The Characterization of Rice Straw Briquette as an Alternative Fuel

in Indonesia

Erry Ika Rhofita

1

, Pablo Lopez Hutardo

2

, Franck Miraux

3

1

Science and Technology Faculty, Islamic State University of Sunan Ampel, Surabaya, Indonesia

2

LCA (Laboratoire de Chimie Agro-industrielle), University of Toulouse INP-ENSIACET, Toulouse, French

3

BioTanah, Paris, French

Keywords: Biomass, briquette, densification, rice straw.

Abstract: Rice straw is largely generated and can be used to produce energy and reduce greenhouse gas emissions. In

Indonesia, rice straw is mostly only used as animal feed and fertiliser; however it is highly promoted to be

made into briquettes or pellets. The goal of this study is to discover the optimum condition for producing

rice straw briquettes. The influence of the briquette formulation (temperature, pressure and particle size)

was studied. The briquettes were prepared by utilising a hydraulic-press briquette machine and analysed by

performing density and compression tests. The results show the characteristics of the briquettes as

increasing in pressure and finer particle size as the temperature increases.

1 INTRODUCTION

Indonesia is one of the fastest growing and

developing countries in Asia with an average

economic growth of 5.05% year and a population of

more than 262 million in 2017 (Anonymous, 2018;

BPS Indonesia, 2013). As a consequence, it is

struggling with energy sustainability for its citizens

and battling environment issues at the same time,

such as climate change and greenhouse gas

emissions (Balat, 2005; Demirbas et al., 2009; Evans

et al., 2010; Omer, 2009). In recent years, the

conversion of biomass to produce fuel and chemicals

is seen as one of the most promising technologies to

reduce dependence on fossil fuels for energy

production. It is estimated that Indonesia produces

146.7 million tons of biomass annually, which is

equal to 470 GJ (Dani and Wibawa, 2018; Prastowo,

2011). There are many kinds of biomass that do not

compete with food supplies and originates from

agriculture, forestry and agroindustry residues.

These residues can be transformed into renewable

energy sources.

Biomass residue that is abundant in Indonesia are

rice straw and rice husks. Prastowo estimated the

potential technical energy of rice straw and rice husk

is 143.3 GJ per year (Prastowo, 2011). Rice straw

and rice husks are highly promoted as electrical

energy in the form of briquettes or pellets through

densification technology. The advantages of

densification include the reduction of handling,

transportation and storage (Clarke et al., 2011;

Jamradloedluk and Wiriyaumpaiwong, 2007;

Tumuluru et al., 2011; Ulker et al., 2012). A number

of studies have been carried out on the densification

of rice straw. Several authors have studied the

characteristics of the rice straw briquette using

binders (Chou et al., 2009; Ndiema et al., 2002;

Rahaman and Salam, 2017; Wang et al., 2018). It

was stated that operating conditions such as

temperature, pressure, size of material,

characteristics of binders and the type of

densification machine have an influence on rice

straw briquette quality (Chou et al., 2009; Nguyen et

al., 2015; Rahaman and Salam, 2017; Tumuluru et

al., 2011). Therefore, the quality of rice straw

briquette has been evaluated with an international

standard for briquettes such as EN ISO 17225-7.

2 MATERIALS AND METHOD

Rice straw was collected in June 2018 from East

Java. It was dried in natural air for 24 hours. The

rice straw was ground in a hammer mill using

different apertures. The properties of the materials

304

Rhofita, E., Hutardo, P. and Miraux, F.

The Characterization of Rice Straw Briquette as an Alternative Fuel in Indonesia.

DOI: 10.5220/0008908200002481

In Proceedings of the Built Environment, Science and Technology International Conference (BEST ICON 2018), pages 304-309

ISBN: 978-989-758-414-5

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

along with its corresponding international standard

are provided on Table 1.

Table 1: Standard used to determine properties of the rice

straw before briquetting

Properties Standard

Moisture content (%)

EN 14774:2009 (European

Committee for

Standardization-CEN, 2009)

Bulk density (kg.m

-3

)

EN 15103:2009 (European

Committee for

Standardization, 2009)

Proximate analysis

(%)

ASTM 1762-84 (American

Society for Testing and

Materials, 2007)

The production of briquettes was made using

variable operating conditions with a box behnken for

3 factors and 3 levels (Table 2).

