The elasticity value (modulus

young) is directly proportional to tensile strength

and inversely proportional to elongation (Nahwi,

2016). Figure 4 showed that there were several

edible films from tilapia bone gelatin with the

addition of carrageenan and gelatin were still

relatively good because they were above the

minimum standard value of elasticity (modulus

young) edible film. According to Japanese Industrial

Standard (1975), the minimum value of elasticity

(modulus young) of edible films is 0.35 MPa (Ariska

and Suyatno, 2015). Edible film that has a value of

elasticity (modulus young) of less than 0.35 MPa

can be caused by several factors, including the

stirring process carried out manually which only

uses a glass stirrer so that the mixture is not evenly

distributed in the solution (Arini et al., 2017) . The

results showed that the best elasticity (modulus

young) was 0.547 MPa with a concentration of 10

grams of gelatin, 6% carrageenan w / w, and 30%

glycerol v / w.

3.5 Solubility

High solubility shows that edible films are easily

degraded in nature and can be used as packaging for

ready-to-eat products. They are also easily dissolved

when consumed directly (Pitak, 2011). However,

low solubility is an important requirement for edible

film to become a packaging for wet and semi-wet

food products (Atef, 2015).

Figure 5: Effect of gelatin and carrageenan concentration

on solubility of edible film

As seen in Figure 5, edible film synthesis with

variations in gelatin weight and carrageenan

concentration showed solubility results ranging from

99.851 to 62.841%. The highest solubility results

based on Figure 4.1 contained 10 grams of gelatin

with a solubility value of 0% carrageenan

concentration was 99,851. Meanwhile, the lowest

solubility results based on Figure 5 showed on 16

grams of gelatin weight and 6% (w / w) carrageenan

concentration with a solubility value of 62.841%.

The lowest value of edible film solubility from this

study is still relatively high compared to Darni and

Utami's study (2010) which made from sorghum

based. It produce the lowest solubility value of

36.825%, and Santoso, et al., (2015) research which

based on starch produce solubility values the lowest

is 41%, thus showing edible film from tilapia bone

gelatin is more suitable as a food packaging that can

be consumed directly (Diova et al., 2013). One type

of food coated with edible film with high solubility

0

0.2

0.4

0.6

0.8

G1 G2 G3

ModulusYoung(MPa)

WGelatin(g)

C1

C2

C3

0

20

40

60

80

100

120

G1 G2 G3

Solubility(%)

WGelatin(g)

C1

C2

C3

Physical Properties of Edible Film from Tilapia Bones (Oreochromisniloticus) with Addition of Caragenan (Kappaphycusalvarezii)

417

value and can be consumed directly is beef sausage

(Estiningtyas, 2010).

There is a decreasing in solubility due to an

increase of carrageenan concentration tends to be

inversely proportional to the solubility of edible film

caused by the increased content of dissolved solids

derived from edible film making materials and the

increasing number of inter-molecular bonds in

edible films (Rusli et al., 2017). Bonds between

molecules in edible film can be increased due to the

side chain of polypeptides in gelatin which binds to

phenol compounds in carrageenan (Pranoto and

Sutono, 2013).

Based on the Negara and Simpen research

(2014), the greater the concentration of gelatin with

the same plasticizer ratio will produce smaller

solubility. This is due to the nature of the gelatin

which forms a gel if it is mixed with water so that

more gelatin in the mixture produces low solubility

and requires heating to dissolve it (GMIA, 2012).

Solubility is also determined by the thickness of the

edible film. Based on Figure 4.1 edible film with a

weight of 10 grams of gelatin and carrageenan

concentration of 0% (w / w) produced the highest

solubility of 99.851%. This is due to edible films

produced from the above variations having the

smallest thickness so that they can dissolve almost

100% in water before 24 hours (Santoso et al.,

2013). From the results of the solubility test it can be

indicated that the increasing of gelatin weight and

carrageenan concentration tends to provide low

solubility in the edible film.

