A Study of the Physical-Mechanical Properties of Bamboo in

Indonesia

Efa Suriani

Science and Technology Faculty, Sunan Ampel Islamic State University, Surabaya, Indonesia

Keywords: Physical Properties, Mechanical Properties, Bamboo

Abstract: An architect or engineer, before making a design, must understand the characteristics, as well as the strength,

workability, and cost efficiency, of the materials to be used. An ecological material such as bamboo is a

sustainable and environmentally friendly material. Therefore, a study of the physical-mechanical properties

of bamboo, especially the bamboo in Indonesia, needs to be done. This research used a qualitative approach

and field observations. The data were collected through literature studies. The data were analyzed

descriptively, and conclusions were drawn from the analysis results. The results of the study show varied

properties depending on the type, length of drying of the sample tested, position of the sample of bamboo

stems taken, and location of the bamboo harvesting. The results also show a significant relationship between

the physical properties and the mechanical properties. The physical properties determine the mechanical

properties of bamboo. The type of bamboo that has a high strength, based on the surveys in the field, is Petung

bamboo. This is in line with the results of the research conducted. In addition, the mechanical properties of

bamboo will increase with the increase in the density of sclerenchyma fibers. In other words, sclerenchyma

fibers affect the strength of bamboo. Therefore, it is necessary to do further research on the chemical properties

of various types of bamboo existing in Indonesia.

1 INTRODUCTION

An architect or engineer, before making a design,

must understand the characteristics, as well as the

strength, workability, and cost efficiency, of the

material to be used. The construction materials used

in Indonesia vary, for example, metal or iron,

concrete or reinforced concrete, and wood

(Tanubrata, 2015).

The decrease in natural resources and the

deteriorating environmental impacts necessitate the

existence of sustainable and inexpensive materials

(Mustakim et al., 2009). Bamboo is a material that

falls into this category. It is an alternative ecological

material to wood and has its potential and challenges

(Suriani, 2017). Ecology is the study of the

interconnection between living things such as

animals, plants, and humans and their environment.

An ecological material is a material that has a positive

impact on the environment. A challenge is present,

namely bamboo material will disappear from the

community if it is not utilized in the culture or daily

life of the community. Therefore, examining the

physical-mechanical properties of bamboo, with and

without preservation, especially the bamboo in

Indonesia, in order to better recognize the

characteristics of bamboo is important. Thus, bamboo

is suitable to use as a building construction material.

The purpose of this article was to obtain an

overview of the physical-mechanical properties of

bamboo, especially the bamboo in Indonesia, with

and without preservation, through a laboratory study.

It also aimed to compare the uses of bamboo by

bamboo entrepreneurs for building construction

works. The findings are expected to increase the

understanding of the characteristics of bamboo in

Indonesia.

According to J. J. Janssen (1981), the factors

affecting the strength of bamboo are as follows:

154

Suriani, E.

A Study of the Physical-Mechanical Properties of Bamboo in Indonesia.

DOI: 10.5220/0008904600002481

In Proceedings of the Built Environment, Science and Technology International Conference (BEST ICON 2018), pages 154-162

ISBN: 978-989-758-414-5

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

a. water content, with the tensile strength of

bamboo decreasing if the water content

increases;

b. the transverse direction of bamboo, with the

maximum tensile strength of the outer part of the

bamboo stem being higher than that of the other

parts—the maximum high tensile strength is

proportional to the high percentage of

sclerenchyma fibers; and

c. the presence or absence of nodia of bamboo. The

inter-nodia section of bamboo is oriented

towards the axial axis, while the nodia of the cells

leads to the transverse axis. The section of the

segment has a lower strength than that of non-

segmented bamboo stems.

According to Morisco (1999), nodia is the

weakest part of the tensile force parallel to the axis of

the bamboo stem because some bamboo fibers turn,

and in nodia the direction of the force is no longer

parallel to all fibers. In general, nodia has the capacity

to bear ineffective loads for strength or deformation.

However, nodia prevents local buckling, which is

important in designing bamboo as a compressive

element or column.

1.1 Physical Properties

According to Wulandari (2014), knowing the

physical properties such as moisture content, density,

and shrinkage is important to overcome defects due

to cracks when bamboo is used. Bamboo processing

must be performed when the bamboo has low

moisture content and high density, so that it does not

undergo any dimensional change due to high

shrinkage. Bamboo is a hygroscopic material, that is,

it has an affinity for water and is able to absorb and

remove water depending on the temperature and

humidity.

According to Liese in Wulandari (2014), the

moisture content in the stem differs between

longitudinal and transverse direction. For transverse

direction, the inside is higher than the outside. It

depends on age, time of felling, and type of bamboo.

One-year-old bamboo’s moisture content is relatively

high (approximately 120–130% of the base or tip).

Bamboo aged 3–4 years has moisture content in base

part higher than that in the end. When logging in a dry

season, the moisture content can be at its minimum.

The internode or inter-bamboo section has lower

moisture content than the nodia part. The higher the

density of bamboo, the smaller the moisture content.

Moisture is the amount of water contained in a

piece of bamboo, expressed as a percentage of its dry

weight. Based on (ISO 22157-2, 2004) regarding

laboratory manuals: Bamboo-Determination of

Physical and Mechanical Properties-Part1:

Laboratory Manual”, the moisture content (MC)

obtained from a test object that is 25 mm high and 25

mm wide and has wall thickness of t mm (according

to the thickness of the bamboo) can be calculated by

the formula below:

MC = [(m - m

0

) / m

0

] x 100, (1)

where

MC

=

moisture content (%),

m

=

the mass of the test piece before drying

(gram), and

m

0

=

the mass of the test piece after drying

(gram).

The water content required under (ISO 22157-1,

2004) is quite high, reaching 12%. This is difficult

because Indonesia has very high relative humidity. To

achieve moisture content of 12%, special treatment

such as drying (not in direct sunlight) or using oven

(with an oven or heat from a lamp) is needed.

Bamboo density is the ratio of the dry mass of a

furnace to an object with a standard mass or volume

of water in the same volume. The standard object

used is water at 4 °C with a density of 1 gr/cm

3

.

According to Liese in (Wulandari, 2014), bamboo

density ranges from 0.5 to 0.9 grams per cubic

centimeter. The outer part of bamboo has higher

density than the inside. In the longitudinal direction

the density increases from the base to the end.