Table 2: Standard use to determine the properties of rice

straw before briquetting

Properties -1 0 +1

Temperature (C)

25 100 175

Pressure (MPa) 10 25 40

Particle size (mm) 1 3 5

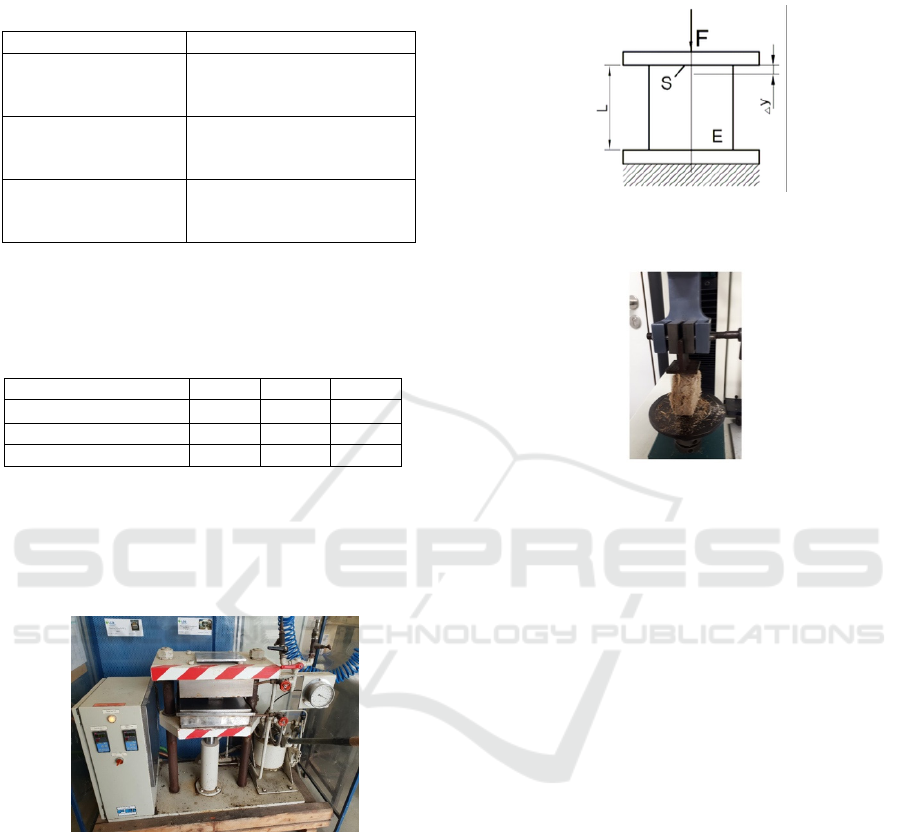

The briquettes were produced in a manual

hydraulic press briquetting machine (Figure 1). Each

briquette was 50 mm in length and width and had

variable height, with a mass of 20 grams of raw

material.

Figure 1: Hot densification system hydraulic press.

The bulk density of the rice straw briquettes was

measured by geometric measurement and weighing.

This can be calculated by using the ratio between the

mass briquette and the volume briquette.

Furthermore, the compressive test of briquette or

mechanical resistance is the maximum crushing load

a briquette can withstand before cracking or

breaking, (Kaliyan and Vance Morey, 2009). The

procedure of the test consists of placing a single

briquette between two flat, parallel plates which

have flat areas greater than the projected area of the

briquette. An increasing load is applied at a constant

rate until the test specimen fails by cracking or

breaking (Figure 2). The displacement of the

briquette compressive test is 10 mm per minute

(Figure 3).

Figure 2: Testing of the rice straw briquette in axial

pressure conditions.

Figure 3: Position of the rice straw briquette in the

compressive test.

3 RESULTS AND DISCUSSION

3.1 Characteristics of rice straw

The characteristics of the rice straw sample are

provided in Table 3. Rice straw has a 26.63%

moisture content which is above the suitable range

for briquette preparation. The desired parameter for

briquettes is between 8% and 12% (Kaliyan and

Vance Morey, 2009; Rahaman and Salam, 2017).

