The Mechanical Properties of Lightweight Concrete Made with

Lightweight Aggregate Volcanic Pumice

Parmo

1

, Tavio

2

, Hafiz Riadi

1

, Efa Suriani

1

, Kusnul Prianto

1

and Faruq Ibnul Haqi

1

1

Faculty of Science and Technology, UIN Sunan Ampel, Jl. A. Yani 117, Surabaya, Indonesia

2

Department Civil Engineering, Faculty of Civil Engineering and Planning, Sepuluh Nopember Institute of Technology,

Surabaya, Indonesia

Keywords: Lightweight Concrete, Lightweight Aggregate, Pumice, Compressive Strength.

Abstract: Pumice is a type of light-colored rock that contains cavities made from glass-walled bubbles and is usually

referred to as volcanic silicate rock glass. These rocks are formed from magma acid through volcanic eruptions

that eject material into the air, which then experiences horizontal transport and accumulates as pyroclastic

rocks. However, there are also pumice rocks that were formed from dead and weathered sea coral. The pumice

stone sea coral species are spread where coastal sea coral reefs grow. In this experiment, volcanic pumice

silicate (SP-2) sourced from Gresik is substituted as coarse aggregate in the manufacturing of lightweight

aggregate concrete. The result obtained was a lightweight aggregate volume silica volcanic pumice SP-2 at

717 kg/m3. In the testing phase, for a mixture of cement, water, sand and pumice lightweight aggregate

concrete, the weight gained per cubic meter of volcanic pumice silicate (SP-2) was 1850 kg/m3. From the test

results, pumice stone qualifies as a lightweight aggregate for the manufacturing of lightweight structural

concrete. In this study, a testing of the compressive strength of the specimen cylinder (15 x 30cm) was also

conducted. Testing results show that concrete compressive strength at age 7, 14 and 28-days obtained values

of 15.23 Mpa, 13.86 Mpa and 13.88 Mpa, respectively. Additionally, splitting tensile strength obtained results

of 5.16 Mpa, 4.70 Mpa and 4.71 Mpa at the same age.

1 INTRODUCTION

Urban population has increased significantly and is

incomparable to the available land that has given rise

to the development of cities. This is indicated by the

increasing number of high-rise buildings and

skyscrapers in the city (Parmo, 2016). The use of

external confinement in concrete columns (Parmo,

2012) and concrete beams (Parmo, 2014) can increase

strength and ductility. Strength and ductility are very

important in designing earthquake-resistant buildings.

As a construction material, concrete has long been

used in civil engineering construction, including in

Indonesia. This is because concrete is easily

molded/casted in accordance to the cross-sectional

shape and size desired. In addition, it has easy

execution and relatively low maintenance costs.

However, concrete has a disadvantage in its ratio of

strength to weight volume. To reduce the weight of

concrete, several studies have been conducted to

produce lightweight concrete with a better Strength-

to-Weight Ratio.

The need for concrete for construction nowadays

continues to increase which has led to the demand of

the development of better concrete technology. The

use of lightweight concrete as a construction material

in earthquake-prone areas serves as a good alternative

due to its lightweight characteristics that can reduce

the burden if affected by an earthquake.

The advantage of such lightweight concrete is that

heavy construction becomes relatively lighter, has

good heat propagation properties (Munir et al., 2009),

is resistant to fire (G. Batis, 2004), is not harmful to

health, is environmentally friendly, and has better

sound propagation properties compared to other

materials such as bricks. However, lightweight

concrete has some drawbacks, such as having low

tension, is brittle (Nugraha, P and Antoni, 2007) and

has a relatively high content of cement. These

weaknesses are continuously being strived to

improve, for example with the addition of fibre

reinforcement, as well as the partial replacement of

cement with other cheaper binder materials

(Abdullah, 2007).

Parmo, ., Tavio, ., Suriani, E., Pr ianto, K. and Haqi, F.

The Mechanical Properties of Lightweight Concrete Made with Lightweight Aggregate Volcanic Pumice.

DOI: 10.5220/0008906500002481

In Proceedings of the Built Environment, Science and Technology International Conference (BEST ICON 2018), pages 167-171

ISBN: 978-989-758-414-5

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

167

Pumice is a natural lightweight aggregate which

is also available for general use, provided it is free of

fine volcanic ash and volcanic material. Pumice

provide better thermal insulation than other types of

lightweight concrete.