3.6 Water Vapor Permeability

Water vapor permeability is the ability of the film to

resist the rate of water vapor that penetrates it

(Wirawan, 2012). Gontard (1993) states, that the

value of water vapor permeability in edible films

must be as low as possible. Low water vapor

permeability values indicate a better barrier to water

vapor (Pranoto, 2013). Observation of the

permeability of edible film water vapor from tilapia

bone gelatin with the addition of carrageenan is

presented in Figure 6. The highest water vapor

permeability value is at 10 grams of gelatin and 0%

carrageenan (w / w) of 1,994 x 10

-12

g / msPa, while

the lowest water vapor permeability value is 13

grams of gelatin and 6% carrageenan (w / w) of

1,305 x 10

-12

g / msPa.

According to Junianto (2013), decreasing water

vapor permeability due to the increasing weight of

gelatin, this is caused by increasing molecular

weight so that the film layer gets denser and reduces

water vapor permeability. Increasing molecular

weight is influenced by the increase of amino acids

in edible films (Cao, 2007). Pranoto (2013) also

stated that films with the addition of carrageenan can

significantly reduce water vapor permeability

compared to films without the addition of

carrageenan. Film derived from gelatin when

combined with carrageenan will significantly reduce

WVP value compared to films without the addition

of carrageenan (Rattaya et al., 2009). The decrease

in WVP value of edible film may be caused by a

decrease in free volume in the edible film matrix as

a result of increased cross linking through covalent

bonds formed due to the addition of herbal extracts

on gelatin-based films (Hoque et al., 2011).

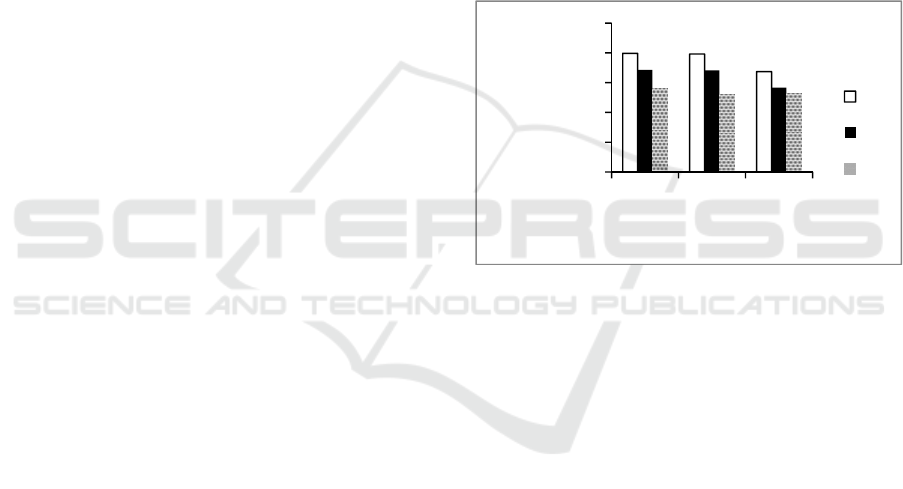

Figure 6: Effect of gelatin and carrageenan concentration

on Water Vapor Permeability of edible film

Cross linking can cause increasing density in the

polymer matrix and also in winding pathways for

water molecules to pass through the tissue. This

causes the free volume in the matrix to decrease so

that the amount of diffusion of water through the

film also decreases (Cao et al., 2007). The inhibition

of the diffusion process of water molecules to pass

through the complex film network results in

decreasing WVP values (Pranoto and Sutono, 2013).

From this it can be indicated that the increasing in

gelatin weight and carrageenan concentration tends

to decrease the WVP value.

3.7 FTIR Analysis

Analysis of functional groups with FTIR aims to

compare the presence of CN (carbon-nitrogen)

groups from edible gelatin films of tilapia with and

without the addition of carrageenan. The shape of

0

5E‐13

1E‐12

1.5E‐12

2E‐12

2.5E‐12

G1 G2 G3

WVP(g/m.s.Pa)

WGelatin(g)

C1

C2

C3

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

418

the absorption peak and wave number can be seen in

Table 1. We can see that the edible film with the

addition of carrageenan has a wave number of

1644.38 cm

-1

while the edible film without the

addition of carrageenan has a wave number of

1642.16 cm

-1

. According to Pranoto (2013) the wave

number peak with the absorption area of 1600-1700

cm

-1

is the absorption peak which indicates the

presence of CN (carbon-nitrogen) structure and peak

which can identify the presence of cross linking. So

that it can be indicated that a cross bond between

gelatin and carrageenan is formed.

