Magnetic and Physical Properties Modification using Sintering

Temperature Variations in the Process of Making Barium

Hexaferrite Permanent Magnet

Wibowo, R Lullus L. G. Hidajat, Sony Wijaya, Eko Surojo

Mechanical Engineering Department, Sebelas Maret University, Surakarta 57128, Indonesia

Keywords: Hard-Magnetic, Barium Hexaferrite, Magnetic Properties, Mechanical Alloying, Sintering.

Abstract: This paper discusses the modification of magnetic hysteresis and particle size of barium hexaferrite

permanent magnet using sintering temperature variatons. The materials used were Barium Carbonate

(BaCO3) and Hematite (Fe2O3) with a stochiometric ratio of (1: 6), obtained by the dry miling mixing

process for 6 hours. Then this material was calcined at 1100°Celsius for 30 minutes and sieved to pass

through the 200 mesh filter. The sample is compacted by 3wt% additive shellac and 5 Ton pressing to form

a pellet with diameter of 5 mm. The next process is samples were sintered at temperatures of 900°C, 1000°C

and 1100°C for 30 minutes. The magnetic hysteresis of this sample were then determined using VSM and

microstructure analysis was determined using SEM. The results showed that the average Hmax and particle

size increase for temperatur of 900°Cto 1000°C and decrease from 1000°C to 1100°C. At sintering

temperature of 1000° C a granullar fusion was formed while new phase had not been formed, whereas at a

sintering temperature of 1100°C a new phase had been formed which causes coercivity decreased. It was

concluded that the optimal modification of magnetic properties and particle size was obtained at sintering

temperature of 1000°C.

1 INTRODUCTION

Permanent magnets are the one of primary

component for modern machinery equipment in

various fields such as automotive machinery,

electronic equipment and energy. Industrial

applications require permanent magnet components

with certain specifications to run the machining

system. Because Indonesia as a developing industrial

country, permanent magnets is demanded so high

that it have to import such permanent magnet

components. Thus, the local magnet industry is

needed to meet domestic magnetic demand (P.

Sardjono et all.,2012).

In electric machinery, a permanent magnet is a

passive component in producing a magnetic field,

which allows work without electric current supplied

to coil or solenoid to maintain the magnetic field.

The induced magnetic in the permanent magnet

material will be maintained, so that when the electric

current is terminated the magnetic field of the

permanent magnet material remain stored (D. Jiles,

1991). Ceramic permanent magnets replace

electromagnets in many applications and widely

used as permanent magnets in electric motors,

generators and speakers (S. Collocot, 2007).

One of the materials to produce ceramic type of

permanent magnet is barium. Barium is a silvery

white metal formed in nature in various forms

commonly in compound forms. This material is

found in nature in two forms of material, namely

barium sulfate and barium carbonate which are

deposits deposited on earth mantle (Clement

International Corporation, 1992). The chemical

properties of barium material i.e. melting point at

720°C, boiling point 1,640ºC, and density of 3,51

gcm

3

(Sunarya, S. A. 2009). This magnetic proper-

ties of the material after magnetization is permanent

(M. I. Alif, 2012,), mechanical properties are very

strong and not easily corroded (Snoek, 1947). In

addition, mix of barium carbonate and oxide ferrite

produces a permanent magnet barium hexaferrite

(Priyono, 2001). The use of M.hexaferit-based

barium magnets, i.e., as a microwave absorber in the

aircraft cabin (D. P. Efhana et all, 2013), and a

permanent magnet based on Ba/Sr-ferrite are used as

measuring instruments on water meters (I. Yusan, et

all,2012). Although it is very potential as a mineral

material to produce magnets, in Indonesia, this

72

Wibowo, ., Hidajat, R., Wijaya, S. and Surojo, E.

Magnetic and Physical Properties Modification using Sintering Temperature Variations in the Process of Making Barium Hexaferrite Permanent Magnet.

DOI: 10.5220/0009006600720076

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 72-76

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

material is a steel industry waste that has not been

managed optimally.

