The Effect of Fuel Temperature on Characteristics, Combustion

Process, Emissions and Performance of Diesel Engine: A Review

Barokah

1

, Semin

2

, Beny Cahyono

2

, Bambang Sampurno

1

,

Parabelem Tinno Dolf Rompas

3

1

Department of Mechanical Engineering,Institut Sepuluh November, Surabaya, Indonesia

2

Department of Marine Tecnology,Institut Sepuluh November, Surabaya, Indonesia

3

Department of Informatic Engineering, Universitas Negeri Manado, Manado, Indonesia

parabelemrompas@unima.ac.id,

Keywords: Fuel Temperature; Combustion; Emission, Performance.

Abstract:

The enormous influence of diesel engines on both the industrial and transport world encourages

to continue to be developed. Renewable technologies have been widely created to achieve

optimum combustion efficiency, as well as diesel fuel that is dominant in exhaust emissions. No

t

all fuels with certain characteristics can burn perfectly. It is necessary to influence the

temperature to achieve combustion as well as to produce optimal performance. This stud

y

discusses the effect of fuel temperature on both characteristics, combustion, performance an

d

emissions in diesel engines. Some noticeable impacts of change such as kinematic viscosity,

density, surface tension are able to make the combustion process such as spray shape,

atomization form, and evaporation shape change. It was concluded that the fuel temperature

affected the combustion, performance and exhaust emissions.

1 INTRODUCTION

The invention of diesel engines has a great influence

on the civilization of industrial sectors worldwide. In

operational terms, diesel engines are knowns for

their tough engines and longer durations than other

engines (Semin et al., 2009a; Semin et al., 2009b;

Akasyah et al., 2015). In terms of performance, this

machine uses compression to produce combustion.

As the compression required is very high, it creates

significant differences as well as materials and fuel

characteristics (Bakar et al., 2015; Semin, 2008).

The application of these machines is not only for the

industrial sector and large-scale transportation but

also up to household scale (Semin et al., 2009a).

In its development, diesel engines have

undergone significant changes in terms of shape to

the technical or operational aspects. It aims to create

the highest efficiency value in terms of its

operations. In addition, exhaust gases from diesel

engines have high emission values such as NOx,

CO, unburn hydrocarbon (HC), and soot and nano

particles (Semin et al., 2009b; Gusti and Semin,

2018; Safarov et al., 2018; Lindl, 2003). There have

been many regulations regarding the threshold of

exhaust both from standard of engine maker and

state regulations. Numbers of effort have been made,

such as some kind of changes in fuel system, air

intake system, combustions system, drive system

components (transmission) and many more.

However, from some of the advantages of diesel

engines, there are some obstacles that are still in

processed to be reduced until now, which the

constraints are the fuel. The fuel characteristics of

this machine differ from Otto machines, which have

lower quality of the content (near the kerosene

stage) (Sandu, 2016). To see the quality of fuel, it

can be seen from the value of Cetane, where the

value is defined as how much fuel would burn

quickly. If the value of citation is high, then it can be

concluded that the fuel is not flammable (Wei and

Geng, 2016) Fuel used in diesel engines has

different qualities and has provisions in accordance

with the standards recommended by both fuel

producers and engine makers (Andsaler et al., 2016).

Fuel levels are classified by their viscosity and

energy content values. In fuels that have high

viscosity, it is very important to do preheating.

54

Barokah, ., Semin, ., Cahyono, B., Sampurno, B. and Rompas, P.

The Effect of Fuel Temperature on Characteristics, Combustion Process, Emissions and Performance of Diesel Engine: A Review.