Bamboo density can be calculated by the formula

below:

ρ = (m / v) x 10

6

, (2)

where

Ρ

=

density, mass divided by volume, in

kg/m

3

,

M

=

mass, in g, of the test piece, oven-dry,

in kg, and

V

=

green volume of the test piece, in mm

3

.

1.2 Mechanical Properties

According to Sumarni (2010), mechanical

properties are the ability of a material to hold forces

or loads from the outside. Mechanical properties

include the tensile strength; compressive strength;

shear strength; flexural strength; stiffness; violence;

and strength split.

According to Hazra (2017), a mechanical

property is a property that deals with changes in the

shape of an object when there is an object resistance

due to the influence of the external forces acting on it.

This property is important to know the strength of

bamboo when used as a construction material.

A Study of the Physical-Mechanical Properties of Bamboo in Indonesia

155

Mechanical properties of bamboo include the

following.

1. Tensile Strength Parallel to Grain

According to Pathurahman (1998) in (Hazra, 2017),

tensile strength parallel to fiber is a measure of

bamboo’s strength in resisting forces that tend to

cause the bamboo to separate from one another.

(Morisco, 1999), in his research from 1994 to 1999,

examined the tensile strength of Ori and Petung

bamboo compared to the stress reinforcement in the

surrounding market of around 2400 kg/cm

2

.

Specimens were taken from the skin of Ori bamboo

and the inside skin of Petung bamboo. Parts were

taken in parts without internodes. The results are

listed in Tables 1 and 2 below.

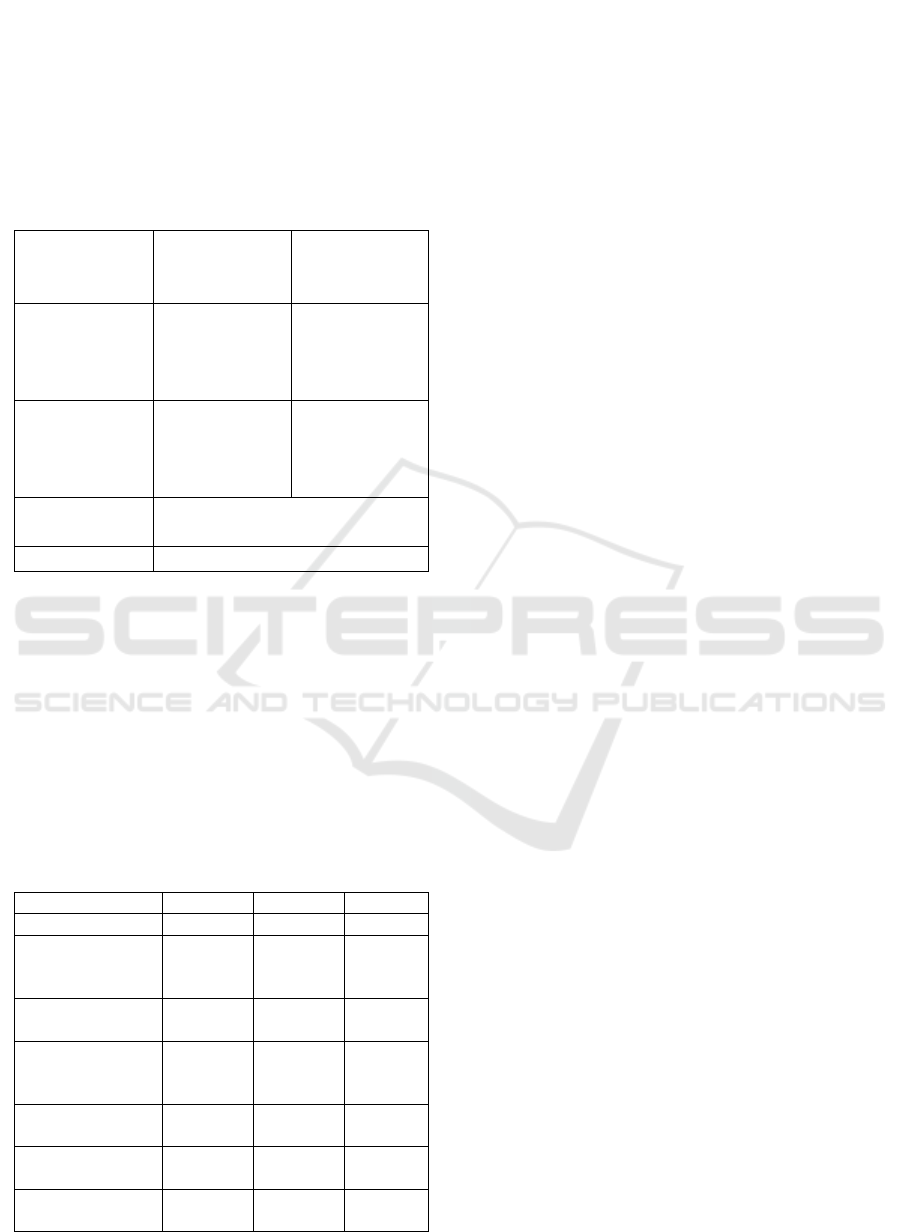

Table 1. Tensile Strength of Average Bamboo

Parts

Types of Bamboo

Tensile Strength (kg/cm

2

)

Petun

g

Tutul

Galah

Tali

Denden

g

Base

2278

2394

1920

1442

2214

Middl

e

1770

2917

3350

1368

2513

End

2080

4488

2324

1735

3411

Source: (Morisco, 1999)

Table 2. Tensile Strength of Average Bamboo (Dry

Oven)

Types of

Bamboo

Tensile Strength

in Internode

(kg/cm

2

)

Tensile Strength

in node

(kg/cm

2

)

Ori

2910

1280

Petung

1900

1160

Hitam

1660

1470

Legi

2880

1260

Tutul

2160

740

Galah

2530

1240

Tali

1515

552

The tensile strength of Ori bamboo skin is quite

high, reaching 5000 kg/cm

2

or 470 MPa, about twice

the tensile stress of steel reinforcement, 240 MPa,

while the average tensile strength of Petung bamboo

is also higher, with only one specimen being lower.