The moisture content also has an effect on energy

consumption during the chopping stage (Mani et al.,

2006). Due to this reason, the rice straw requires

drying before the chopping and compressing

process. The moisture content of rice straw depends

on the condition and equipment used for storage and

wiping. Other studies reported that moisture content

of the rice straw is influenced by the variety, climate

and cultivation conditions (Zhang et al., 2012).

Rice straw has a low bulk density; densification

may improve it through size reduction as it increases

the contact surface area between particles. The

average bulk density of rice straw is 166.29 kg.m

-3

for long grain rice straw and 162.03 kg.m

-3

for short

grain rice straw (Zhang et al., 2012). Kadam et al.

reported the bulk density of rice straw after

The Characterization of Rice Straw Briquette as an Alternative Fuel in Indonesia

305

harvesting was over 227 kg.m

-3

and increased by

20% after densification (Kadam et al., 2000). The

rice straw occupies more space and has a lower

calorific value than the briquette. The calorific value

of rice straw is 15.60 MJ.kg

-1

, depending on the ash

content. Rice straw contains the least amount of ash

and fixed carbon. Its calorific value shows that rice

straw has potential for bio-energy. Paula et al.

studied the calorific value, volatiles content, fixed

carbon content, and ash content of rice straw, which

was respectively 15.09 MJ.kg

-1

, 65.47%, 15.86%

and 18.67% (Paula et al., 2011). Kargbo et al.

explained that the bulk density and calorific value of

rice straw are low and is not significant to the

performance of the energy combustion and

emissions from chlorinated organic compounds and

NOx (Kargbo et al., 2010).

Table 3: Properties of rice straw

Properties

Rice

straw

Literature

(Brand et al.,

2017)

Moisture content (%) 26.63 23.03

Bulk density (kg.m

-3

) 112.87 106.89

Volatile content (%) 75.76 79.71

Fixed carbon content

(%)

11.01 11.23

Ash content (%) 13.32 9.07

Calorific value (MJ.kg

-

1

)