DOI: 10.5220/0009006300540060

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 54-60

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

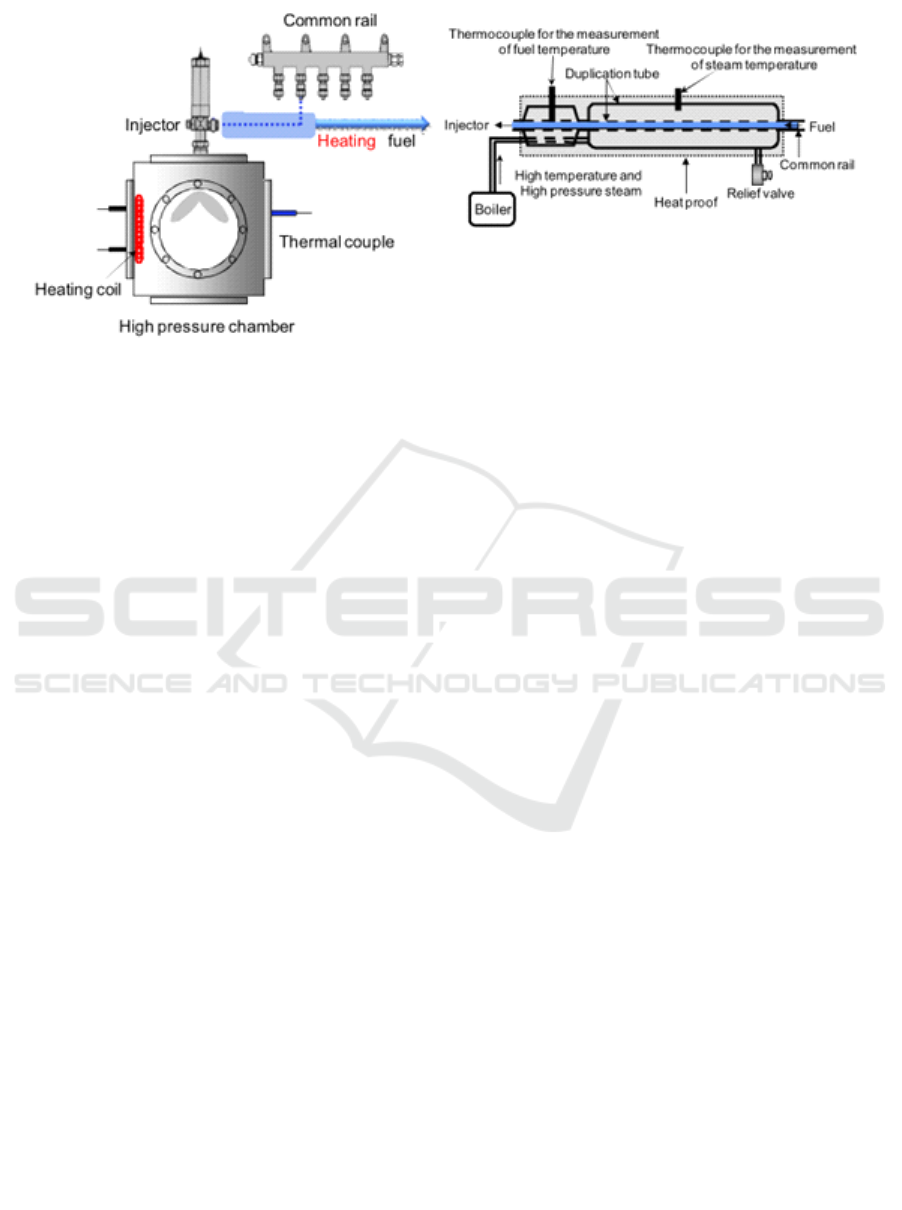

Figure 1 shows one form of preheating. In this

preheated form uses the insulation method, in which

the fuel is heated through the steam fluid. The

preheated is located between common rails with

injector (Park et al., 2009) This is because the fuel in

the engine in accordance with the reference that has

been given and does not inhibit the combustion

process that it can produce optimal performance

(Lindl, 2003; Espinosa-Martinez et al., 2016).

2 LITERATURE STUDY

2.1 Combustion Diesel Engine

The diesel engine invented by Rudolf Diesel 1892

which is a compression ignition engine which has

been widely used today (Heywood, 1988). While the

patent was obtained on February 23, 1893 related to

Design Methods for Combustion Engines.

Diesel engines are, in principle, energy

converters that convert chemically bound fuel

energy into mechanical energy (effective work) by

supplying the heat released by combustion in an

engine to a thermodynamic cycle (Mollenhauer and

Tschoeke, 2010).

2.2 Engine Performance

The performance levels of diesel engines are

influenced by a changing fuel inlet temperature

(Foster and Jung, 2002). With high fuel temperatures

it causes high injection pressure resulting in shorter

ignition delays which ultimately affect engine

performance (Rahim et al., 2012).

At present, diesel engines are getting attention

because in addition to fuel efficiency also due to the

high torque characteristics (Henein et al., 1992; Han

et al., 2001)

2.3 Engine Exhaust Emissions

Exhaust gas emissions from diesel engines are a

fatal problem in the use of diesel engines. With the

development of modern society, environmental

pollution has become one of the major problems for

humans (Smith, 1993). Current industrial carbon

emissions due to the burning of fossil fuels and the

manufacture of cement numbering around 1,200

million tons of carbon (Mt.C) (Grubler, 1993).

Emissions from ships need to be controlled

because they are ozone depleting substances. Among

them are Nitrogen oxides (NOx), Sulfur oxide

(SOx), volatile organic compounds (VOC) (Marpol,

2006)

3 METHODS

The method used is by reviewing several journals

related to the effect of heating the fuel on the

performance and exhaust emissions of diesel

engines. The activity begins with formulating the

problem, namely the problem of the need for heating

the fuel. The next is collecting journals from several

accredited publishers and indexed by Scopus.

Figure 1: Fuel Heating system and high pressure chamber.

The Effect of Fuel Temperature on Characteristics, Combustion Process, Emissions and Performance of Diesel Engine: A Review

55

From the journal discussed both the problem and

the results then identified. The results of the review

are concluded and will be followed up on the

development of subsequent research (Figure 2).