Round-shaped like a pipe, bamboo has a moment of

high humidity, making it to be good for holding the

bending moment. This was evident in the Yogyakarta

earthquake on May 26, 2006, where a house with a

bamboo or wood frame system was found to remain

intact.

According to the 1995 International Network for

Bamboo and Rattan (INBAR) in (Permana, 2017), the

tensile strength of the cross-section is divided into

two parts, namely

a. the inside, which is approximately 70% of the

thickness of the stem, with tensile strength of

70.6 MPa and

b. the outside, which is approximately 30% of the

thickness of the stem, with tensile strength of

205.2 MPa.

2. Compressive Strength Parallel to Grain

According to Hazra (2017), compressive strength

parallel to fiber is the strength of bamboo to retain the

force from the outside in the direction parallel to the

fiber which tends to shorten or compress the bamboo

part together. Janssen (1981) stated that factors that

affect the compressive strength of parallel fibers

include the following:

a. moisture content—low moisture content

increases the compressive strength of parallel

fibers in bamboo;

b. the position of the specimen in the bamboo—the

closer to the end the specimen position in the

bamboo stem is, the greater the compressive

strength parallel to the fiber;

c. specific gravity—the greater the specific gravity,

the greater the compressive strength level,

because the cellulose content is higher; and

d. the percentage of sclerenchyma fibers—these

fibers tend to increase from the base of the stem

to the tip of the stem.

Morisco (1999), in his study, tested bamboo

compressive strength using bamboo inter-nodia with

a length of twice its diameter, so that buckling was

deemed absent (Table 3).

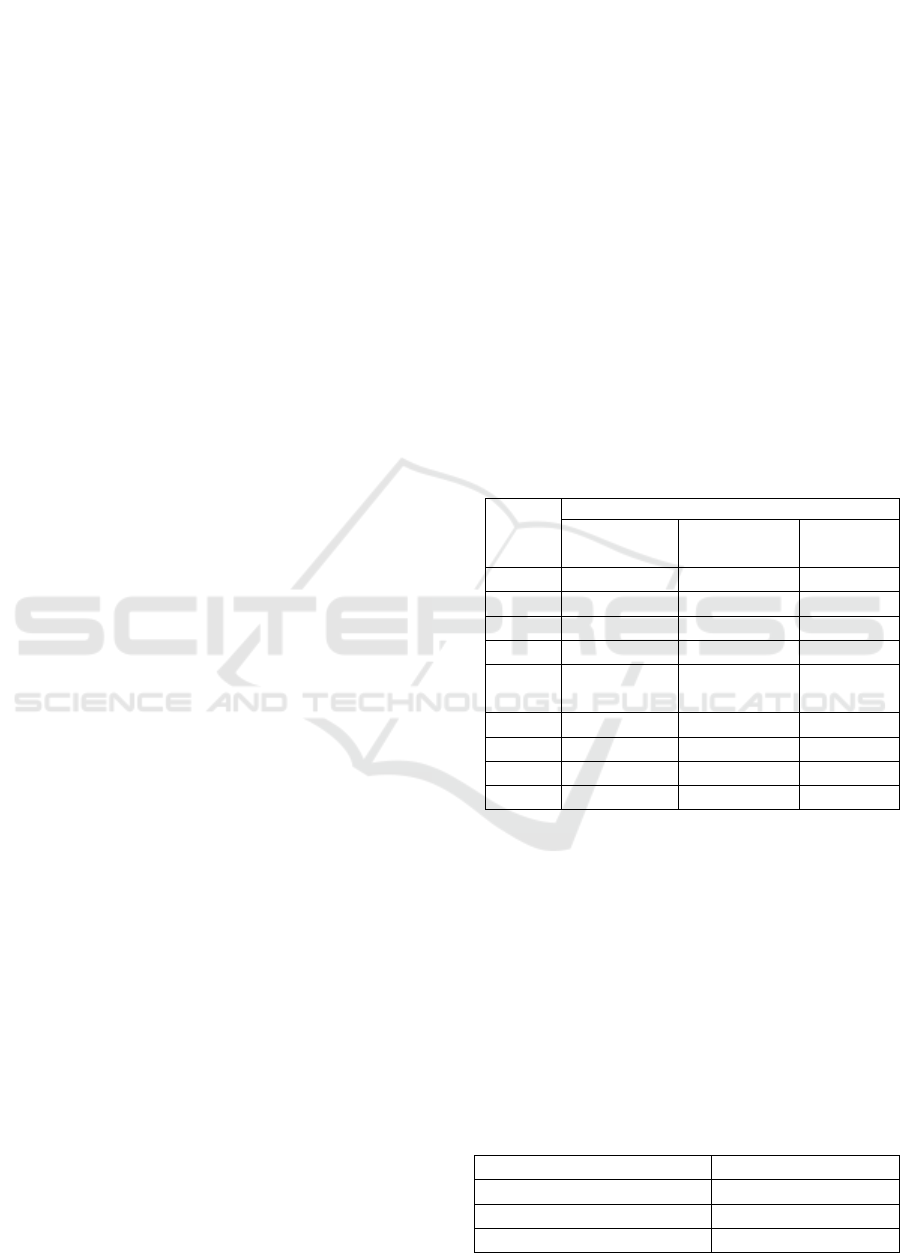

Table 3. Compressive Strength of Average Round

Bamboo.

Parts

Types of Bamboo

Compressive Strength (kg/cm

2

)

Petun

g

Tutul

Galah

Tali

Denden

g

Base

2769

5319

3266

2152

4641

Middl

e

4089

5428

3992

2880

3609

End

5479

4639

4048

3354

3238

3. Shear Strength Parallel to Grain

The shear strength parallel to fibers is bamboo’s

ability to resist forces which tend to cause some parts

BEST ICON 2018 - Built Environment, Science and Technology International Conference 2018

156

of the bamboo to shift with other adjacent parts. The

higher the specific gravity, the higher the shear

strength. Janssen (1981) also stated that factors that

influence the parallel shear strength of fibers include

the following:

a. moisture content—shear strength decreases with

the increase in moisture content;

b. whether or not there are nodia (segments)—

examples of bamboo specimens have nodia with

higher shear strength due to the bamboo fibers of

the nodia that adhere to one another; and

c. position of the test sample—the shear strength

decreases from the base position to the end.