In this research, barium ferrite permanent magnet

manufacturing was performed by using powder

metallurgy method. The raw material are Barium

Carbonate (BaCO

3

) and Oxide Ferrite (Fe

2

O

3

) with a

stoichiometric ratio of 1:6, using the milling process.

The next process is calcination, compaction, and

sintering treatment. The heat treatment process has

generally been known to have a negative impact on

magnetic properties, but this process cannot be

avoided in the process of metallurgy powder in order

to make a strong magnet that can be utilized in

machinery. Sintering is a heat treatment process that

is employed to produce a dense material by

adjusting the treatment for components of metal or

ceramic powder. For this reason, a study of sintering

conditions is needed to obtain high quality

permanent magnet materials.

The next phase of this research is analysis using

a scanning electron microscope (SEM) method to

determine the microstructure. While the magnetic

properties of the sample was observed through

hysteresis curve analysis using Vibrating Sample

Magnetometer (VSM).

2 RESEARCH METHODOLOGY

The powder metallurgy method is used in this

research The stoichiometric ratio for barium

carbonate and oxide ferrite is (1: 6) was determined.

The first process of making samples is the materials

were scaled using digital scales. After weighing

according to the desired composition the material

was mixed using ball milling in a wet state, so that

the mixture obtained had a high homogeneous level.

The next processeswere calcination, compaction,

and sintering heat treatment. Powder material before

calcination is shown in Figure 1 (a). Figure 1 (b) is a

ball milling device for mixing for 6 hours. The

calcination process was then carried out to form the

crystalline phase of barium hexaferrite with a

temperature of 1100ºC with a holding time of 30

minutes. Figure 1 (c) shows the material after

calcination process.

Powder material produced from the calcination

process is then sieved using 200 mesh size filter in

order to obatin homogen particle size powder. Then

2% additive material was added as a binder. At the

compaction stage the material that was initially in

the form of granulars, was compacted to form a solid

specimen as pellets with a pressure of 5 tons. The

specimen was shown in Figure 2. Furthermore the

specimens were subject to sintering heat treatment

with variations in temperature of 900°C, 1000°C,

and 1100°C with a holding time of 30 minutes.

The sintering treatment was conducted to

perform granule fusion and to reduce porosity.

Heating variations is for temperature of 900°C,

1000°C, and 1100°C with a holding time of 30

minutes. It was expected that a bonding process

between magnetic fragments had been occured

without changes ofmagnetic phase, so that a solid

and hard magnetic material is obtained (Strant,

Wahlfarth, et al, 1952). Holding time 30 minutes

after sintering process was performed to eliminate

residual stress so that the material does not crack

easily and then improves its coercivity. Furthermore,

test of magnetic properties using a vibrating

magnetometer sample (VSM) was conducted to

obtain hysteresis curve of each sample. The

microstructure of sample was investigate susing

scanning electron microscopic (SEM) test.

Figure 2: Specimens after compaction.

(a) (b) (c)

Figure 1: (a) powder before calcination; (b) ball milling machine; (c) after

calcination.

Magnetic and Physical Properties Modification using Sintering Temperature Variations in the Process of Making Barium Hexaferrite