4 RESULTS AND DISCUSSION

4.1 Influences on Fuel Characteristics

Conventional diesel fuel sources are classified as

non-renewable energy. This has received special

attention for oil and gas producers due to the

depletion of source reserves. Several efforts have

been developed, such as the application of fuels

derived from vegetable oils, natural gas, and many

more (note: normally we use “etc” rather than

“many more”). From various sources of fuel, of

course, have different characteristics, especially fuel

made from vegetable oil. Fuel derived from these

sources has higher viscosity value than conventional

fuels due to the bonding of chemical chains,

especially high fatty acids. In contrast, natural gas

fuel is lighter and has smaller viscosity but has a

very high calorific value compared to other fuels

(Foster and Jung, 2002).

Figure 2: Flowchart of study.

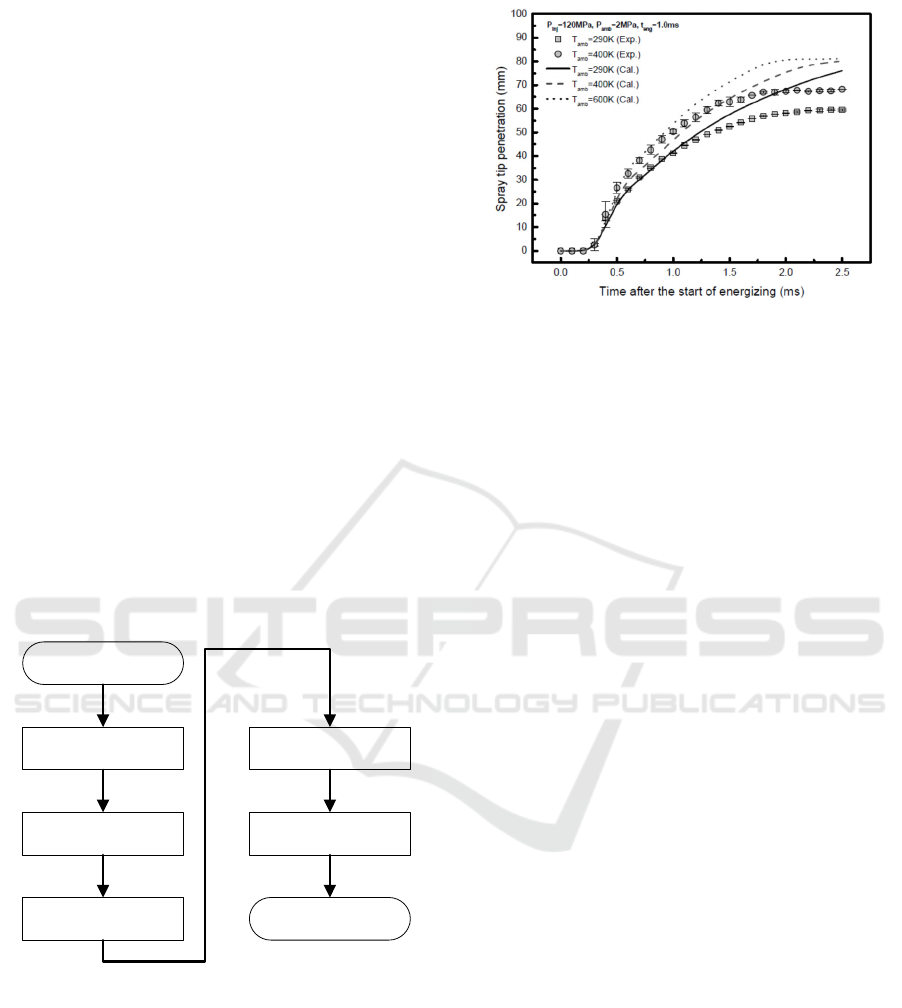

Figure 3: Effect of time after the start of energizing on

spray tip penetration.

In diesel engines operation, the engine maker has

determined the amount of viscosity of fuel (CSt) that

must be obeyed. Specifically when the operational

use blend fuel, the need for the treatment of

viscosity and mixture is maintained (not separated or

not settled). As has been done by (Park et al., 2010)

in which to keep the viscosity value fixed at

optimum condition, the treatment is preheating.

Figure 3 shows that the addition of some

temperature variables ranging from 290K, 330K,

360K, 430K, to 500K. The effects on the direct

characteristics are density, kinematic viscosity and

surface tension. The result proves that the most

optimal fuel in terms of spray penetration and spray

angle cone is at a temperature of 290K and 360K.

This is because the heat of the fuel generates the

angular momentum during a small injection so that

the energy to ignition is also getting smaller.