15.60 17.65

3.2 Characteristics of rice straw

briquettes

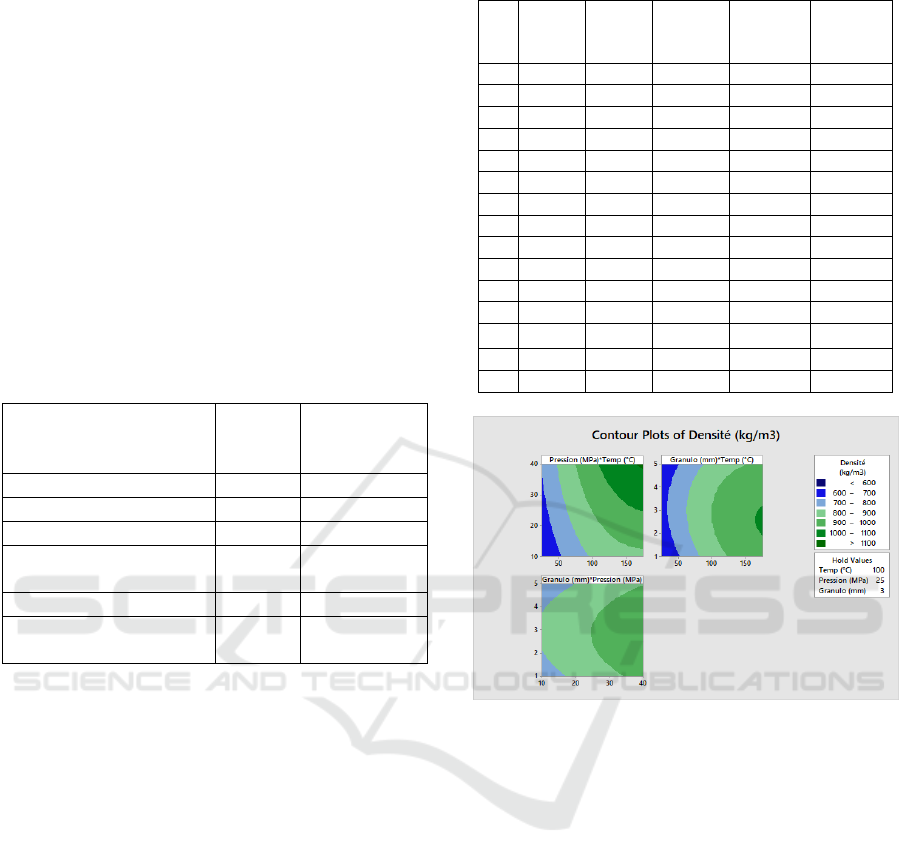

The characteristics of the rice straw briquettes are

provided in Table 4. The densities of briquettes are

provided in Figure 3. The highest densities were

observed in the briquettes with the highest

proportion in temperature, pressure and particle size

at respectively 100C, 40 MPa and 3 mm. The

stabile densities of the rice straw briquette increased

proportionally as temperature and pressure

increased. Mani explained that the bulk density of

pellet or briquette depend on the material properties

such as moisture, particle size, temperature, and

pressure. The higher moisture content along with

large particle size reduces the bulk density (Mani et

al., 2006, 2003; Tumuluru, 2014).

Table 4: Properties of rice straw

E

x

p

T

(C)

P

(MPa)

Particle

size

(mm)

Density

(kg.m

-3

)

Comp.

Test

(MPa)

1 100 10 1 791 0.750

2 100 10 5 756 0.897

3 100 40 1 912 1.890

4 100 40 5 854 1.245

5 25 25 1 618 0.356

6 25 25 5 660 0.115

7 175 25 1 917 1.985

8 175 25 5 884 1.952

9 25 10 3 538 0.112

10 25 40 3 695 0.456

11 175 10 3 888 2.450

12 175 40 3 1178 2.050

13 100 25 3 897 0.975

14 100 25 3 907 1.140

15 100 25 3 902 0.856

Figure 4: Effects of temperature, pressure and particle size

(y) on the density of rice straw briquette (x).

Increasing densification temperature with a

lower moisture content of rice straw and the

maximum pressure might have allowed the water in

the material to exit quickly. Less moisture content

results in maximum bulk density. The optimum

temperature of the experiment to obtain the highest

density and compression strength is around >125C

(Figures 4 and 5). Increasing the temperature will

strengthen the bond and adhesion of particles, which

will indirectly increase the contact with lignin.

Lignin plays an important role in the compacting

process that will improve solid bridges among

particles, and fewer cavities for the uptake of

moisture available. Therefore the water absorption

of the briquette could be reduced.

Increasing the densification temperature will

increase the compression strength of the briquette,

where the highest value of compression strength

could be achieved to some extent. Kers et al.

explained that once the temperature is lower than the

BEST ICON 2018 - Built Environment, Science and Technology International Conference 2018

306

optimum value, the briquette has lower compressive

strength. By increasing the temperature of

densification, the volatile compounds can burn out

from the pressed material (Kers et al., 2010).