4. Flexural Strength of Bamboo

Hazra (2017) stated that flexural strength is the ability

of a load-bearing material to work perpendicular to

the axis extending the fiber in the middle of the

material supported by both. According to Janssen

(1981), knowing the flexibility or flexural strength of

bamboo is very important because the use of bamboo

as a construction material is only limited to curvature.

Flexural strength is influenced by several factors,

including moisture content; nodia (segments)

availaibility; axial position in the stem; and the shape

and size of the test object.

According to Tular and Sutidjan (1961) in

(Morisco, 1999), the results of bamboo testing for

flexural strength obtained show a strong range from

686 kg/cm

2

to 2940 kg/cm

2

and permitted voltage of

98.07 kg/cm

2

.

5. Dowel-Bearing Strength

Eratodi ( 2014) defined dowel-bearing strength as a

strong mechanical bolt property of a material

determined based on the results of a test that

illustrates the strong limits of the material around the

hole which is pressurized by the bolt.

2 RESEARCH METHODS

This study aimed to obtain an overview of the

physical-mechanical properties of bamboo,

specifically the bamboo in Indonesia. This research

used a qualitative approach. The data were collected

through literature studies and field observations. The

data were analyzed descriptively, then conclusions

were obtained from the results of the study.

The chosen locations were CV Nusantara Bamboo

Company, Yogyakarta, and CV. Adi Galery Bamboo,

Wonosobo. The sources for the literature study

included books, final assignments, and journals

related to the physical-mechanical properties of

bamboo or bamboo material. The data were analyzed,

and the analysis results were concluded to achieve the

research objectives.

3 RESULTS AND DISCUSSION

3.1 Literature Study

The results of a study related to the physical-

mechanical properties of various types of bamboo are

discussed first in this chapter. This information was

obtained from journals, final assignments, and books.

Research was first conducted on the mechanical

properties of Petung bamboo, including the parallel

compressive strength, the perpendicular compressive

strength, the parallel shear strength, and the flexural

strength of the fiber (Made Oka, 2005). The

mechanical properties of Petung bamboo at average

moisture content of 12.63% are described in Table 4.

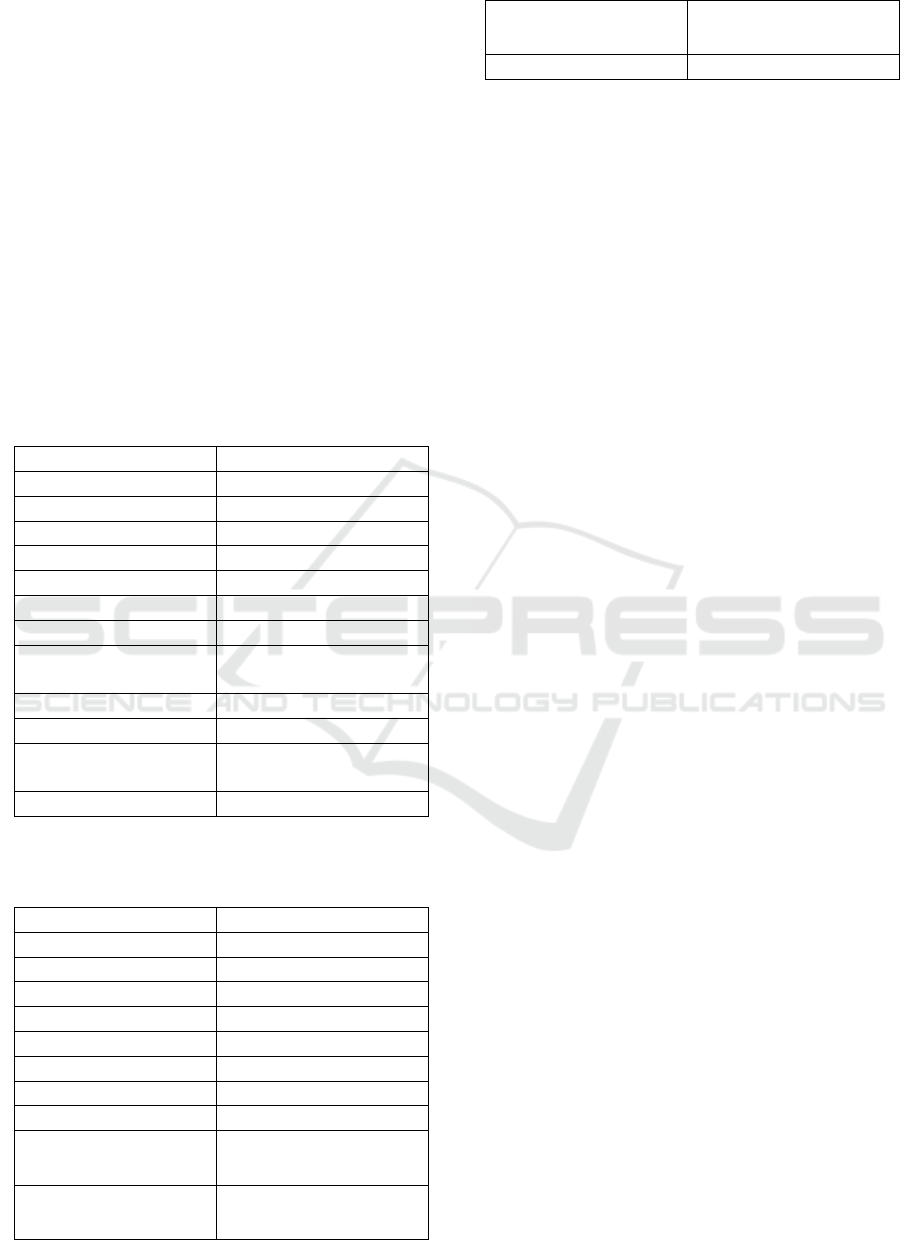

Table 4. Mechanical Properties of Petung Bamboo

Sample

No

Mechanical Properties (MPa)

Compressive

Strength //

Compressive

Strength ┴

Tensile

Strength //

1

50.11

45.11

421.44

2

41.80

46.74

409.51

3

58.06

61.33

375.58

49.99

51.06

402.18

Shear

Strength //

Flexural

Strength //

Elasticity

1

8.06

110.79

15,099.40

2

6.98

98.38

11,394.58

3

7.83

177.23

14,744.99

7.62

128.80

13,746.33

Source: Oka (2005) in (Hazra, 2017).