Table 1: Wave Numbers of FTIR analysis.

Absorption

Area

Wave Length (cm

-1

)

(G1) (G2)

amide A 3429,82 3409,54

amide I 1642,16 1644,38

Cross-linking occurs between the side chains of

polypeptides in gelatin with phenol compounds in

carrageenan (Pranoto, 2013). This is also reinforced

by the decrease of the free NH group on edible film

with the addition of carrageenan which is indicated

by wave number 3409, 54 cm

-1

while for edible film

without addition of carrageenan has a wave number

3429, 82 cm

-1

.

4 CONCLUSIONS

Increasing the weight of gelatin and the addition of

carrageenan concentrations can affect the

mechanical properties of the edible film. The greater

the concentration of gelatin and carrageenan, the

thickness increases, the tensile strength decreases,

the elongation value tends to increase, and the

elasticity (modulus young) tends to decrease, and

influences the hydrofibality properties of edible film

which decreases solubility and permeability

moisture on the edible film from the gelatin of the

tilapia bone. This is reinforced by the presence of

cross linking as indicated by the results of FTIR

analysis. The more cross-linking that is formed, the

edible film matrix will also be more tight so that it is

not easy for water to pass through.

REFERENCES

Arini, D., M. S. Ulum., & Kasman., 2017. “Manufacture

and Testing of Mechanical Properties on Durian Seed

Flour Biodegradable Plastics”. Journal of Science and

Technology, Vol. 6, No. 3, pp. 276-283.

Ariska, & R.E., Suyatno. 2015. Pengaruh Konsentrasi

Karagenan Terhadap Sifat Fisik dan Mekanik Edible

film dari Pati Bonggol Pisang dan Karagenan dengan

Plasticizer Gliserol. Prosiding Seminar Nasional

Kimia. Universitas Negeri Surabaya. Surabaya.

ASTM., 1996. Standard Test Methods for Water Vapor

Transmission of Material. E96-95, Annual Book of

ASTM. PA: American Society for Testing and

Materials. Philadelphia.

Atef, M., Rezaei, & M., Behrooz, R., 2015.

“Characterization of Physical, Mechanical, and

Antibacterial Properties of Agar Cellulose

Bionanocomposite Films Incorporated With Savory

Esseential Oil”, Food Hydrocolloids, Vol. 33, No.1,

pp. 118-131.

Athukorala, Y., Lee, K.W., Song, C.B., Ahn, C.B., Shin,

T.S., Cha, Y.J., & Shahidi, F., Jeon., 2003. “Potential

Antioxidant Activity of Marine Red Alga (Grateloupia

filicina) extracts”, Journal of Food Lipids, Vol. 10, pp.

251-265.

Cao, N., Fu, Y., & He, J., 2007. “Mechanichal Properties

of Gelatin Films Cross-Linked , Respectively, by

Ferulic Acid and Tannin Acid”, Journal of Food

Hydrocolloids. Vol. 21, pp. 575-584.

Darni, Y., & Utami, H., 2010. “Studi Pembuatan Dan

Karakteristik Sifat Mekanik Dan Hidrofibitas

Bioplastik Dari Pati Sorgum”. Jurnal Rekayasa Kimia

dan Lingkungan, Vol. 7, No. 4, pp. 88-93.

Diova, D.A., Darmanto, & Y.S., Rianingsih, L., 2013.

“Karakteristik Edible Film Komposit Semirefined

Karaginan Dari Rumput Laut Eucheuma Cottoni Dan

Beeswax”. Jurnal Pengolahan dan Bioteknologi Hasil

Perikanan, Vol. 2, No. 3, pp. 1-10.

Estiningtyas, & Heny. R., 2010. Aplikasi Edible Film

Maizena Dengan Penambahan Ekstrak Jahe Sebagai

Antioksidan Alami Pada Coating Sosis Sapi. Final

Report. Fakultas Pertanian Program Studi Teknologi

Hasil Pertanian Universitas Sebelas Maret. Surakarta.