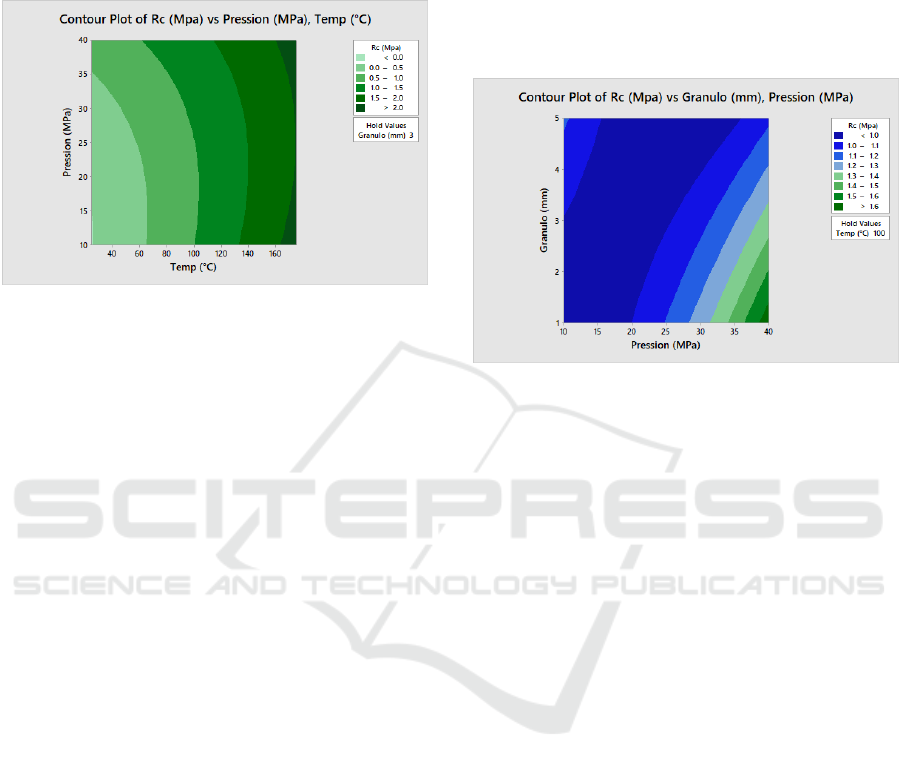

Figure 5: Effect of pressure (y) on temperature of

experiment (x).

The bulk density of the rice straw briquette

increased proportionally as pressure increased from

25 MPa to 40 MPa (Figure 4). Literature has found a

significant relation between the pressure and bulk

density of briquettes (Chin and Siddiqui, 2000;

Oladeji and Enweremadu, 2012; Saikia and Baruah,

2013; Thabuot et al., 2015). Table 4 shows that

increasing the pressure of densification also led to

increased compressive resistance of the briquette.

This is one of the important factors that influence the

compressive strength of briquettes. The briquette

strength will increase with the applied pressure until

a limit value of the compacting material is reached.

Kaliyan and Morey explained that increasing

pressure from 15 to 100 MPa increased the tensile

strength of pellets from 0.5 to 2.0 MPa.

Furthermore, by increasing the pressure above 100

MPa and up to 165 MPa, the tensile strength of the

pellet started to decrease and levelled off at 1.5-2.0

MPa (Kaliyan and Vance Morey, 2009). Muazu and

Steemann found that the higher compaction pressure

of densification had a positive effect on the density

and compressive strength of the briquette (Muazu

and Stegemann, 2015).

Mani explained that the particle size of a material

influences on the density of briquette. (Mani et al.,

2003). They found that grinding the rice straw into a

smaller particle size resulted in a higher bulk density

and lower moisture content. The coarser rice straw

creates natural fissures, which is susceptible to

breakage. Furthermore, the moisture content will

increase and reduce the bulk density of the briquette

and also reduce durability. Increasing pressure of

densification increased the tensile strength of

briquette. The effect of particle size did not

significantly improve the compressive strength

(Figure 5). Mitchual et al. indicated that finer

particle size had a significant effect on the bulk

density and compression strength of briquettes

(Mitchual et al., 2012). The briquette’s strength is

very important for briquette transportation,

manipulation and storage.

Figure 6: Effect of particle size (y) on the compressive

strength of rice straw briquettes (x).

4 CONCLUSION

In this study, the characteristics of rice straw

briquette were investigated and is concluded as

follows:

1. The characteristics of the rice straw assessed in

the study showed that rice straw had a high

calorific value (15.60 MJ.kg

-1

) and low ash

content (13.32%). There is also is an indication

that rice straw is a potential source of bioenergy.

2. There was a positive correlation between the

temperature and pressure with the density and

compression test of the briquette. However, the

relationship between particle size and

compression test were unpredictable.

3. The optimum conditions of densification in

proportion to temperature, pressure and

particle size were

100C, 40 MPa and 3 mm,

respectively.

REFERENCES

American Society for Testing and Materials, 2007. ASTM,

D 1762-84: Standard Test Method for Chemical

Analysis of Wood Charcoal.

Anonymous, 2018. Indonesia GDP Annual Growth Rate

[WWW Document]. Trading Econ. URL

The Characterization of Rice Straw Briquette as an Alternative Fuel in Indonesia

307

https://tradingeconomics.com/indonesia/gdp-growth-

annual?hc_location=ufi

Balat, M., 2005. Usage of Energy Sources and

Environmental Problems. Energy Explor. Exploit.