Research on Petung bamboo's mechanical

properties over the past 10 years by UGM DTSL

students was conducted by Irawati and Saputra (2012)

in (Hazra, 2017). The average moisture content was

15.38%, the density was 0.72 grams/cm

3

, and the

bamboo age was 3–5 years. The analysis statistics

obtained are described in Table 5.

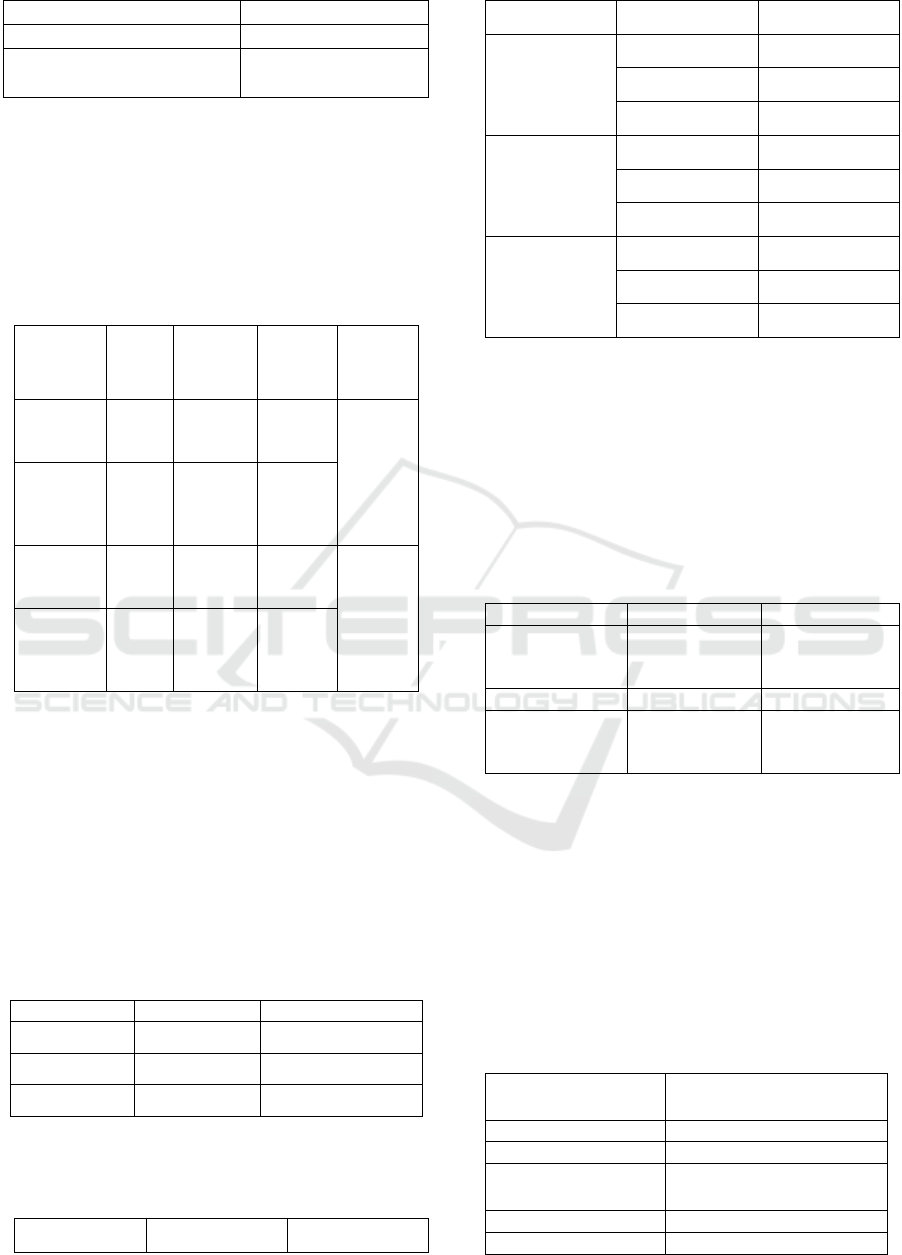

Table 5. Mechanical Properties of Petung Bamboo.

Mechanical Properties

MPa

Flexural Strength

134.97

Tensile Strength //

288.00

Compressive Strength //

49.20

A Study of the Physical-Mechanical Properties of Bamboo in Indonesia

157

Compressive Strength ┴

24.19

Shear Strength //

9.51

Modulus of Flexural

Elasticity

12,888.47

Source: Irawati dan Saputra in Hazra (2017).

According to the research by Widjaja (2000),

Apus bamboo has mechanical properties as follows:

for bamboo aged 3 years, the average moisture

content on green stems is 54.3%, and the average

moisture content on dry stems is 15.1%. The results

are described in Table 6.

Table 6. Mechanical Properties of Apus Bamboo

Apus

Bamboo

MOR

N/mm

2

Compres

sive

Strengh

N/mm

2

Shear

Strength

N/mm

2

Tensile

Strength

N/mm

2

Green

with

nodes

102

24

7.68

294

Green

with

internode

s

71.5

23.5

5.99

Dry air

with

nodes

87.5

37.5

7.47

299

Dry air

with

internode

s

74.9

33.9

7.65

Source: (Widjaja, 2000)

Triwiyono and Morisco in Permana (2017)

conducted research on the moisture content of Petung

bamboo in wet and dry air conditions. Measurement

of the moisture content of wet bamboo was carried

out one day after logging, and measurement of air-

dried bamboo’s moisture content was carried out after

1.5 months. Moisture content research was also

carried out by Yasin (2009) in Permana (2017). The

results of the study are in Tables 7 and 8.

Table 7. Moisture Content of Average Petung

Bamboo

Parts

Wet

Dry air

Base

36.076%

5.227%

Middle

37.832%

6.678%

End

36.765%

7.203%

Source: Triwiyono and Morisco in Permana (2017)

Table 8. Moisture Content of Average Petung

Bamboo.

Number Culm

Number Sample

Moisture

Content (%)

Culm 1

1

13.23

2

12.93

3

12.45

Culm 2

1

13.08

2

12.71

3

12.70

Culm 3

1

12.74

2

12.46

3

13.16

Source: Yasin in Permana (2017).