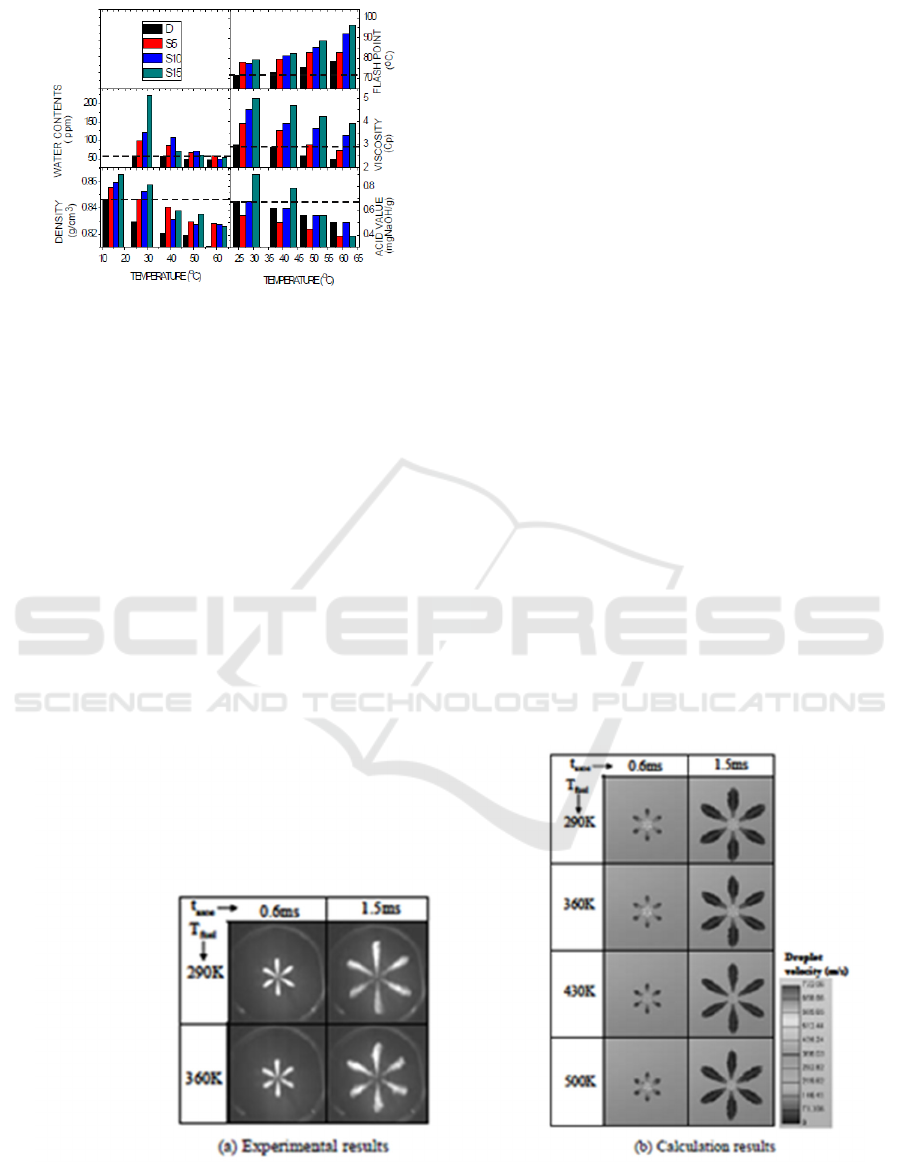

Figure 4 shows that changes in fuel temperature

have shown a change in characteristics not only in

the form of viscosity, density, fuel tension, but also

the water content in the fuel is reduced (Akasyah et

al., 2015; Park et al., 2010). This results in more

optimal combustion in the combustion chamber. The

effect temperature, density and water content can

be seen in the graph below.

Start

Problem formulation

Collect relevant

research journals

Compile discussion of

problems and result

results of the papper

review

Stop

concluded

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

56

Figure 4: Effect of Temperature on density, acid value,

viscosity, and flash point.

4.2 Effect on Combustion Process

Fuel having different characteristics will also impact

on different combustion. This is because the

components that become the basic principles of the

formation of sparks such as the value of cetane

number, flash point, viscosity, density, calor heat

vaporization and etc. An uneven difference (e.g.

blending) will result in less than perfect combustion

when the mixture is not homogeneous (Prabu et al.,

2018).

Research conducted by (Park et al., 2015), where

one of the variables performed is a change in fuel

temperature to see the effect on combustion, spray

shape and characteristics that occur. Data of

temperature variations are taken from 240K to 310K

using diesel fuel (Figure 5). The result obtained

showed that the temperature of fuel injected is

increased and then the density, kinematic viscosity

decreased. The quantity of injection per round also

shows that the graph increases with increasing fuel

temperature. The increase of some parameters above

results in injection rate, start of injection also

increases; this is due to decreased viscosity. In

addition, other advantages obtained are the

penetration of the delay spray resulting in perfect

evaporation and optimal air-fuel ratio composition.

Furthermore, a change in fuel temperature also

affects in-cylinder pressure, maximum (peak)

pressure, ignition delay and heat release rate

(Nanthagopal et al., 2017; Hafiz et al., 2016). This

occurs because in addition to the presence of

viscosity and density, there is also a change of

cetane values and lighter movement when injection

occurs.

The same impact resulted from research

conducted by (Park et al., 2010) who conducting

research to determine the effect of temperature

changes on the characteristics of spray injection.

The parameters analyzed include spray

penetration, atomization performance and evapora-

tion characteristic. In addition, it also sees the

phenomenon that occurs in SMD with a change in

fuel temperature.