23, 141–167.

https://doi.org/10.1260/0144598054530011

BPS Indonesia, 2013. Proyeksi Penduduk Indonesia

Indonesia Population Projection 2010-2035. Badan

Pusat Statistik, Jakarta.

Brand, M.A., Jacinto, R.C., Antunes, R., da Cunha, A.B.,

2017. Production of briquettes as a tool to optimize

the use of waste from rice cultivation and industrial

processing. Renew. Energy 111, 116–123.

https://doi.org/10.1016/j.renene.2017.03.084

Chin, O.C., Siddiqui, K.M., 2000. Characteristics of some

biomass briquettes prepared under modest die

pressures. Biomass Bioenergy 6.

Chou, C.-S., Lin, S.-H., Lu, W.-C., 2009a. Preparation and

characterization of solid biomass fuel made from

rice straw and rice bran. Fuel Process. Technol. 90,

980–987.

https://doi.org/10.1016/j.fuproc.2009.04.012

Chou, C.-S., Lin, S.-H., Peng, C.-C., Lu, W.-C., 2009b.

The optimum conditions for preparing solid fuel

briquette of rice straw by a piston-mold process

using the Taguchi method. Fuel Process. Technol.

90, 1041–1046.

https://doi.org/10.1016/j.fuproc.2009.04.007

Clarke, S., Eng, P., Preto, F., 2011. Biomass Densification

for Energy Production.

Dani, S., Wibawa, A., 2018. Challenges And Policy For

Biomass Energy In Indonesia 15, 7.

Demirbas, M.F., Balat, M., Balat, H., 2009. Potential

contribution of biomass to the sustainable energy

development. Energy Convers. Manag. 50, 1746–

1760.

https://doi.org/10.1016/j.enconman.2009.03.013

European Committee for Standardization, 2009. BS EN

15103, Solid Biofuels. Determination of Bulk

Density.

European Committee for Standardization-CEN, 2009. EN

14774-3, Determination of moisture content e Part 3:

oven dry method. Moisture in general analysis

sample.

Evans, A., Strezov, V., Evans, T.J., 2010. Sustainability

considerations for electricity generation from

biomass. Renew. Sustain. Energy Rev. 14, 1419–

1427. https://doi.org/10.1016/j.rser.2010.01.010

Jamradloedluk, J., Wiriyaumpaiwong, S., 2007.

Production and Characterization of Rice Husk Based

Charcoal Briquettes. KKU Eng. J. 34, 391–398.

Kadam, K.L., Forrest, L.H., Jacobson, W.A., 2000. Rice

straw as a lignocellulosic resource: collection,

processing, transportation, and environmental

aspects. Biomass Bioenergy 18, 369–389.

https://doi.org/10.1016/S0961-9534(00)00005-2

Kaliyan, N., Vance Morey, R., 2009. Factors affecting

strength and durability of densified biomass

products. Biomass Bioenergy 33, 337–359.

https://doi.org/10.1016/j.biombioe.2008.08.005

Kargbo, F., Xing, J., Zhang, Y., 2010. Property analysis

and pretreatment of rice straw for energy use in

grain drying: A review. Agric. Biol. J. N. Am. 1,

195–200.

https://doi.org/10.5251/abjna.2010.1.3.195.200

Kaur, A., Roy, M., Kundu, K., 2017. Densification Of

Biomass By Briquetting: A Review. Int. J. Recent

Sci. Res. 8, 20561–20568.

https://doi.org/dx.doi.org/10.24327/ijrsr.2017.0810.0

916

Kers, J., Kulu, P., Aruniit, A., Laurmaa, V., Križan, P.,

Šooš, L., Kask, ü, 2010. Determination of physical,

mechanical and burning characteristics of polymeric

waste material briquettes. Est. J. Eng. 16, 307.

https://doi.org/10.3176/eng.2010.4.06

Mani, S., Tabil, L.G., Sokhansanj, S., 2006. Effects of

compressive force, particle size and moisture content

on mechanical properties of biomass pellets from

grasses. Biomass Bioenergy 30, 648–654.

https://doi.org/10.1016/j.biombioe.2005.01.004

Mani, S., Tabil, L.G., Sokhansanj, S., 2003. An Overview

of Compaction of Biomass Grinds 15, 10.