Wulandari (2014) on her research has shown as it

seen in Table 9, the physical properties of local

bamboo species in West Sumbawa Regency are that

the higher the water content, the higher the value of

development and shrinkage, and the higher the

density, the higher the value of development and

depreciation.

Table 9. Physical Properties of Bamboo from West

Sumbawa.

Information

Bamboo

Value

Highest

Moisture

Content

Tali

11.666%

Highest Density

Tutul

0.613 g/cm

3

Highest

Shrinking and

Swelling

Duri and Betak

0.637% and

0.618%

Source: Wulandari (2014)

The physical and mechanical properties of Apus

bamboo in Turgo (Yogyakarta), according to

Permana (2017), are listed in Table 10. The

specimens were dried for 1 month (30 days) after

being treated with preservation in the laboratory.

Mechanical properties of Apus bamboo are inversely

proportional to water content but directly

proportional to density.

Table 10. Physical-Mechanical Properties of Apus

Bamboo.

Physical

Properties

Value

Moisture Content

13.93%

Density

717.96 kg/m

3

Mechanical

Properties

Value

Tensile Strength

270.94 MPa

Compressive

48.97 MPa

BEST ICON 2018 - Built Environment, Science and Technology International Conference 2018

158

Strength

Flexural Strength

70.46 MPa

Shear Strength

(Node)

5.14 MPa

Shear Strength

(Internode)

4.02 MPa

Dowel Bearing

Strength

37.38 MPa

Modulus of Tensile

Elasticity

18.058 MPa

Modulus of

Compressive

Elasticity

25.582 MPa

Modulus of Flexural

Elasticity

19.514 MPa

Source: Permana (2017)

The physical and mechanical properties of Apus

bamboo in Sayegan (Yogyakarta), according to Hazra

(2017) are shown in Table 11. Mechanical properties

increase with the increase in density of bamboo and

decrease with the increase in water content.

Table 11. Physical-Mechanical Properties of Apus

Bamboo.

Physical Properties

Value

Moisture Content

14.60%

Density

546.28 kg/m

3

Mechanical

Properties

Value

Tensile Strength

223.36 MPa

Compressive Strength

40.89 MPa

Flexural Strength

60.07 MPa

Shear Strength (Node)

5.46 MPa

Shear Strength

(Internode)

4.84 MPa

Dowel bearing

strength

f

e maks

17.07 MPa

f

e5%

16.56 MPa

Modulus of Tensile

Elasticity

20.893 MPa

Modulus of

Compressive Elasticity

12.102 MPa

Modulus of Flexural

Elasticity

15.464 MPa

Source: Hazra (2017)

According to Basri & Pari (2017), physical

properties are identified to determine the stability of

bamboo. Knowing the drying properties is the basis

for determining the optimum drying temperature.

Testing of physical properties is carried out in the

direction of diameter and thickness of bamboo stems.

To determine the drying temperature, the wood

drying method is adopted. Defects such as

deformation (gripping & wrinkling) and broken ends

are observed. The result is a close relationship

between the fresh moisture content of bamboo and the

density and shrinkage of bamboo stems. The research

results are listed in Table 12.

Table 12. Optimum drying temperature.

Bamboo

Optimum Temperature

(Initial and Final Temperature)

Temen and Ori

45–70 °C

Ampel and

Ater

40–60 °C

Petung

33–50 °C

Source: Basri and Pari (2017)

Triwiyono and Morisco in Basri and Pari (2017),

also conducted research on density or specific gravity

in wet and dry conditions. The results are listed in

Table 13 as follows.

Table 13. Average Density of Petung Bamboo.

Parts

Wet

Dry air

Base

0.639

0.664

Middle

0.703

0.727

End

0.717

0.760

Source: Triwiyono dan Morisco in Permana (2017)

Furthermore, according to Awaludin in Hazra

(2017), in relation to the bolt strength based on the

D5764 standard, the mechanical properties of

bamboo are similar to those of wood because both are

composed of fibers. The compressive force used is the

compressive force of the test results which intersect

with the off-set line method 5% D (D is the diameter

of the bolt). Strong results of Wulung bamboo are

shown in Table 14.

Table 14. Dowel-Bearing Strength of Wulung

Bamboo.

Group

Name

Wulung Bamboo

f

5%

(MPa)

f

e maks

(MPa)

A

27.15–39.17

40.49–45.88

B

28.38–41.22

34.83–49.36

C

32.24–38.94

37.93–43.26

D

35.43–40.00

36.06–42.63

Source: Awaludin in Hazra (2017).

Note:

- A = D12.2 mm with guide holes

- B = D15.6 mm without guide holes

- C = D12.2 mm with guide holes

- D = D15.6 mm without guide holes

Research on the mechanical properties of

bamboo Betung aged ±4 years to obtain the maximum

value of stiffness and flexural strength in different

positions and with different tensile strength parallel to

the bamboo fiber expressed in MOE and MOR has

been carried out by Yoresta (2013).

A Study of the Physical-Mechanical Properties of Bamboo in Indonesia

159

The standard used is ASTM D143-05. The results

show a significant difference, namely, the position of

the upper fiber leather bamboo (press area) has a

higher value of MOE (Modulus of elasticity) and

MOR (Modulus of rupture) than does the bottom

(tensile area). The values can be seen in the following

table.

Table 15. Value of MOE and MOR of Betung

Bamboo.

Bamboo

Position

MOE (Modulus

of elasticity)

kg/cm

2

MOR (Modulus

of rupture)

kg/cm

2

Position of the

top grain skin

(compression

area)

62,118.90

826.36

Position of the

bottom grain

skin (tension

area)

51,563.20

633.38

Shear Strength Parallel to

Grain

Betung Bamboo

2309.00 kg/cm

2

Source: Yoresta (2013)

According to Mustafa (2009), Petung bamboo that

is aged 3–5 years has good strength. However,

building shops usually mix between young, mature

and old bamboo (due to the method of clearing in one

clump), so there is no clear distinction to know the

quality of bamboo. For this reason, a study of the

physical and mechanical properties of young, mature,

and old Petung bamboo was carried out (case study:

base section). The results of the study are listed as

follows.