Figure 5: Comparison between the experimental and calculation results according to the variation of the diesel

fuel

temperature.

The Effect of Fuel Temperature on Characteristics, Combustion Process, Emissions and Performance of Diesel Engine: A Review

57

The results obtained from this research include

changes in fuel temperature which decreases density,

also decreases kinematic viscosity and surface

tension (Figure 6). Then in terms of spray shape and

develvzopment patterns of all temperatures are

almost the same. Increasing fuel temperatures will

make the spray tip penetration value smaller because

density, viscosity, surface tension are smaller so that

the value of injection momentum is small. In

addition, those are also affected by injection

pressure and ambient gas condition. Temperature

also affects the spray cone angle, where the greater

the temperature of the fuel produces the greater the

degree (Li et al., 2016). This is because the density

is directly proportional to the cone angle. In

addition, the change in fuel temperature also affects

the spray momentum and SMD, which is the

instantaneous decrease after fuel is injected due to

the speed of injection. In general it shows that the

temperature increases will decrease the SMD, this is

due to the effect on the viscosity and the shape of the

fuel during break up.

From some researches above, it can be

concluded that the fuel temperature affects the

combustion process in diesel engine. This is because

with a change in temperature, it will change the

characteristics of the fuel. In addition, the influence

on the characteristics and the combustion process

also affect the performance which will be discussed

in the next paragraph.

4.3 Influences on Performance

The treated fuel that is heated before entering into

the combustion chamber will affect the performance

of the machine. As the research conducted by

(Rahim et al., 2012), which is about the influence of

fuel temperature of biodiesel blends on performance.

Parameters in the form of temperature variables used

ranges from 300K to 500K using a machine with a

turn reaching 4000 rpm. From these studies it is

stated that high temperatures affect the amount of

injection pressure into the combustion chamber. The

greater the pressure given the greater the power

generated by the machine. This is because the

quantity of a large injection resulted in an injection

period (ignition delay) faster. In addition, the higher

the temperature will also affect the combustion

energy such as thermal efficiency, torque, break

mean effective pressure and fuel consumption

(BSFC). This is certainly due to changes in charac-

teristics such as viscosity, density, and heat energy.