Permanent Magnet

73

3 RESULTS AND DISCUSSION

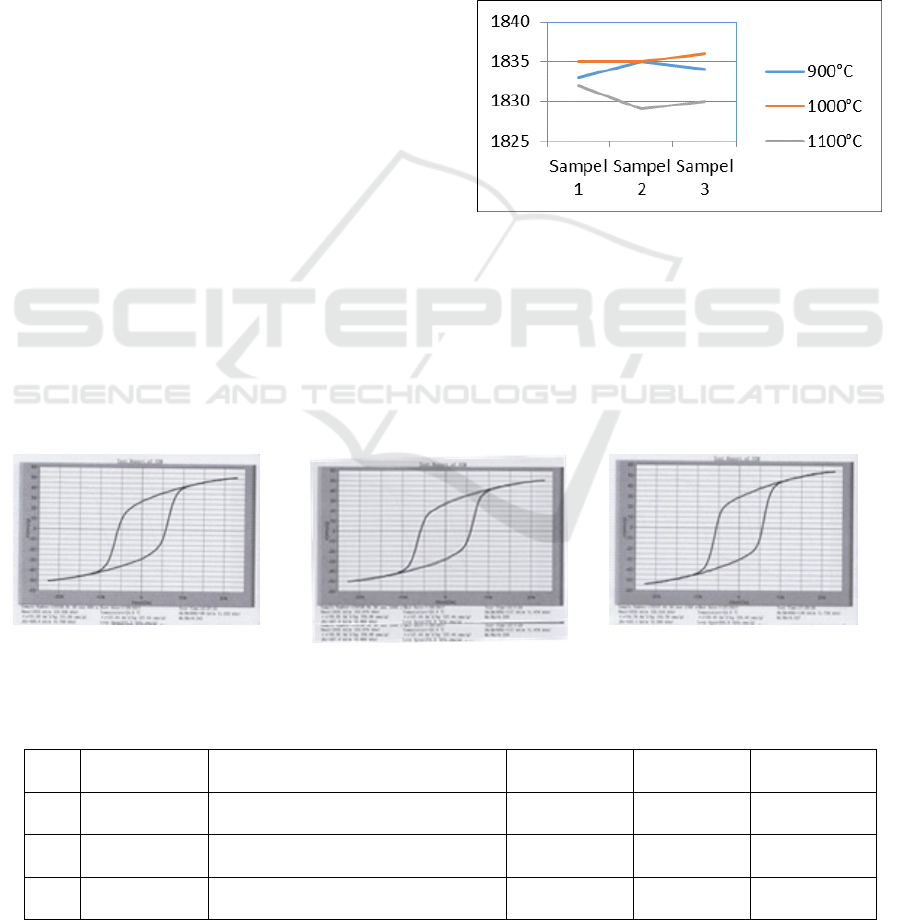

Results shows the effect of sintering temperatures on

magnetic properties and microstructure of the

magnetic samples. Temperature variation results in

changes in the properties of magnetic materials both

magnetic properties and physical properties. These

changes include coercivity, maximum energy pro-

ducts of magnetic properties, and microstruc-ture.

3.1 Characterization of Magnetic

Properties

Characterization of magnetic properties was based

on values contained in the hysteresis curves of are

shown in fig. 3. Figure 3 shows the hysteresis curve

produced from barium hexaferrite material for three

sintering temperature variations, namely: 900°C,

1000°C, and 1100°C and holding time 30 minutes.

Tabel 2 shows that at temperature of 900°C the

H

max

value of 1835kA/m (23.058 kOe) at test

temperature of 25.3°C, Hc 449.8kA/m (5,653 kOe)

and 53,10emu/g of magnetic saturation were

obtained. While at temperature 1000°C H

max

value

of 1836kA/m (23.076 kOe) at test temperature of

25.0°C. Hc 467.9 kA/m (5,880 kOe)were obtained

and at 1100°C Hmax value of 1832 kA/m (23.016

kOe) at test temperature 24.9°C. Hc 443.1 kA/m

(5,569 kOe) were obtained. The results of Hmax for

each samples is shown graphically in fig. 4. Figure 4

shows graphs of VSM test results.

Figure 4. shows the effect of sinters temperatures

on magnetic coercivity. It was find that from the

hysteresis curve, the effect of sintering temperature

on magnetic coercivity at sintering temperature

1100

O

C has the smallest value of 1832 kA/m

(23,016 kOe), while at 1000

O

C has value of 1836

kA/m (23,076 kOe). The highest value from

hysteresis curve is for sintering temperature of

1000

O

C. In addition, during the sintering process

morphological of the particles are possibly changes.

Morphological changes in particles is not only

change the density between granules but also

microstructure changes.

Figure 4: Graph of H

max

values.