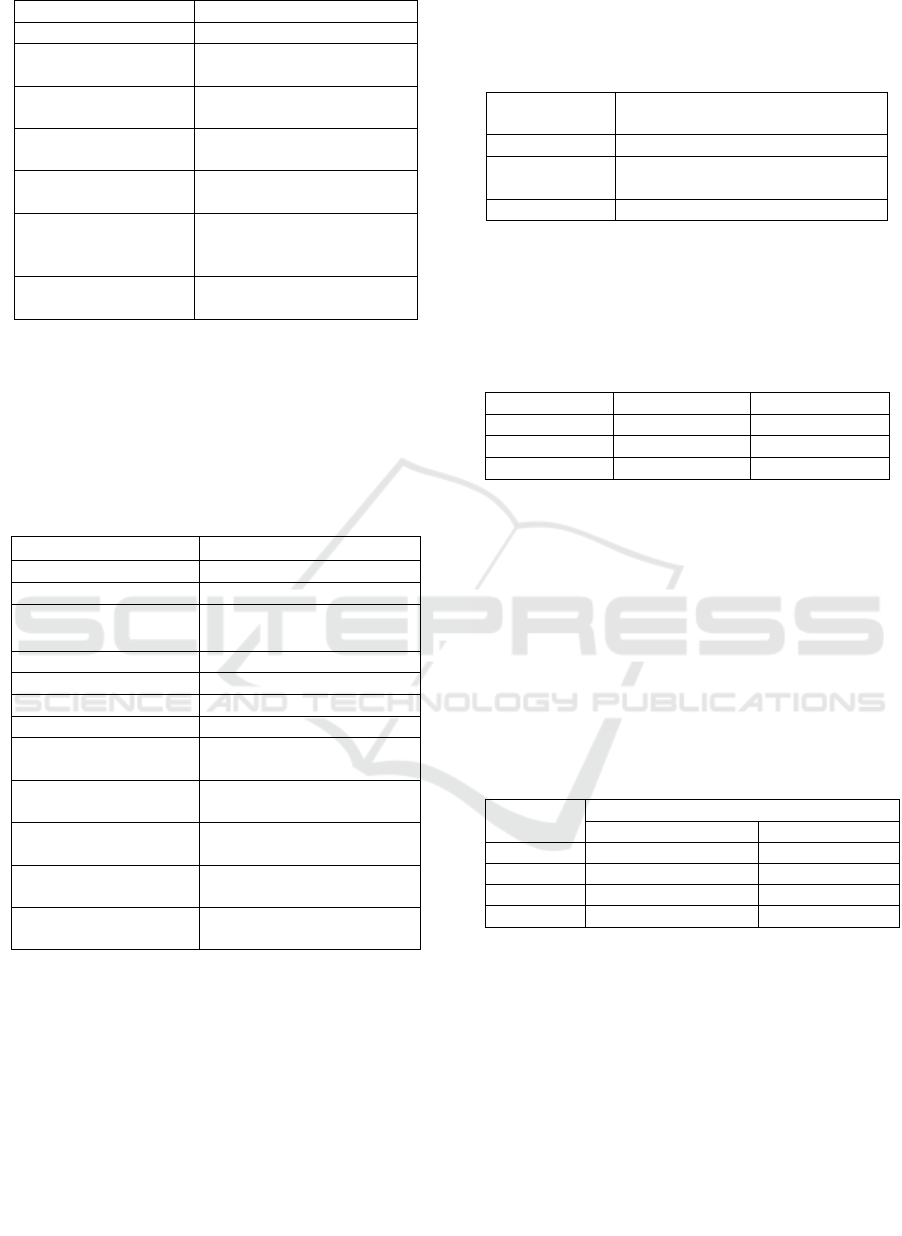

Table 16. Physical-Mechanical Properties of Petung

Bamboo.

Character

Young

Adult

Old

Density (gr/cm

3

)

0.695

0.809

0.742

Density of

Sclerenchymal

fibers(mm

2

/mm

2

)

0.4257

0.4290

0.4284

Compressive

Strengh (Mpa)

37.52

46.59

43.13

Stress Limit

Proportion

(Mpa)

33.10

42.33

38.40

Modulus of

Elasticity (Mpa)

3773.15

4719.13

3783.93

Shear Strength

(Mpa)

6.86

9.94

8.95

Tensile Strength

(Mpa)

151.54

217.89

186.09

Source: Mustafa (2009)

Based on the table, the density of bamboo and the

density of sclerenchymal fibers have an influence on

the quality or strength of bamboo. Other results show

that the highest strength is found in adult bamboo,

while the lowest is found in young bamboo. Thus,

adult bamboo can be utilized. Another advantage of

using adult bamboo is that it enables preservation of

bamboo clumps. In addition, the mechanical

properties of bamboo will increase with the increase

in the density of sclerenchymal fibers. In other words,

sclerenchymal fibers affect the strength of bamboo.

3.2 Observations and Interview

Observations or surveys in the field were carried out

by the researchers. There were two locations

reviewed by bamboo entrepreneurs or craftsmen,

namely, Purwomartani, Yogyakarta, and Kaliwiro,

Wonosobo. The researcher looked directly into the

process of bamboo production from the beginning of

bamboo processing until it is used either as a

construction material or others. The researchers also

conducted an interview with one of the employees or

workers who oversaw the bamboo production.

In Yogyakarta, the bamboo production starts

with cutting down bamboo, then placing it in a

workshop to be preserved. Bamboo is cleaned and

washed so that mold and mildew disappear from the

surface of the bamboo. This is done so that fungus,

which can cause a decrease in the quality of bamboo,

have no potential to develop.

The preservation process lasts for a maximum of

10 days before the bamboo is laid and placed in good

air circulation (by allowing space between bamboo

pieces) for 2 days. Then, the bamboo can be sent to

the location with an estimated travel time (loading) of

1 day. Thus, the total time from the preservation and

drying until the bamboo can be used is 13 days.

The bamboo type that is continuously produced is

Petung bamboo. The prices for non-preserved and

preserved bamboo are distinguished. The price of

durable bamboo can be 3 times the price of non-

preserved bamboo. In addition, the base of the

bamboo fares at a higher price than do the middle and

end parts. This is because it is considered the

strongest or the thickest (has high strength), so it is a

good choice if used as a building construction

material, which has been proven in the field.