Fardhyanti, D.S., & Julianur, S.S., 2015 .” Karakterisasi

Edible Film Berbahan Dasar Ekstrak Karagenan Dari

Rumput Laut (Eucheumacottonii)”. Jurnal Bahan

Alam Terbarukan, Vol. 4, No. 2, pp. 68-73.

Fatma, Malaka, R, & Taufik, M. 2016. “Pengaruh Variasi

Persentase Gliserol Sebagai Plasticizer Terhadap Sifat

Mekanik Edible Film Dari Kombinasi Whey

Dangke Dan Agar”. Jurnal Ilmu & Teknologi

Peternakan, Vol 4, No. 2.

Febianti, F., Heni Tri A., & Fadilah., 2015. Studi

Pembuatan dan Karakteristik Sifat Mekanik Edible

Film Berbahan dasar Umbi Suweg (Amporphophallus

campanulatus) dengan Pewarna dan Rasa Secang.

Prosiding SENATEK 2015 Fakultas Teknik.

Universitas Muhammadiyah Purwokerto.

Physical Properties of Edible Film from Tilapia Bones (Oreochromisniloticus) with Addition of Caragenan (Kappaphycusalvarezii)

419

Ghanbarzadeh, B., Almasi, H., Entezami, & Ali A., 2010.

“Improving The Barrier and Mechanichal Properties

of Corn Starch-Based Edible Film: Effect OfCitric

Acid and Carboxymethyl Cellulose”. Industrial Crops

and Products, No. 33, No. 2011, pp. 229-235.

GMIA. 2012. Gelatin Handbook. Gelatin Manufactures

Institute of America

Gontard, N., Gulbert, S., & Cuq, J.L., 1993. “Water and

Glycerol as Plasticizers Affect Mechanical and Water

Vapor Barrier Properties of an Edible Wheat Gluten

Fil”. Journal of Food Science, Vol. 58, No. 1, pp. 206-

211.

Hadinto, D., 2011. “Pengaruh Konsentrasi Karagenan

Terhadap Sifat Fisik dan Mekanik Edible Film”.

Agroteksos, Vol. 21, No. 2-3, pp. 151-157.

Hoque, Md.S., Benjakul, & S., Prodpran, T., 2011.

“Effects of Partial Hydrolysis and Plasticizer content

on the properties of film from cuttlefish (Sepia

pharaonis) Skin Gelatin”, Journal of Food

Hydrocolloids, Vol. 25, pp. 82-90.

Julianto, G.E., 2011. “Karakteristik Edible Film dari

Gelatin Kulit Ikan Nila Merah dengan Penambahan

Plasticizer Sorbitol dan Asam Palmitat”. Jurnal

Perikanan, Vol. 13, No. 1, pp. 27-34.

Junianto, K.H., & Maulina, I., 2013. “Karakteristik

Cangkang Kapsul yang Terbuat dari Gelatin Tulang

Ikan”. Jurnal Akuatika. Vol. 4, No. 1, pp. 46-54.

Maryani, Surti, Titi., Ibrahim, & Ratna., 2010. “Aplikasi

Gelatin Tulang Ikan Nila Merah

(Oreochromisniloticus) Terhadap Mutu Permen Jelly”,

Jurnal Saintek Perikanan, Vol. 6, No. 1, pp. 62-70.

Nagai, T., & Suzuki, N., 2000. “Isolation of Collagen from

Fish Waste Material-Skin, Bone, Fins”, Journal of

Food Chemistry, Vol. 68, pp. 277-281.

Nahwi, & Naufal F., 2016. Analisis Pengaruh

Penambahan Plastisizer Gliserol pada Karakteristik

Edible Film dari Pati Kulit Pisang Raja, Tongkol

Jagung dan Bonggol Enceng Gondok. Final Report.

Fakultas Sains dan Teknologi Universitas Islam

Negeri Maulana Malik Ibrahim, Malang.

Negara, I.M.S., & Simpen, I.N., 2014. “Sintesis dan

Karakterisasi Edible Film Berbahan Baku Gelatin

Hasil Isolasi Kulit Ceker Ayam Boiler”. Jurnal Kimia,

Vol. 8, No. 1, pp. 120-126.