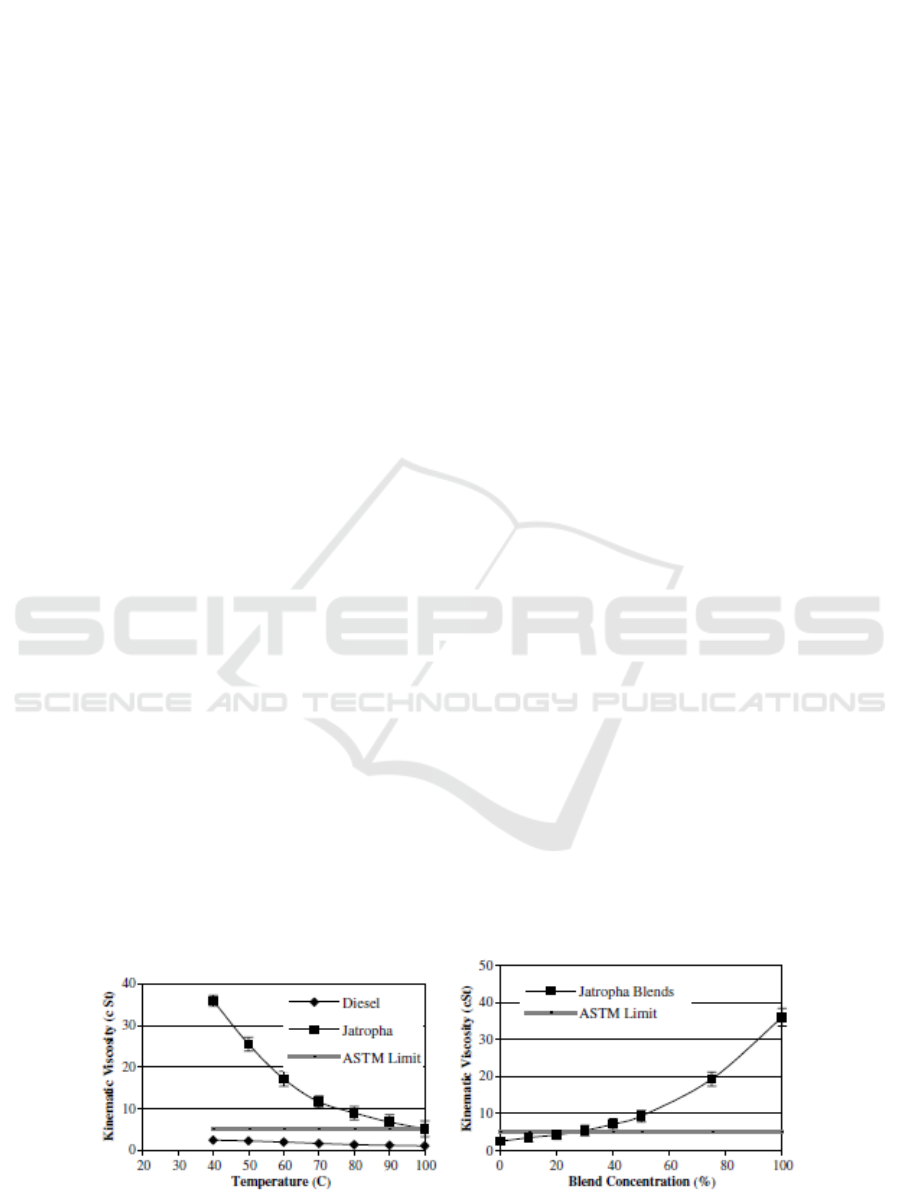

Subsequent studies of the effect of fuel

temperature on performance have also been

performed by (Agarwal and Agarwal, 2007), as

shown in Figure 6 where temperature variation

coincides with the magnitude of injection pressure to

see its effect.

The fuel used is jatropa oil and then compared to

diesel fuel. With preheater treatment where it is

heated to a temperature of 100 ° C, jatropa oil fuel

has a smaller viscosity and greater power with less

fuel consumption compared to jatropa oil without

preheated treatment. Similar results were performed

by several researchers including (Foster and Jung,

2002; Khalid et al., 2003), by heating the fuel from

25 ° C, 35 ° C, 55 ° C, 65 ° C, 75 ° C to 80 ° C. The

optimal temperature with proof of power and the

energy generated increased by 5%. However, fuel

heating above 55 ° C indicates a power down to

7.5% even though the fuel consumption used is

constant. It can be concluded that the effect of

changes in fuel temperature has an effect on the

performance of diesel engines. The changes occur in

power, torque, fuel consumption (BSFC), thermal

efficiency, and break mean effective pressure

(BMEP) (Yilmaz, 2012; Feroskhan et al., 2018;

Tajuddin et al., 2016)]. This is due to changes in fuel

characteristics that result in performance is also

changed.

Figure 6: Effect of temperature and with mineral diesel on viscosity of Jatropha oil.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

58

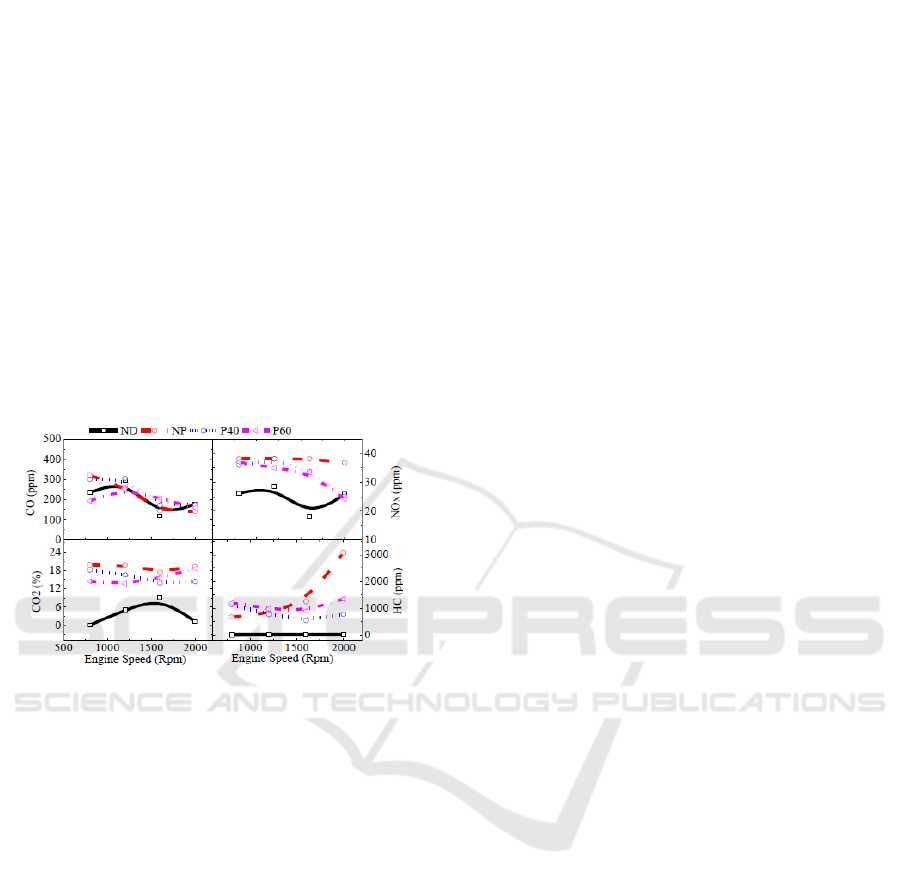

4.4 Effect on Exhaust Emissions

The final stage of the effect of changes in fuel

temperature is on the flue gas. In some studies, it has

been stated that preheat of fuel also has an effect

especially on emission gases which have potential

emission such as NOx, CO, hydrocarbon, particulate

and others. Emission of preheated as shown in

Figure 7 where preheated biodiesel fuel i.e. CPO,

jatropa, and WCO. The results obtained from these

studies include the changes in NOx, CO, CO2 and

HC. The preheated fuel that reached is able to

change the composition of NOx and CO becomes

smaller when mixing occurs around 5%. Then the

CO2 composition is getting bigger along with the

preheated. But with the increase in the mixing ratio

between vegetable oil fuel and diesel fuel will result

in greater emissions.