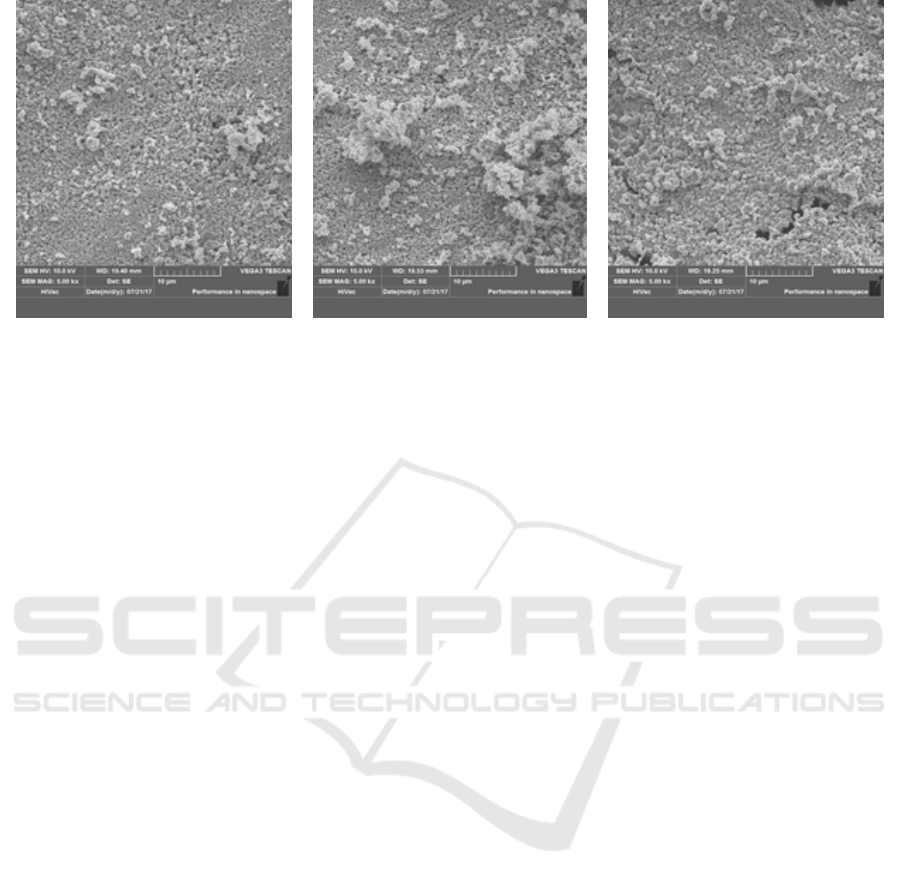

3.2 Microstructures

Microstructure pictures from the SEM process are

shown in fig. 5. The magnification used is 5000

times for each samples with sintering temperature of

900°C, 1000°C, and 1100°C and a holding time of

30 minutes.

(a) Sinterin

g

of 900°C (b) Sinterin

g

of 1000°C (c) Sinterin

g

of 1100°C

Figure 3: Hysteresis curves.

Table 2: Magnetic properties of barium ferrite magnets for temperature variations of sinterings.

No

Heat

Temperature

Material composition Hmax Hc

Magnetic

Saturation

1 900

O

C barium carbonate : oxide ferrite (1:6)

1835kA/m

(23.058 kOe)

449,8kA/m

(5,653 kOe)

53,10emu/g

2 1000

O

C barium carbonate : oxide ferrite (1:6)

1836kA/m

(23.076 kOe)

467,9 kA/m

(5,880 kOe)

53,10emu/g

3 1100

O

C barium carbonate : oxide ferrite (1:6)

1832kA/m

(23.016 kOe)

443.1 kA/m

(5,569 kOe).

55,20emu/g

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

74

(a) Temperature of 900°C (b) Temperature of 1000°C (c) Temperature of 1100°C

Fi

g

ure 5: Microstructure photo

g

raphs.