The bamboo production process is different in

the Wonosobo area. After being bought from the

market or from a bamboo farmer, bamboo is

immediately cleaned then soaked for 3 days for a

preservation purpose. Next, the bamboo is dried for

BEST ICON 2018 - Built Environment, Science and Technology International Conference 2018

160

about a week. The bamboo is ready to be processed

or produced for construction or crafting purposes.

The bamboo which is considered to have high

strength, similar to the bamboo production in

Yogyakarta, is Petung bamboo in the base area

because it is thick and hard.

3.3 Discussion

The results of the research on the physical-

mechanical properties of bamboo, especially the

bamboo in Indonesia, vary depending on the type,

length of drying of the sample object to be tested,

position of the sample of bamboo stems taken, and

location of the bamboo harvesting. The results show

a significant relationship between physical properties

and mechanical properties. The results are recorded

as follows.

Table 17. Physical-Mechanical Properties of Betung

Bamboo

Information

Range

Dry Moisture Content

12.63–15.38%

Density

0.72–0.809 gram/cm

3

Flexural Strength

128.80–134.97 MPa

Tensile Strength //

151.54–402.18 MPa

Compressive Strength //

37.52–49.99 MPa

Compressive Strength ┴

24.19–51.06 MPa

Shear Strength //

6.86–9.94 MPa

Modulus of Flexural

Elasticity

12,888.47–13,746.33

MPa

MOE

62,118.90 kg/cm

2

MOR

826.36 kg/cm

2

Density of Sclerenchyma

fibers

0.4257–0.4290

(mm

2

/mm

2

)

Stress Limit Proportion

33.10–42.33 (MPa)

Source: Researcher’s analysis (2018)

Table 18. Physical-Mechanical Properties of Apus

Bamboo.

Information

Range

Dry Moisture Content

13.93–15.1%

Wet Moisture Content

54.3%

Density

546.28–717.96 kg/m

3

Flexural Strength

60.07–70.46 MPa

Tensile Strength //

223.36–299 MPa

Compressive Strength //

33.9–48.97 MPa

Shear Strength //

4.02–7.65 MPa

MOR

74.9 MPa

Modulus of Tensile

Elasticity

18,058–20,893 MPa

Modulus of Compressive

Elasticity

12,102–25,582 MPa

Modulus of Flexural

Elasticity

15,464–19,514 MPa

Dowel Bearing Strength

17.07–37.38 MPa

Source: analysis result (2018)

4 CONCLUSIONS

The results of this study vary depending on the type,

length of drying of the sample object to be tested,

position of the sample of bamboo stems taken, and

location of the bamboo harvesting. However, the

results show a significant relationship between

physical properties and mechanical properties. The

physical properties and mechanical properties of

bamboo produced significantly influence each other.

The physical properties determine the mechanical

properties of bamboo. The findings of this study

include the following. The type of bamboo that has

high strength based on surveys in the field is Petung

bamboo. This is in line with the results of the research

conducted. In addition, the mechanical properties of

bamboo will increase with the increase in the density

of sclerenchyma fibers. In other words, sclerenchyma

fibers affect the strength of bamboo. Therefore, it is

necessary to do further research on the chemical

properties of various types of bamboo in Indonesia.

REFERENCES

Basri, E., Pari, R., 2017. Sifat Fisis Dan Pengeringan Lima

Jenis Bambu (Physical and Drying Properties of

five bamboo Species). Jurnal Penelitian Hasil

Hutan 35, 1–13.

Eratodi, I.G.L.B., 2014. Sambungan Balok-Kolom Bambu

Laminasi Menggunakan Pelat Baja Dikarter Dan

Baut (Disertasi). Program Pascasarjana Fakultas

Teknik UGM, Yogyakarta.

Hazra, S., 2017. Sifat Fisika Dan Mekanika Bambu Apus

(Studi Kasus: Sayegan) (TUGAS AKHIR).

Departemen Teknik Sipil Dan Lingkungan

Fakultas Teknik UGM, Yogyakarta.

ISO 22157-1, 2004. Bamboo-Determination of physical

and mechanical properties-part1:Requirement.

ISO 22157-2, 2004. Bamboo-Determination of physical

and mechanical properties-part1:Laboratory

Manual.

Janssen, 1981. Bamboo in Building Structures. Eindhoven

University of Technology, Netherlands.

Janssen, J.J., 1981. Bamboo in building structures.

https://doi.org/10.6100/ir11834

A Study of the Physical-Mechanical Properties of Bamboo in Indonesia

161

Made Oka, G., 2005. Cara Penentuan Kelas Kuat Acuan

Bambu Petung. Majalah Ilmiah Mektek Vol. VI,

pp 99-105.

Morisco, 1999. Rekayasa Bambu. Nafiri Offset,

Yogyakarta.

Mustafa, S., 2009. Karakteristik Sifat Fisika dan Mekanika

Bambu Petung pada Bambu Muda, Dewasa, dan

Tua (Studi Kasus: Bagian Pangkal).

Mustakim, Tanuwidjaja, T., Andry, W., Budi, F., 2009.

Bambu sebagai Material yang Berkelanjutan dan

Affordable untuk Perumahan.

Permana, I., 2017. Sifat Fisika Dan Mekanika Bambu Apus

(Studi Kasus: Bambu Daerah Turgo) (TUGAS

AKHIR). Program Studi Teknik Sipil

Departemen Teknik Sipil dan Lingkungan,

Yogyakarta.

Sumarni, S., 2010. Struktur Kayu. Yuma Pustaka.

Suriani, E., 2017. Bambu Sebagai Alternatif Penerapan

Material Ekologis: Potensi dan Tantangannya.

EMARA Indonesian Journal of Architecture Vol

3 Nomor 1 – Agustus 2017, 33–42.

Tanubrata, M., 2015. Bahan-Bahan Konstruksi Dalam

Konteks Teknik Sipil. JURNAL TEKNIK SIPIL

11, 76–168.

Widjaja, E.A., 2000. Bamboo Diversity And Its Future

prospect in Indonesia. Sustainable Utilization of

Forest Products.

Wulandari, F.T., 2014. Sifat Fisika Empat Jenis Bambu

Lokal Di Kabupaten Sumbawa Barat. MEDIA

BINA ILMIAH 8, 1–5.

Yoresta, F.S., 2013. Sifat Mekanis Bambu Betung

(Dendrocalamus asper) 1, 5.

BEST ICON 2018 - Built Environment, Science and Technology International Conference 2018

162