This study aims to gain an innovative material

utilization of pumice as a lightweight aggregate for use

in the manufacturing of lightweight concrete. The

burden of building with lightweight concrete is

relatively small so it is expected to accommodate

vertical urban growth and support comprehensive

planning of a city that is healthy, safe and comfortable.

2 CONCEPT OF LIGHTWEIGHT

CONCRETE

According to Mulyono (2004), lightweight aggregate

is an aggregate with a density of about 300 - 1850 kg/

m3. SNI-03-2641-2002 regulates lightweight

concrete criteria limits in the density to be < 1900

kg/m3. The essence of lightweight aggregate is an

aggregate with a density that is lightweight and highly

porous, which can be made from natural aggregates

and fabricating results. Based on this understanding,

there are two methods for making lightweight

concrete using lightweight aggregate. The first is

formed by using a porous lightweight aggregate with

a small density. The concrete formed is called

lightweight aggregate concrete. The second is to

make the mass of mortar highly porous, ie by

increasing the air content in it.

There are several methods to reduce the density of

concrete or produce lighter concrete, as follows

(Tjokrodimuljo, 1996):

a. Creating bubbles of gas/air in the mortar, causing

the concrete to have a large number air pores in it.

b. Using lightweight aggregates, such as baked clay,

pumice or artificial aggregates so that the concrete

made will be lighter than regular concrete.

c. Making concrete without using grains of fine

aggregate or sand, which is referred as non-sand

concrete.

According to ASTM C.330, lightweight

aggregates can be divided into two: natural and

artificial aggregates. Natural lightweight aggregates

includes types of diatomite, pumice, scoria, volcanic

tuff Dinder and everything including original

volcanic rocks. Artificial lightweight aggregates can

be made from the process of heating and cooling

industry cinder. Artificial lightweight aggregates

include expanded clay, shale, slate, perlite,

vermiculite, and fly ash (Mulyono, T., 2004).

According to the heavy volume and minimum

compressive strength that must be met, and also retain

earnings, lightweight concrete can be divided into

three categories (Dobrowolski, 1998):

a. For non-structures, a density of 240 kg/m

3

to 800

kg/m

3

and a compressive strength of 0.35 MPa to

7 MPa is generally used for dividing walls or walls

for insulation.

b. For lightweight structures, a density of 800 kg/m

3

to 1400 kg/m

3

and a compressive strength of 7

MPa to 17 MPa is generally used for walls that

also bear burdens.

c. For other structures, a density between 1400

kg/m

3

to 1800 kg/m

3

and a compressive strength

of more than 17 MPa can be used as normal

concrete.

3 CONCEPT OF PUMICE

Pumice is a light-coloured rock that usually resembles

a layer of glass, with a unit weight of 500 to 900

kg/m

3

(Mulyono, 2004: 286). According to Murdock

and Brook (1999: 396), pumice is a natural

lightweight aggregate and that is suitable for general

use as well. Provided it is free of fine volcanic ash and

volcanic material that is not native such as clays,

pumice can be made into a satisfactory lightweight

concrete with a density of 720 kg/m

3

to 1440 kg/m

3.

Pumice provides better thermal insulation than other

lightweight concrete.

Pumice is a type of light-coloured rock that

contains cavities made of glass-walled bubbles and is

usually referred to as volcanic silicate rock glass.

These rocks are formed from magma acid through

volcanic eruptions that eject material into the air,

which then experiences horizontal transport and

accumulates as pyroclastic rocks. Pumice has high

vesicular properties and contains a number of cells

and plenty of cellular structured foam due to the

expansion of natural gas contained therein and in

general as a freelance or fragments in a volcanic

reaction. While the minerals contained in pumice

include feldspar, quartz, obsidian, cristobalite, and

tridymite. The existence of pumice is always

associated with a series of volcanoes, from old quarter

to tertiary.