The magnetic analysis and microstructure

analysis of barium hexaferrite material were

perform-ed. It was obtain that H

max

value is 1835

kA/m (23,058 kOe) at 900°C, and increasesto 1836

kA/m (23,076 kOe) at a temperature of 1000°C, then

decreases to 1832 kA/m (23,016 kOe).

Microstructure analysis was conducted the

microstructure photographs for samples with sinter

temperature of 900°C is shown in fig. 5. (a), sinter

temperature of 1000°C is shown in fig. 5(b), and

sinter temperature of 1100°C is shown in fig. 5(c). It

can be seen that grain size increasesfor temperature

900°C to 1000°C than it decrease in grain size for

temperature 1100°C. At sintering temperature of

1000°C, formation of a structure of granules fusion

was indicated and then the magnetic coercivity

increases. These results are in accordance with the

reference journal which states that at high sintering

temperature then coercivity increases and at

temperature of 1100°C it decreases (Shi, T, S. &

Grile. D, 2012,).

4 CONCLUSION

From the discussion of the research, it can be

conclude that VSM test results shows that sintering

temperature increases than Hmax values increases.

The highest Hmax value is obtain-ed at sinter

temperature of 1000°C and decreases at a

temperature of 1100ºC. Therefore the optimum

modification of hysteresis magnetic was at sinter

temperature 1000ºC. SEM test results show that

sintering temperature increases than the grain size

increase. The largest grain size is achieved at a

temperature of 1000°C. Therefore the optimum

modification of grain size was at sinter temperatur of

of 1000°C.

REFERENCES

Clement International Corporation, 1992. “Toxi-

cological Profile for Barium”. July,

D. Jiles, 1991. Introduce to MAgnetism and

Magentic Materials. Springer-Science +

Business Media, B. V.

D. P. Efhana, A. D. E. Septyani, V. Dita, Fitriana, A.

Setiawan, & M. Zainuri, 2013.

“PEMBUATAN PELAPIS PENYERAP GE-

LOMBANG MIKRO BERBASIS M-

HEXAFERRITE BaFe12-xZnxO19 Dari Pasir

Alam Pada Kabin Pesawat". Prosiding

Elektronik Pimnas, DIKTI

I. Yusan, C. Kurniawan, A. P. Tetuko, & P.

Sardjono, 2012. “Pengembangan MagNet

Permanen Berbasis Ferrite Untuk Produk

Meter Air PT Multi Instrumentasi, Bandung”,

Prosiding Pertemuan dan Presentasi Ilmiah

KIM LIPI ke-38, pp 98-107. LIPI

M. I. Alif, 2012. “Komposit Barium Ferrit Dengan

Pengikat Kaca Cult,” Unnes Phys. J.

P. Sardjono et al.,2012, “Inovasi teknologi

pembuatan magnet permanen untuk

membangun industri magnet nasional,” Pros.

InSINas, pp. 102–108.

Priyono, A. Wibowo, & M. Nur, 2001, “Preparasi

Serbuk Barium Ferrite Untuk Menghasilkan

Medan Koersive Tinggi : Tinjauan Pada proses

sintering,” Jurnal Berkala Fisika vol. 4, no. 2,

pp. 45–48.

Magnetic and Physical Properties Modification using Sintering Temperature Variations in the Process of Making Barium Hexaferrite

Permanent Magnet

75

S. Collocot, 2007.“Rare-Earth Per-Manent

Magnets: New Magnet Materials And

Applications,” pp. 1–8.

Shi, T, S. & Grile. D, 2012, “Pengembangan Bahan

Magnetik Barium Heksaferite Dari Mine-Ral

Yarosit Alam Dan Karakter-Isasinya.” Jurnal

Bionatura-Jurnal Ilmu-ilmu Hayati dan Fisik,

vol. 14, no. 2, pp. 156–163.

Sunarya, S. A. 2009, Pusat Perbukuan Departemen

Pendidikan Nasional. Depertemen Pendidikan

Nasional,

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

76