Research with preheated treatment of fuel using

magnetic fuels has resulted in changes in exhaust

emission levels (Salih and Al-rawaf, 2015). From

comparison between preheated treated and untreated

fuels showed lower CO, HC and CO2 levels. Similar

results are shown by research from (Agarwal and

Agarwal, 2007) where jatropa oil fuels treated in

preheater produce lower emission levels than jatropa

oil fuels that are not given the preheater treatment.

The results are CO2, Smoke Opacity, CO, and HC.

From the review of several research above, it can be

concluded that temperature change (after preheat)

can give significant change such as characteristic

shape, combustion process, performance result and

exhaust emission generated. With the results of these

studies are expected to be developed more

specifically in order to achieve optimal operational

results.

Figure 7: Emission of preheated WCO 5 at 50%

load conditions.

5 CONCLUSIONS

The temperature change (after preheat) can give

significant changes such as characteristic shape,

combustion process, performance result and exhaust

emission generated. The results of these studies are

expected to be developed more specifically in order

to achieve optimal operational results.

ACKNOWLEDGEMENTS

The author would like to thank the ministry of

maritime affairs and fisheries for giving scholarships

and the department of marine engineering of Institut

Sepuluh Nopember of Surabaya which provides

learning opportunities.

REFERENCES

Agarwal, D., Agarwal A. K., 2007. Performance and

emissions characteristics of Jatropha oil (preheated

and blends) in a direct injection compression

ignition engine. Appl. Therm. Eng., vol. 27, no. 13,

pp. 2314–2323.

Akasyah, M. K., Mamat, R., Abdullah, A., Aziz, A.,

Yassin, H. M., 2015. Effect of ambient temperature

on diesel-engine combustion characteristics

operating with alcohol fuel. Int. J. Automot. Mech.

Eng., vol. 11, no. 1, pp. 2373–2382

Andsaler, A. R., Khalid, A., Jaat, N., Sukarman, M. I.,

2016. Effects of ambient density on flow

characteristics of biodiesel spray injection using

computational fluid dynamics. ARPN J. Eng. Appl.

Sci., vol. 11, no. 8, pp. 5499–5505.

Bakar, R. A., Semin, Ismail, A.R., 2008. Fuel Injection

Pressure Effect on Performance of Direct Injection

Diesel Engines Based on Experiment. American

Journal of Applied Sciences. vol.5 no.3 pp: 197-202

Bakar, R. A., Semin, Ismail, A. R., 2015. Effect of Engine

Performance for Four-Stroke Diesel Engine Using

Simulation. at:

https://www.researchgate.net/publication/265362940

22 July 2015. Automotive Focus Group, Faculty of

Mechanical Engineering University Malaysia

Pahang

Espinosa-Martínez, E. G., Martin-del-Campo, François, C.

J.L., Espinosa-Paredes, G., 2016. Effect of heat

transfer correlations on the fuel temperature

prediction of SCWRs. EPJ Nucl. Sci. Technol., vol.

2, 35.

Feroskhan, M., Ismail, S., Reddy, M. G., Teja, A. S.,

2018. Effects of charge preheating on the

The Effect of Fuel Temperature on Characteristics, Combustion Process, Emissions and Performance of Diesel Engine: A Review

59

performance of a biogas-diesel dual fuel CI engine.

Eng. Sci. Technol. an Int. J. pp. 2–9.

Foster, B. D. B., Jung, W., 2002. The Influence of the

Fuel Inlet Temperature.

Gusti, A. P., Semin, 2018. Effect of ship speed on ship

emissions. Asian Journal of Scientific Research. pp.

1-6.

Grubler, A., 1993. Emission reduction at the global levelt.

Energy Vol. 18. No. 5. pp. 539-581.

Hafiz, N. M., Mansor, M. R. A., Mahmood, W. M. F.,

Ibrahim, F., Abdullah, S., Sopian, K., 2016.

Numerical Study of Hydrogen Fuel Combustion in

Compression Ignition Engine under Argon-Oxygen

Atmosphere. J. Teknol. vol. 78, no. 6–10, pp. 77–83.

Han, Z., Henein, N., Nitu, B., Bryzik, W., 2001. Diesel

engine cold start combustion instability and control

strategy. SAE International; [SAE paper 2001-01-

1237].

Henein, N., Zahdeh, A., Yassine, M., Bryzik, W., 1992.

Diesel engine cold starting: Combustion instability.

SAE International; [SAE paper 920005].

Heywood, J. B., 1988. Internal combustion engine

fundamentals. In: Duffy A, Morriss JM, editors.

New York, McGraw-Hill, Inc.