The existence of pumice is always associated with

a series of volcanoes. The chemical and physical

properties of pumice include: oxides SiO

2,

Al

2

O

3,

Fe

2

O

3,

Na

2

O, K

2

O, MgO, CaO, TiO

2,

SO

3,

and

Cl, lost incandescent (loss of ignition) of 6%, pH 5,

bulk density 480 to 960 kg/cm

3,

water absorption of

16.67%, a specific gravity of 0.8 g / cm

3,

a low sound

BEST ICON 2018 - Built Environment, Science and Technology International Conference 2018

168

conduction (sound transmission) , the ratio of

compressive strength to high loads, low thermal

conductivity, and resistant to fire for up to 6 hours (

http://www.tekmira.esdm.go.id ).

4 EXPERIMENTAL SECTION

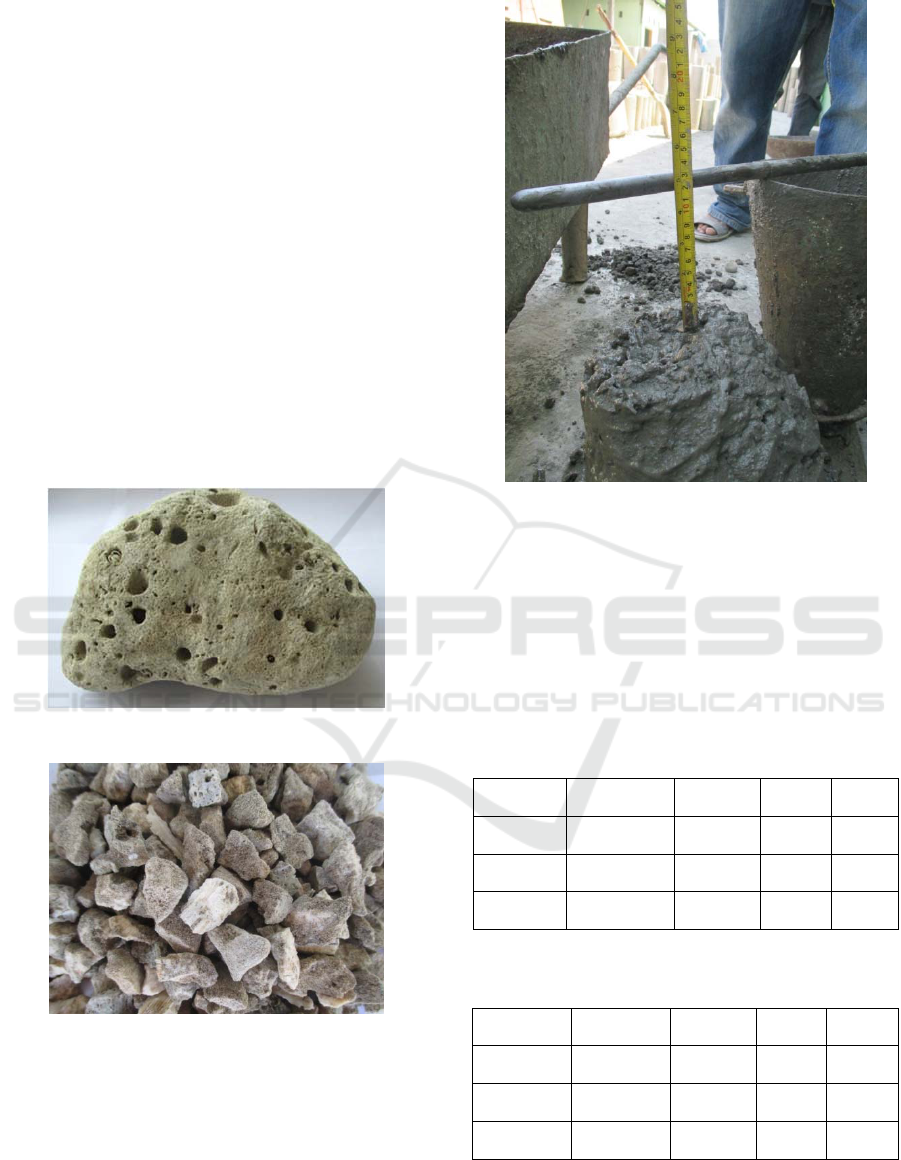

In this research, the materials used include: a). Type I

cement with a unit weight of 1310 kg/m3; b). Fine

aggregate from Lumajang, East Java with the

physical properties of: unit weight of 1571 kg/m3,

water content of 10.12%, bulk density of 2.410

gr/cm3, specific gravity of SSD at 2.430 gr/m3,

absorption of 0,801 %, and sludge levels of 1.12%;

and c). coarse aggregate of pumice (100%) with a

volume weight of 717 kg/m3. Figure 1 shows the

shape of pumice, while Figure 2 shows the pumice

after it was processed as a coarse aggregate sized 2/3

cm.