Mitchual, S.J., Mensah, K.F., Darkwa, N.A., 2012. Effect

of Species, Particle Size and Compacting Pressure

on Relaxed Density and Compressive Strength of

Fuel Briquettes. Proc. 55th Int. Conv. Soc. Wood

Sci. Technol. 55, 1–9.

Muazu, R.I., Stegemann, J.A., 2015. Effects of operating

variables on durability of fuel briquettes from rice

husks and corn cobs. Fuel Process. Technol. 133,

137–145.

https://doi.org/10.1016/j.fuproc.2015.01.022

Ndiema, C.K.., Manga, P.., Ruttoh, C.., 2002. Influence of

die pressure on relaxation characteristics of

briquetted biomass. Energy Convers. Manag. 43,

2157–2161. https://doi.org/10.1016/S0196-

8904(01)00165-0

Oladeji, J.T., Enweremadu, C.C., 2012. The Effects of

Some Processing Parameters on Physical and

Densification Characteristics of Corncob Briquettes.

Int. J. Energy Eng. 2, 22–27.

https://doi.org/10.5923/j.ijee.20120201.04

BEST ICON 2018 - Built Environment, Science and Technology International Conference 2018

308

Omer, A.M., 2009. Energy use and environmental

impacts: A general review. J. Renew. Sustain.

Energy 1, 053101.

https://doi.org/10.1063/1.3220701

Paula, L.E. de R. e, Trugilho, P.F., Napoli, A., Bianchi,

M.L., 2011. Characterization of residues from plant

biomass for use in energy generation. Cerne Lavras

17, 237–246. https://doi.org/10.1590/S0104-

77602011000200012

Prastowo, B., 2011. Biomass Resource in Indonesia :

Indonesia s Solid Biomass Energy Potential 15.

Rahaman, S.A., Salam, P.A., 2017. Characterization of

cold densified rice straw briquettes and the potential

use of sawdust as binder. Fuel Process. Technol.

158, 9–19.

https://doi.org/10.1016/j.fuproc.2016.12.008

Saikia, M., Baruah, D., 2013. Analysis of Physical

Properties of Biomass Briquettes Prepared by Wet

Briquetting Method. Int. J. Eng. Res. Dev. 6, 12–14.

Thabuot, M., Pagketanang, T., Panyacharoen, K.,

Mongkut, P., Wongwicha, P., 2015. Effect of

Applied Pressure and Binder Proportion on the Fuel

Properties of Holey Bio-Briquettes. Energy Procedia

79, 890–895.

https://doi.org/10.1016/j.egypro.2015.11.583

Tumuluru, J.S., 2014. Effect of process variables on the

density and durability of the pellets made from high

moisture corn stover. Biosyst. Eng. 119, 44–57.

https://doi.org/10.1016/j.biosystemseng.2013.11.012

Tumuluru, J.S., Wright, C.T., Hess, J.R., Kenney, K.L.,

2011. A review of biomass densification systems to

develop uniform feedstock commodities for

bioenergy application. Biofuels Bioprod. Biorefining

5, 683–707. https://doi.org/10.1002/bbb.324

Ulker, O., Imirzi, O., Burdurlu, E., 2012. The Effect Of

Densification Temperature On Some Physical And

Mechanical Properties Of Scots Pine (Pinus

Sylvestris L.). BioResources 7, 5581–5592.

Wang, Y., Wu, K., Sun, Y., 2018. Effects of raw material

particle size on the briquetting process of rice straw.

J. Energy Inst. 91, 153–162.

https://doi.org/10.1016/j.joei.2016.09.002

Zhang, Y., Ghaly, A.E., Li, B., 2012. Physical Properties

Of Rice Residues As Affected By Variety And

Climatic And Cultivation Onditions In Three

Continents. Am. J. Appl. Sci. 9, 1757–1768.

https://doi.org/10.3844/ajassp.2012.1757.1768

The Characterization of Rice Straw Briquette as an Alternative Fuel in Indonesia

309