Khalid, A. et al., 2013. The Comparison of Preheat Fuel

Characteristics of Biodiesel and Straight Vegetable

Oil. Appl. Mech. Mater. vol. 465–466, no.

December, pp. 161–166.

Li, X., Sun, Z., Gu, L., Han, J., Wang, J., Wu, S., 2016.

Research of fuel temperature control in fuel pipeline

of diesel engine using positive temperature

coefficient material. Adv. Mech. Eng. vol. 8, no. 1,

pp. 1–11.

Lindl, B. B., 2003. Heaters for Heat Management.

Marpol, 2006. Appendices to Annex VI Appendix I Form

of IAPP Certificate. Marpol Consolodated Edition

2006.

Mollenhauer, K., Tschoeke, H., 2010. Handbook of Diesel

Engines, DOI 10.1007/978-3-540-89083-6_1,

Springer-Verlag Berlin Heidelberg

Nanthagopal, K., Ashok, B., Varatharajan, V., An &, V.,

2017. Study of effect of exhaust gasbased fuel

preheating on ethanol–diesel blends operation in a

CI engine. Clean Techn Env. Policy. vol. 19, pp.

2379–2392.

Park, S. H., Kim, J. H., Suh, H. K., Lee, C. S., 2009.

Experimental and numerical analysis of spray-

atomization characteristics of biodiesel fuel in

various fuel and ambient temperatures conditions.

International Journal of Heat and Fluid Flow. 30(5),

pp. 960–970.

Park, S. H., Kim H. J., Lee C. S., 2010. Comparison of

experimental and predicted atomization

characteristics of high-pressure diesel spray under

various fuel and ambient temperature. J. Mech. Sci.

Technol. vol. 24, no. 7, pp. 1491–1499.

Park, Y., Hwang, J., Bae, C., Kim, K., Lee, J., Pyo, S.,

2015. Effects of diesel fuel temperature on fuel flow

and spray characteristics. Fuel. vol. 162, pp. 1–7.

Prabu, S. S., Asokan, M. A., Prathiba S., Ahmed S.,

Puthean, G., 2018. Effect of additives on

performance, combustion and emission behaviour of

preheated palm oil/diesel blends in DI diesel engine.

Renew. Energy. vol. 122, pp. 196–205.

Rahim, R., Mamat, R., Taib, M., Abdullah A., 2012.

Influence of fuel temperature on a diesel engine

performance operating with biodiesel blended. J.

Mech. Eng. Sci. vol. 2, pp. 226–236.

Salih, A. M., Al-rawaf, M. A., 2015. The Effect of

Increasing of Diesel Fuel Temperature Upon the

Engine Performance By Using Two Magnetic Fields

University of Technology - Baghdad-Iraq Al-

Mansour University College - Baghdad-Iraq. J. Al

Rafidain Univ. Coll. no. 35, pp. 1681 – 6870.

Safarov, J., Ashurova, U., Ahmadov, B., Abdullayev, E.,

Shahverdiyev, A., Hassel, E., 2018. Thermophysical

properties of Diesel fuel over a wide range of

temperatures and pressures. Fuel. vol. 216, no.

November 2017, pp. 870–889.

Sandu, V., 2016. Diesel Fuel Heater Using Engine

Coolant. Transilvania University of Braşov, vol. 9,

no. 2, p. 58.

Semin, Ismail, A. R., Bakar, R. A., 2008. Comparative

Performance of Direct Injection Diesel Engines

Fueled Using Compressed Natural Gas and Diesel

Fuel Based on GT-POWER Simulation. Am. J. Appl.

Sci. vol. 5, no. 5, pp. 540–547.

Semin, Ismail, A. R., Bakar, R. A., 2009a. Combustion

Temperature Effect of Diesel Engine Convert to

Compressed Natural Gas Engine Marine

Engineering. American J. of Engineering and

Applied Sciences, pp. 212-216

Semin, Idris, A., Bakar, R. A., 2009b. Effect of Port

Injection CNG Engine Using Injector Nozzle Multi

Holes on Air-Fuel Mixing in Combustion. European

Journal of Scientific Research. vol.34 no.1, pp.16-24

Smith, K. R., 1993. Fuel combustion, air pollution

exposure, and health: the situation in developing

countries. Annu. Rev. Energy Environ. 18. 529–566.

Tajuddin, A. S. A., Khalid, A., Hadi, S. A., Nursal, R. S.,

2016. Effects of Preheat Biodiesel Fuel Derive From

Crude Palm Oil, Jatropha Oil and Waste Cooking

Oil on Influences of Preheat Biodiesel Fuel on

Performance and Emissions of Diesel Engine.

Wei, L., Geng, P., 2016. A review on natural gas / diesel

dual fuel combustion, emissions and performance.

Fuel Process. Technol. vol. 142, pp. 264–278.

Yilmaz, N., 2012. Effects of intake air preheat and fuel

blend ratio on a diesel engine operating on biodiesel-

methanol blends. Fuel. vol. 94, pp. 444–447.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

60