Figure 1: The shape of pumice.

Figure 2: Lightweight aggregate pumice.

To obtain the level of concrete viscosity, the

slump is tested (Figure 3) which describes concrete

workability and obtained an average slump value of

11.45 cm. A lightweight concrete specimen made

from lightweight pumice aggregate was obtained,

after casting the volcanic pumice silicate (SP-2) was

of 1850 kg/m3.

Figure 3: Slump testing.

In this research, a specimen cylinder was prepared

with a diameter of 15 cm and height of 30 cm. Three

test specimens were taken for compressive strength

testing, while another three specimens were taken for

testing tensile strength, with a total of six specimens.

The details of the research plan can be viewed on the

table below.

Table 1: Testing of Objects Made From Pumice Aggregates

For Lightweight Concrete Compressive Strength.

Specimen

Specification o

f

Gravity

Age of

Specimen

% Pumice Amount

Cylinder (SP

2)

1.6 7 days 100 1

Cylinder (SP

2)

1.6 14 days 100 1

Cylinder (SP

2)

1.6 28 days 100 1

Table 2: Testing the Splitting Tensile Strength of

Lightweight Concrete Aggregate Pumice Stone.

Specimen

Specification

of Gravity

Age of

Specimen

% Pumice Amount

Cylinder (SP

2)

1.6 7 days 100 1

Cylinder (SP

2)

1.6 14 days 100 1

Cylinder (SP

2)

1.6 28 days 100 1

The Mechanical Properties of Lightweight Concrete Made with Lightweight Aggregate Volcanic Pumice

169

5 RESULTS AND DISCUSSION

5.1 Compressive Strength Testing

Results

In general, the use of volcanic pumice aggregate gave

a positive contribution to cylinder compressive

strength, f’c. Further details can be viewed on table 3.

Table 3: Results of Lightweight Concrete Compressive

Strength Testing of Volcanic Pumice Aggregate.

Speci-men SG

Age o

f

S

pec

i

-

men

Compressive

Strength

(Mpa)

Average

Compressive

Strength (Mpa)

Cylinder

(SP2 7)

1.6

7 days

15.23

14.32

Cylinder

(SP2 14)

14 days 13.86

Cylinder

(SP2 28)

28 days 13.88

From the concrete strength test results of the

lightweight pumice aggregate, the lightweight

concrete obtained can be classified as a Moderate

Strength Concrete with a compressive strength value

of less than 16.35 Mpa.

5.2 Splitting Tensile Strength Testing

Results

Splitting tensile strength tests were performed on the

cylindrical concrete specimens with diameters of 15

cm and 30 cm. Further details can be seen on table 4.

Table 4: Splitting Tensile Strength Test Results of

Lightweight Concrete Made From Volcanic Pumice

Aggregate.

Specimen

Specification

of Gravity

Age of

Speci-

men

Spliting

Tensile

Strength

(Mpa)

Average

Splitting

Tensile

Strength

(Mpa)

Cylinder (SP2

7)

1.6

7 days

5.16

4.86

Cylinder (SP2

14)

14 days 4.70

Cylinder (SP2

28)

28 days 4.71

The test results of splitting tensile strength show

that lightweight aggregate concrete sides pumice can

increase the value of the tensile strength divided by

an average of 4.86 Mpa.

5.3 Relationship between Compressive

Strength and Splitting Tensile

Strength

Data regarding the compressive strength and tensile

strength of the lightweight aggregate concrete sides

pumice was obtained by testing the compressive

strength and tensile strength divided by the specimen

cylinder. Compressive strength and splitting tensile

strength of the lightweight aggregate concrete sides

pumice were interconnected and influenced each

other. This data graphed the relationship between the

compressive strength and tensile strength of

lightweight aggregate concrete sides of pumice. A

graph of the relationship between compressive

strength and tensile strength with the ages of concrete

sides is shown on Figure 4.