Ningsih, Sri H., 2015. Pengaruh Plasticizer Gliserol

Terhadap Karakteristik Edible Film Campuran Whey

Dan Agar. Final Report. Fakultas Peternakan

Universitas Hasanudin, Makasar.

Nofiandi, Dedi, Widi N, & Putri, A. S. L., 2016.

“Pembuatan dan Karakteristik Edible film dari

Poliblend Pati Sukun-Polivinil Alkohol dengan

Propilenglikol sebagai Plasticizer". Jurnal Katalisator,

Vol. 1, No. 2.

Pitak, N., & Rakshit, S.K.., 2011. “Physical And

Antimicrobial Properties Of Banana Flour/Chitosan

Biodegradable and Self Sealing Films Used For

Preserving Fresh-Cut Vegetables”, LWT- Food

Science and Technology, Vol. 44, pp. 2310-2315.

Pranoto, Y., Lee, C.M., & Park, H.J. 2006.

“Characterizations of Fish Gelatin Films Added with

Gellan and K-Carragenan. Swiss Society of Food”

Science and Technology, Vol. 40, pp. 766-774.

Pranoto, Y., & Sutono, D., 2013. “Ekstrak Rumput Laut

(Kappaphycus alvarezii) Sebagai Cross Linking Agent

pada Pembentukan Edible Film Gelatin Kulit Ikan

Nila Hitam (Orochromis mossambicus)”. AGRITECH,

Vol. 33, No. 2, pp. 168-175.

Prayitno, Emiliana, Wachid, & Nur., 2012. Pemanfaatan

Limbah Kulit Ikan Nila dari Industri Fillet Untuk Kulit

Jaket. Majalah Kulit. Karet dan Plastik, Vol. 28, No.

1, pp. 51-59.

Putra, A.D., Vonny S.J., & Efendi R., 2017. “Penambahan

Sorbitol Sebagai Plasticizer Dalam Pembuatan Edible

Film”. Jurnal Teknologi Hasil Pertanian, Vol. 4,

No.2, pp. 1-15.

Rahayu, Fadjar., Fithriyah, & Nurul.H., 2015. Pengaruh

Waktu Ekstraksi Terhadap Rendemen Gelatin Dari

Tulang Ikan Nila Merah, Seminar Nasional Sains dan

Teknologi 2015, Fakultas Teknik Universitas

Muhammadiyah Jakarta.

Rattaya, S., Benjakul, S., & Prodpran, T. 2009. “Properties

Of Fish Skin Gelatin Film Incorporated With Seaweed

Extract”. Journal Of Food Engineering, Vol. 95, pp.

151-157.

Rusli, A., Metusalach, Salengke, & Tahir, M.M., 2017,

“Karakterisasi Edible Film Karagenan Dengan

Pemlastis Gliserol”, JPHPI, Vol. 20, No. 2, pp. 219-

229.

Santoso, B., Marsega, A., Priyanto, G., & Pambayun, R.,

2015, “Perbaikan Sifat Fisik, Kimia, dan Antibakteri

Edible Film Berbasis Pati Ganyong”. AGRITECH,

Vol. 36, No. 4, pp. 379-386.

Setiani, W., Sudiarti, T., & Rahmidar, L., 2013, “Preparasi

dan Karakterisasi Edible Film dari Poliblend Pati

Sukun-Kitosan”, Valensi, Vol. 3, No. 2, pp. 100-109.

Sinaga, L.L., 2013. “Karakteristik Edible Film dari

Ekstrak Kacang Kedelai dengan Penambahan Tepung

Tapioka dan Gliserol Sebagai Bahan Pengemas

Makanan”. Jurnal Teknik Kimia Universitas Sumatera

Utara, Vol. 2, No. 4, pp. 12-16.

Wirawan, Sang Kompiang.,Prasetya, Agus., & Ernie.,

2012. “Pengaruh Plasticizer Pada Karakteristik Edible

Film dari Pektin”, Reaktor, Vol. 14, No. 1, pp. 61-67.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

420