Figure 4: Graph of the Relationship between Compressive

Strength and Split Tensile Strength of Lightweight Pumice

Concrete at Concrete Age of 7, 14 and 28 days.

Table 5: The Relationship between Splitting Tensile

Strength and Compressive Strength of Lightweight Pumice

Concrete.

Testing

Nilson and

Winter Testing

Result

Lightweight

Concrete Pumice

Testing Results

Split Tensile

Strength o

f

Lightweight

Pumice Concrete

(ft)

0.333 √f’c to

0.448 √f’c

0.309 √f’c to 0.372

√f’c

Based on Table 5, it can be seen that the tensile

strength of lightweight concrete sides pumice

obtained average test results that was within the

interval of 0.309 √f ’c to 0.372 √f'c (MPa). The value

of these approaches provides a smaller interval of

restrictions given by Nilson and Winter of 0.333 √ f'c

to 0.448 √ f'c (MPa).

0000

00

0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,9

1

024

Compressive and tensile strength

(MPa)

Age (days)

Compressive

Strength

Split Tensile

Strength

BEST ICON 2018 - Built Environment, Science and Technology International Conference 2018

170

6 CONCLUSIONS

The conclusion that can be drawn from the results of

this research are as follows :

Judging from the properties, a feisty, lightweight

aggregate pumice can be used as a construction

material for lightweight concrete.

From the compressive strength test results,

lightweight concrete pumice can be classified as

a lightweight concrete structure (Moderate

Strength Concretes).

The greater the value of the compressive

strength, the greater the value of the splitting

tensile strength .

The values for the splitting tensile strength of

lightweight concrete sides pumice obtained

average test results within the interval of 0.309

√f‘c to 0.372 √ f’c (Mpa). The value of these

approaches provides a smaller interval of

restrictions given by Nilson and Winter at 0.333

√f ‘c to 0.448 √ f'’c (Mpa).

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the Ministry of

Research, Technology and Higher Education of the

Republic of Indonesia for the funding received. The

authors would also like to thank the Director and

laboratory staff of PT. Merak Jaya Beton (Batching

Plan Surabaya) who assisted in completing this

research.

REFERENCES

Abdullah, et al., 2007, Beton Busa Sebagai Bahan

Konstruksi Bangunan Teknik Sipil, Universitas Syiah

Kuala, Darussalam Banda Aceh.

Dobrowolski, Joseph A., 1998, Concrete Construction

Handbook, McGraw-Hill. New York.

http://www.tekmira.esdm.go.id

Mulyono, T., 2004, Teknologi Beton, Penerbit ANDI,

Yogyakarta.

Murdock, L. J., dan Brooks, K. M., 1991, Bahan dan

Praktek Beton, terjemahan Hindarko, S., Penerbit

Erlangga. Jakarta.

SNI-03-2641-2002, 2002, Ligthweigth Concrete for

Structural. National Standardization Board (BSN).

Jakarta.

Parmo and Tavio, 2016. Inovasi Sambungan Mekanis

Sambungan Baja untuk Beton Bertulang, EMARA-

Indonesian Journal of Architecture, Vol. 1, N0. 2, Hal.

85-89.

Parmo, Soehardjono, A., and Tavio, 2012. Perbaikan

Kekuatan dan Daktilitas Kolom Beton Bertulang yang

Mendapat Beban Gempa Menggunakan Glass Fiber

Reionforced Polymer, Jurnal Teknologi Kejuruan, Vol.

36, N0. 1, Hal. 75-86.

Parmo and Taufikkurahman, 2014. Perbaikan Kekuatan dan

Daktilitas Balok Beton Bertulang Menggunakan Glass

Fiber Reionforced Polymer (GFRP) Strips, Jurnal

Ilmu-ilmu Teknik Sipil "SISTEM", Vol. 10, N0. 3, Hal.

63-71.

Tjokrodimuljo, K., 1996, Teknologi Beton, Nafiri.

Yogyakarta

The Mechanical Properties of Lightweight Concrete Made with Lightweight Aggregate Volcanic Pumice

171